Login

Shoutbox

You must login to post a message.

allenb

04/23/2024 7:01 PM

Paul Kalb

renatoa

04/23/2024 4:34 AM

Coffee_Rabbit_Hole

and Michaelion,

and Michaelion,

renatoa

04/21/2024 2:35 AM

compactjack and GreenGenie

?

?

?

?allenb

04/19/2024 8:27 AM

eximwind

renatoa

04/18/2024 12:36 AM

bijurexim, greyberry2, N C,

Forum Threads

Newest Threads

Skywalker roaster modsHello from Montreal ...

War on Farmers by Su...

Kaleido Roaster PID ...

Rainfrog's Roastmast...

Hottest Threads

| Skywalker roaster... | [297] |

| Skywalker, the AL... | [214] |

| Skywalker Roasts | [94] |

| Rainfrog's Roastm... | [54] |

| War on Farmers by... | [40] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,223

Newest Member: Paul Kalb

Members Online: 0

Total Members: 8,223

Newest Member: Paul Kalb

View Thread

Who is here? 1 guest(s)

|

TC4 with aArtisanQ_PID

|

|

| BenKeith |

Posted on 01/17/2018 10:44 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

Shoot, I thought I might slip one over on you. To keep from getting this tread any more off subject, I sent you a PM. |

|

|

|

| greencardigan |

Posted on 02/13/2018 6:52 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Hi All, I hope to release a small update to aArtisanQ_PID soon which adds a few features. I've attached a beta version of version 6.4 if anyone wants to test. - Support for LCD screens other than the LCDApter. Given that LCDapters are a bit hard to source, I thought it would be worthwhile adding support for the cheap I2C LCDs available online on eBay etc. Thanks BenKeith for sending me the LCD for testing. - Support for two buttons directly connected to the Arduino input pins (ability to reset timer and toggle PID). This may be useful if an LCDapter is not being used (the LCDapter allowed buttons to be connected to the LCDapter board). Let me know if you have any issues.

greencardigan attached the following file:

Edited by greencardigan on 02/13/2018 8:17 PM |

|

|

|

| Piezo |

Posted on 04/07/2018 6:00 AM

|

|

Newbie  Posts: 8 Joined: March 31, 2018 |

While working on my TC4 roaster application, I came across an issue between 6.3 and 6.4. I'm working with a TC4 board with both potis connected. With 6.3 the values from heater and fan are been transferred to artisan correctly. With 6.4 , heater works fine, but fan transfers the values multiplied by 10, meaning if I have e.g. 55 in the TC4, I have 550 in Artisan. |

|

|

|

| Piezo |

Posted on 04/07/2018 6:03 AM

|

|

Newbie  Posts: 8 Joined: March 31, 2018 |

By the way, how can I get the sliders in Artisan stains in sync. with TC4? When I turning a pot from the TC4, the sliders in Artisan stay where they are ... Thanks in advance, Thomas |

|

|

|

| renatoa |

Posted on 04/07/2018 6:13 AM

|

|

Administrator  Posts: 3008 Joined: September 30, 2016 |

Check Alarms. Not exactly what you want, i.e. not continuous following, just some predefined levels, but no idea if something closer to your intended purpose... |

|

|

|

| Piezo |

Posted on 04/07/2018 6:49 AM

|

|

Newbie  Posts: 8 Joined: March 31, 2018 |

Quote renatoa wrote: Check Alarms. Not exactly what you want, i.e. not continuous following, just some predefined levels, but no idea if something closer to your intended purpose... Sorry, I unfortunately was not precise enough. What I want is when I turn the potis (fan or heather), the sliders in Artisan should also move to the values I choose with the potis in TC4. Thanks, Thomas |

|

|

|

| Will2 |

Posted on 04/07/2018 8:06 AM

|

|

1/4 Pounder  Posts: 154 Joined: March 24, 2015 |

Quote ... when I turn the potis (fan or heather), the sliders ... I think this is not possible or necessary. Likewise, when you move the sliderss, you do not turn potentiometers on the box. Try to ask Marko. Viliam

|

|

|

|

| renatoa |

Posted on 04/07/2018 8:37 AM

|

|

Administrator  Posts: 3008 Joined: September 30, 2016 |

Piezo, understood perfectly what you want, but not sure if possible. When you turn the pot, the actual heater value will be sent by TC4 to Artisan, as a response to READ message. You can see the values as LCD, if you add an ArduinoTC4_56 entry in the Extra Device tab of Device Assignment dialog. However, according to Artisan code, the only way to move a slider as the result of an external, non UI action (i.e. non interactive) is via an Alarm or an Event playback. |

|

|

|

| greencardigan |

Posted on 05/28/2018 11:14 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote ROSTARN wrote: I have a resistive heater on OT1, AC fan on OT2 and ZCD on IO2. My wish is to add a pwm output on io3 with the neat DCFAN command. So far i hooked up an LED on io3 for testing. Here is my findings: -On CONFIG_PAC2 its not possible to control IO3 pwm output with either DCFAN command or IO3 command. -On CONFIG_PAC3_IO3HTR its possible to control IO3 PWM output with IO3 command but not DCFAN command. But then its not possible to control the OT1 output with ot1 command. Probably as i should be, its not the config I use. Would it be memory issues like will2 suggest or is it possible to implement this feature in CONFIG_PAC2 since io3 is undefined, perhaps a 5th config? Hopefully I'm not the only one with a home built electric drum roaster :) Sorry for Hijacking your thread Matthias, perhaps we should move this discussion elsewhere? You could try using the AWRITE command to do PWM on IO3 pin or other spare pwm pin. Command format example is AWRITE;D03;127. I'm also going to try a small change to the code to try allowing IO3 commands to work in CONFIG_PAC2 mode. I'll post back here after I try this. Just got to sort out an Arduino software issue first. My install seems to be playing up. |

|

|

|

| greencardigan |

Posted on 05/29/2018 5:51 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Here's a version 6.5 for testing. - Added support for IO3 and DCFAN commands when using Phase Angle Control and IO2 for the Zero Cross Detector. - Added support for two more directly connected buttons for use in standalone mode. Please let me know if you have any problems with this version.

greencardigan attached the following file:

|

|

|

|

| ROSTARN |

Posted on 05/29/2018 1:33 PM

|

|

Newbie  Posts: 13 Joined: April 06, 2018 |

It works!  Ramping up is working but in my case of a geared DC motor I need a ramping down feature as well since sudden stops creates a big stress on the gears. I did however manage to add it and now the DCFAN command is ramping up and down very nicely. I did a quick test with all three outputs at the same time and didnt encounter any issues with memory or processing power. It needs more testing though and I will report back if I find any problems. A thought is why not add the feature of ramping down if there are more roasters using the same setup? If you are using a DC fan then you probably wont notice or care if the fan is ramping down when lowering the speed :) Oh, another thing. When enabling ACKS ON, there seems to be an issue with compiling the sketch. Might want to take a look when you got the time. Many thanks for helping out! /Johan |

|

|

|

| ChrisR |

Posted on 05/29/2018 2:05 PM

|

|

Newbie  Posts: 49 Joined: October 17, 2017 |

I'm planning on driving a gas valve using the PWM on IO3 (2.2khz). Would the new version still work if I select the correct time base in the user.h file? Also, I would love to drive both the gas valve using PWM on IO3 and a dc fan using either IO1 or IO2. Is that possible with the current version? |

|

|

|

| greencardigan |

Posted on 05/29/2018 7:33 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote ROSTARN wrote: A thought is why not add the feature of ramping down if there are more roasters using the same setup? If you are using a DC fan then you probably wont notice or care if the fan is ramping down when lowering the speed :) Oh, another thing. When enabling ACKS ON, there seems to be an issue with compiling the sketch. Might want to take a look when you got the time. Many thanks for helping out! /Johan I understand the DCFAN command and slew code was added to prevent power related issue on a specific roaster. Something to do with large increases in fan speeds. But I see no issue with having it slew on the downwards changes too. Did you want to share your code changes for this? Might save me time :) Yep, there's been issues with the ACKS ON for ages. I haven't really investigated it. Possible a memory issue? |

|

|

|

| greencardigan |

Posted on 05/29/2018 7:45 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote ChrisR wrote: I'm planning on driving a gas valve using the PWM on IO3 (2.2khz). Would the new version still work if I select the correct time base in the user.h file? Also, I would love to drive both the gas valve using PWM on IO3 and a dc fan using either IO1 or IO2. Is that possible with the current version? This version shouldn't impact the way any previous setup works. How were you changing the PWM to 2.2khz? I haven't really touched any of that code. I think when using CONFIG_PWM mode it defaults to 3.922kHz pwm in IO3 and slow 1kHz on OT1 and OT2. However, the slow PWM can be adjusted in user.h to be up to 3.9kHz. However, it might require modifying the 'Heater and Fan Duty Dispay Options' so it know which output is which. Another option is using the AWRITE,Dxx,xxx command to do PWM out on other spare pwm pins. |

|

|

|

| ChrisR |

Posted on 05/29/2018 10:37 PM

|

|

Newbie  Posts: 49 Joined: October 17, 2017 |

i must have misunderstood. I thought the "CONFIG_PAC2_IO3HTR" puts the IO3 in fast PWM mode and by changing the timebase in user.h i could adjust the base frequency on IO3. I will use the "CONFIG_PWM" mode for my gas roaster. Just a general question, what would be the base frequency on IO3 when in "CONFIG_PAC2_IO3HTR" mode? |

|

|

|

| greencardigan |

Posted on 05/29/2018 11:03 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

CONFIG_PAC2_IO3HTR does do fast pwm on IO3 (3.9kHz I think. I?ve not confirmed this though). However, it does not do pwm on OT1 or OT2. It does phase angle of OT2. |

|

|

|

| ChrisR |

Posted on 05/30/2018 12:25 AM

|

|

Newbie  Posts: 49 Joined: October 17, 2017 |

Which default output does the software uses to control heater in CONFIG_PWM mode? IO1, IO2 or IO3? |

|

|

|

| greencardigan |

Posted on 05/30/2018 12:42 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

CONFIG_PWM mode does slow pwm for heater on OT1. See here for a Configuration Options PDF https://github.co...ptions.pdf |

|

|

|

| ROSTARN |

Posted on 05/30/2018 1:21 PM

|

|

Newbie  Posts: 13 Joined: April 06, 2018 |

Quote I see no issue with having it slew on the downwards changes too. Did you want to share your code changes for this? Might save me time :) Sure thing! Im happy to be able to contribute in the great effort you guys and Jim made creating this great software. =) I send you a PM since Im having trouble uploading. /Johan |

|

|

|

| greencardigan |

Posted on 05/30/2018 3:58 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Thanks! That looks perfect. I'll include in the trunk version ready for next release. |

|

|

|

| greencardigan |

Posted on 05/30/2018 11:46 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote ChrisR wrote: I'm planning on driving a gas valve using the PWM on IO3 (2.2khz). Would the new version still work if I select the correct time base in the user.h file? Also, I would love to drive both the gas valve using PWM on IO3 and a dc fan using either IO1 or IO2. Is that possible with the current version? I had a play with the PWM outputs last night. In CONFIG_PWM mode I was able to get 2.2kHz pwm for heater on OT1 (adjustable in user.h) and 3.9kHz for DC fan on IO3. Sounds like this will suit your setup. 3.9kHz is the default for IO3, but it can be adjusted but not through user.h. |

|

|

|

| greencardigan |

Posted on 05/30/2018 11:57 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Also I've updated the Configuration Options PDF with a bit more detail and some example setups. See attached. Let me know if you see any errors or have an example use that you think should be included.

greencardigan attached the following file:

|

|

|

|

| ChrisR |

Posted on 05/31/2018 6:45 PM

|

|

Newbie  Posts: 49 Joined: October 17, 2017 |

Quote greencardigan wrote: Also I've updated the Configuration Options PDF with a bit more detail and some example setups. See attached. Let me know if you see any errors or have an example use that you think should be included. The configuation update is great. Thank you. |

|

|

|

| ChrisR |

Posted on 05/31/2018 11:50 PM

|

|

Newbie  Posts: 49 Joined: October 17, 2017 |

I'm having issues adjusting OT1 using serial command "ot1,100" in Artisan to set the PWM to max on OT1 or anything higher than 0 on my TC4C board. L1 lights up and I read 0 V on OT1. I'm in CONFIG_PWM mode. I can do it for Io3. Any reason why it would not work?

Edited by ChrisR on 06/01/2018 12:26 AM |

|

|

|

| greencardigan |

Posted on 06/01/2018 12:35 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

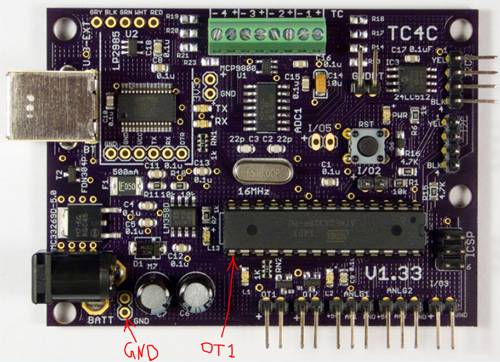

Hmm maybe its because the OT1 and OT2 ports are not directly connected to the ATmega's output pins like the IO3 pin is. You could try measuring the voltage between the actual output pin and a ground point. See image. Have you set OT1 to 2.2kHz? TC4C schematic is here. https://github.co...33-sch.pdf

greencardigan attached the following image:

|

|

|

|

| Jump to Forum: |

Similar Threads

| Thread | Forum | Replies | Last Post |

|---|---|---|---|

| aArtisanQ_PID and Arduino UNO R4 | Dataloggers/Controllers/Rate of Rise Meters | 2 | 03/01/2024 12:13 PM |

| Using aArtisanQ_PID with an old TC4 | Dataloggers/Controllers/Rate of Rise Meters | 12 | 02/14/2023 10:50 AM |

| How do I get the latest aArtisanQ_PID libraries? | Dataloggers/Controllers/Rate of Rise Meters | 3 | 02/06/2023 5:44 PM |

| aArtisanQ_PID thermocouple jumps when active PID channel | Dataloggers/Controllers/Rate of Rise Meters | 16 | 06/10/2021 9:57 AM |

| Loading aArtisanQ_PID in Arduino | Dataloggers/Controllers/Rate of Rise Meters | 14 | 05/28/2018 8:32 PM |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman