Login

Shoutbox

You must login to post a message.

renatoa

04/18/2024 12:36 AM

bijurexim, greyberry2, N C,

renatoa

04/17/2024 9:27 AM

, branchu

, branchurenatoa

04/14/2024 5:56 AM

TheOtherJim and papajim,

!

!

!

!allenb

04/11/2024 6:33 PM

Zemona

renatoa

04/11/2024 9:19 AM

Mrbones and sgupta,  ?

?

?

?Forum Threads

Newest Threads

Rainfrog's Roastmast...War on Farmers by Su...

Kaleido Roaster PID ...

Green coffee sellers

Wet beans - Estimati...

Hottest Threads

| Skywalker roaster... | [292] |

| Skywalker, the AL... | [214] |

| Skywalker Roasts | [94] |

| Rainfrog's Roastm... | [53] |

| My first popcorn ... | [47] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 2

Members Online: 0

Total Members: 8,211

Newest Member: bijurexim

Members Online: 0

Total Members: 8,211

Newest Member: bijurexim

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

Fan suggestion for 250g (0.5lbs)

|

|

| yello |

Posted on 06/09/2016 10:37 PM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

I am in the very early planning stages of a fluidbed roaster for home use. I am the only coffee drinker here, so I aim at just 250g bean load. I have a fan question. Firstly, I like to use DC, most likely 12V or 24V. I think they are easier (cheaper) to control than AC fans. Will a centrifugal fan/blower work? For example, a Sanyo Denki 9BMB12P2K01 will deliver ~57CFM (~2m?/min) I have to admit, I don't really understand the flow / pressure relation (yet). As heat source I plan a simple 2000W heat gun element. That should be sufficient for 250g from my research here. Hope I can get some feedback here.

yello attached the following image:

************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| oldgearhead |

Posted on 06/10/2016 7:13 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

A hand-held cordless vacuum cleaner motor-blower should dp the trick...I know others on the forum have used them..

No oil on my beans...

|

|

|

|

| oldgearhead |

Posted on 06/11/2016 6:54 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

The blower I use for 440 gram loads is rated at 100 inches H2O (pressure) and 100 CFM (flow), not at the same time. Most blowers of the type you posted aren't able to produce enough pressure at the flow required to fluidize green coffee beans.Yes, 2K watts should be plenty of heat. You may need a means to lower the wattage. Yesterday, I roasted two batches with a wattage setting of 1085. However, the ambient was 82F and my roaster re-claims heat from the roast chamber... Sounds like you have a fine start. What are you using for a roast chamber? DC may not be cheaper to use for blower control given all the dimmers and router controllers available. I've had good luck with a single-board AC controller. However, I usually use my variable transformer because it's more precise and i already had it. Edited by oldgearhead on 06/11/2016 7:02 AM No oil on my beans...

|

|

|

|

| btreichel |

Posted on 06/11/2016 9:52 AM

|

|

1/4 Pounder  Posts: 185 Joined: May 07, 2007 |

I was lifting 280 gram loads with the fan that comes in a P1 using a variac and running and140 volts. At the end of the roast, about 90 volts. The P1 was completely striped to the metal base with a hurricane lamp as a chamber. |

|

|

|

| yello |

Posted on 06/11/2016 11:38 PM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Thanks for feedback. What's a P1? As roast chamber I'm looking for a heat resistant glass tube. Preferably something thin to hear the cracks better. And looks nicer to the eye too. For the control, I am pretty familiar with PWM, Arduino etc. And since I am close to China I can get 'stuff' fast and cheap. I got that hamster wheel roaster and I am not in a great hurry. Some error is ok, in the end we can only learn from errors ;-) One added question: any idea about the exhaust air temperature? I will start roasting outside, but eventually like the idea about a cyclone dust collector. The cheap ones are plastic, I guess that can be a sticky issue.... ************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| btreichel |

Posted on 06/11/2016 11:59 PM

|

|

1/4 Pounder  Posts: 185 Joined: May 07, 2007 |

http://forum.home...ead_id=270 http://www.homede...lsrc=aw.ds Edited by btreichel on 06/12/2016 12:04 AM |

|

|

|

| oldgearhead |

Posted on 06/12/2016 9:09 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

A glass RC is a very good choice because it allows you to see both the color development and the bean expansion. I should say everything about my roaster is unique, but there are a few others than are similar: __Hot air temperature is controlled by a manual, display,variable duty cycle, % output controller and it is set based on the ambient air temperature at the start of each roast. If the ambient temperature is 30?C the controller is set to 70%, which will allow a 1000 watt setting. If the ambient temperature is 6?C the controller is set for 100%, resulting in a 1550 watt setting. The goal of this control is to mix the hot air from the RC with the cooler ambient temperature to achieve 55?C for the blower inlet air The only changes made for very cold (5-15?C) weather is to insulate 3/4 of the roast chamber. __During each roast I use only the blower control (presently a variable auto-transformer) to control the temperature of the bean mass. __Cooling to >66?C is accomplished in the RC. Cooling takes 4-6 minutes to complete. __Chaff collection is also accomplished in the RC. There is a 30 mesh, convex screen located in the top of the RC that traps the chaff. The action of cooling insures the chaff will all end up piled on top of the bean column. It is then easily vacuumed off. Lots of words, above. But for the past 5 years its been very simple to operate. http://forum.home...ad_id=2207

oldgearhead attached the following image:

Edited by oldgearhead on 06/12/2016 9:17 AM No oil on my beans...

|

|

|

|

| yello |

Posted on 06/14/2016 12:00 AM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Quote __Hot air temperature is controlled by a manual, display,variable duty cycle, % output controller and it is set based on the ambient air temperature at.... Does the ambient temp really matters i when you use some type of PID control? In the end just the temp inside the chamber matters. Your design is nice. I will probably do something similar. I need to think how to get the beans out after roast and cool. Eventually I like to make coffee from it. For the chaff collection I will probably go in 2 phases: Phase 1: Roast outside ;-) Phase 2: Do some sort of cyclone dust collector. I am still in the very early stages. Must bought online a 2000W heater element, some Mica sheets, 2 different blowers. Still looking for the glass tube. Must heat safe, sure. Most I see are borosilicate (it's OK I guess) but quite thick wall, like 4mm or so. With such thick wall and of course the fan and dancing bean noise I worry that the cracking noise might get difficult to hear. What's your wall thickness? ************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| oldgearhead |

Posted on 06/14/2016 7:11 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

I do not use PID nor do I control the temperature of the air entering the RC. Instead I set the heater controller percent on-time to control the temperature of the air entering the blower. My desired blower inlet air temperature is 55C, and the temperature of the ambient air is critical. I've found using ( % on = 95 - ambient in degrees C) works quite well. I prefer to control the temperature of the bean mass by adjusting the air volume control, I've been using a simple 'J' tube for bean evacuation from the RC for 5 years and it works perfectly. "J' tubes have been used for decades by commercial grain handlers to evacuate small amounts of grain from an enclosed space. The term 'J-tube' is a Mississippi-Cajun term to describe a pipe containing an air stream with a smaller diameter hose connected to it to form a 'T". In othrt words a venturi-vacuum. Edited by oldgearhead on 06/14/2016 7:18 AM No oil on my beans...

|

|

|

|

| greencardigan |

Posted on 06/14/2016 6:30 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I use the replacement glass tubes used for camping gas lanterns. They are borosilicate. Not sure if you can find them where you are. They are usually fairly short at approximately 100 - 120mm long so need a chimney on top probably. The blower in my 1/3 kg air roaster is a 600W vacuum cleaner blower from a 240V handheld vacuum cleaner. It's a bit too powerfull. I run it using phase angle control using an Arduino and TC4. Starting at 20% power and reducing to about 10% at the end of roast. |

|

|

|

| yello |

Posted on 06/25/2016 8:54 AM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Quote The blower I use for 440 gram loads is rated at 100 inches H2O (pressure) and 100 CFM (flow), not at the same time. Most blowers of the type you posted aren't able to produce enough pressure at the flow required to fluidize green coffee beans. I can confirm that now. Neither of the 2 fans moved a bean. They draw about 2A at 12V, quite a bit, but still... Before I didn't look at the inH2O, I need to do some research into that. 100 inH2O would be nearly 20000pa, quite massive. I checked those jumping castle blowers, and they usually have around maybe 10 inH2O. Seems I look at totally wrong blowers. Will check vac motors too now.... ************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| allenb |

Posted on 06/25/2016 3:15 PM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

Quote Before I didn't look at the inH2O, I need to do some research into that. 100 inH2O would be nearly 20000pa, quite massive. I checked those jumping castle blowers, and they usually have around maybe 10 inH2O. Seems I look at totally wrong blowers. Will check vac motors too now.... I was able to measure the "H2O on a large Sivetz fluidbed several years ago and the highest reading was around 15" and from memory is typically able to loft beans effectively in most fluidbed designs. 10" might be fine but might take some experimentation to get the surface area of the RC inlet dialed in to achieve flight. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| yello |

Posted on 06/26/2016 1:14 AM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

I will do some more fan research and might stop thinking about 12V. I mean, I think this San Ace "9CRA0912P0G001" can lift a bean, or two. But I would run into the next problem - a 12V powersupply that can deliver 9A. My lab supplies can handle only up to 5A or so. So, now looking at vacuum cleaner motors. Most don't have a pointed outlet, like this one:  Something like this would be easier, right? >>  Another alternative would be a cheap leaf blower:  What you think is most suitable? PS: Little update: I changed the bottom of the bean holder from a sheet with holes to just a wide mesh, and now it tumbles a few beans at over full power. It's more a confirmation that it doesn't work. ************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| oldgearhead |

Posted on 06/26/2016 6:12 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

You must have both pressure and flow. The smallest roaster Sivetz built was designed to stick on the end of a common heat gun, like the the 1112 degree F Bosch model 1942 flowing 23 CFM. As I recall it was able to roast 175 gram loads. Heat gun centrifugal blowers quickly run out of pressure as the load increases. Vacuum cleaner and spa blowers are ideal for the task, but you must deal with harnessing the pressure side to supply your roaster. I do remember reading about a 'leaf blower' roaster build, but I don't know if it worked well enough to float 350 gram loads.. We need 'Freshbeans' to enter this conversation... Edited by oldgearhead on 06/26/2016 6:20 AM No oil on my beans...

|

|

|

|

| allenb |

Posted on 06/26/2016 10:55 AM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

Quote Something like this would be easier, right? >> I've found mounting the non-volute, standard vac motor easier to mount than the one you posted below the text above. Only requires you to provide an opening in your enclosure to allow the motor end to slide through and 4 screws to fasten it in. Leaf blowers can provide plenty of lift and flow but are extremely noisy at full rpm and mounting would be cumbersome. Obviously, most vac motors are inherently noisy if run at full speed but leaf blowers are quite a few db louder from my experience. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| yello |

Posted on 06/29/2016 10:41 PM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Quote I've found mounting the non-volute, standard vac motor easier to mount than the one you posted below the ... Can you elaborate on that? To me it sounds more difficult. I would have the separate the IN side from the OUT side with some sort of air tight enclosure. Whereas on the other type I just connect a soft hose. So when you say 'easier' I am getting curious. You have any image? I would be interested. Your type motor is quite a bit cheaper then those with hose connection. ************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| allenb |

Posted on 06/30/2016 7:49 AM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

Here's a link to a gas fired fluidbed with standard, non-volute vac motor mounted as described: http://forum.home...post_41862 Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 06/30/2016 9:43 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Sorry, haven't been checking in as I should. When I do check in, the screenname is now "JETROASTER", not "Freshbeans". Yello, I can see your point. The tangential discharge blowers are pretty easy to work with if your design allows for it. Simply hook up a flexible hose and put the blower anywhere you want. Your second image would be a good choice. Tangential discharge are typically just a few bucks more. Search "Ametek". I can bring up technical drawings for most of what they offer. They will all be a bit bigger than needed, but simply bleed off the unwanted airflow. Cheers, Scott |

|

|

|

| JETROASTER |

Posted on 06/30/2016 1:26 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Here's one similar to your second image.....with one less fan. ametek Part#: 119512-00. A little less pressure might be a better fit for you Search the web. Anywhere from $79.00 U.S. on up. Cheers, Scott |

|

|

|

| btreichel |

Posted on 06/30/2016 6:43 PM

|

|

1/4 Pounder  Posts: 185 Joined: May 07, 2007 |

Does vacuum draw translate directly to static pressure? I can think of reasons why, and some as to why not. Such as, is there a different blade design for vac, vs. static? On the experimental front I have lofted around 300 grams of green in a 3 inch hurricane lamp chimney with a 4 in h20 static rating. That's w/o burner etc. But also a lot less static pressure than a vac motor. |

|

|

|

| JETROASTER |

Posted on 07/01/2016 2:00 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Pressure is the resistance to flow. As a very general statement, blowers that have high pressure ratings might produce less flow, but they tend to maintain that flow rate through restrictive enviroments. Conversely, blowers that produce high flow rates might only maintain that flow rate when faced with little restriction. This is why the vacuum blowers work well for fluid bed roasting. They maintain constant CFM despite the obstruction of coffee beans, burners, perf plates etc. Here's the specs from the 2 stage, tangential discharge that you have pictured. Look at the intersection of airflow vs pressure. http://dev.ametek...355-00.pdf Cheers, Scott |

|

|

|

| yello |

Posted on 07/04/2016 5:10 AM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Quote allenb wrote: Here's a link to a gas fired fluidbed with standard, non-volute vac motor mounted as described: http://forum.home...post_41862 Allen A big 谢谢 from here. This answered all my questions. But one motor unrelated question: I added a picture for better understanding. Firstly, I totally like the asymmetrical chamber bottom. But I wonder, you used a sheet with holes. Doesn't it pose quite a bit of air resistance? Wouldn't a stainless steel mesh be better for the airflow (less resistance)? @JETROASTER I will go for a vac motor and use that at low level. With the PC type fans I would have to get a VERY strong one, and they also ain't cheap. And still will have to use them at near max power.

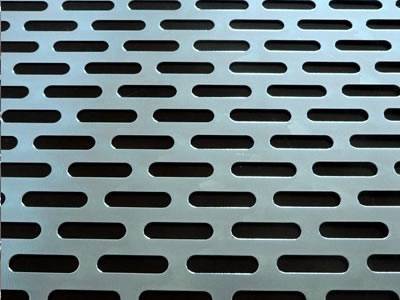

yello attached the following image:

************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

| allenb |

Posted on 07/04/2016 9:32 AM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

In order to produce an evenly flowing spouting bed, there has to be a certain amount of resistance between the upstream and downstream side of the bottom plate otherwise you end up with a randomly spouting, chaotic bean movement. While it is possible to roast good coffee in a low to no resistance design, (Sonofresco, Freshroast), there are typically problems with insufficient spouting during the first couple of minutes of a roast due to it's inability to create sufficient velocity in any one area of the plate. It also can create challenges in finding an ideal location for the bean temp probe. The only possible advantage I can see to using a low resistance design is it allows the use of lower pressure blowers. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| oldgearhead |

Posted on 07/04/2016 4:40 PM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

The perf top from a small cocktail shaker make a pretty good center-sprout system:

oldgearhead attached the following image:

No oil on my beans...

|

|

|

|

| yello |

Posted on 07/05/2016 9:28 PM

|

|

Newbie  Posts: 17 Joined: June 05, 2016 |

Quote allenb wrote: In order to produce an evenly flowing spouting bed, there has to be a certain amount of resistance between the upstream and downstream side of the bottom plate otherwise you end up with a randomly spouting, chaotic bean movement. While it is possible to roast good coffee in a low to no resistance design, (Sonofresco, Freshroast), there are typically problems with insufficient spouting during the first couple of minutes of a roast due to it's inability to create sufficient velocity in any one area of the plate. It also can create challenges in finding an ideal location for the bean temp probe. The only possible advantage I can see to using a low resistance design is it allows the use of lower pressure blowers. Allen I wasn't aware of that. With that in mind I would probably use 2 sheets together, similar as in the attached image, and shift one little by little to find a good opening size. For the sheets I would go as thin as possible to have less heat storage (faster cooldown).

yello attached the following image:

************************************

Just learning the basics with a Dieckmann R?stmeister |

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Similar Threads

| Thread | Forum | Replies | Last Post |

|---|---|---|---|

| Small Batch (100-250g) fluid bed roaster fan question | Fluidbed Roaster | 7 | 06/11/2017 3:24 PM |

| Yet Another 250g-500gm FB Roaster | Fluidbed Roaster | 30 | 01/03/2016 10:51 AM |

| Suggestion on "drum mass" versus "bean mass" | Drum Roasters | 1 | 10/26/2014 5:21 AM |

| Suggestion for newbie | Roasting Coffee | 5 | 11/24/2013 9:57 AM |

| Need Suggestion on My Old Primitive Roaster | Drum Roaster (Store Bought and Commercial) | 12 | 10/09/2013 9:00 AM |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman