Login

Shoutbox

You must login to post a message.

renatoa

04/18/2024 12:36 AM

bijurexim, greyberry2, N C,

renatoa

04/17/2024 9:27 AM

, branchu

, branchurenatoa

04/14/2024 5:56 AM

TheOtherJim and papajim,

!

!

!

!allenb

04/11/2024 6:33 PM

Zemona

renatoa

04/11/2024 9:19 AM

Mrbones and sgupta,  ?

?

?

?Forum Threads

Newest Threads

Rainfrog's Roastmast...War on Farmers by Su...

Kaleido Roaster PID ...

Green coffee sellers

Wet beans - Estimati...

Hottest Threads

| Skywalker roaster... | [292] |

| Skywalker, the AL... | [214] |

| Skywalker Roasts | [94] |

| Rainfrog's Roastm... | [53] |

| My first popcorn ... | [47] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 1

Members Online: 0

Total Members: 8,211

Newest Member: bijurexim

Members Online: 0

Total Members: 8,211

Newest Member: bijurexim

View Thread

Who is here? 1 guest(s)

|

Adding thermo probes to SR500

|

|

| Johnh |

Posted on 04/12/2017 10:18 AM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

I've added on thermoprobe to the SR500. this is an 8" long rigid probe that I installed through the top by drilling a hole. The probe has a collar on it so I can set the location of the tip. Right now I have it about 1/2" above the bottom of the roasting chamber. It's probably as close to a bean temp as i'm going to get. Now I want to add an environment temp probe. I'm thinking about drilling through the side of the base unit, through the heat shield and putting the probe just below the roasting chamber in about the middle of the plenum. downside is if I roast without a probe I have a big hole in the heat shield which I'd have to find a way to plug (False probe most likely) Another option would be to drill another hole in the top and set the probe so it stays up towards the top of the chamber. This is just measuring the air temps after it's been passed through the beans. It's a bit easier to do, but Im not sure the information is useful. Thoughts? |

|

|

|

| walt_in_hawaii |

Posted on 04/12/2017 8:56 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

pics might help... |

|

|

|

| Johnh |

Posted on 04/13/2017 9:34 AM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

I can try: Pics are (or should be) the existing bean temp probe. and 2 options for location of the environment temp.

Johnh attached the following images:

|

|

|

|

| Johnh |

Posted on 04/13/2017 10:12 AM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

In the above pics. The left most pic is one option for an ET probe. this is easy - drill a second hole through the lid and mount the probe so that it stays high, up out of the bean mass. But, it is reading air temps after it's passed through the beans. I'm not sure what that information is useful for. The middle picture is looking down on the base. I've positioned the probe I have about where I could mount another probe. It would go through the wall of the base and be in the hot air plenum directly below the glass roasting chamber. The right picture is my unit as it is now with the long probe inserted through the lid. You can see the probe extends to between the metal bands on the glass roasting chamber. This is what I monitor for bean temps. |

|

|

|

| renatoa |

Posted on 04/13/2017 10:49 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

Not sure what the usefulness of exhaust temp would be... the input temp is more important, imo. I mean a hole at the base, with probe near the perforated plate. Roasters: DIY: TO based IR 200-640g

Moded commercial: Skywalker, Dieckmann RoestMeister, Nesco, popper(s). Electrics: TC4ESP, MS6514, USB/Artisan/Apps, PID controllers Grinders: Arco, Xeoleo ghost burrs, Krinder, vintage PeDe Dienes, MBK Feldgrind Brew/presso: ALM pour over, Arin lever, Staresso Mirage, Hario Cafeor dripper, Flair, Kompresso, Rota Aeropress, Gaggia Mini |

|

|

|

| Johnh |

Posted on 04/13/2017 11:26 AM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

Thats what I was thinking as well. It's still a manual roasting process. The new probe shipped a couple of days ago, This may be this weekends project. |

|

|

|

| walt_in_hawaii |

Posted on 04/13/2017 11:34 AM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

I don't think you need an ET probe in an air roaster, mine didn't. And your BT probe looks dead centered... I think you'll find that the bean temp it records will be on the 'cooler' side. As you go closer to the circumference, the temp goes up. I picked a location about halfway out, as I recall. |

|

|

|

| Johnh |

Posted on 04/13/2017 12:09 PM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

It's just the angle of the photo. It's roughly halfway from center to edge of chamber. The First photo is where that probe is. I just backed it out to show how I could place a downstream ET. |

|

|

|

| renatoa |

Posted on 04/13/2017 12:20 PM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

In this design, BT probe should be in the center of vortex, to minimize the air influence and measure beans as much as possible. If there is any vortex, as in a popper... Roasters: DIY: TO based IR 200-640g

Moded commercial: Skywalker, Dieckmann RoestMeister, Nesco, popper(s). Electrics: TC4ESP, MS6514, USB/Artisan/Apps, PID controllers Grinders: Arco, Xeoleo ghost burrs, Krinder, vintage PeDe Dienes, MBK Feldgrind Brew/presso: ALM pour over, Arin lever, Staresso Mirage, Hario Cafeor dripper, Flair, Kompresso, Rota Aeropress, Gaggia Mini |

|

|

|

| Johnh |

Posted on 04/17/2017 10:34 AM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

It occurs to me that drilling a hole in the chamber wall may be unnecessary. I'm wondering now about using a surface mounted thermocouple on the exterior of the shroud. this would be relatively easy - though I'm not sure exactly what max temperature of the shroud would be. Most thigh temperature tapes I can find are rated at a max temp of 500F. I think that would be adequate. Looking at the teardown page on the SR500 it looks as though the temp of the shroud is part of the temp monitoring of the machine itself. |

|

|

|

| renatoa |

Posted on 04/17/2017 11:52 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

270C seems a reasonable absolute maximum for the hot air to hit beans. Many consider an even low value, at 250C (480F). Roasters: DIY: TO based IR 200-640g

Moded commercial: Skywalker, Dieckmann RoestMeister, Nesco, popper(s). Electrics: TC4ESP, MS6514, USB/Artisan/Apps, PID controllers Grinders: Arco, Xeoleo ghost burrs, Krinder, vintage PeDe Dienes, MBK Feldgrind Brew/presso: ALM pour over, Arin lever, Staresso Mirage, Hario Cafeor dripper, Flair, Kompresso, Rota Aeropress, Gaggia Mini |

|

|

|

| Johnh |

Posted on 04/17/2017 12:33 PM

|

|

Newbie  Posts: 14 Joined: April 10, 2017 |

This might be worth a try. They did not publish a clear picture of what I'm considering. But if the metal chamber wall I can see through the vents is really the chamber wall (i.e. not a double wall ) I should be able to place a thermocouple on the outside face of the shroud. Not as good as actual air temp - time lag of the wall, plus deficiencies in measuring surface temps, But perhaps a place to start. I may disassemble the base and inspect the construction. I have a couple thermocouples that came with the Amprobe TMD56 - I just need to find some of the tape to secure the thermocouple to the chamber wall. |

|

|

|

| renatoa |

Posted on 04/17/2017 12:50 PM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

You might consider extracting the wires and junction from the thermocouple enclosure, which make it too bulky for this job. The active part of a thermocouple is really small, can fit in a 2 mm diameter hole, making possible placement in the hot air vents. http://www.alamy.com/search.html?qt=K%20type%20thermocouple%20junction&imgt=0 Roasters: DIY: TO based IR 200-640g

Moded commercial: Skywalker, Dieckmann RoestMeister, Nesco, popper(s). Electrics: TC4ESP, MS6514, USB/Artisan/Apps, PID controllers Grinders: Arco, Xeoleo ghost burrs, Krinder, vintage PeDe Dienes, MBK Feldgrind Brew/presso: ALM pour over, Arin lever, Staresso Mirage, Hario Cafeor dripper, Flair, Kompresso, Rota Aeropress, Gaggia Mini |

|

|

|

| JitterzZ |

Posted on 01/26/2019 11:20 PM

|

|

1/4 Pounder  Posts: 151 Joined: October 08, 2018 |

Quote renatoa wrote: Not sure what the usefulness of exhaust temp would be... the input temp is more important, imo. I mean a hole at the base, with probe near the perforated plate. Can I do profile roasts based on input temp alone, or should I measure other temps? Thank you. |

|

|

|

| renatoa |

Posted on 01/27/2019 2:47 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

Instead an erroneous BT temperature, that give you false information, better have good roasts based on input only, actually, the hot air temperature is much important than some believe... check this thread: https://forum.hom...post_62977 Experimented in the past with drum setups that were impossible to adapt a real bean probe, and indeed, the results based on the "recipe" above were better than any other approach. |

|

|

|

| allenb |

Posted on 01/27/2019 8:20 AM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

Quote JitterzZ wrote: Quote renatoa wrote: Not sure what the usefulness of exhaust temp would be... the input temp is more important, imo. I mean a hole at the base, with probe near the perforated plate. Can I do profile roasts based on input temp alone, or should I measure other temps? Thank you. I agree with Jim that finding a good reliable BT probe spot in a fluidbed is a crap shoot but in the interest of dialing in for the best possible cup, it's a must to take the time to find the spot that will give you the closest bean temperature reading. Unfortunately, in most compact built fluidbed roasters, there is no accurate means of measuring hot air input temperature as the air stream is heavily stratified. If home built and a means is incorporated to allow using a swirl chamber in the build, one can get a pretty good read on input temperature but with all of my store bought FBs, I can move the probe by 1/4" and the reading will change by 50 degrees even if measuring slightly above the RC bottom screen. I experimented with a freshroast a few years back and found placing the probe at the top of the RC within the top portion of the lid consistently gave me around 400F at start of first crack and allowed me to hold a desired rate of rise throughout the roast. Take the time to find a BT location that gives you a repeatable BT temperature. Don't worry about how close you are to the scientifically deduced "real" first crack bean temperature as it's not important. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 01/27/2019 9:04 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

Agree about the last phrase, same beans bag, roasted in 4-5 various roasters (I mean different builds/principle) gave FC anywhere between 185 and 205C, and all were good roasts in the end. All you need is a reference of the FC start, to watch the evolution from that point forward... and sometimes backward ;) |

|

|

|

| JitterzZ |

Posted on 01/27/2019 2:10 PM

|

|

1/4 Pounder  Posts: 151 Joined: October 08, 2018 |

WOW! You guys are GREAT!!!!!! A lot of very helpful info to digest and experiment with. I just purchased a HeatSnob to experiment with on my Freshroast SR500, so I'm just trying to get a baseline of where I should begin. I really enjoy the hands-on intuitive feel of manual fluid bed roasting versus the set-it and forget it feel of my Behmor 1600+. In the near future I plan on building a small fluid bed similar to the one in this thread that Beaner put together ( https://forum.hom...post_40357 ), and then move my way up to something like this one that allenb built here https://forum.hom...post_41881. Lots of fun and lots of great people on this forum. Thank you guys.  |

|

|

|

| renatoa |

Posted on 01/28/2019 2:33 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

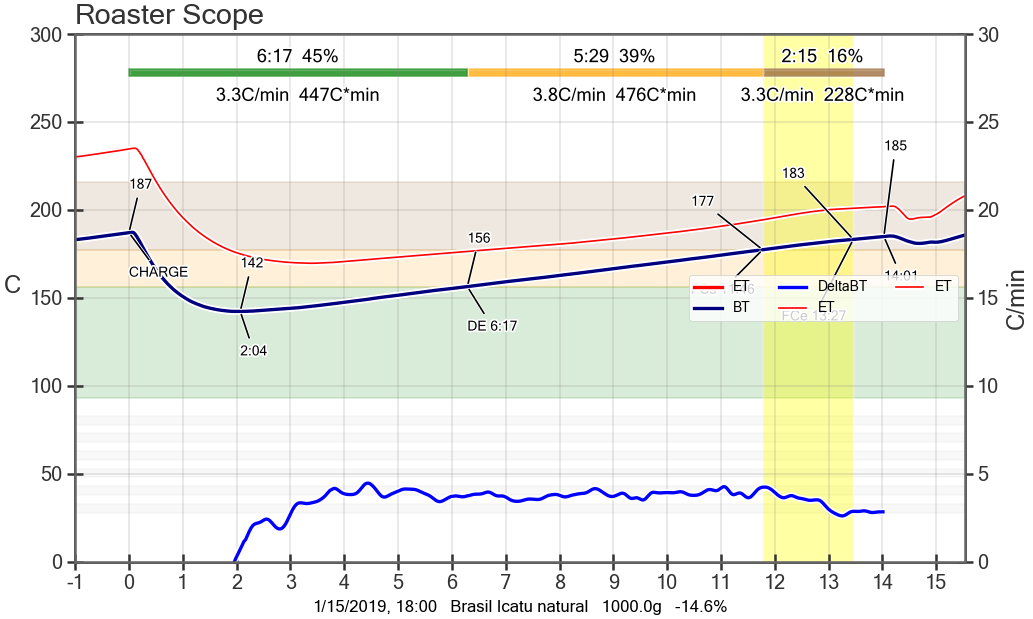

Check attached roast profile to see how dramatical can affect bad probe placement the temperature readings and the false results you can get from such setup. The culprit is the 1 kg drum roaster Dalian. Quiz: let's see how many weird situations can we count from the profile and the possible mistake that were done, and fixes.  ...

renatoa attached the following image:

|

|

|

|

| Jump to Forum: |

Similar Threads

| Thread | Forum | Replies | Last Post |

|---|---|---|---|

| Want to buy SR500 | Fresh Roast 8 and NEW SR 500 | 11 | 04/02/2024 10:24 AM |

| SR500 on the blink | Fresh Roast 8 and NEW SR 500 | 7 | 03/07/2024 9:54 AM |

| Adding a ventilation to the Quest M6 | Quest M3 Roaster | 4 | 12/10/2022 12:13 PM |

| Probing the SR500 | Roasting Coffee | 6 | 05/04/2020 5:36 AM |

| Declining RoR on SR500? | Fresh Roast 8 and NEW SR 500 | 3 | 02/16/2020 1:02 PM |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman