Login

Shoutbox

You must login to post a message.

renatoa

04/17/2024 9:27 AM

, branchu

, branchurenatoa

04/14/2024 5:56 AM

TheOtherJim and papajim,

!

!

!

!allenb

04/11/2024 6:33 PM

Zemona

renatoa

04/11/2024 9:19 AM

Mrbones and sgupta,  ?

?

?

?renatoa

04/10/2024 1:09 AM

, Ed K

, Ed KForum Threads

Newest Threads

War on Farmers by Su...Kaleido Roaster PID ...

Green coffee sellers

Wet beans - Estimati...

Skywalker roaster mods

Hottest Threads

| Skywalker roaster... | [292] |

| Skywalker, the AL... | [214] |

| Skywalker Roasts | [94] |

| My first popcorn ... | [47] |

| War on Farmers by... | [39] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 2

Members Online: 0

Total Members: 8,208

Newest Member: branchu

Members Online: 0

Total Members: 8,208

Newest Member: branchu

View Thread

Who is here? 1 guest(s)

|

5 Lb Roaster Perf Plate Design Help!

|

|

| allenb |

Posted on 11/12/2019 5:28 PM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

We're not finding you argumentative and I'd be asking the same questions until I got somewhere so no worries there! When you were needing to hit over 600 F to maintain desired ROR, let us know what the profile looked like in time/temp. I'm assuming you were never exceeding 30 F/min? Depending on how thin the spout is you're seeing, it might improve going to RR's recommended perf plate % of cross sectional area. It doesn't take much for a fluidbed to do weird things. I'm interested to hear how your perf plate test comes out. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/13/2019 6:18 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Not much change in bean mass movement. What I dont get is it doesnt make much difference if i have 3 pounds or 5 pounds, or even 6. The spout looks about the same although at least its more centered. I wonder if its a volume issue? I didnt try to roast though, so maybe thats what i should be expecting for greens movement, and the roast characteristics will be different On temperature, when I was having to hit over 600, I was finishing the roast in about 15 minutes. ROR was ok in the beginning, around 50 at first, then droppong steadily after the beans hit about 225. It levels off at about 15 for the rest of the roast, but thats me pushing the ET higher and higher to maintain that. |

|

|

|

| CoffeeInterest |

Posted on 11/13/2019 9:17 PM

|

|

Newbie  Posts: 16 Joined: November 23, 2018 |

Perf plate does matter, but less so with an asymmetrical chamber. You have enough clearance to accommodate the batch size you want. You need the right blower as well. My experience has been that the Ametek 122170-18 is the best you can use. Additionally, you probably have too much shielding around your burner to prevent a good consistency of air and flame. Brush flame torches like the Gods BP?s, the Seiverts, Exacts are absolutely perfect for this. They won?t blow out. |

|

|

|

| tamarian |

Posted on 11/13/2019 10:45 PM

|

|

1/2 Pounder  Posts: 320 Joined: January 21, 2012 |

Quote I do want to talk more about the heat issue. Do I need to move more beans? I feel like I am moving a small number of beans compared to the total bean mass and that may be part of the total issue. If it helps, I'm thinking in the theoretical sense. So what is it about a 20 pound roaster that allows the heat to stay lower? I feel like i'm not getting my question across correctly, but maybe you all will understand what i am after. Is it an air volume issue? air pressure? cross section of beans moving? One thought i had, is my perf plate hole density is a lot tighter then most of what i see on here. The movement looks right for this size and design. Asymmetrical helps with larger batches. But if the roast is progressing fine, decently controlled and gives uniform color without roast defects then it is time to put some nice beans and roast them. See how you and others like the taste, compared to same beans on a different roaster. Weld bulk, nails and any obstructions near the perforated plated can cause fires. Some beans can get trapped and collect heat until red. If there is little movement at the bottom left, increase the angle. If spouting is stronger in one area, make sure the roaster is level, and seal any leaks. Wa'il. 1 Kg PID'ed gas-fired fluid bed roaster, GS/3MPS, K10F

|

|

|

|

| pisanoal |

Posted on 11/14/2019 6:42 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote tamarian wrote: Quote I do want to talk more about the heat issue. Do I need to move more beans? I feel like I am moving a small number of beans compared to the total bean mass and that may be part of the total issue. If it helps, I'm thinking in the theoretical sense. So what is it about a 20 pound roaster that allows the heat to stay lower? I feel like i'm not getting my question across correctly, but maybe you all will understand what i am after. Is it an air volume issue? air pressure? cross section of beans moving? One thought i had, is my perf plate hole density is a lot tighter then most of what i see on here. The movement looks right for this size and design. Asymmetrical helps with larger batches. But if the roast is progressing fine, decently controlled and gives uniform color without roast defects then it is time to put some nice beans and roast them. See how you and others like the taste, compared to same beans on a different roaster. Weld bulk, nails and any obstructions near the perforated plated can cause fires. Some beans can get trapped and collect heat until red. If there is little movement at the bottom left, increase the angle. If spouting is stronger in one area, make sure the roaster is level, and seal any leaks. Thanks for the reply! Really happy to have you on the thread. So I'm not sure how far back you have read, but ive roasted 3 batches. The first 2 I had ti get the ET up to almost 700 F in order to get close to my intended profile. This doesn't seem right? So to your first comment, i guess i would say I'm not happy with how it controls yet. I do have some issues with movement around the back left due to obstructions from the glass and mlunting hardware. The welds are actually really good. It was TIG welded at a fab shop, amd done really well so that shouldnt be an issue. I have however been thinking of soldering in a steeper angled plate at the very top (maybe an inch or so) of the angled plate to help get that back corner moving. I definitely checked level on the roaster and continue to have the same issues, thin spout. Depending on changes i make to my perf plate, it moves from front corner to back corner to middle-ish. It also seems really high in order the get the beans moving. I made a makeshift perf plat out if aluminum to test, its 1.5 inches wide, and has around 120 1/8 holes. I noticed your roaster seems to have a much more spread out perforation pattern for an even larger perf plate area. Do you think i need to try significantly less holes? My open area compared to cross sectional area is like 3.5 percent. Yours based on your drawings is like .5. |

|

|

|

| pisanoal |

Posted on 11/15/2019 10:45 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote CoffeeInterest wrote: Perf plate does matter, but less so with an asymmetrical chamber. You have enough clearance to accommodate the batch size you want. You need the right blower as well. My experience has been that the Ametek 122170-18 is the best you can use. Additionally, you probably have too much shielding around your burner to prevent a good consistency of air and flame. Brush flame torches like the Gods BP?s, the Seiverts, Exacts are absolutely perfect for this. They won?t blow out. Really sorry, I completely missed this post. I really appreciate the feedback. With your blower recommendation, are you suggesting I'm lacking in CFM or pressure? Just looking to compare my blower to the one you recommended. I do have a good bit of shielding around my burner, but I'm not sure id say its too much preventing the consistency you are talking about. I could see having trouble maintaining heat that way? But I have plenty of heat getting to my air stream, and it does not seem to fluctuate wildly. |

|

|

|

| pisanoal |

Posted on 11/15/2019 10:54 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Update: I ran lots of tests with different perf plate designs, flattened it out, more hole, less holes, bigger holes, etc. Ultimately I decided to go with a stepped design (pictured below). Essentially, a 1.5" flat perf plate, and a steeper angle from the end of the original solid 45. This dramatically improved the speed at which beans are being returned to the perf plate. I still had issues with the back corner which was the result of two things. 1. Thermocouple Placement for bean mass. It was about 1.5 inches off the angled plate towards the back, but it extended almost all the way across the RC. 2. Geometry of the Square RC. I started realizing that there were several 6" square builds on here, but no one either finished, reported back, or hit their target bean load (it was always way less). If someone found different results, please point me to the thread. It seemed the only successful ones were circular. Since there are no "corners" I think that improves both bean loft characteristics, and return characteristics. I temporarily added in a steep plate where the 45 plate meets the back wall. Not much change. Removed the TC and viola. That combination did the trick. So I'm going to a shorter TC and I'm going to move it up to the faster moving beans to keep from slowing down the back lower corner, and add in that steeper plate. I haven't roasted yet, because my mods are held in by duct tape... So ill need to make some semi-permanent modifications in order to do a roast test. Photo attached of changes, original is in blue, red is proposed changes.

pisanoal attached the following image:

|

|

|

|

| renatoa |

Posted on 11/15/2019 12:26 PM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

You can use a flat TC, to not disturb the beans flow. |

|

|

|

| pisanoal |

Posted on 11/15/2019 1:37 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote I havent seen a flat one, unless you,are talking about just the twisted wire ones. Do you have a link to one by chance? |

|

|

|

| renatoa |

Posted on 11/15/2019 1:50 PM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

Yes, the naked junction, in a kapton foil sandwich, posted some days ago in other thread. https://perfectpr...cts/tl0225 Actually, the link was just to ilustrate the concept, I am DIY mine using a higher temperature rating kapton, the posted model is 200 C only. |

|

|

|

| pisanoal |

Posted on 11/15/2019 1:55 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Thanks. I may try that. I have a shorter TC too |

|

|

|

| CK |

Posted on 11/15/2019 2:33 PM

|

|

1/2 Pounder  Posts: 250 Joined: December 07, 2018 |

Interesting concept with the flat TC, but be mindful it may be reading the metal wall temperature instead of the BT. |

|

|

|

| pisanoal |

Posted on 11/15/2019 9:02 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote CK wrote: Interesting concept with the flat TC, but be mindful it may be reading the metal wall temperature instead of the BT. Yeah you would have to figure out a way to suspend it in the coffee bean mass at the angle the beans are moving i think |

|

|

|

| renatoa |

Posted on 11/16/2019 1:59 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

I plan to test a sandwich consisting of an outer layer of kapton, toward the wall, a single layer should be enough to make the wall influence negligible, and an inner layer of copper, on top and in contact with junction, thus increasing the contact area with beans. This way I hope to have the best approach to this difficult temperature picking scenario. |

|

|

|

| tamarian |

Posted on 11/16/2019 5:19 AM

|

|

1/2 Pounder  Posts: 320 Joined: January 21, 2012 |

Quote I do want to talk more about the heat issue. Do I need to move more beans? I feel like I am moving a small number of beans compared to the total bean mass and that may be part of the total issue. If it helps, I'm thinking in the theoretical sense. So what is it about a 20 pound roaster that allows the heat to stay lower? I feel like i'm not getting my question across correctly, but maybe you all will understand what i am after. I am more hands-on and find that taste trumps theory. Most theories on roasting are based on drums. Each roaster has its own characteristics. So it more important to see how does it taste? Where did you place ET probe? Some locations may reach even higher if air flow is too high. With fluid beds you just need to initiate the circular movement and gradually decrease air flow as the roast progresses. If you place ET probe above the beans, away from the air flow, it should not be much higher than BT. If below perforation it will a lot higher, depending on metal and thickness. Getting rid of dead zones with steeper angle is crucial to taste (avoiding taste defects) and safety. Adjusting perforation may help with efficiency, and possibly taste. But you need a reference point with taste, to see if any changes are worth it. But it may be easier to just adjust air flow as a starter. Wa'il. 1 Kg PID'ed gas-fired fluid bed roaster, GS/3MPS, K10F

|

|

|

|

| pisanoal |

Posted on 11/16/2019 7:45 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote tamarian wrote: I am more hands-on and find that taste trumps theory. Most theories on roasting are based on drums. Each roaster has its own characteristics. So it more important to see how does it taste? Where did you place ET probe? Some locations may reach even higher if air flow is too high. With fluid beds you just need to initiate the circular movement and gradually decrease air flow as the roast progresses. If you place ET probe above the beans, away from the air flow, it should not be much higher than BT. If below perforation it will a lot higher, depending on metal and thickness. Getting rid of dead zones with steeper angle is crucial to taste (avoiding taste defects) and safety. Adjusting perforation may help with efficiency, and possibly taste. But you need a reference point with taste, to see if any changes are worth it. But it may be easier to just adjust air flow as a starter. So my ET probe is about an inch below my perf plate, however, i am also scorching my silicone gasket on my door which is rated for 600 degrees. Thats in the bean spout area above tbe perf plate. So i guess its probably ok to go a little higher then recommended ET since the beans arent quite seeing that high of temp? 675 still seems sway to high though. I am definitely getting scorching on the beans too but not sure if its related to bean movement and dead spots or super high ET. It also tastes scorched which makes sense since some beans are. Anyways, after i get the steeper plate on the back wall in place, bean movement will be greatly improved and we will see what things look like from there. Hopefully i can get a roast with a reasonable ET and I can get a reasonable taste test in. Did you do a build thread on your 10kg roaster? |

|

|

|

| CoffeeInterest |

Posted on 11/16/2019 8:16 AM

|

|

Newbie  Posts: 16 Joined: November 23, 2018 |

Quote pisanoal wrote: Quote CoffeeInterest wrote: Perf plate does matter, but less so with an asymmetrical chamber. You have enough clearance to accommodate the batch size you want. You need the right blower as well. My experience has been that the Ametek 122170-18 is the best you can use. Additionally, you probably have too much shielding around your burner to prevent a good consistency of air and flame. Brush flame torches like the Gods BP?s, the Seiverts, Exacts are absolutely perfect for this. They won?t blow out. Really sorry, I completely missed this post. I really appreciate the feedback. With your blower recommendation, are you suggesting I'm lacking in CFM or pressure? Just looking to compare my blower to the one you recommended. I do have a good bit of shielding around my burner, but I'm not sure id say its too much preventing the consistency you are talking about. I could see having trouble maintaining heat that way? But I have plenty of heat getting to my air stream, and it does not seem to fluctuate wildly. It?s all about pressure when you get into the bigger loads. CFM is related, but it?s more on how well the loft motor can handle 6-10# or bouncing beans on its air bed. My first motor struggled a lot at 6lbs. The Ametek I shared easily lofts more than 22# of green. |

|

|

|

| renatoa |

Posted on 11/16/2019 9:01 AM

|

|

Administrator  Posts: 3005 Joined: September 30, 2016 |

At 260?270 ?C; 500?518 ?F is cellulose melting point https://en.wikipe.../Cellulose His 600 F rated silicone gasket is scorching... so the degrees are there, whatever is the ET probe placed... what to say more... These are facts, not related to drum or a specific roasting method. |

|

|

|

| pisanoal |

Posted on 11/16/2019 4:33 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote renatoa wrote: At 260?270 ?C; 500?518 ?F is cellulose melting point https://en.wikipe.../Cellulose His 600 F rated silicone gasket is scorching... so the degrees are there, whatever is the ET probe placed... what to say more... These are facts, not related to drum or a specific roasting method. I agree. And that gasket is in contact with the beans. So regardless its currently not transferring heat efficiently to the bean mass. |

|

|

|

| pisanoal |

Posted on 11/16/2019 4:37 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote It?s all about pressure when you get into the bigger loads. CFM is related, but it?s more on how well the loft motor can handle 6-10# or bouncing beans on its air bed. My first motor struggled a lot at 6lbs. The Ametek I shared easily lofts more than 22# of green. Thats what I assumed but wanted to make sure i wasnt missing something. Thr motor im using is rated for 120" WC. So I should have plenty of pressure. The flow is rated at 95 CFM. So the big difference between the one you recommended and the one i have is the air flow. |

|

|

|

| pisanoal |

Posted on 11/18/2019 10:43 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

I was away this weekend and unable to do anything on this project but think about it. When I got home, I cut a piece of acrylic to make a steeper angled plate "all the way" down to the perf plate instead of just at the back corner. Bean mass movement was significantly improved, spouting characteristics were not but I think that's ok. What was changed that will help me control the heat transfer is I can move the beans a lot better with a lot less air. Before, I was having to really loft the beans in order to get "satisfactory" movement in the back corner. So I'm hoping this solves my heat issue. I don't want to spend the $$ for the fab shop to TIG weld this thing back in there for me, so I think ill just tack it in there and make it air tight with rtv instead of seal welding it. Some thoughts: I think that with a cylindrical RC, you don't get dead spots as easily as with a square. To combat the dead spot issue, a steeper than 45 degree angle seems to be a really good idea for higher roast volumes. Thanks goes to tamarian for sticking that rock in my shoe. I'll check back after I get to try a roast. |

|

|

|

| pisanoal |

Posted on 11/19/2019 10:13 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote CoffeeInterest wrote: Quote pisanoal wrote: Quote CoffeeInterest wrote: Perf plate does matter, but less so with an asymmetrical chamber. You have enough clearance to accommodate the batch size you want. You need the right blower as well. My experience has been that the Ametek 122170-18 is the best you can use. Additionally, you probably have too much shielding around your burner to prevent a good consistency of air and flame. Brush flame torches like the Gods BP?s, the Seiverts, Exacts are absolutely perfect for this. They won?t blow out. Really sorry, I completely missed this post. I really appreciate the feedback. With your blower recommendation, are you suggesting I'm lacking in CFM or pressure? Just looking to compare my blower to the one you recommended. I do have a good bit of shielding around my burner, but I'm not sure id say its too much preventing the consistency you are talking about. I could see having trouble maintaining heat that way? But I have plenty of heat getting to my air stream, and it does not seem to fluctuate wildly. It?s all about pressure when you get into the bigger loads. CFM is related, but it?s more on how well the loft motor can handle 6-10# or bouncing beans on its air bed. My first motor struggled a lot at 6lbs. The Ametek I shared easily lofts more than 22# of green. I tried my new angled plate design and it helped a little but was still having issues with the temperature. I also had to turn the air back up at the end of the roast to keep beans moving which i thought was really odd. I hypothesized that maybe the dlow falloff at the pressure required to loft the beans was significant enough to not be able to deliver enough BTUs. I tried two blowers tonight and finally had a successful roast! I was able to keep my ROR where i wanted and the ET stayed under 500 degrees. I was stuck on having enough pressure because that seems to be what people think is most important, but the pressure vs flow curve definitely comes into play when pushing the limits of the blower pressure. The blower you recommended is almost twice the CFM at close to the same pressure so i think it would act as my two blowers. Do you see any issues with this? How quiet is the blower you recommended? Looks like a low power draw too? Do you have a source that isnt $200. |

|

|

|

| allenb |

Posted on 11/20/2019 4:51 PM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

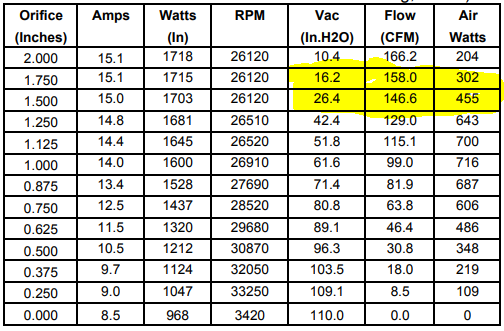

In looking at Dans spouting bed tests in the downloads section, it makes sense you would need more than 100 cfm to loft and effectively agitate 5 lbs +. These tests are done with a totally different roast chamber and relatively shallow bean bed depth compared to yours and yet show that at 5 lbs +, need more than 100 cfm.

allenb attached the following image:

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 11/20/2019 5:25 PM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

Quote I was stuck on having enough pressure because that seems to be what people think is most important, but the pressure vs flow curve definitely comes into play when pushing the limits of the blower pressure. Good point. A regular fan or blower curve will show x flow in cfm at x static pressure. As we start to approach the flow limit of a particular blower, pressure drops quickly. Pressure is important but remember that most fluidbed roasters require no more than around 20" water column to get even the most demanding bed of beans lofting and many only need less than 10". It's unfortunate that most spec sheets for vacuum blowers show only the air flow through x size hose port and maximum pressure/vacuum in inches of H2O at deadhead (no flow). To me, the most important spec to us roaster builders for a vacuum motor is cfm since all vacuum blowers will have way more static pressure capability than we will ever need. A vacuum blower capable of 200" pressure or vacuum but can only muster 50 cfm through a 2" port is useless to us. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 11/20/2019 7:34 PM

|

|

Administrator  Posts: 3858 Joined: February 23, 2010 |

In looking at the static pressure/cfm chart amatek publishes for the blower you're thinking of using, it will move a lot of air at high static pressures. At the static pressure you're likely to be encountering in order to loft the beans effectively (somewhere in the 20's, looks like this fan will do around 150 cfm which should give you good headroom and not have to run it full tilt and will be quieter. Model: 122170-18

allenb attached the following image:

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Jump to Forum: |

Similar Threads

| Thread | Forum | Replies | Last Post |

|---|---|---|---|

| Kaleido Roaster PID parameters | Roasting Coffee | 2 | 04/13/2024 3:07 PM |

| Skywalker roaster mods | Other Roasters | 293 | 04/07/2024 4:31 PM |

| Skywalker, the ALM chinese one pound roaster | Other Roasters | 215 | 04/02/2024 1:48 AM |

| My first popcorn mod roaster (vahegan) | Fluidbed Roaster | 48 | 03/24/2024 12:04 PM |

| Fatamorgana electric drum roaster | Other Roasters | 2 | 03/24/2024 10:03 AM |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman