Login

Shoutbox

You must login to post a message.

renatoa

11/05/2024 3:32 AM

, anotherhd

, anotherhdrenatoa

11/04/2024 2:09 PM

cm0512,

renatoa

11/01/2024 2:26 PM

brandonloyal ballard ,

?

?

?

?renatoa

10/30/2024 11:25 AM

geeheeb and Rugger

geeheeb and Ruggerrenatoa

10/29/2024 5:28 AM

, thomasi

, thomasiForum Threads

Newest Threads

Propane Fluid Bed Ro...Coffee popper and br...

Skywalker, the ALM c...

Leaf Vac bean cooler

The History of Coffee

Hottest Threads

| Skywalker roaster... | [389] |

| Skywalker, the AL... | [294] |

| Skywalker Roasts | [108] |

| War on Farmers by... | [63] |

| Propane Fluid Bed... | [37] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,556

Newest Member: anotherhd

Members Online: 0

Total Members: 8,556

Newest Member: anotherhd

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

Propane Fluid Bed Roaster Design

|

|

| jfern |

Posted on 10/23/2024 5:08 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Hi Everyone, I am new to the Home Roasters forum. I have been home roasting for about 6 years on a small DIY roaster and am looking to upscale my roast capacity to 3 pounds per batch. I acquired a roast chamber that accommodates this capacity, but am struggling to find specs online for heat and air chambers for a fluid bed roaster. Additionally, I salvaged a 120V/9A Lamb vacuum motor and have purchased a 50,000btu propane burner for the project. Would anyone have advice for designing a roaster this size. In particular, I am looking for information about distance from the burner flame to the perf opening in the roast chamber and how to regulate gas flow efficiently as to not scorch the beans. I appreciate any insights and suggestions. Thank you! Justin |

|

|

|

| renatoa |

Posted on 10/24/2024 2:29 AM

|

|

Administrator  Posts: 3192 Joined: September 30, 2016 |

Welcome! You could also take a look at bubble bed designs, which are close to FB, but less power hungry, and also allow for a flavor of "conductive" heat transfer to be added. |

|

|

|

| jfern |

Posted on 10/24/2024 12:19 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

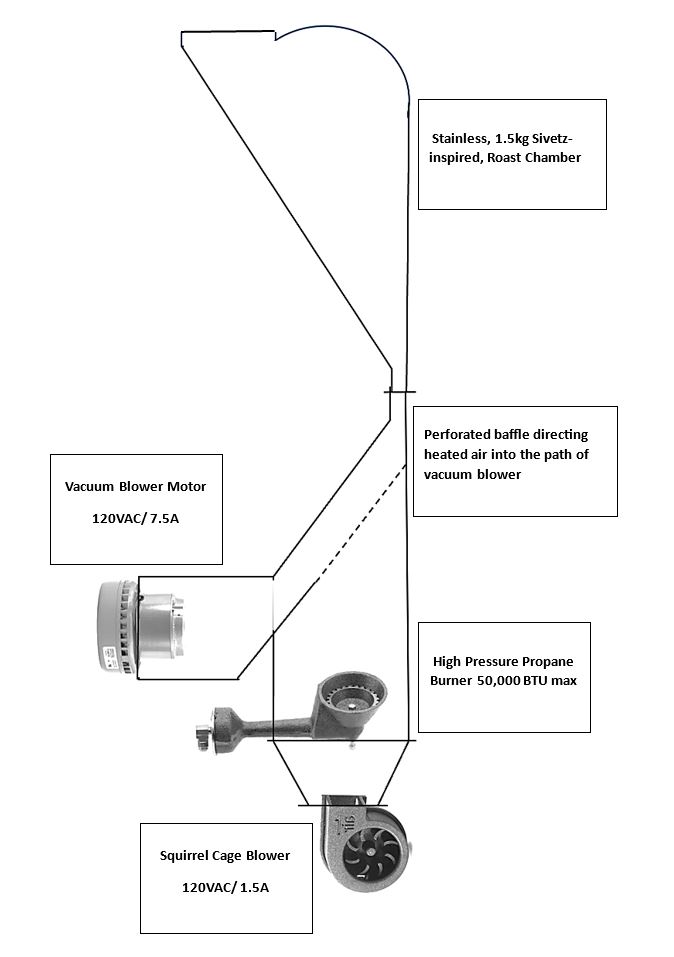

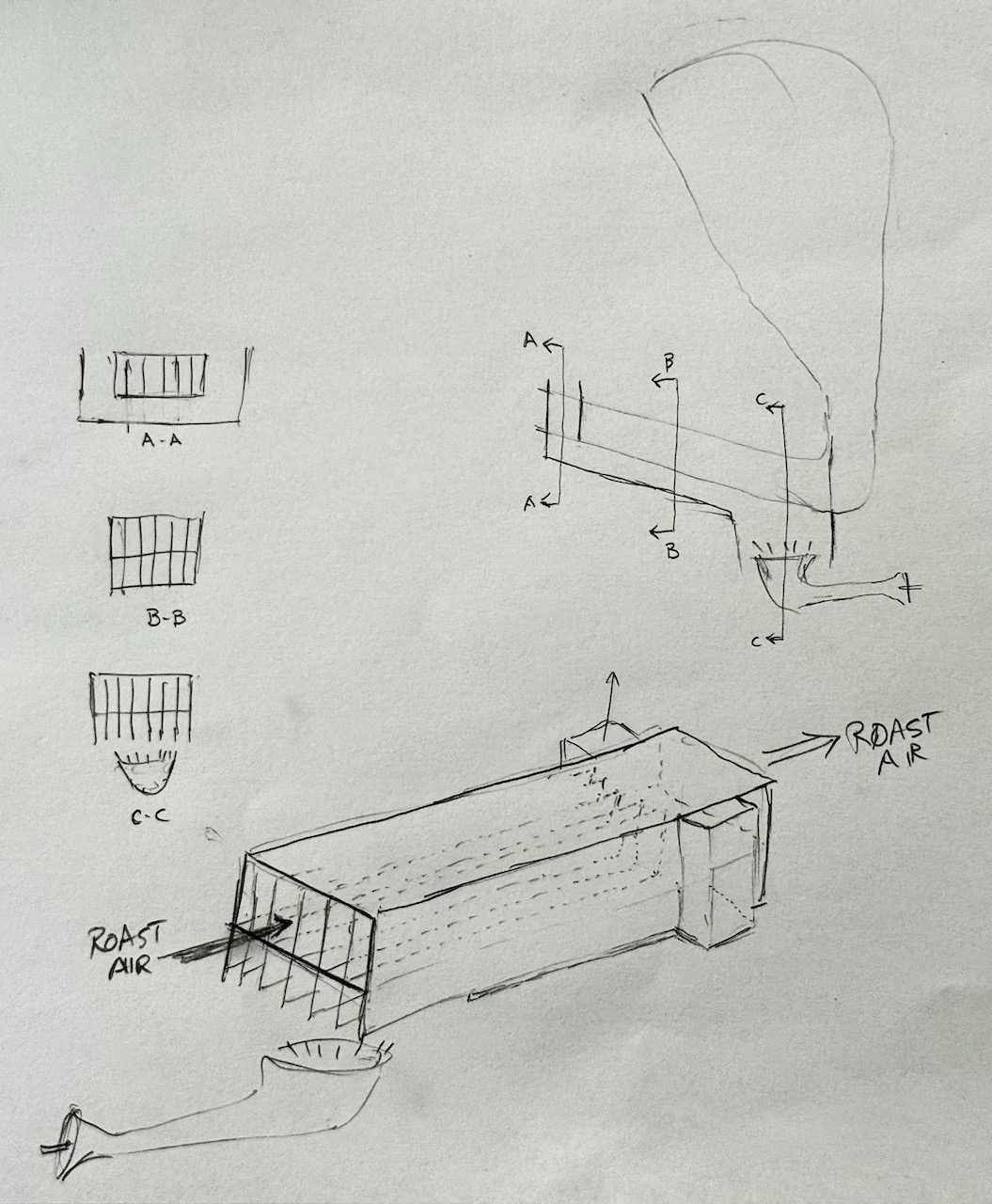

Thank you for the warm welcome and the recommendation Renatoa! Unfortunately, I am locked in on a concept and determined to figure out the best specs and design for a 1.5 kg fluid bed roaster designed around a stainless steel roast chamber I was gifted. I want to do my best to build combustion and vacuum chambers that will mate well with this design. If you are willing to put eyes on the image attached and give feedback on whether this concept could work it would be greatly appreciated. Thank you!

jfern attached the following image:

|

|

|

|

| jfern |

Posted on 10/24/2024 12:28 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

I should ad that the design relies on a more "passive" channel for combustion, rather than placing the burner directly in the path of the blower. The hope is this will allow me to manage the intense heat of the burner which is rated at 50,000 BTU max and avoid extinguishing the flame.. |

|

|

|

| jwmelvin |

Posted on 10/24/2024 9:55 PM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

Seems difficult to modulate the lower blower to maintain slow but positive flow into the roast chamber. Also means the burner outlet is in an area of increased pressure relative to it's intake, which impairs its flow (not important if using forced aspiration). I think you'd want the burner either in the main flow but shielded, or with some heat-exchanger arrangement. |

|

|

|

| progen |

Posted on 10/25/2024 2:05 PM

|

|

1/4 Pounder  Posts: 93 Joined: December 17, 2019 |

Quote jwmelvin wrote: Seems difficult to modulate the lower blower to maintain slow but positive flow into the roast chamber. Also means the burner outlet is in an area of increased pressure relative to it's intake, which impairs its flow (not important if using forced aspiration). I think you'd want the burner either in the main flow but shielded, or with some heat-exchanger arrangement. Yeah, from the few examples of gas powered ones I've seen, there is some heat exchanging device and it's not the open flame in the path of the incoming air. For what it's worth, to the OP, I think a 3lb hot air roaster can still be run off electricity. My 6lb capable one is still running off electricity. I did think of switching it to being gas powered but the heat exchanger part will require a lot of redesigning and I've already spent quite a bit of money on 10mm² and 16mm² wiring. |

|

|

|

| jfern |

Posted on 10/25/2024 9:49 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Thank you! I appreciate the honest feedback! It seems the lower blower may be obsolete, and the better approach is to position the burner directly in the air flow with some sort of shielding to avoid extinguishing the flame? Also, jwmelvin, would you please provide more information about a heat exchanger arrangement, if it's not too much trouble? Progen, I would have preferred to do an electric build, but I live in a rental home and do not have easy access to a 240V outlet. The roaster would be used outdoors under an open carport. |

|

|

|

| progen |

Posted on 10/26/2024 8:46 AM

|

|

1/4 Pounder  Posts: 93 Joined: December 17, 2019 |

Quote jfern wrote: Thank you! I appreciate the honest feedback! It seems the lower blower may be obsolete, and the better approach is to position the burner directly in the air flow with some sort of shielding to avoid extinguishing the flame? Also, jwmelvin, would you please provide more information about a heat exchanger arrangement, if it's not too much trouble? Progen, I would have preferred to do an electric build, but I live in a rental home and do not have easy access to a 240V outlet. The roaster would be used outdoors under an open carport. The copper coils in an instant bathroom heater is a heat exchanger. Same with the thermoblock in cheaper espresso machines. The convection medium is not in direct contact with the heat source. With hot air heating, obviously a long metal tube heated by open flames will then heat up the air travelling inside it to the roasting chamber. The larger the heated area, the greater the efficiency of heat transfer but that also brings new headaches like having to increase the output of your heat source. So you can think LOOSELY of a drum roaster as being more like a storage heater since the drum absorbs and stores more heat while losing less and slower when the heat source is removed whereas a hot air roaster is more like an instant heater. Needs more power but responds to changes faster. |

|

|

|

| jfern |

Posted on 10/26/2024 2:18 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

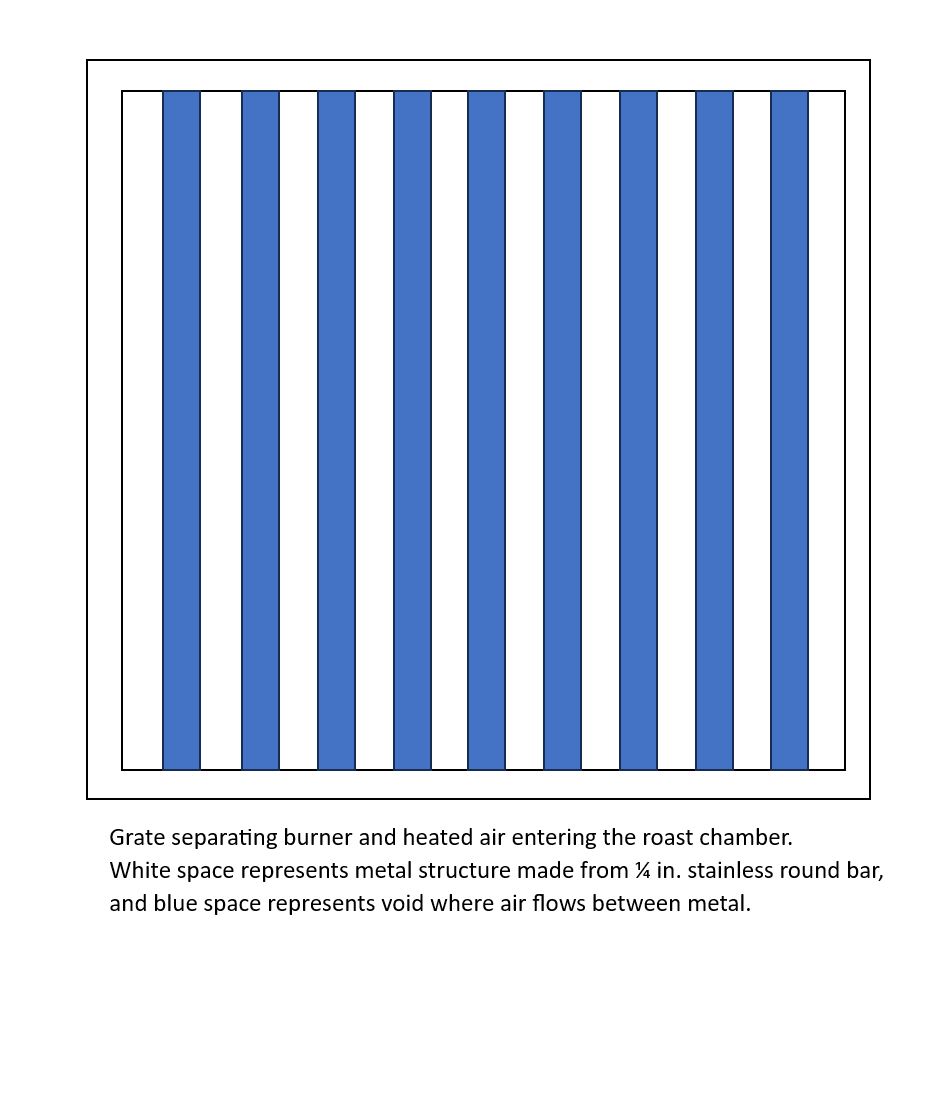

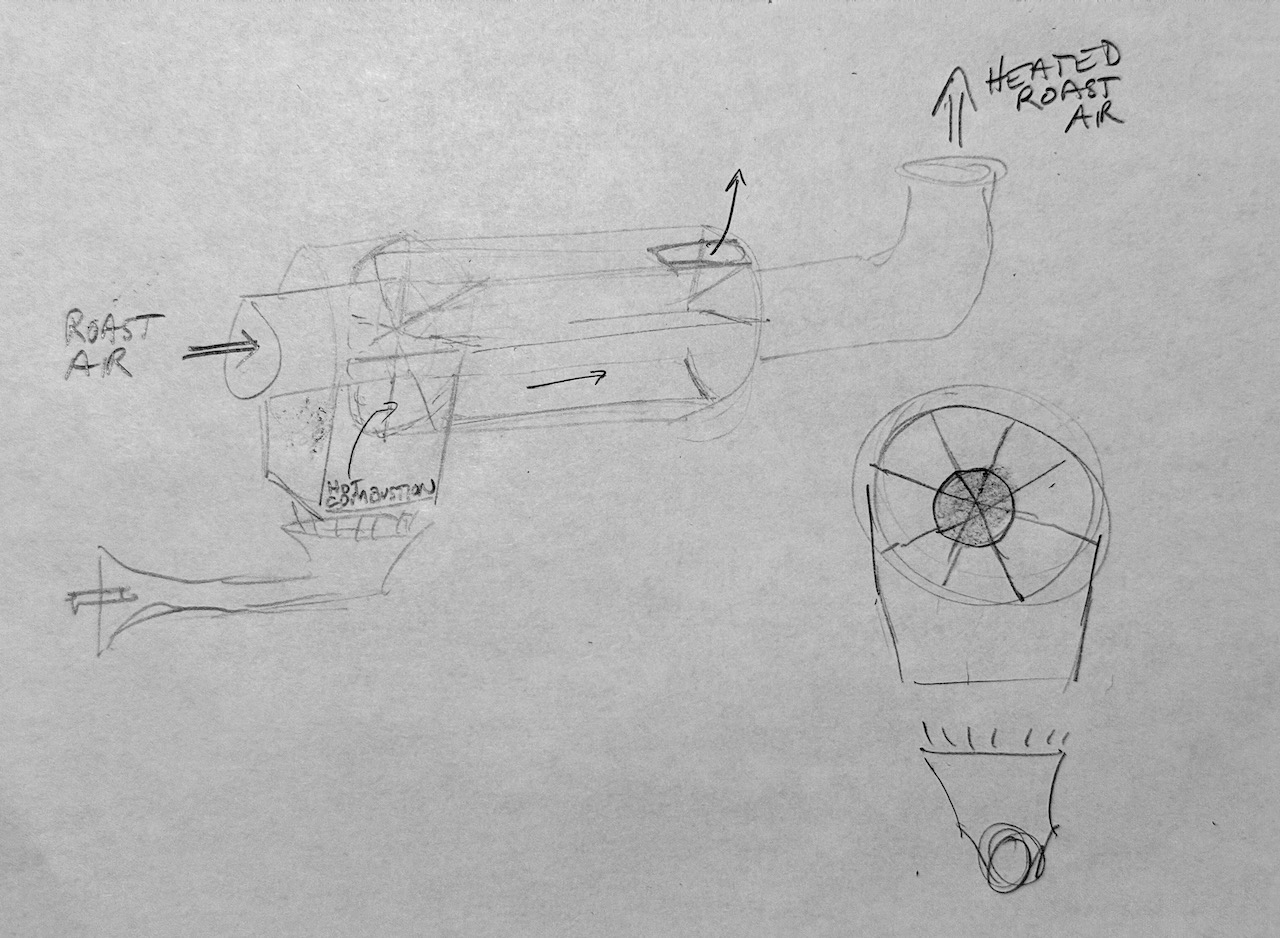

Good illustrations, Progen! In the context of an air roaster, could the heat exchange consist of 1/4 inch round steel bar laid in a parallel pattern to create a grate the heated air passes through before reaching the roast chamber? I've attached an example below. Thank you!

jfern attached the following image:

|

|

|

|

| jfern |

Posted on 10/26/2024 3:17 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

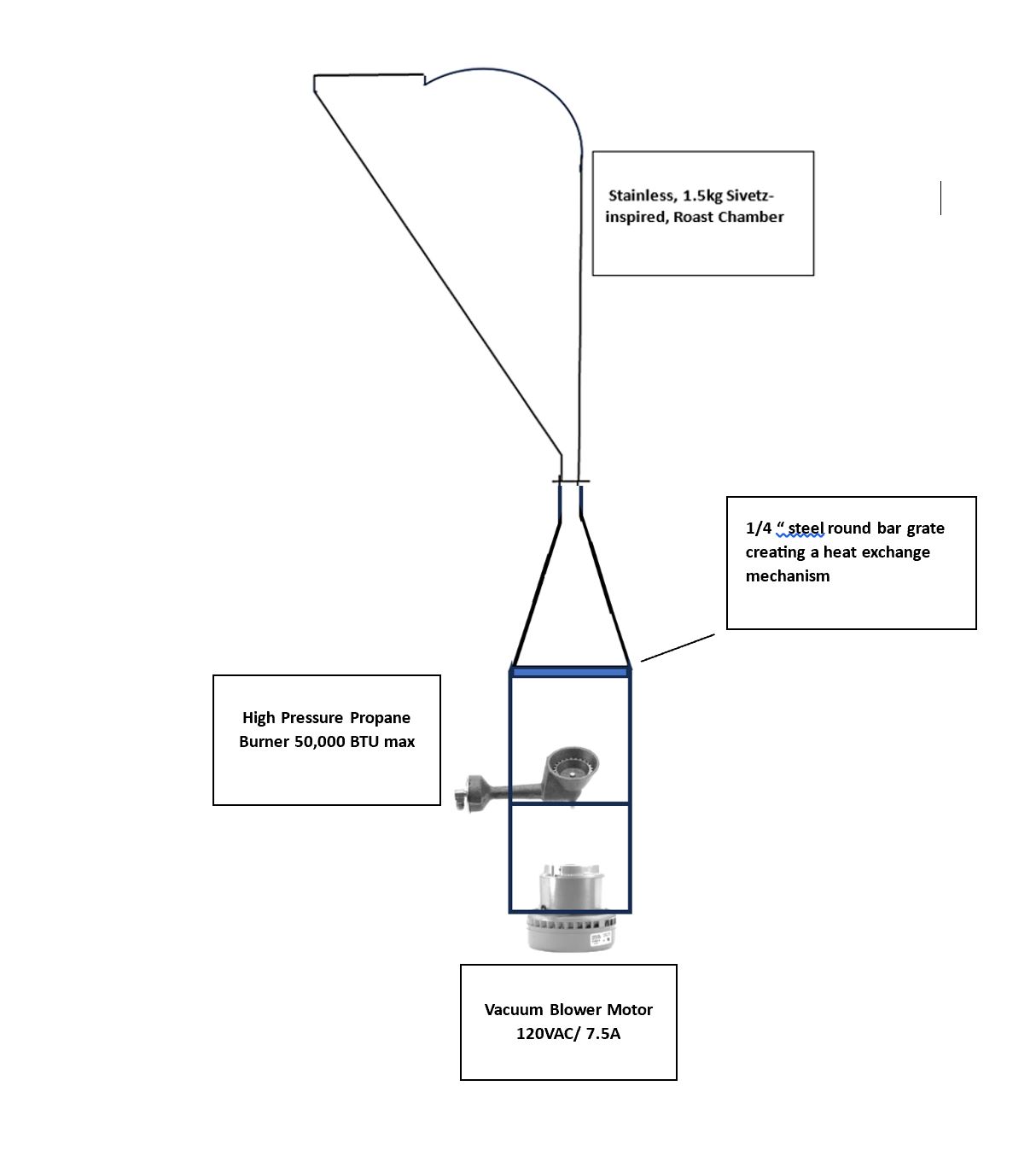

Would a design with a heat exchange mechanism look something like this?

jfern attached the following image:

|

|

|

|

| Tim David |

Posted on 10/26/2024 3:30 PM

|

|

Newbie  Posts: 1 Joined: October 10, 2024 |

Hey Justin, interesting setup you’re building! Just curious, have you ever thought about commercial machines for the brewing end, like the Franke A1000? I’ve seen it used in some businesses for high-volume brewing after roasting, and the quality is top-notch for those who love precision. Not quite what you’re building, but thought it might be of interest if you’re scaling up! |

|

|

|

| allenb |

Posted on 10/27/2024 12:36 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

Quote jwmelvin wrote: Seems difficult to modulate the lower blower to maintain slow but positive flow into the roast chamber. Also means the burner outlet is in an area of increased pressure relative to it's intake, which impairs its flow (not important if using forced aspiration). I think you'd want the burner either in the main flow but shielded, or with some heat-exchanger arrangement. As mentioned by jwmelvin, your atmospheric burner's air intake to it's venturi must be within the combustion (high pressure) side of the works. If not, any pressure above atmospheric will blow backwards through the burner and out through the venturi inlet bell. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 10/27/2024 1:12 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Thank you for the clarification Allenb! I am certainly not an engineer, and approach these concepts in an intuitive manner with much trial and error. However, I have just enough sheet metal for one shot at this build, so not much margin for error. My assumption was that high air pressure entering the venturi opening (via a vacuum blower) would rapidly disperse the propane preventing combustion, but I think you and jwmelvin are saying the venturi opening must be at equal air pressure to the environment of the flame. If so, do you think it would be possible to use the style of burner in the illustration, or is there a better option. I've seen the Sievert 2941 torch head referenced in this style of roaster, but these are difficult to come by. It seems about 5,000-10,000 btus are needed per pound of coffee, but please offer any insight you have. Thank you for your time! |

|

|

|

| jwmelvin |

Posted on 10/27/2024 8:32 PM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

Your sketches regarding a heat exchanger aren't quite there. A heat exchanger is used to separate two fluid volumes: the heater and the roast air. So flame would burn inside a tube that passes through the air flow. (Ideally, multiple smaller tubes so that you maximize surface area; an automobile radiator is a heat exchanger.) It's more difficult to build for sure. As for a venturi burner, they are quite sensitive to pressure because the induced flow is not particularly strong. If the air is fed from a port in the roast airflow close to where the burner output is, there would be minimal difference between those pressures, so the burner has a chance of working. I can't say I've experimented with something like that, though. A venturi burner might be challenging in that application and a pain to tune properly. |

|

|

|

| jfern |

Posted on 10/27/2024 10:53 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

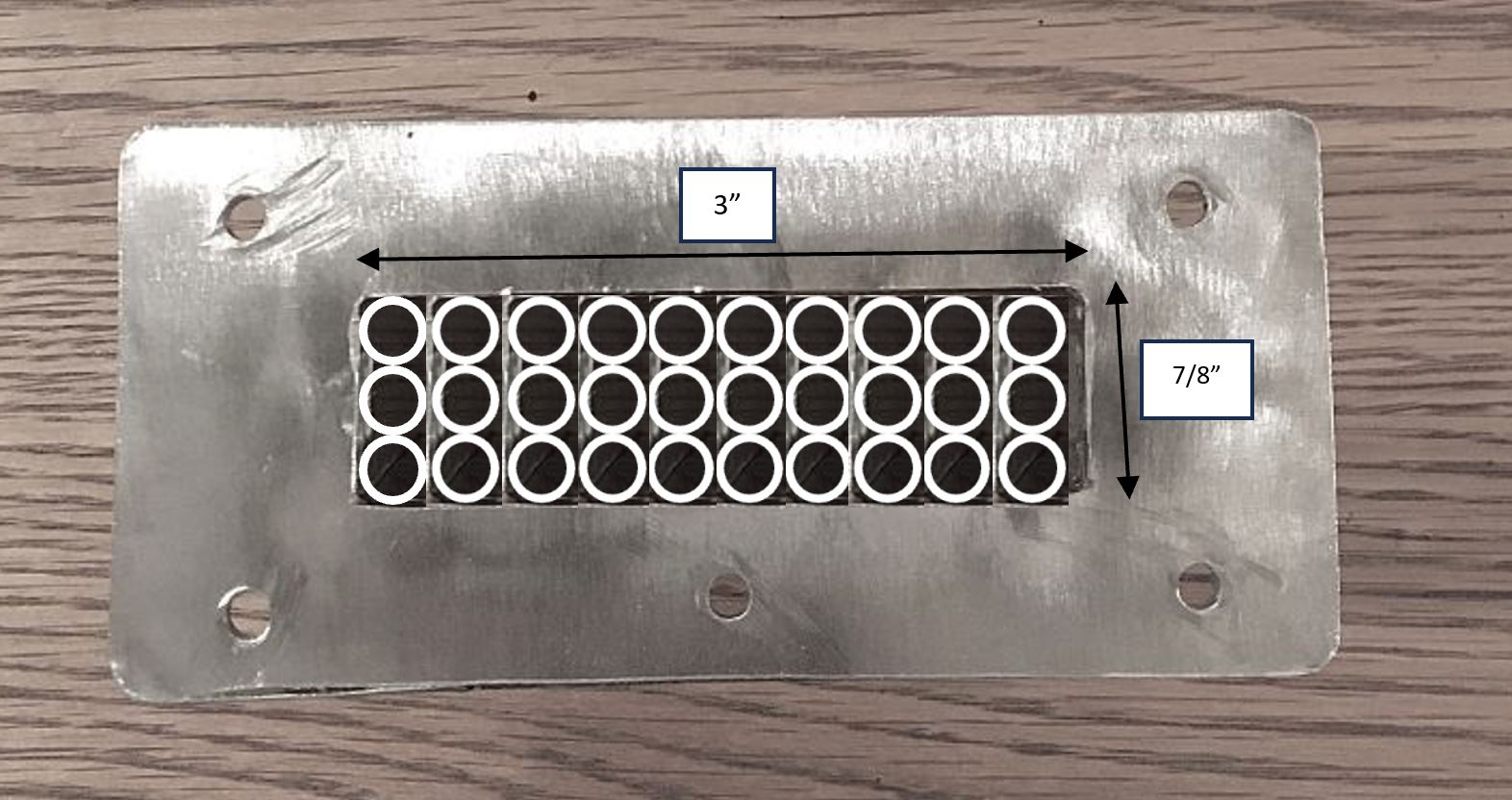

Thanks, Jwmelvin! I have attached a few images of the bracket I will use to mate the roast chamber to the heat chamber. It is roughly 2 1/2" high. The inner dimensions are 3" x 7/8". Image 2B includes 3 rows of 10, small diameter stainless tubing extending the height of the bracket. Would this constitute a heat exchanger?

jfern attached the following images:

|

|

|

|

| jwmelvin |

Posted on 10/28/2024 8:03 AM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

I intended something like my sketch. But it would benefit from longer tubes carrying the burner output, and some consideration of the total area of those tubes, etc. The point is that hot burner gas flows through the tubes and roast air flows across those tubes to transfer heat from the burner gas to the roast air. I have a hard time imagining that you will get the temperature you need in the roast air without a very careful design. My sketch is not it! Edited by jwmelvin on 10/28/2024 8:09 AM |

|

|

|

| jfern |

Posted on 10/28/2024 1:02 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Awesome concept! Thank you for taking the time to sketch this out for me! With this design, the venturi and flame are not in direct contact with the air flow, which circumvents the problem of shielding the flame. Oh, so this is what a heat exchanger is! Got it! Do you have any suggestions for length, thickness, or diameter of tube that would work in this arrangement? If the questions are too much, it's okay to set a boundary! Thanks! |

|

|

|

| jwmelvin |

Posted on 10/28/2024 2:14 PM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

Sorry, I don't have specific suggestions because I've never attempted this. It seems like a potentially fun quest, but one that seems likely to be more difficult than you anticipate. It's entirely possible that it will not work even with an optimal design. Perhaps the better option is to keep the burner in the roast air, but manage the pressures appropriately. That could simplify a lot of things. I imagine you could start with a single chimney on the burner to figure out how much resistance it can handle on its output. Then use an array of tubes with similar total cross sectional area. Multiple individual tubes will have more resistance than a single larger one, but it could be a starting place. The smaller the burner tubes are, the better, because it improves heat transfer. Similarly, the thinner the wall thickness, the better. But you'll trade off in burner longevity. You want the tubes to be long enough that the exit temperature is about the same as your target roast-air temp; i.e., maximize the energy used from the combustion gas. Of course, alternatively, you could have one large chimney coming up from the burner, with an array of transverse tubes carrying the roast air. |

|

|

|

| jfern |

Posted on 10/28/2024 8:48 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

I really appreciate your insights, and will certainly consider the concepts you've shared as I continue in the initial design phase. You may be right about the need to keep the design simple, because I don't want to get in over my head and loose momentum. Thanks, Jwmelvin! |

|

|

|

| jwmelvin |

Posted on 10/28/2024 9:24 PM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

It occurs to me what you may have intended with your initial sketches. One could use a finned heat exchanger to move combustion heat into the roast air; e.g., heat an aluminum mass that has fins in the airflow. My inclination is that it will be tough to capture all the heat, but it seems possible maybe? |

|

|

|

| jwmelvin |

Posted on 10/29/2024 7:18 AM

|

|

Newbie  Posts: 16 Joined: December 21, 2022 |

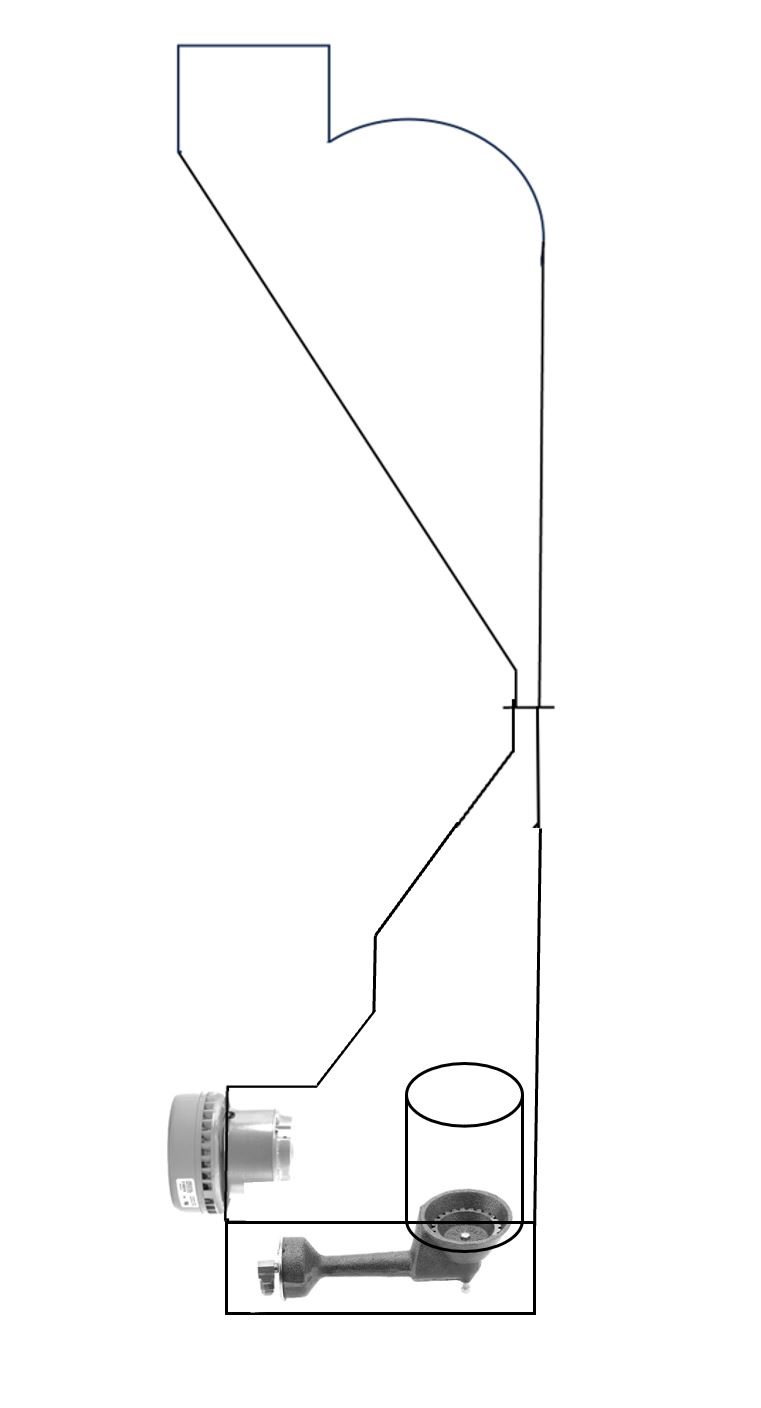

Here are a couple sketches of how I might go about a design without tubes. Not sure it's any easier to make...

jwmelvin attached the following images:

|

|

|

|

| jfern |

Posted on 10/29/2024 12:10 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

More great concepts to work from! I'm always amazed to see the ideas that are generated in community! It keeps things in perspective and reminds me that I am not as self-reliant as I think I am, and that's a good thing! Thanks again, Jwmelvin! |

|

|

|

| allenb |

Posted on 10/31/2024 1:27 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

Quote jfern wrote: Thank you for the clarification Allenb! I am certainly not an engineer, and approach these concepts in an intuitive manner with much trial and error. However, I have just enough sheet metal for one shot at this build, so not much margin for error. My assumption was that high air pressure entering the venturi opening (via a vacuum blower) would rapidly disperse the propane preventing combustion, but I think you and jwmelvin are saying the venturi opening must be at equal air pressure to the environment of the flame. If so, do you think it would be possible to use the style of burner in the illustration, or is there a better option. I've seen the Sievert 2941 torch head referenced in this style of roaster, but these are difficult to come by. It seems about 5,000-10,000 btus are needed per pound of coffee, but please offer any insight you have. Thank you for your time! Pretty much any propane burner, including the one you have in the drawing, will work if implemented correctly although some burners require less space to accommodate them. The Sievert and similar torch style burners have an advantage of not consuming a lot of space but are pricy as you stated. The blower air stream will not disperse the propane but one has to design the location of components so that the blower air stream entering the enclosure doesn't aim directly at either the venturi end nor the actual burner combustion ring. When I built my gas fired fluidbed, I included a sheet metal shroud around the combustion end of the burner that protected the flame from turbulence. One thing to consider with having a burner within the pressurized enclosure is you will typically have somewhere between 5" and 20" of water column air pressure provided by the blower to the enclosure. A low pressure gas burner that has around 15" water column propane pressure at the venturi orifice as with most store bought grills, will not be suitable since the air pressure within the enclosure will not be much less than that which will prevent full flow out of the orifice. Your burner must be a high pressure type propane burner which operates in lbs/sq in, not inches/H2O. FYI, a heat exchanger is a nice concept but in order to get decent exchange, one has to have a huge surface contact area in order to get any kind of efficiency. It would require a lot of space and lots of finned tubes with fins on both the combustion side and the roasting air side of the exchanger. They typically require lots of engineering time and experimentation/trial builds. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 10/31/2024 3:22 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

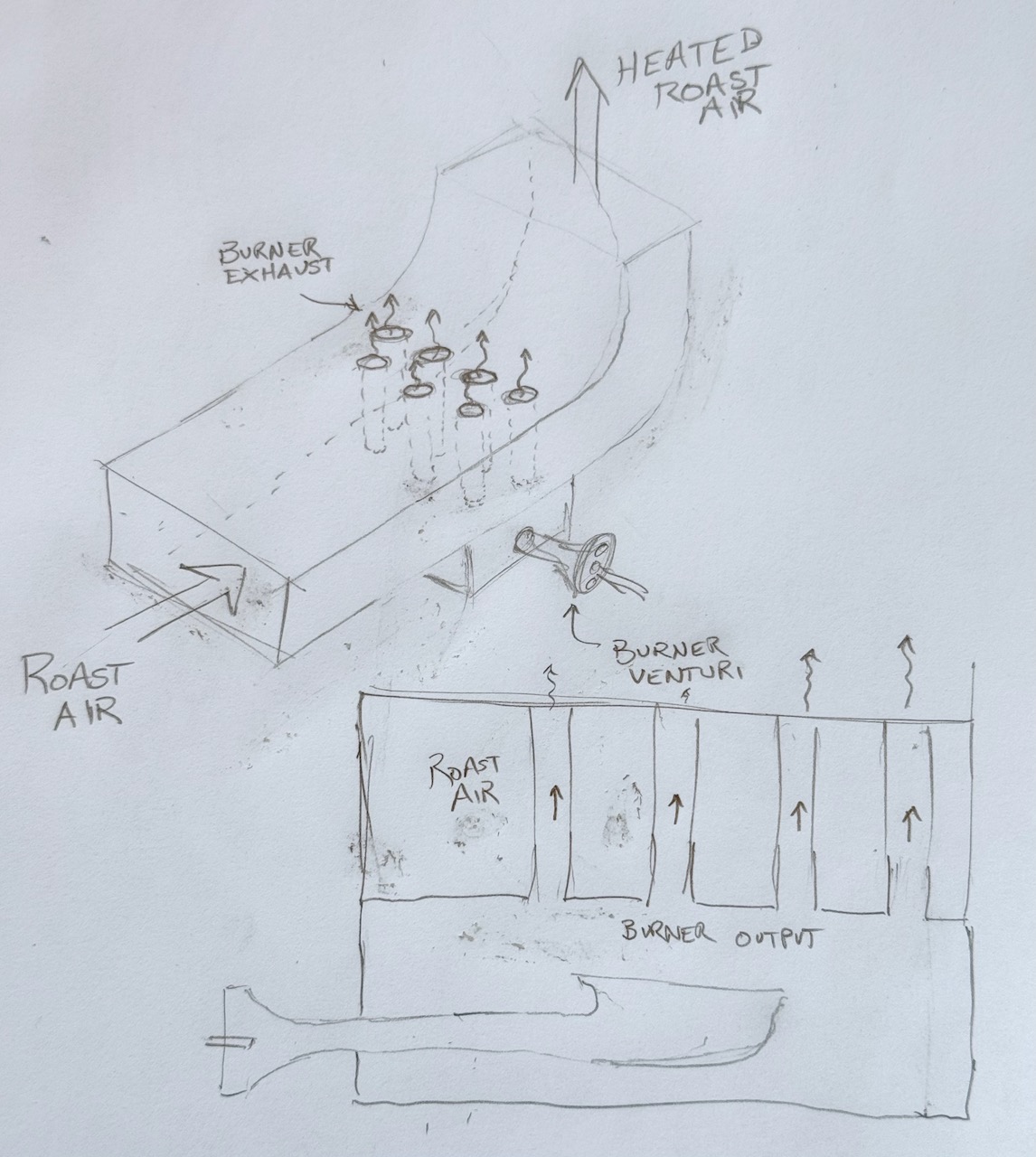

Thank you for the valuable feedback Allenb! I romanticized the heat exchanger concept once I understood it's function. However, I could not come up with a design that would be cost effective in regards to time and materials. I will likely try to shield the flame using something like a cross section of 5" diameter pipe, and position the burner in a box directly beneath the air chamber. I recognize the illustration attached is rudimentary, but do you think it would work? Also, would you be willing to share some specs or a schematic from your propane fluid bed roaster? Thanks!

jfern attached the following image:

|

|

|

|

| allenb |

Posted on 10/31/2024 4:00 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

Here's a link to the 1lb gas fired fluidbed build: http://homeroaste...post_41862 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman