Login

Shoutbox

You must login to post a message.

renatoa

11/05/2024 3:32 AM

, anotherhd

, anotherhdrenatoa

11/04/2024 2:09 PM

cm0512,

renatoa

11/01/2024 2:26 PM

brandonloyal ballard ,

?

?

?

?renatoa

10/30/2024 11:25 AM

geeheeb and Rugger

geeheeb and Ruggerrenatoa

10/29/2024 5:28 AM

, thomasi

, thomasiForum Threads

Newest Threads

Propane Fluid Bed Ro...Coffee popper and br...

Skywalker, the ALM c...

Leaf Vac bean cooler

The History of Coffee

Hottest Threads

| Skywalker roaster... | [389] |

| Skywalker, the AL... | [294] |

| Skywalker Roasts | [108] |

| War on Farmers by... | [63] |

| Propane Fluid Bed... | [37] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,556

Newest Member: anotherhd

Members Online: 0

Total Members: 8,556

Newest Member: anotherhd

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

Propane Fluid Bed Roaster Design

|

|

| jfern |

Posted on 11/01/2024 9:20 AM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Great design, Allenb! I remember seeing your videos a few years ago and admiring your ingenuity! I just never got up the courage to build my own until now! I have a few questions, if you are open to fielding them. Have you continued to roast on this machine? Have you made any useful design modifications? Were you able to produce consistent roasts within an 8-12 minute window? Also, what would you estimate the distance to be from your flame to the beans, and would there be any benefit to a taller chimney with fins or channels at the outlet to maximize heat flow? Sorry for all the questions! No pressure at all, but if you are open to a brief phone conversation, it could provide an opportunity to address a few rapid fire questions. Thank you for your time! |

|

|

|

| allenb |

Posted on 11/01/2024 12:15 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

Thanks for the complement jfern! I sold the roaster to snwcmpr not long after building it but Ken has done lots of roasts on it and never heard any issues with being able to do consistent roasts in that time range. On distance from flame to beans? Not entirely sure but at least 2 or 3 inches I would guess. But, that design includes a turbulator plate which can be seen in the videos. It's a can lid with slots cut around the perimeter and the tabs tilted into an angle which causes the combustion gases and incoming air from the blower to completely mix in a vortex prior to hitting the bottom of the roast chamber so there is no flame impingement on any part of the roast chamber. I would highly recommend that for your design as it totally removes that potential issue. Not sure I follow your question on the chimney with adding length and fins to it. Maybe add some verbiage to define better. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 11/01/2024 5:08 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

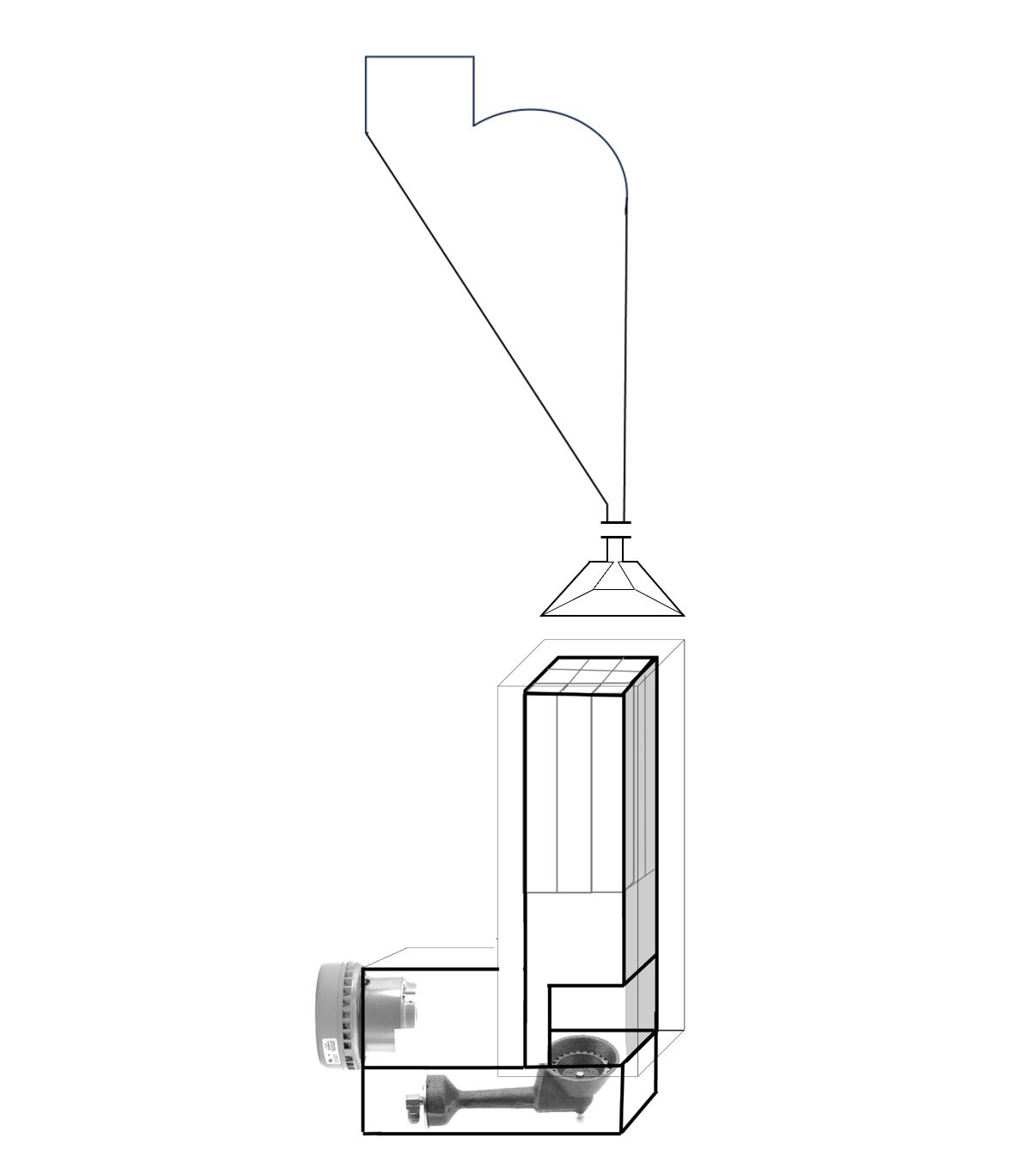

Thanks for responding, Allenb! To clarify, I wonder if lengthening the chimney and adding segmented channels like rows of square tubing inside the chimney would make heat flow more efficient and prevent the flame from reaching the roast chamber. I've attached another concept below.

jfern attached the following image:

|

|

|

|

| allenb |

Posted on 11/02/2024 11:55 AM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

All you need is a simple air swirling turbulator out of sheet metal. Very cheap and extremely effective.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 11/02/2024 5:37 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Okay! Thank you for the direction, Allenb! I will try to scale up and copy your design from your video. Does the shape of the tube matter? My reason for asking is that it's cheaper for me to fold stainless steel sheet into a square chimney as opposed to purchasing 5" diameter 304 tubing. Also, because my burner is 50,000 btus high pressure, should the height of the chimney be significantly higher than yours in the video to prevent too much heat transfer? I appreciate your thoughtful suggestions, and for taking the time to respond to my ramblings. |

|

|

|

| jfern |

Posted on 11/02/2024 5:58 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

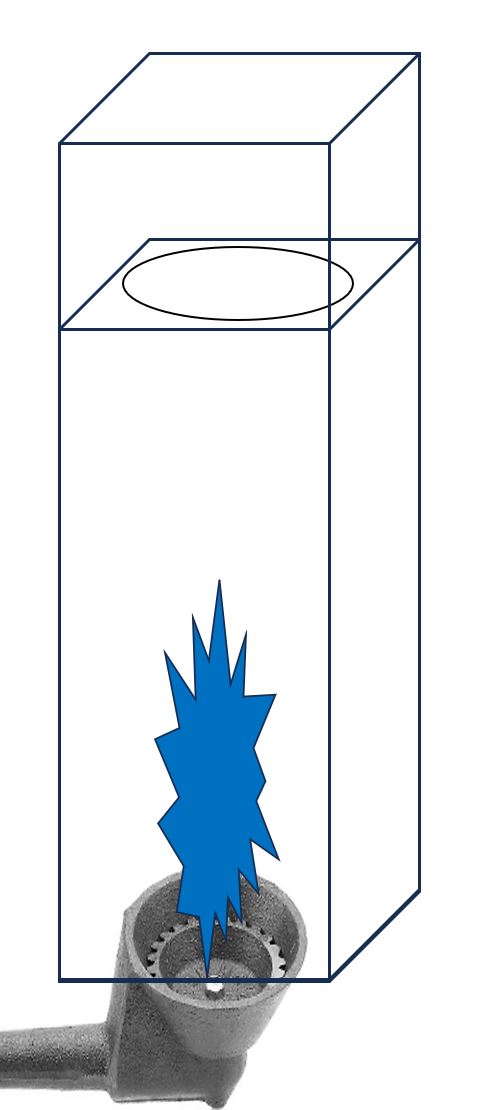

Square tube turbulator?

jfern attached the following image:

|

|

|

|

| allenb |

Posted on 11/03/2024 8:35 AM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

The shape of the enclosure doesn't matter, as you have shown in your drawing will work fine. On height of the enclosure, I would leave at least 8" above the burner before the turbulator plate to give it enough space to form proper combustion. Then, another 4" above the turbulator plate prior to hitting the inlet of the RC for proper mixing.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 11/03/2024 3:04 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

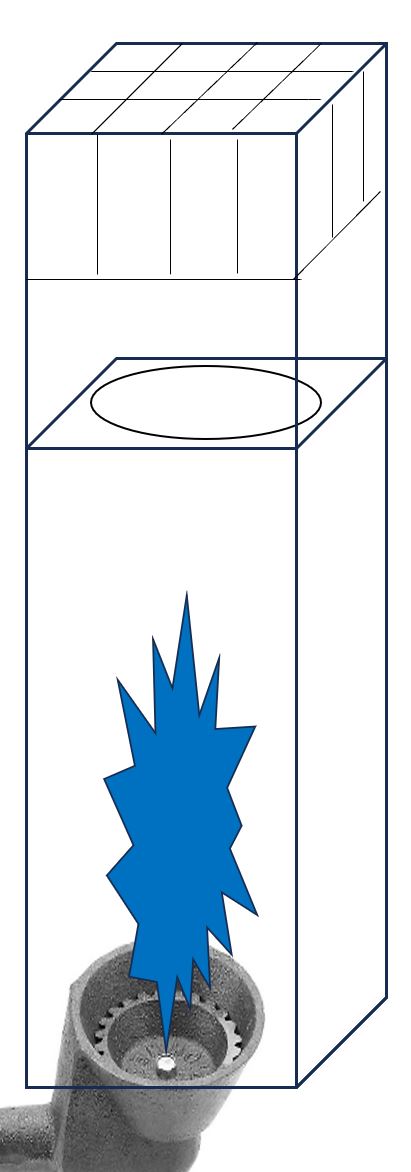

Thank you, Allenb! This gives me some practical specs to work with! Do you think there is any advantage to including heat exchange tubes in the compartment between the turbulator and the RC inlet?

jfern attached the following image:

|

|

|

|

| allenb |

Posted on 11/03/2024 3:22 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

A heat exchanger would not add any positive function to the roaster so no, not needed. Can you describe what you believe it would accomplish?

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 11/03/2024 4:34 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

I thought I'd cover all my bases in regards to channeling heated air into the roast chamber without any possibility of the flame interacting with the beans. The assumption was that more metal in the hot air stream would increase thermal mass and heat exchange before entering the RC. I may not be understanding these concepts as well as I think though! |

|

|

|

| allenb |

Posted on 11/03/2024 5:45 PM

|

|

Administrator  Posts: 3899 Joined: February 23, 2010 |

Ok, I follow you now but no, that will not serve any useful function since the combustion gasses (flame products) and incoming air from the blower will be thoroughly mixed when leaving the swirl plate (turbulator) well before entering the roast chamber perf plate.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jfern |

Posted on 11/03/2024 7:14 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Thank you for the clarification, Allenb! I appreciate your time and expertise! Hope to get started with fabrication soon. |

|

|

|

| jfern |

Posted on 11/06/2024 7:29 PM

|

|

Newbie  Posts: 20 Joined: October 15, 2024 |

Hi Allenb, would you mind giving some feedback on this turbulator disc design. It's 4 1/2" in diameter with 16 fins, fabricated from 20 gauge stainless sheet. Thanks!

jfern attached the following image:

Edited by jfern on 11/06/2024 7:48 PM |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman