Login

Shoutbox

You must login to post a message.

allenb

09/07/2024 10:25 AM

1trakmind

renatoa

09/06/2024 9:41 AM

, n0n4m3

, n0n4m3renatoa

09/05/2024 2:35 AM

GabiZ and pawantanwar,

renatoa

09/02/2024 6:15 AM

, robair

, robairallenb

09/01/2024 3:51 PM

clarkwisconsin

Forum Threads

Newest Threads

My Sight Glass FB Ro...Guatemala Acetenango...

Green coffee reviews

Air vs Drum roaster

War on Farmers by Su...

Hottest Threads

| Skywalker, the AL... | [263] |

| War on Farmers by... | [53] |

| Green coffee reviews | [10] |

| Help and recommen... | [10] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,478

Newest Member: 1trakmind

Members Online: 0

Total Members: 8,478

Newest Member: 1trakmind

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

1lb Fluidbed build, progress and photos

|

|

| Erichimedes |

Posted on 10/17/2013 10:04 PM

|

|

1/4 Pounder  Posts: 58 Joined: August 07, 2013 |

I installed the thermocouple in the heater outlet of my roaster, with great results! It seemed to follow the temperature really well, and responded really quickly to changes I made. I'm psyched! |

|

|

|

| allenb |

Posted on 10/18/2013 8:50 AM

|

|

Administrator  Posts: 3884 Joined: February 23, 2010 |

Quote Erichimedes wrote: I tried a BT probe in the bottom of the RC about 3/4" below the glass, with a 1/2" probe, and it didn't get very accurate readings. I compared it with a thermocouple dropped in the top right in the middle of the rolling bean mass, and it was about 60 deg F off at the end of the roast. My guess at this point is to try a longer thermocouple probe? What has been others' experience with this? You're making great progress on this build! From experimenting with many fluidbeds over the years I've found only a couple of locations for BT that produce beneficial results and don't vary depending on where ET happens to be at a given moment. One is a little above the static green level and no further than 1/4" in from the roast chamber outer wall (round RC). The other is also near the RC outer wall but much further up near the top of the RC but this one has only been useful with my Sirocco sample roaster and Freshroast. I've found when placing the sensor lower into the bean mass that environment temperature has too much influence on the bean temperature sensor. You mentioned needing to move the sensor further into the RC. There is a minimum distance on sensor length extending into the RC that won't allow skewed readings from conduction to the RC wall or RC exterior. I'm not sure what the minimum is but I would not go less than 1" for a typical bare thermocouple and for 1/8" dia. sheathed probes not less than 2". Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| oldgearhead |

Posted on 10/18/2013 8:59 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

I started out in 2011 with two TC 'K' probes: a 0.50 inch located 1.5 inches blow the perf plate mounted through the sink drain tube, and a very long one (BMT) through the top and down into the bean mass. What I quickly learned was the BMT probe was very accurate (400?F at first crack), and the lower one would track the BMT -30?F. Also by adding restriction to the RC air outlet I could measure the process varible (PV) temperature of the business end of the RC (perf plate), without beans. So, when I decided to trap all the chaff in the RC, I quit using the BMT probe, and rely on: __ET = Total roast time __PV = Hot air temperature __Sight __Smell __Sound __Temperature (0.50 inch probe) Recently I've been adjusting only the blower speed, during the roast and set the temperature based on the test weight of the green beans.

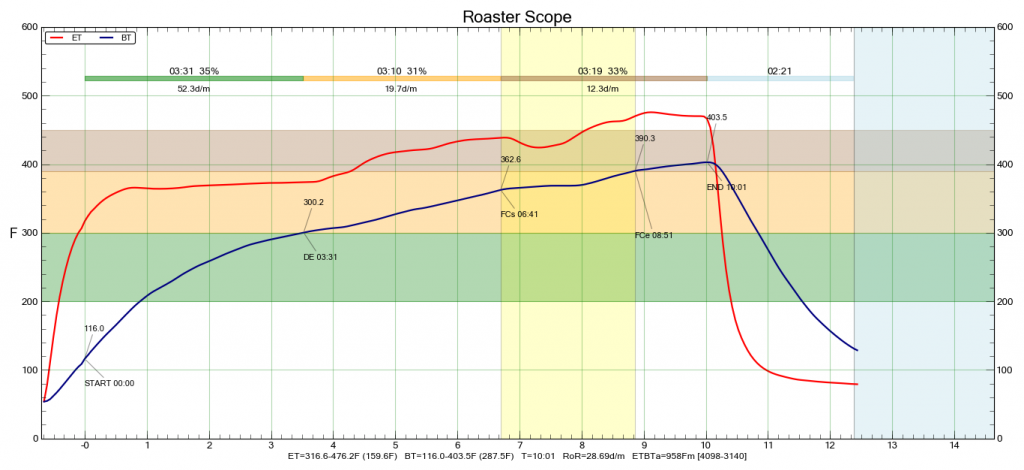

oldgearhead attached the following image:

No oil on my beans...

|

|

|

|

| Airhan |

Posted on 11/15/2013 11:57 PM

|

|

1/2 Pounder  Posts: 228 Joined: September 29, 2013 |

Did you ever end up painting/staining your wooden enclosure?

Aaron

"Grind it like it did you some great injustice!"D.L.Clark |

|

|

|

| Erichimedes |

Posted on 11/16/2013 1:29 PM

|

|

1/4 Pounder  Posts: 58 Joined: August 07, 2013 |

Airhan, no! I've been meaning to, and actually right now is a good time for it too, since I'm waiting on a power supply for the Arduino/TC4. I'll probably get to it in the next couple weeks, and I'll post photos when it's done. I've also finally made a hot air return pipe, so that will be installed, and I will be experimenting with recirc and posting the results here. |

|

|

|

| SmokNmirz |

Posted on 01/15/2014 6:45 AM

|

|

Newbie  Posts: 30 Joined: September 11, 2013 |

Erichimedes, any updates to this project? What type of welder were you using in the livingroom??!!? If I tried that my wife would keep bringing up the name of Bobbit... L-1p, HG-1-motorized, Monolith Flat, (ordered) mini500Plus.

If whatever you do does not put a smile on your face then rethink what you are doing. |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman