Login

Shoutbox

You must login to post a message.

renatoa

04/29/2024 1:50 AM

, OptomAvad

, OptomAvadallenb

04/26/2024 11:19 AM

Mongke

renatoa

04/26/2024 7:26 AM

, bmartin1000

, bmartin1000renatoa

04/25/2024 2:03 AM

AGZ and Intercolcoffee

allenb

04/23/2024 7:01 PM

Paul Kalb

Forum Threads

Newest Threads

Understanding the CurveSkywalker, the ALM c...

War on Farmers by Su...

Lift blower

Roast Color Meter - ...

Hottest Threads

| Skywalker roaster... | [306] |

| Skywalker, the AL... | [215] |

| Rainfrog's Roastm... | [54] |

| War on Farmers by... | [41] |

| Understanding the... | [29] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 3

Members Online: 0

Total Members: 8,239

Newest Member: OptomAvad

Members Online: 0

Total Members: 8,239

Newest Member: OptomAvad

View Thread

Who is here? 1 guest(s)

|

PID Controlled Air roaster question

|

|

| BenKeith |

Posted on 02/14/2016 7:52 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

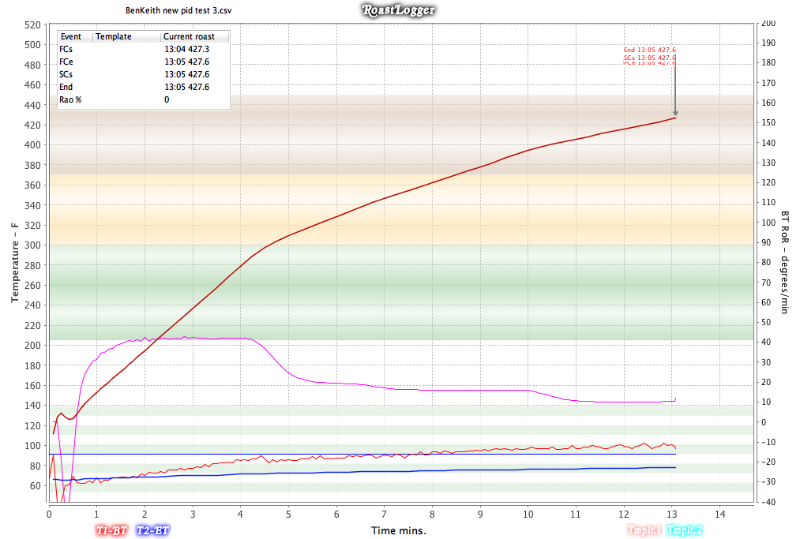

For starters. let me just say I have been using air roaster of a long time. Close to two years ago, reading about the TC4 on here, I built one and installed in a Hearthware Gourmet. Not happy with it, I gutted a Hearthware Precision and installed the TC4 in it. Still not happy with the bean movement, I gutted a iRoast2 and installed the TC4 in it. Among other things, all of these roasters also had the heaters rewound so they are 2,200-2,400 watts. Now that I have full control of the roaster so it almost never has to run 100%, I've been working on getting very precise control of the roast curves so I can start working on learning flavor profiling. This is a sample curve I did for some beans I wanted to take to 428F in 13:00. I had the following profile: 150F @ :50 300F @ 4:25 340F @ 6:30 398F @ 10:05 (FC) 428F @ 13:00 It hits each of the times and temps either dead on or within a couple of seconds. A profile I have been using is just to the end of the FC with some Brazilian's 150F @ 50 300F @ 4:00 340F @ 6:00 398F @ 9:20 414F @ 11:40 This is the 428F test profile  Does this totally suck for something you would roast with and if so, what and where do I need to change. This is also the same strategy I'm using for the 414F roast, just different times for the temps. |

|

|

|

| PhilH |

Posted on 02/24/2016 4:45 PM

|

|

Newbie  Posts: 47 Joined: September 10, 2015 |

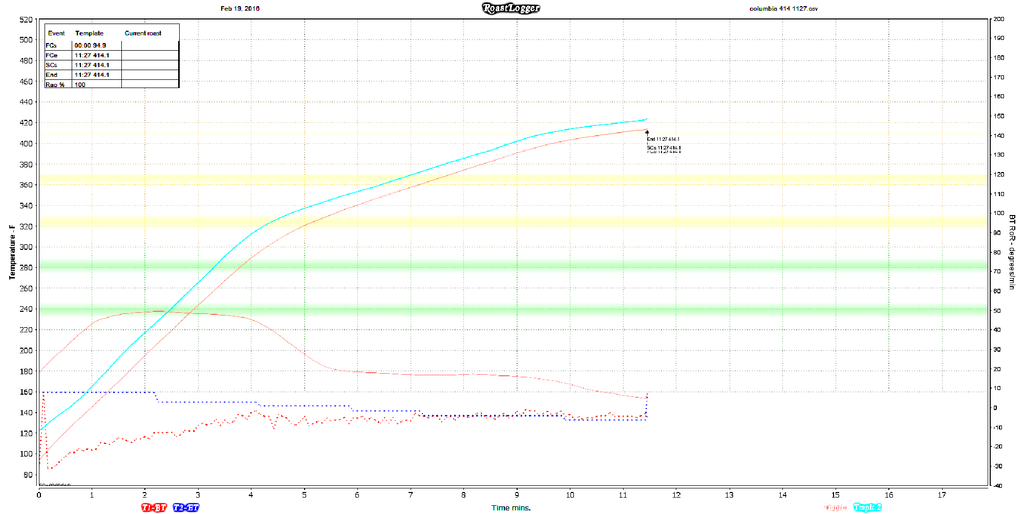

Hi Ben I have also spent some time hunting for the optimum roast profile. I am using TC4/aArtisanQ_PID w/local profiling, Artisan logging, gas fired FB with 500-1200g loads which is giving pretty good profile control see http://forum.home...ad_id=4715 I am thoroughly enjoying experimenting with ever evolving profiles and beans am very pleased with results Of course it is very subjective and everyone seems to have an opinion so for what its worth here's my current thinking I am roasting a bit faster than your profile I have based my approach on Scott Rao's ideas - in particular: - a constantly falling ROR - experimenting with 21-26% development time following FCs and aiming for a total roast time of around 11-11.5 minutes A lot depends on your TC positioning which will give significant variation in apparent BT I preheat to 110C (230F), charge the beans, apply 100% heat manually and start the PID/Profiling approx 25-30 secs later my current fave profile (getting very good results with Yirgacheffe and Kenya AB) TempF, TempC, Time(S),Time(m),ROR degC/m 230, 110, -25, -0:25, 176, 80, 0, 0, 198, 92, 20, 0:20, 36 225, 107, 50, 0:50, 30 253, 123, 90, 1:30, 24 295, 146, 160, 2:40, 20 311, 155, 190, 3:10, 18 329, 165, 230, 3:50, 15 352, 178, 290, 4:50, 13 365, 185, 320, 5:20, 14 380, 194, 370, 6:10, 10 392, 200, 410, 6:50, 10 401, 205, 446, 7:26, 8 410, 210, 500, 8:20, 6 approx FCs is 207C@8:30 419, 215, 560, 9:20, 5 428, 220, 625, 10:25,4.6 Approx Drop is around 11:10 - 11:30 (total 450, 232, 840, 14:00,3.3 time from charge) depending on desired Dev % 455, 235 999 16:39 2.41 I hope this is helpful I would also love to hear other peoples ideas and approaches on this redgs Phil Crem ONE LFPP, Compak K10F, 6kg FB LPG/PID aArtisanQ_PID, UNO/LCDapter

|

|

|

|

| BenKeith |

Posted on 02/24/2016 10:08 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

This 414 degree roast is an exact copy of a profile Rob Hoos said he uses on a Brazilian  Of course he's doing it on a drum roaster and I'm doing it on an air roaster so I have to be very careful with the air. After the first couple of minutes, I'm backing the air way down or it will dry the roast out too much. Reading his book on Flavor Profiling got me to doing much longer roast. For several years I was running about 8:30 for 420 degree roast and 10-11 minutes for espresso. However, I almost never take any roast past a couple of snaps into the SC. It also got me to trying lighter roast. It wasn't that long ago I would have ever dreamed of stopping a roast just as the last few snaps of the FC were finishing up, but using this profile, I actually get a darker roast than I would have before. For the past several months I've been working on duplicating drum roast with my air roaster, and having pretty good success on most but it's a fine line between have a good roast and a baked tasting roast. I'm finding the air flow is super critical and I'm talking a couple of percent at the wrong time can make a difference between vey good and baked. I could never start my roast off at 100%. Right now, I have a couple of key points I want hit precisely because the rest of the roast is based of that. I want to hit 145F in :45 and 200F in 1:00. To do this, I start with 25% heat and 100% fan with the beans in the roaster. I've tried dropping in a hot chamber but I get variations in start temps doing that. When the bean temp reaches 100F, I start the roast and the PID is controlling it from that point on. The heat may go to 100% for the first few seconds but after that it never does. Then at certain SV's the fan speed is dropped so bean movement is not too heavy. Now, as I play with different flavor profiles, I'm trying taking time off different stages. I will make a note of where what time/temp a certain smell was in a stage and then make changes to try and highlight it. I'm working on profiles between the longer roast and the short roast I used to do. That's the nice part about a PID, if want to make a change, I can do it to the degree within a couple of seconds when I want it. I also find it get better control if I keep my PID inputs to a minimum, that's why you only see a few SV's in mine. Edited by BenKeith on 02/24/2016 10:21 PM |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman