Login

Shoutbox

You must login to post a message.

renatoa

04/29/2024 1:50 AM

, OptomAvad

, OptomAvadallenb

04/26/2024 11:19 AM

Mongke

renatoa

04/26/2024 7:26 AM

, bmartin1000

, bmartin1000renatoa

04/25/2024 2:03 AM

AGZ and Intercolcoffee

allenb

04/23/2024 7:01 PM

Paul Kalb

Forum Threads

Newest Threads

War on Farmers by Su...Lift blower

Roast Color Meter - ...

Skywalker roaster mods

Hello from Montreal ...

Hottest Threads

| Skywalker roaster... | [306] |

| Skywalker Roasts | [94] |

| Rainfrog's Roastm... | [54] |

| War on Farmers by... | [41] |

| Green coffee sellers | [18] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 2

Members Online: 0

Total Members: 8,232

Newest Member: OptomAvad

Members Online: 0

Total Members: 8,232

Newest Member: OptomAvad

View Thread

Who is here? 1 guest(s)

|

5 Lb Roaster Perf Plate Design Help!

|

|

| pisanoal |

Posted on 11/05/2019 8:06 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

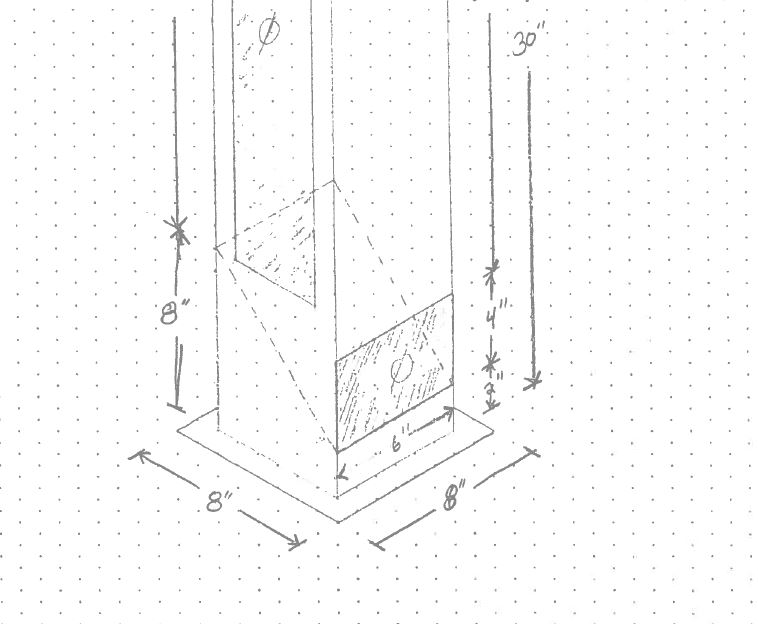

So I have been building a 5 Lb fluidbed roaster for a friend of mine and I think I may have made a mistake that will be a PIA to fix. I designed the perf plate at a 45 degree angle to slide down towards the bean empty door so the beans all slide out. That means the solid part of the asymmetrical bottom and the perf plate are on the same 45 degree angle. I am having issues getting my greens to spout properly and I think it has to do with the uneven bed depth of the beans over the perf plate. Another potential issue is that I don't have all the gaps and cracks sealed up yet, so its possible that I am losing too much volume and pressure to properly spout. However, I have sealed up enough during the initial trial to get the beans to spout, but a small volume of beans shoot high up in the RC, so I'm not getting great bed movement. I aimed for 14% open area for my perforations which seemed to be the design parameter to shoot for based on a post made by allenb in a sticky in this subforum so I think that should be ok. My vacuum blower is quoted at being able to produce 120" WC so I should have enough pressure. Do I need to somehow make the perf plate area flat or do you think ill be ok once I get it all sealed? My hunch says I need to make it flat. Any other options that don't involve taking it back to the fab shop? Drawing is attached, as well as a picture looking inside the viewing window and from the dump door.

pisanoal attached the following images:

|

|

|

|

| pisanoal |

Posted on 11/05/2019 9:41 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

I think I found my issue. Somehow I ended up recalculating my actual perf plate to be 3" which left me a huge amount of open area. Total percentage of the roaster footprint open area is like 20%. I went back to allenb's calculation on the roaster rob design sticky. allenb let me know if this looks right if you see it. Your percent open area compared to the cross-sectional area of the 4" RC in your ex calcs is 3.5%. (.4418/3.142 = .035) Is this a good design parameter? The reason I ask it that way is because I bought perforated plate, and its open area is 40%. So my perforate plate area compared to my cross-section is much lower to get the same open area %. I came up with 0.5" wide perf plate. I have 33 1/8" holes per sq inch. Roaster width is 6", so that gives me 3" of perf plate area. 40% open area gives me 1.2 sq in of open area. 1.2/36 = 0.33 So percent of total roaster cross-sectional area open for air flow is 3.5%. My next question is, if that is right, is that too narrow? Should I maybe go 1" and plug half the holes? Should I also flatten out the bottom? Or does that not matter as much since I will have the right open area. Sorry this post is probably a bit all over the place, but hopefully you can make sense of it. |

|

|

|

| allenb |

Posted on 11/05/2019 5:36 PM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

Sivetz designed some of his roast chambers with the perf plate at the bottom of the angled plate on the same plane as with your design and worked fine. But, the coffee bed depth was many times taller than the height of the top edge of the perf plate and only occupied a relatively small area of the bottom in proportion to the full cross section of coffee further up the chamber. This allowed good coupling of the bottom strata of coffee without having a tendency to try and short circuit the lifting air so to speak. I haven't done the math with your roaster but my advice would be to block off 1/2 of the upper most portion of your plate with a thin layer of sheet metal using a few machine screws going through the perf holes and nuts on the bottom side to hold it down. Play with varying sizes of covering until you get a stable lift. Sivetz included blocking plates with some of his large fluidbeds so one could use them at different altitudes with their varying air densities so this isn't uncommon. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/05/2019 7:55 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote allenb wrote: I haven't done the math with your roaster but my advice would be to block off 1/2 of the upper most portion The math compared to your post in the sticky shows i would have a 1/2 inch section at the bottom. That sounds small and im worried about it not moving a large enough cross section of the bean mass ro creat circulation. I wonder what the Sivetz roaster angle was of the perf plate? The reason is I noticed the air flow direction is out towards the front wall, which is to be expected. But seems like it would cause issues throwing the beans on the right direction. I did some tests today and couldnt get stable stable lift. The other issue is the beans along the top of the angled plate dont seem to want to move. I blocked off all but about 1". I probably should have tried some more options but i got frustrated. Im considering taking it back to the machine shop and having them change it so there is a flat at the bottom so the air flow direction is better. |

|

|

|

| allenb |

Posted on 11/05/2019 8:58 PM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

The angle on the 1+ bag Sivetz I used to roast on was somewhere near 45 degrees and the throw of the beans was up and not toward the vertical wall. Something to consider with this type of roast chamber is there is an optimum charge of beans for being able to obtain a high density spout and as you reduce from there, the spout will thin out some and become erratic. This is the case with all fluidbed roasters to some degree or another. With the RC you've built, the width or height of the perf plate will necessarily need to be very narrow compared to length for the air to be able to "grab" and loft the beans. Otherwise, the air will choose the path with the lesser bean density or weight near the top of the plate. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/06/2019 10:14 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote allenb wrote: With the RC you've built, the width or height of the perf plate will necessarily need to be very narrow compared to length for the air to be able to "grab" and loft the beans. Otherwise, the air will choose the path with the lesser bean density or weight near the top of the plate. Thank you so much for this post. This is exactly what was happening. It was really pronounced when I tried loading 1 lb at a time with the blower going so I could see if I was just overloading the roaster. The beans at the top of the plate where lofting instead of the bottom. My issue at that time was I had a big air leak around the dump door but same basic idea in that it lowered the air velocity for bean loft. I rechecked my calculations and found that I was misinterpreting the data on the perf plate. The specs quoted an open area for a 12" x 12" sheet, so I got a % OA and recalculated to come up with 3/4" width of perf plate. I taped the rest off and was able to get good and stable been circulation from 4 to almost 8 lbs! It would probably do more but I don't think my RC will handle that much during a roast. Thanks again! You definitely saved me a whole bunch of frustration, time and money. |

|

|

|

| greencardigan |

Posted on 11/06/2019 3:01 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

That's great! I tried a sloped perf plate once in a cylindrical roast chamber but didn't get working properly. Could you share again what you ended up with so it's easy to find later? |

|

|

|

| allenb |

Posted on 11/06/2019 5:39 PM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

I agree with greencardigan, that's great news! Hopefully with a little luck and the engineering skills I can see you've got plenty of, the rest of the build and tweaking to get it to your expectations will go well and be fun at the same time. Keep us posted! 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/07/2019 8:24 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote greencardigan wrote: That's great! I tried a sloped perf plate once in a cylindrical roast chamber but didn't get working properly. Could you share again what you ended up with so it's easy to find later? Sure! Assuming you mean in this thread in a concise manner... here it goes. The original problem was I could not get beans to lift in a 6" x 6" square RC. Goal weight was 5 pounds. The angled plate and perf plate were set on the same plane at approximately 45 degrees. I originally sized the perf plate to be WAY to big. it was 3" by 6". I made two mistakes that led to the calculation. One was the wrong design parameter, the other was the wrong open area of my perf plate. My Perf Plate was purchased from onlinemetals.com Its 1/8" holes. Open Area is 40" per 12"x12" section which gives about 28% open area. Design Parameter (for asymmetrical bottom) : I looked at some calculations allenb put together from roasterrob's designs and took it one step further to come up with a percent open area as compared to the corss-sectional area of the roaster. 3.5% open area is the design parameter. For my roaster: 6 x 6 = 36 sq in 36*0.035 = 1.26 sq in (open area needed) 1.26 / 0.28 = 4.5 sq in of perf plate material (OA required divided by percent OA of my perf material) 4.5sq in/ 6" = .75" So my perf plate needed to be brought down to a 3/4" by 6" piece. For trials, I taped off the extra perf plate openings and left a 3/4" section at the very bottom. Long term solution is the machine shop is making me a plate out of stainless that I can bolt in to cover the perforations. My buddy lives in the mountains and after allenb's comment, I wanted to make sure that plate could be popped out and altered or a new one made if conditions change. Video of 8ish pounds. The bottom left corner doesn't move very well because of the bracket holding the glass. I need to bevel it more. |

|

|

|

| allenb |

Posted on 11/09/2019 7:49 AM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

Bean flow is perfect for beginning of roast and is almost identical to the flow I had with the big Sivetz at start of roast. As beans lose moisture the circulation of the beans will increase and eventually need air flow to be backed off in stages. I was looking at Tamarians perf plate for his 10kg build and it would be interesting to see how the dimensions and other details compare in proportion to yours.

allenb attached the following image:

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/10/2019 10:36 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

I put everything together and roasted yesterday. I had issues with beans spouting from the back corner of the perf plate, so I have that to figure out. The fab shop covered up an extra line of holes, but i wouldnt think that little bit would make a difference. I need to check to make sure the roaster is level first and then play around with the open area. I checked the calculations on tamarians perf plate and it looks like he only has .5% open area. Its hard to tell of its 3 or 5 mm holes. For 5 mm it would be 1.5% as assuming the plate is the footprint of the roaster. |

|

|

|

| allenb |

Posted on 11/10/2019 5:30 PM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

Tamarians roaster has 3mm holes. At what stage of the roast did the issue occur with spouting only happening at the back corner?

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/10/2019 7:30 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote allenb wrote: Tamarians roaster has 3mm holes. At what stage of the roast did the issue occur with spouting only happening at the back corner? It stays like that all through the roast. I'm also curious about ET probe readings. Mine is hitting over 675 at times, usually towards the end of the roast. But I need to have it high in order to maintain ROR I'm curious what others with several pound fluidbed roasters are seeing if they have an ET probe. Mine sits just below the perf plate. Also curious on roast times. My issue is definitely not with the burner. I scorch my door gasket with anything over 650 on the ET probe. So my question is, stay below that or find a higher temp gasket? |

|

|

|

| pisanoal |

Posted on 11/10/2019 7:31 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote allenb wrote: Tamarians roaster has 3mm holes. At what stage of the roast did the issue occur with spouting only happening at the back corner? Is this even an issue if the bean movement is ok? |

|

|

|

| pisanoal |

Posted on 11/10/2019 7:35 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

|

|

|

|

| renatoa |

Posted on 11/11/2019 1:14 AM

|

|

Administrator  Posts: 3014 Joined: September 30, 2016 |

This oven is overloaded, imo. This could explain high ET also. The 6 liters of RC volume for 1 kg of greens rule is not there, as good I can evaluate volumes by the eye. |

|

|

|

| pisanoal |

Posted on 11/11/2019 7:11 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote renatoa wrote: This oven is overloaded, imo. This could explain high ET also. The 6 liters of RC volume for 1 kg of greens rule is not there, as good I can evaluate volumes by the eye. Thanks for the reply. Its about 18 liters. There are about 6 lbs of greens in there. So seems I'm right on the money with that rule, technically a little under? That's a good amount of the way through the roast which may be what is throwing your volume estimate off. BT is at close to 375 there. More important then RC volume would be cross sectional area to bean depth i would think? Theoretically I could add volume by making it taller, but that wouldn't help my case at all. I will try less greens in there though. Original design volume was 5 lbs. I was trying to push it a little bit as my buddy has picked up some sales volume. Hypothetically, as long as im not getting scorching or tipping, high ET is ok in a fluidbed, correct? |

|

|

|

| renatoa |

Posted on 11/11/2019 7:25 AM

|

|

Administrator  Posts: 3014 Joined: September 30, 2016 |

According to quote below, it isn't ... Quote Under controlled roasting conditions, the bean environment temperature should never exceed 536 degrees F. A wider safety margin would be achieved by limiting the maximum environment temperature to 520 degrees F. These temperature limits minimize damage to the cell matrix and enhances cup complexity, roasting yield, and product shelf life. ...By Carl Staub https://legacy.sw...ng-process I have to admit, though ... that I rarely jumped the 600 F limit, with not so dramatic results...  The rules have to be known, in order to break them, creatively... it's a saying in photography.  |

|

|

|

| pisanoal |

Posted on 11/11/2019 7:39 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Is that for fluidbed roasting? I know there are some rules for ET on drums, but hadnt found anything on fluidbed. |

|

|

|

| renatoa |

Posted on 11/11/2019 11:11 AM

|

|

Administrator  Posts: 3014 Joined: September 30, 2016 |

For any type of roast... is the temperature of the convection medium, where beans are immersed... |

|

|

|

| allenb |

Posted on 11/11/2019 7:01 PM

|

|

Administrator  Posts: 3860 Joined: February 23, 2010 |

I agree with Renatoa that you're exceeding the limit with this roaster. There is a practical bean bed height limit for any fluidbed in relation to the number of square inches in cross section. When the limit is exceeded, you go from a relatively continuous stream to an erratic pulsation due to collapsing pockets of air. I imagine that there is less tendency for the denser green coffee with less column height to do this as much. I've heard some claim that going up to 550 F caused no noticeable degradation in cup quality in fluidbed roasting but would not recommend going over that. It is true that the lowest possible environment temperature should be sought that will still get your coffee through the profile on time. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| pisanoal |

Posted on 11/11/2019 8:36 PM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Quote allenb wrote: I agree with Renatoa that you're exceeding the limit with this roaster. There is a practical bean bed height limit for any fluidbed in relation to the number of square inches in cross section. When the limit is exceeded, you go from a relatively continuous stream to an erratic pulsation due to collapsing pockets of air. I imagine that there is less tendency for the denser green coffee with less column height to do this as much. I've heard some claim that going up to 550 F caused no noticeable degradation in cup quality in fluidbed roasting but would not recommend going over that. It is true that the lowest possible environment temperature should be sought that will still get your coffee through the profile on time. I was initially confused on why you thought it was overloaded. But i rewatched my video and now i understand... So this..."When the limit is exceeded, you go from a relatively continuous stream to an erratic pulsation due to collapsing pockets of air" is only happening in the video because I turned the air down. If i had kept it turned up it would be a continuous stream. I was trying to keep a temp profile and failing miserably. I should be within the general design parameters for the weights I am roasting. In fact in RoasterRob's sticky, he uses a 6" RC for 2.3 kg, granted its cylindrical, but that also means it has less cross-sectional area. I do want to talk more about the heat issue. Do I need to move more beans? I feel like I am moving a small number of beans compared to the total bean mass and that may be part of the total issue. If it helps, I'm thinking in the theoretical sense. So what is it about a 20 pound roaster that allows the heat to stay lower? I feel like i'm not getting my question across correctly, but maybe you all will understand what i am after. Is it an air volume issue? air pressure? cross section of beans moving? One thought i had, is my perf plate hole density is a lot tighter then most of what i see on here. Edited by pisanoal on 11/11/2019 8:51 PM |

|

|

|

| renatoa |

Posted on 11/12/2019 4:11 AM

|

|

Administrator  Posts: 3014 Joined: September 30, 2016 |

Regarding heat... somewhere in this informational mess surrounding us, Schulman explain his routine for finding a given oven roasting capacity: drop inside an initial estimate of beans, at 200 C charge temp, and keep them there at constant 250 C air temperature, and good agitation, until FC. If FC is in the 10 minutes ballpark, you are good, else play with quantity accordingly. |

|

|

|

| pisanoal |

Posted on 11/12/2019 9:42 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Useful information. Thank you. I still wonder if there is a way to increase the "apparent" capacity of the RC. For example, if i had one line of holes at the bottom of the RC, I would be able to roast a certain small volume of coffee. But if i were to drill another line of holes, my capacity would be increased (more hot air to the beans). You can take this model to the optimal point at which you have reached your true maximum capacity which would look something like highest bean charge with the "best" agitation of beans while still maintaining your suggested heat curve. I guess my question is where is my limitation coming from and why do you think that? Is it.. a) the actual footprint of my roaster, or b) my perf. plate design I've stuck to the rules of thumb for a as best I can tell. So that's why I'm so focused on b. I also realize there are a myriad of other possibilities (blower, air inlet design, air outlet design, internal resistance, bean type, air temp, etc) Also, I feel like I sound like I am being argumentative. So I just want to say that is not my intent. I very much value the input you guys are giving me. A lot of it is me trying to understand where your coming from on your responses so I can figure out if I can do anything about it. Anyways, Thanks again for your help, its truly appreciated. Edited by pisanoal on 11/12/2019 9:52 AM |

|

|

|

| pisanoal |

Posted on 11/12/2019 11:07 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

I've been studying the RoasterRob's design elements thread and I've come up with a couple of things to try. He states he uses roughly 20-25% of x-section for perf. plate. I was at 12.5% in the latest video. I'm even lower on my last roast He also states too high perforation density per area can cause issues with bean movement which is exactly the issue I'm fighting and definitely describes what my hunch has been. So my fix is I have some aluminum plate that I am going to drill a new perf plate design into, and temporarily install that into the roaster. The plan is to use the spacing Rob has laid out over 25% of the x-section. I'll leave it close to the 45 at first and then try it at less then 45, maybe even all the way flat and see what I end up with. Hopefully i have time to do all of that this evening. I'll be sure to post results. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman