Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 4

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

All About the Bubble Bed Roaster

|

|

| allenb |

Posted on 03/11/2010 9:16 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Much of what I'll be posting here is also covered, although piecemeal, in a previous thread started by Klemenv (see "Rotational Axis Roaster") on 2-22-2010. The reason for re-posting the material is to allow greater visibility to folks who may not find it in the previous thread. What is a bubble bed roaster? For a quick overview of the roaster take a cylindrical fluid bed roaster and chop the bottom conical portion off and replace it with a flat perforated plate with a repeating pattern of closely spaced hole areas surrounded by sparsely spaced hole areas which allow high and low air flow zones across the surface of the plate. Introduce a high volume but lower pressure and lower temperature (lower than typical fluid beds) convection air through the plate. The resulting bean movement resembles rapidly boiling water. Due to almost constant contact between most of the beans and convection air the environment temperature for a medium roast (according to some claims) never needs to exceed 460 F and this while completing a roast in less than 5 minutes. There seems to be a scarcity of information regarding bubble bed roaster technology within the home-roast blogging community and the internet in general. The reason is likely due to the newness of the technology and next to no exposure of the few batch and shop roasting models being manufactured today. I'm only aware of two companies producing a bubble bed roaster, Nepro out of Germany, who seems to have started the ball rolling with their patenting of the special perforated plate which produces the bubble bed convective bean movement and Coffee Lab out of San Francisco, who produces a model called the "Rotational Axis Roaster" (I was first made aware of this roaster by Klemenv's post from 2-22-10). Coffee Labs offering is very recent and uses an interesting arrangment of multiple air nozzles mounted in the bottom plate of the roast chamber creating a similar bean movement but what appears to be less bubble bed and more rotational movement. In viewing the video of this roaster I'm not certain if it can be considered a true bubble bed roaster and I haven't spent enough time reading their patent to know if it is even claimed to be. Edited by ginny on 03/09/2013 2:16 PM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 03/11/2010 9:24 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Brief history of bubble bed technology The fluid bed drying machine industry as well as coal-fired boiler manufacturers created the technology in order to prevent product from falling out of fluid suspension. By creating multiple high and low air flow zones on an air distribution plate they were able to create product movement resembling a boiling liquid eliminating the problem of bed collapse and drastically improving heat transfer. In 1999 Nepro patented their perforated plate and started production of their "Vortex Fluidat" line of roasters. The advertised benefit of the technology was twofold; (1) ability to flash roast (total roasting time of 30 seconds to two minutes) causing increased fractures and pores with resulting "high yield" coffee (more brew strength per ounce) and (2) lower environment temperature throughout the roast cycle. Don't ask how you get a batch of coffee to go from room temperature through C1 in 30 seconds without having a brown exterior and green damp interior but somehow they do it. The patent docs for the perforated plate can be viewed at Wikipatents, Patent Storm, and Free Patents On line. Patent # for the perforated plate is 6338303. The patent describes a rectangular plate but you can apply the pattern ratios to a circular plate as well. Here is a video from Nepro showing bubble bed bean action from overhead:https://web.archi.../nepro.htm Here is a video from Nepro showing their 1kg shop roaster in action Notice the four small domed plumes which are not easy to spot without watching it several times. I previously thought this roaster would have needed 5 or 6 high density perf areas to achieve the bubble bed action but they obviously pulled it off with 4. If you look closely at the bottom of the glass roast chamber you will see a perforated metal cylindrical ring maybe 2" or so tall. The convection air path is up through the beans, into the space above them and then returning back through the beans near the perimeter and out through the perforated 2" rim. My guess is the air then makes its way back to a chaff screen/cyclone then back to the fan and electric heating elements. This design is an almost 100% recirculating design which is claimed to produce a better cup due to the absence of oxygen/oxidation during the roast. Neuhaus Neotec obviously spent a ton of research time on this issue before settling on using recirculation on their RFB (rotating fluidized bed) as well. It appears as long as you're using low environment temperatures and not causing the oils to burn after vaporizing during the hotter stages of the roast you can recirculate without causing off notes. I've experimented with a horizontal rotating (centrifugal) cone home-build a few years ago using about 75% recirc'd air and did not find any degradation in taste nor any smokiness during cupping. I personally would never want to roast without at least 10% makeup fresh air during the later stages of the roast. Edited by allenb on 09/10/2023 9:43 AM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 03/11/2010 10:04 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Home build a bubble bed? In the thread started by Klemenv it was pondered what kind of fan to use if firing with gas? One suggestion was to use a belt drive with slinger on the fan shaft as used by Sivetz. Using nichrome electric heat, if you recirc, which you would probably need to do with the high cfm needed, you would subject the blower to at least 250 f which would most likely reduce motor life. An option is to use a double sided blower wheel and pull in your 10-20 % makeup through a volute opening on the motor side of the casing pulling ambient air across the motor. I used this type of arrangement on the centrifugal cone setup and it kept the motor running cool. I've given some thought on how to simplify the trial and error of finding the right pattern and hole count densities for the perf plate. One idea is to use a one gallon paint can and use the bottom of the can as the perf plate. You could mark the pattern using a template then punch the holes from the inside. The diameter of a paint can would probably be at the lower limit of what you could get away with and still maintain bubble bed movement. My guess is that this diameter would probably allow near a 1 lb batch. Using the paint can one could attach an air plenum and fan to the outside bottom of the can for ambient temperature bean lift and pattern experimentation. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| klemenv |

Posted on 03/12/2010 5:17 PM

|

|

Newbie  Posts: 11 Joined: February 17, 2010 |

Great post Allen. Right now I am on tight with time, but I plan to try to build bubble bed roaster myself. I have feeling, that specific pattern is not so important. Two (or more) areas or bigger pressure (or bigger density of holes) repel beans. Think of two (or more) positively charged points. You know, + and + repels. If I recall from my physics days, two repelant points would cause caotical movements of beans. 4 repelant points would create even bigger caos. Caotical movement of beans would result in even heating. Regardless of any particular specific on pattern or shape of areas. Edited by klemenv on 03/12/2010 5:18 PM |

|

|

|

| allenb |

Posted on 03/13/2010 8:56 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

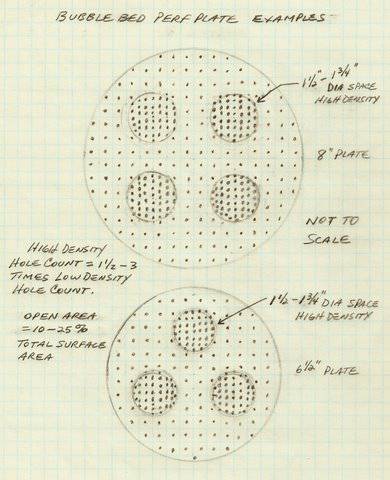

Thanks Klemen, Are you here in the states? As far as getting around to building is concerned I can relate. My last build (1lb drum) took me over a year due to laziness and being too picky. Hey, if you get it done in a couple of years its the fun of planning, testing, re-planning, final build and then those tense moments hovering over it while its transforming that first real batch of your favorite stash into brown gold that makes this craft worth it to us coffee nuts. Not sure how critical the pattern will end up being. Jobst implies that the specific size of high density areas and how far apart they are from each other will depend on the nature of the material being suspended. In other words, experiment till it works right. I've attached a sketch of a couple of plates for an example. The 8" diameter plate would hopefully handle a 1kg batch but this would need testing. The holes shown on the sketch are for example only. I included on the sketch the ratio of high density to low density hole count as I interpret it from Jobst Zoellner's patent # 6338303. Also included is % of open area versus total plate area which again is an interpretation from the patent. I would highly suggest reading the patent more than once as it seems a little contradictory in some areas. I would like someone to let me know if I'm right about the % open area. In the sketch is a pattern that might work for a 6"- 6.5" diameter plate for a smaller batch size. This might work for the paint can or any can around that size for experimental purposes. An idea for a setup that could be altered on the fly is to take two cans around 6" diameter, one on the bottom could have a high output vacuum cleaner motor/blower bolted to the bottom of it. Strap it or duct tape that can to the upper can with the perf pattern. Use a variac to vary the output to come up with the right pressure/flow to get the bed suspended. I'm not shure if a commercial vacuum motor/blower would move enough air to get the thing going but who knows? If it worked you could then measure the static pressure needed and then figure out what kind of radial or centrifugal fan you're going to need. I guess measuring the static pressure isn't a possibility unless you have access to a magnahelic or something similar. I would love to know if there is an inexpensive means of measuring this. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 03/13/2010 12:45 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Thanks John, I'll give the attachment another go:

allenb attached the following image:

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| John Despres |

Posted on 03/13/2010 2:05 PM

|

|

Administrator  Posts: 2221 Joined: January 09, 2008 |

Aha! Now things make much more sense to me! Thanks for the illustration, Allen. John Respect the bean.

John Despres Fresh Roast 8, Gene Cafe, JYTT 1k, Quest M3, Mazzer Mini, Technivorm, various size presses and many more brewers. |

|

|

|

| Dan |

Posted on 03/15/2010 10:28 AM

|

|

1 1/2 Pounder  Posts: 1662 Joined: October 24, 2005 |

Allen, That's very interesting. You are right, a true fluid bed will have an evenly perforated bottom plate with uniform pressure and flow across the bottom, which effectively suspends the entire particle bed. The visual effect is that it appears to be a fluid. If heat is added to the air flow, the particles (aka beans) will be "on the heat" 100% of the time. At the other extreme are the so-called spouting beds with a central perforated plate that is a fraction of the bed chamber's diameter. This lifts the central portion, which then falls to the perimeter, and eventually re-enters the spout, creating a flow of particles that are "off the heat" most of the time. This is generally considered valuable for roasting coffee. The bubble-bed you mention can be seen as an intermediate design between fluid bed and spouting bed. Such a design will use more air volume, which translates into more energy needed per roast. It will also tend to keep the beans "on heat" for a greater percentage of the time. This may or may not be valuable, and depends on the roasting profile you want to obtain. Interesting stuff! |

|

|

|

| seedlings |

Posted on 03/15/2010 10:42 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Does any air actually flow through the 75% of the plate that has low hole-density? Allen, with your BB roaster up-and-running, can you throw some beans in (with the heat off) and sacrifice a handful of painted beans thrown on top, then film just a little bit so that we can get the feel of the circulation? I wonder if the high-density areas could be 1.5" holes covered with screen instead of all the drilling. CHAD Edited by seedlings on 03/15/2010 10:43 AM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Ringo |

Posted on 03/15/2010 10:56 AM

|

|

Pounder  Posts: 474 Joined: January 14, 2010 |

For my test on my roaster I have been using dried navy beans from the grocery store. Cheep and not sacraficing coffee beans. I know some beans have to die but want to keep the numbers down. |

|

|

|

| allenb |

Posted on 03/15/2010 7:06 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Dan, There have been some interesting studies done in Japan comparing cup quality from various types of fluid beds. Using the same coffee and profile one was done with an airflow that kept the bed fully fluid where no bean in the entire bed was very close to another during the entire roast. Another was roasted maintaining close contact. Not sure how close but I?m assuming probably as close as you would have in a very low spouting bed or bubble bed. The fully fluidised roast with little bean to bean contact was reported to be flat and baked tasting where the one with close contact was quite good. There seems to be something going on with heat transfer between the beans, conductive, radiant, whatever that seems to be necessary for proper development. From what I?ve seen in videos of the bubble bed, they maintain good bean to bean contact while allowing air flow to circulate throughout most of the bed at the same time. I know this doesn?t make logical sense but somehow they pull off both equally well. In regards to energy consumption with spouted versus bubble you're right, there?s going to be more power consumed during a roast but since the bubble bed allows a reduced environment temperature it may not be as much as I originally thought. Also, if we can recirculate a percentage of roasting air the power consumption may be equal or less. This would obviously only be true when using a suitable bed depth to allow efficient heat transfer from air to beans. All of this needs a real world test in a home-build. You mentioned the beans being "on heat" more. Definitely will be but at a lower temp instead of in the heat (higher temp heat) then come around for the next ride into the spout. I would love to cup an A-B comparison test of the same coffee done with spouted and with bubble to see if the lower environment temp makes a difference at all. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 03/15/2010 7:09 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Chad, Yes, the low density hole areas provide two important things; one, convection flow in non-spouting areas and two, to keep the ?air hockey table? effect which allows beans to continually migrate from one spout to the next. I don?t think the screened over 1.5? holes would work if one is to try and maintain the ratios needed according to the patent doc. On the other hand it might work fine. Definitely worth a try especially with how long it takes to drill a zillion holes. It would be important to not have a non-slick surface anywhere outside the high density perf areas. I haven't built a bubble bed but hope to as soon as I can get some time and drive to start building again. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 03/15/2010 9:18 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote Ringo wrote: For my test on my roaster I have been using dried navy beans from the grocery store. Cheep and not sacraficing coffee beans. I know some beans have to die but want to keep the numbers down.  I'm all for testing without screwing up good stock but I'm curious, are navy beans close enough in relative density/weight per unit area to coffee to provide a good indicator?. Were you using them in a fluid bed or drum? If this works I'm going to the local general store! 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| John Despres |

Posted on 03/15/2010 9:48 PM

|

|

Administrator  Posts: 2221 Joined: January 09, 2008 |

Dried navy beans... D'OH!!!! Excellent idea!:BowDown: John Respect the bean.

John Despres Fresh Roast 8, Gene Cafe, JYTT 1k, Quest M3, Mazzer Mini, Technivorm, various size presses and many more brewers. |

|

|

|

| seedlings |

Posted on 03/15/2010 10:52 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote allenb wrote: I haven't built a bubble bed but hope to as soon as I can get some time and drive to start building again. Aaaah. I misunderstood, and thought you had one up and running. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| RoasterRob |

Posted on 03/16/2010 4:43 AM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

Hey Allen forget the variac for controlling the VC motor, use a triac based dimmer. That is how all VCs with variable speed work. I have built my own 1kw 230v dimmers which work real well. I would expect a VC blower to have plenty of flow and pressure for this type of application. The larger wattage units don't necesarrily have higher flow than the medium size units ie 1000watt versus 1600watt. Rob VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| allenb |

Posted on 03/16/2010 11:56 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Rob, Are there previous posts discussing the type of triac speed controls for the universal motors? Sounds like a much better way to go. Is the VC blower a standard vacuum cleaner unit or one designed for higher cfm-less inches/water column? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| RoasterRob |

Posted on 03/16/2010 12:22 PM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

By VC blower i just mean the blower out of a vacuum cleaner. I used the circuit diagram from here http://www.epanor...immer.html the 230v 1kw dimmer. Not sure if it would work with 110V. A 1kw VC will loft an 8" dep bed of coffee and have the green beans up to a height of near 16" on my roaster. So for a 8" area with beans less than 2" deep I would expect it would work fine. Rob VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| bvwelch |

Posted on 03/16/2010 8:06 PM

|

|

1 1/2 Pounder  Posts: 1064 Joined: December 27, 2007 |

CHAD, does your 'router speed controller' work OK with your Kirby motors? Seems like it should. I picked up an old junker VC from the local repair man, but haven't tested it yet. Cost me $10. |

|

|

|

| endlesscycles |

Posted on 03/16/2010 9:21 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

the router speed controller is nearly perfect. I've used it on various VC motors. I don't know what else I would even consider buying at this point.

-Marshall Hance

Asheville, NC |

|

|

|

| allenb |

Posted on 03/16/2010 10:00 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote RoasterRob wrote: By VC blower i just mean the blower out of a vacuum cleaner. I used the circuit diagram from here http://www.epanor...immer.html the 230v 1kw dimmer. Not sure if it would work with 110V. A 1kw VC will loft an 8" dep bed of coffee and have the green beans up to a height of near 16" on my roaster. So for a 8" area with beans less than 2" deep I would expect it would work fine. Rob Rob, In looking over the triac circuits he mentions some circuits being better for inductive loads which I assume the universal to be somewhat inductive. Have you seen another circuit that supposedly is better for motors on that site? With the lifting capacity you found to be possible (8" area, lifting to 16" height) then it would certainly work. Thanks for the tip on the circuits. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| RoasterRob |

Posted on 03/17/2010 1:12 AM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

Despite the comments about inductive loads the light dimmer 1kw 230v circuit has worked flawlessly for me using 900watt to 1100watt VC universal motors (well over a 1000 roasts). No interference with any other devices and i have been able to control the motor from full noise down to nearly stalling. I have stripped down several VCs and found the same basic components as this circuit. The 8" is the bean bed height before it is lofted, the perf area is about 5.4 sqr inches. I am really gonna need to try and get some youtube clips up of my roaster in action. cheers Rob Edited by RoasterRob on 03/17/2010 1:14 AM VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| allenb |

Posted on 03/17/2010 9:51 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I look forward to the video clips. I saw the video where the guy copied your design. I think you could produce a much superior video than his. Thanks for the clarification on the lift capacity (8" bed depth). If I end up using the triac control I'll want to use the one you linked to especially after the number of roasts you've gotten out if it. I'm thinking his referring to an "induction load" he was leaning more toward a true induction load which would probably cause a lot more headaches for the circuit. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 04/10/2010 9:40 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I've put together a bubblebed mock up rig for testing different perf plate hole patterns and finally got decent bean movement although it looks different from the Nepro video at the perimeter layer of beans. It took adding an outer perimeter ring of high density holes to get the extreme outer layer to move properly. Otherwise, I was able to use the hole pattern described in the perf plate patent by Jobst Zoellner. The diameter is 6.375" and seems to work best with a charge weight of 2 lbs. I'm guessing the cfm to be around 150. I'll try and borrow a magnahelic to measure static pressure in the near future and will post results. I've posted a video of it in action on Youtube: Allen Edited by allenb on 04/02/2023 7:55 AM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| RoasterRob |

Posted on 04/11/2010 1:06 AM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

Hi Allen. If that was 2lb of green, now try 1.6lb of roasted and see how that behaves. Is that roaster rig able to take the next step and run heated air? I have a wooden 10kg roaster test rig, never took that the to the final step could be fun to watch :up-late: Rob VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman