Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 8

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

Build a Chaff Collector Cyclone

|

|

| allenb |

Posted on 04/23/2010 5:38 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I'm looking for info on building a home brew chaff collector. It needs to accomplish the following: - Easy to build (relatively) -Off the shelf hardware variety parts -Utilize a 5 gal bucket for collection bin -No sheet metal fabrication required -No wire screen for filtration but some kind of cyclonic action -Doesn't need to be high efficiency in dust size particles -Work with a small blower (100 cfm, 1-2" static) I can introduce some bypass air into the inlet to reduce the temperature down from roasting temps. I'll want to use it in the air stream of roaster exhaust and cooling tray exhaust. Allen Edited by seedlings on 04/25/2010 8:35 PM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| endlesscycles |

Posted on 04/23/2010 7:14 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

ebay search: dust cyclone. $89. Can't do better.

-Marshall Hance

Asheville, NC |

|

|

|

| allenb |

Posted on 04/24/2010 12:16 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Is this the dust collector you're referring to on ebay? http://cgi.ebay.c...602_263622 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| seedlings |

Posted on 04/24/2010 11:17 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Looks good to me. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| DavidG |

Posted on 04/24/2010 11:54 AM

|

|

1/2 Pounder  Posts: 218 Joined: April 20, 2009 |

Allen, Here's a link to a detailed narrative from a home-woodworker, and his adventure in building a cyclone dust collector. Our chaff should be easier, I would think, to separate than their sawdust (based on particulate size, density, drag, etc.) http://www.woodce...ndex.shtml Also, he is recycling back into his shop an ENORMOUS volume of air, so for us roasters we can probably skip the steps of (i) building the impeller fan from scratch [use shop vac], (ii) fabricating the "dust spiral", (iii) building the secondary filters and boxes, (iv) custom 6" ducting to every tool station in the shop with valves to direct airflow. Unbelievable design, though. This guy plays in a different league than me!! David Edited by DavidG on 04/24/2010 12:11 PM europiccola | yama + coryrod | chemex | AP | clever

wbp1 | wepp1 | bm/hg | co hybrid (still coming soon...) |

|

|

|

| endlesscycles |

Posted on 04/24/2010 1:57 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

Quote allenb wrote: Is this the dust collector you're referring to on ebay? http://cgi.ebay.c...602_263622 That's the one. I'm getting one for sure, and will report back if you haven't already pulled the trigger. -Marshall Hance

Asheville, NC |

|

|

|

| allenb |

Posted on 04/24/2010 4:47 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote DavidG wrote: Allen, Here's a link to a detailed narrative from a home-woodworker, and his adventure in building a cyclone dust collector. Our chaff should be easier, I would think, to separate than their sawdust (based on particulate size, density, drag, etc.) http://www.woodce...ndex.shtml Also, he is recycling back into his shop an ENORMOUS volume of air, so for us roasters we can probably skip the steps of (i) building the impeller fan from scratch [use shop vac], (ii) fabricating the "dust spiral", (iii) building the secondary filters and boxes, (iv) custom 6" ducting to every tool station in the shop with valves to direct airflow. Unbelievable design, though. This guy plays in a different league than me!! David I'm approaching an extreme level of laziness at this point in my life and the woodshop sheet metal cyclone would be way too much work for me. I do appreciate the link though. He's done one heck of a home-build rig and there's a lot of very useful design ideas/tips. I stumbled on this very low-tech rig today that I think would work perfect for chaff and hopefully would catch even the smaller particulates coming out of a roaster although not fine dust. http://www.jarkma.../bench.htm The neat part of it is there's no cone shape so any kind of drum of a smallish diameter would probably suffice. Instead of the shop-vac for air movement you could use your choice of blower. You would probably need to go with no less than 2.5" dia duct/hose capable of high temp air. Construction time should be minimal. Thoughts, comments please 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 04/24/2010 4:59 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote endlesscycles wrote: Quote allenb wrote: Is this the dust collector you're referring to on ebay? http://cgi.ebay.c...602_263622 That's the one. I'm getting one for sure, and will report back if you haven't already pulled the trigger. I checked the guys website and his products look top-notch. I want to try the junk yard approach before ordering one. I'm interested to hear how it does after you've had time to run some chaff through it. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| seedlings |

Posted on 04/24/2010 8:15 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

How about a 5 gal bucket and a paint can? Glue/mount the bottom of the paint can to the underneath of the lid. Cut a hole through the bucket lid, through the paint can bottom for the outlet. Cut a hole in the top, side, of the bucket for the inlet. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| endlesscycles |

Posted on 04/24/2010 9:39 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

Quote seedlings wrote: How about a 5 gal bucket and a paint can? Glue/mount the bottom of the paint can to the underneath of the lid. Cut a hole through the bucket lid, through the paint can bottom for the outlet. Cut a hole in the top, side, of the bucket for the inlet. CHAD That's WAY more sophisticated than my current arrangement, which sees one or maybe two particulates of chaff fly out the window during a 6lb roast. In other words: Great idea! -Marshall Hance

Asheville, NC |

|

|

|

| DavidG |

Posted on 04/25/2010 4:08 PM

|

|

1/2 Pounder  Posts: 218 Joined: April 20, 2009 |

Quote seedlings wrote: How about a 5 gal bucket and a paint can? Glue/mount the bottom of the paint can to the underneath of the lid. Cut a hole through the bucket lid, through the paint can bottom for the outlet. Cut a hole in the top, side, of the bucket for the inlet. genius. I want to make one, now. David europiccola | yama + coryrod | chemex | AP | clever

wbp1 | wepp1 | bm/hg | co hybrid (still coming soon...) |

|

|

|

| allenb |

Posted on 04/25/2010 6:00 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Excellent! I'll also be making one. This allows minimal expended labor, able to be built out of common hardware variety stuff and can be thrown together in a short time. From what I just read on a DIY cyclone site you can save some work by cutting the upper inlet tangential hole in the drum the size of the inlet tube and just shove it in 3 to 4" keeping it hugging the outer edge. This eliminates having to cut the tube into the weird geometric shape to fit the drum's outer curvature. This has a positive effect in reducing turbulence and a resulting increase in cfm. You want to keep the inlet as close to the top of the bucket as possible. Chad, you may have to patent this. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| seedlings |

Posted on 04/25/2010 8:34 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

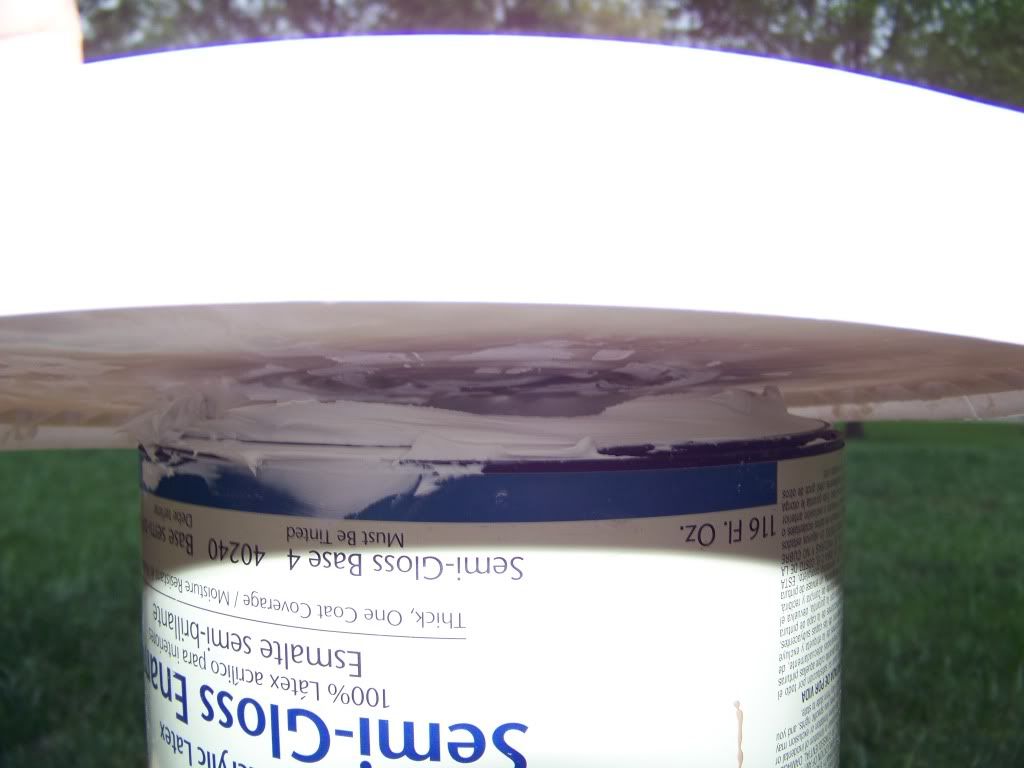

seedlings diy coffee roaster chaff collector cyclone using a 5 gallon bucket and paint can: Caulk (or glue) top of paint can:  To the underneath of the 5 gallon bucket lid:  Screw lids together (or wait for adhesive to dry):  Viola:  Cut outlet hole in top of bucket lid, through paint can, and inlet hole in upper side of bucket:   Operation: Took 45 minutes, including looking around for the most empty paint can and cleaning it out. CHAD Edited by seedlings on 04/25/2010 9:09 PM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| allenb |

Posted on 04/26/2010 7:15 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

You don't waste any time. I would have had to ponder the thing for at least a month before getting off the rear end. From what I've read in the DIY cyclone world your inlet arrangement (centered instead of tangential) would cause some chaff to get sucked into the paint can and into your shop vac. Any sign of chaff inside your shop vac? I know the 1 lb San Franciscan table top roaster has the inlet centered but I think it has a sheet metal vane inside diverting the air into a centrifugal vortex around the drum. This is a guess only. Allen Edited by allenb on 04/26/2010 7:17 PM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| John Despres |

Posted on 04/26/2010 7:45 PM

|

|

Administrator  Posts: 2221 Joined: January 09, 2008 |

I like it!!! Do we need something as strong and noisy as a shop vac? Maybe a smaller squirrel cage fan since chaff is so light. Dunno. Thoughts? John Respect the bean.

John Despres Fresh Roast 8, Gene Cafe, JYTT 1k, Quest M3, Mazzer Mini, Technivorm, various size presses and many more brewers. |

|

|

|

| seedlings |

Posted on 04/26/2010 7:48 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Just so happens I have a small squirrel cage fan... better go try it out, huh? I'll let you know. Allen, you're right it should come in tangential, but I was lazy and cut a circle instead of an ellipse. Plus, the "rim" around my 5 gal bucket gave me less-than-optimum placement. Still, there was no chaff in the shop vac. Down to the garage... CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Ringo |

Posted on 04/26/2010 8:10 PM

|

|

Pounder  Posts: 474 Joined: January 14, 2010 |

I used a small squarl cage fan its works great, till I opened the cleanout door and chaff went all over the garage. So i learned to turn fan off when I clean it out.;)

Edited by Ringo on 04/26/2010 8:12 PM |

|

|

|

| endlesscycles |

Posted on 04/26/2010 8:21 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

Make sure your fan matches or exceeds your roaster output.

-Marshall Hance

Asheville, NC |

|

|

|

| seedlings |

Posted on 04/26/2010 8:25 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Well, there's too much fabrication needed to match a 9 inch squirrel cage opening to a 3 inch hole for test purposes - so tonight's test has been scrapped. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Turingalad |

Posted on 05/30/2015 1:28 AM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

(preface: feel free to put my thread wherever it belongs, or let me know if I should start my own...) I know this is an old thread, but I'm desperate for a chaff-collecting/vent solution for my 1K drum roaster and was wondering: 1) does the paint bucket withstand the heat? (...seedlings...?) 2) does there absolutely have to be a cone? if so, does size/shape of cone matter? Would a paint bucket with just the slightest degree of narrowing from top to bottom work? 3) would I fry a shop vac if I had high heat from a roast pumping through it constantly? (Thinking about a small 1.5hp sho vac attached to variable speed controller to slow it down considerably.) 4) is there currently, or could there be, a thread where people show off their different DIY Chaff-collecting vents? I'm in an interesting position where I have lots (like, I work for a super pack-rat, apocalypse-prepping, end-times hoarder with barns full... ) of good materials, and pretty much any tool at my disposal. Only thing keeping me is an executable idea, good blue print, and skills (if any are required), like... I don't know how to weld. But maybe this is my chance to learn? |

|

|

|

| Lawnmowerman |

Posted on 05/30/2015 2:03 AM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

Hi this is Ben. I recently cobbled together a smaller version cyclone. It is used on a heat gun bread machine roaster, and is passive, because the heatgun provides plenty of pressure to make it work just well enough to catch the small amount that isn't kept in the initial chaff accumulation area. I didn't use a cone. This is all part of a new roaster build, and will be in its own thread. It is nearly complete.

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

| Turingalad |

Posted on 05/30/2015 2:14 AM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Lawnmowerman, can't wait to see pics! Do you happen to have a sneak-peak of the chaff-collector? or sketch or something? I've got a real math-y question... if I know the diameter of intake pipe, and measurements of cylinder/cyclone, how do I measure the hole that the pipe goes into (like these pictures I found...) so I cut it accurately? (The material I could hypothetically use would be able to be flat for cutting purposes, prior to molding it into the cyclone shape, or cylinder.)   |

|

|

|

| bud |

Posted on 05/31/2015 10:01 AM

|

|

Newbie  Posts: 21 Joined: April 01, 2012 |

sweet, love the build. bud

"the beer was very cold and wonderful to drink"

brew with old perc |

|

|

|

| Lawnmowerman |

Posted on 05/31/2015 1:14 PM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

I will post pics today. The piece you are showing(i call it a diverter), I took from a vacuum cleaner canister. I just mounted it sideways.

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

| Lawnmowerman |

Posted on 05/31/2015 2:17 PM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

I used a 6 inch canister with a cookie tin style lid. The bread maker roaster captures most of the chaff because of its design. The cylone has a lower half which is just the canister and the diverter. The "cone" and chimney adapter are divided on opposite sides of the lid. There is a connection hose to the cooler so it blows smoke right out the same chimney, and not into my garage.The chimney adapter is an enchilada sauce can (because I can't help it). I threw this together in about a half hour. I admit it's rough. But it works perfectly. With no output fan necessary. Hope I didn't forget anything. Ben.

Lawnmowerman attached the following images:

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman