Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

Build a Chaff Collector Cyclone

|

|

| LongLeafSoaps |

Posted on 08/22/2015 9:37 AM

|

|

1/4 Pounder  Posts: 167 Joined: August 09, 2015 |

Quote allenb wrote: You don't waste any time. I would have had to ponder the thing for at least a month before getting off the rear end. From what I've read in the DIY cyclone world your inlet arrangement (centered instead of tangential) would cause some chaff to get sucked into the paint can and into your shop vac. Any sign of chaff inside your shop vac? I know the 1 lb San Franciscan table top roaster has the inlet centered but I think it has a sheet metal vane inside diverting the air into a centrifugal vortex around the drum. This is a guess only. Allen Hi, new here & my 1st post... I know this is an old thread, but my thought would be rather than to cut an elongated hole and have to fuss with filling in w/caulk or something to direct the PVC inlet pipe to the sidewall of the bucket, is to go ahead and place the inlet hole square into the side of the bucket for your PVC pipe (like shown above in seedlings post), and on the inside of the bucket just use a 90 degree elbow to direct the air & chaff around the bucket wall instead of towards the paint can outlet pipe (or whatever you choose to use for the air outlet pipe).... Edited by LongLeafSoaps on 08/22/2015 9:48 AM |

|

|

|

| ChicagoJohn |

Posted on 08/22/2015 11:39 AM

|

|

Pounder  Posts: 513 Joined: June 15, 2015 |

Quote LongLeafSoaps wrote: use a 90 degree elbow to direct the air & chaff around the bucket wall instead of towards the paint can outlet pipe (or whatever you choose to use for the air outlet pipe).... Sounds like a good idea, LongLeafSoaps, for all the reasons you mentioned as far as fabrication and also because the right angle turn will help to reduce the velocity initially as well as to direct the flow against the outer wall where drag will further reduce it. The problem with bean chaff is that its high aspect ratio in combination with low mass gives it a very low settling rate compared to particulates like saw dust. So many beans; so little time.... |

|

|

|

| LongLeafSoaps |

Posted on 08/25/2015 6:42 AM

|

|

1/4 Pounder  Posts: 167 Joined: August 09, 2015 |

Quote ChicagoJohn wrote: The problem with bean chaff is that its high aspect ratio in combination with low mass gives it a very low settling rate compared to particulates like saw dust. Sawdust definitely weighs more than chaff...popcorn hulls weighs more than chaff! Oh, and hey...I used to live in Hazelcrest, Ill. I could look down the street and see Sears Tower when I would get my mail! Miss Chicago except for the traffic!=D Edited by LongLeafSoaps on 08/25/2015 6:48 AM |

|

|

|

| oldgearhead |

Posted on 08/25/2015 6:44 PM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Oh I went through several hoops trying to integrate a baffle-separator (used in industry to collect red-dog) into my one-pound, electric, fluid-bed roaster. The best I was able to do was 80%. Therefore, I just put a 40=mesh screen over the RC and after cooling vacuum the chaff off the top of the beans..very simple, and more effective...try it.. No oil on my beans...

|

|

|

|

| JETROASTER |

Posted on 08/26/2015 1:59 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

I hope this link is helpful. It's a bit dry, but some good info to be had. My take away; Inlet geometry matters. Tall inlets are better than wide inlets. Angle of inlet is also significant. Cheers, Scott http://www.scienc...4X10004178 |

|

|

|

| Ringo |

Posted on 08/26/2015 3:37 PM

|

|

Pounder  Posts: 474 Joined: January 14, 2010 |

With a cyclone you are spinning the air centrifugal force holds the dust to the outside wall, the air that goes up the center should be clean. When you need to remove very fine dust you make a smaller diameter cyclone but use more that one. So the air spins faster. Coffee chaff is easy to remove if you come in at a tangent so the air spins. I have multiclones on a boiler at work that removes 5 micron particulate, but each one is only 8 inches across. Each multiclone has maybe 40 tubes in it. The one I built for my roaster is maybe 18 inch straight diameter pipe with no funnel at the bottom. The chaff just falls to the bottom every couple weeks I open an access door and clean it out. I have seen commercial roasters that use this same system.

All you need in life is ignorance and confidence, and then success is sure. Mark Twain

|

|

|

|

| alexcampbell |

Posted on 09/06/2015 12:55 PM

|

|

Newbie  Posts: 42 Joined: December 16, 2013 |

I am building a cyclone for my new roaster, but I think this is overthought sometimes. I have been using this setup for 2 years where it just dumps from my poppery into a bucket. No chaff escapes this setup as the velocity of the air is dropped so low. I used to put a towel over the bucket, but found it unnecessary. Current Chaff Collection Current Chaff Collection |

|

|

|

| renatoa |

Posted on 01/14/2018 4:15 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Looking at commercial roasters cyclones, even for the smallest machines, under 1 kg, they look too big for me... Is there any design criteria for a cyclone, can we speak about a rating, or capacity, derived from the airflow and/or machine capacity ? Asking because I found an incredible cute and cheapo cyclone, full cast aluminium, but looks like a toy near a commercial unit... 25 mm admission and exhaust holes, size of a beer bottle, what do you think ? It is rated for 45-70 cubic meters per hour, though... typical airflow for 1 kg commercial roaster. Edited by renatoa on 01/14/2018 4:22 AM |

|

|

|

| dmccallum |

Posted on 01/31/2018 1:16 PM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

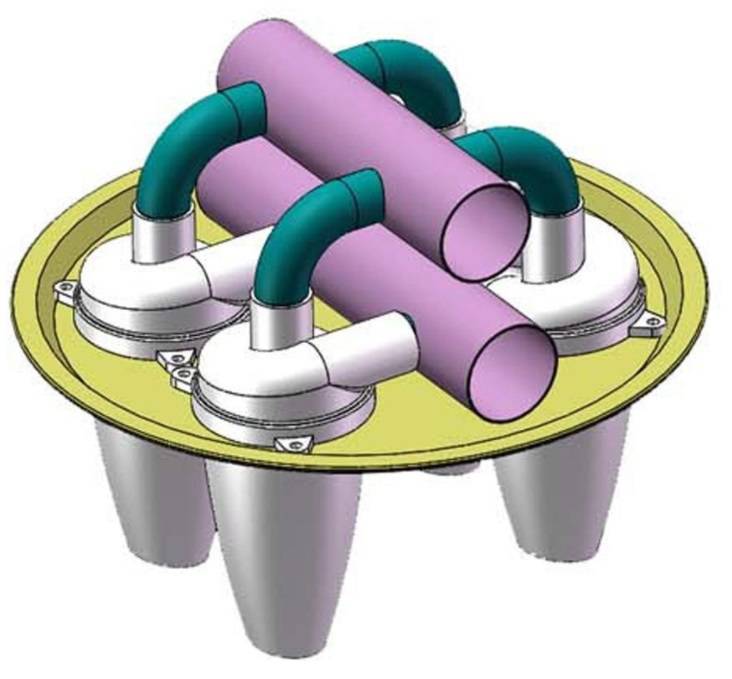

I based my cyclone on a thien principal. https://forum.hom...owstart=80 In the course of designing it I could help but notice that it's dimensions corresponded to the first stage on our regular dyson vac. I also noticed that it scaled smaller than this in the Dyson cordless vacume which I also have. It's first stage is also a thien which should serve for coffee roasting. The Dyson handlheld vac above pulls 160 CFM through this small thien cyclone. Should be easy to develop something from a short length of 130mm stainless tube.

dmccallum attached the following image:

Edited by dmccallum on 02/02/2018 5:53 AM |

|

|

|

| dmccallum |

Posted on 02/02/2018 3:37 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

Quote renatoa wrote: Asking because I found an incredible cute and cheapo cyclone, full cast aluminium, but looks like a toy near a commercial unit... 25 mm admission and exhaust holes, size of a beer bottle, what do you think ? It is rated for 45-70 cubic meters per hour, though... typical airflow for 1 kg commercial roaster. Refer this link here. In particular Allenb's comment about his 1lb drum roaster draw https://forum.hom...rowstart=0 Refer also http://www.tradit...inute.html Your suggested 45-70 cubic meters per hour correlates to the cfm rates Allen was talking about. |

|

|

|

| renatoa |

Posted on 02/02/2018 4:52 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Ok, the mini cyclone arrived meanwhile, it is incredible how they can made this full cast Aluminium piece and sell for less than 10 GBP shipped from China to EU... You can see it attached to my current TO oven in the picture below. To have a better sense of the size, total height is 19 cm, diameter is 8 cm and pipe(s) diameter are 25 ID / 29 OD (mm). Not tested yet, next roast soon. OK, airflow match with Chinese specifications, does it really means is good for 1 kg roaster ? <confused> Then why commercial roasters cyclones are SO big ? Source: eBay or Aliexpress. search: "Aluminium Cyclone extractor" .

renatoa attached the following image:

Edited by renatoa on 02/02/2018 7:12 AM |

|

|

|

| dmccallum |

Posted on 02/02/2018 8:37 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

Quote Ahh, the Dust Commander. It's been around a while but had only seen it in plastic. Great find and look forward to hearing how you get on with it. Are you aware this thing is just the cyclone - not the complete sealed assembly? You'll have to mount the thing into a bin of some sort which is sealed to receive the chaff. Sorry if I'm stating the obvious.

dmccallum attached the following images:

Edited by dmccallum on 02/02/2018 8:56 AM |

|

|

|

| renatoa |

Posted on 02/02/2018 9:43 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Is a tin can from whatever food or paint recipient ok ? Thinking to cut an 8 cm circle in the lid, mount the cyclone in that hole with silicone sealant, anything else needed ? |

|

|

|

| dmccallum |

Posted on 02/02/2018 10:47 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

Quote renatoa wrote: Is a tin can from whatever food or paint recipient ok ? Thinking to cut an 8 cm circle in the lid, mount the cyclone in that hole with silicone sealant, anything else needed ? Probably. It just needs to form a seal and be able to withstand the suction you're going to apply to it so it doesn't collapse (which is unlikely). |

|

|

|

| greencardigan |

Posted on 02/04/2018 9:36 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Awesome! It does look undersized for a 1kg air roaster, but could be just right for a lower airflow roaster. |

|

|

|

| renatoa |

Posted on 02/21/2018 3:55 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Is there any standard to connect a cyclone for roasters? For power and for control, if separate plugs. Or it's a proprietary stuff, each its own... Asking for a potential commercial roaster design, intended to be sold modular, with chaff collector as an option. |

|

|

|

| CharcoalRoaster |

Posted on 02/12/2020 1:02 PM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

I know this is an old thread but has anyone ever upcycled a vacuum cleaner cyclone separator assembly and just used that to separate out the chaff? We use vac motors for FB blowers all the time so why not use the dust separator assembly for chaff separation/collection? |

|

|

|

| renatoa |

Posted on 02/12/2020 1:52 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Aren't they made from plastic? So melting when passing +200 C air...  Some of us used the Dust Commander aluminium version cyclone, good for up to 1 kg roasters. |

|

|

|

| CharcoalRoaster |

Posted on 02/12/2020 2:54 PM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

I use PVC for air intake and heat reclamation on my current build with no melting issues. Would it be that much different? |

|

|

|

| renatoa |

Posted on 02/13/2020 1:23 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

In this case we are talking about different heat circuits and purposes... my cyclone is sucking air directly from the roast chamber, to separate chaff. Used Kapton tape to seal the joins, a normal electrician duct tape melt after a while. |

|

|

|

| noolname |

Posted on 04/08/2020 4:32 AM

|

|

Newbie  Posts: 2 Joined: April 08, 2020 |

How Use Successes ?yclone? |

|

|

|

| renatoa |

Posted on 06/09/2024 3:56 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

In addition of the alu cyclone discussed above years ago, https://vi.aliexp...98664.html ... I want to signal a new model, significantly bigger capacity, good for machines about 1 kg and even more. 40 vs 25 mm inlet/outlet diameter, 16 vs 10 cm the cyclone chamber. Some links for immediate view: vi.aliexpress.com...02854.html https://www.amazo...ref=sr_1_4 ... probably valid for some months, that's why is good to have a product name/code  Unlike the smaller cyclone, this one has a code you can search later for more info: SN40T10. The complete combos, fitted with canisters, that you see listed as Application examples in Aliexpress page, are also available for purchase, if you search for SN40T10. Edited by renatoa on 06/09/2024 4:20 AM |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman