Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 9

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

CoffeeAir II Roaster Build

|

|

| seedlings |

Posted on 04/29/2010 10:37 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

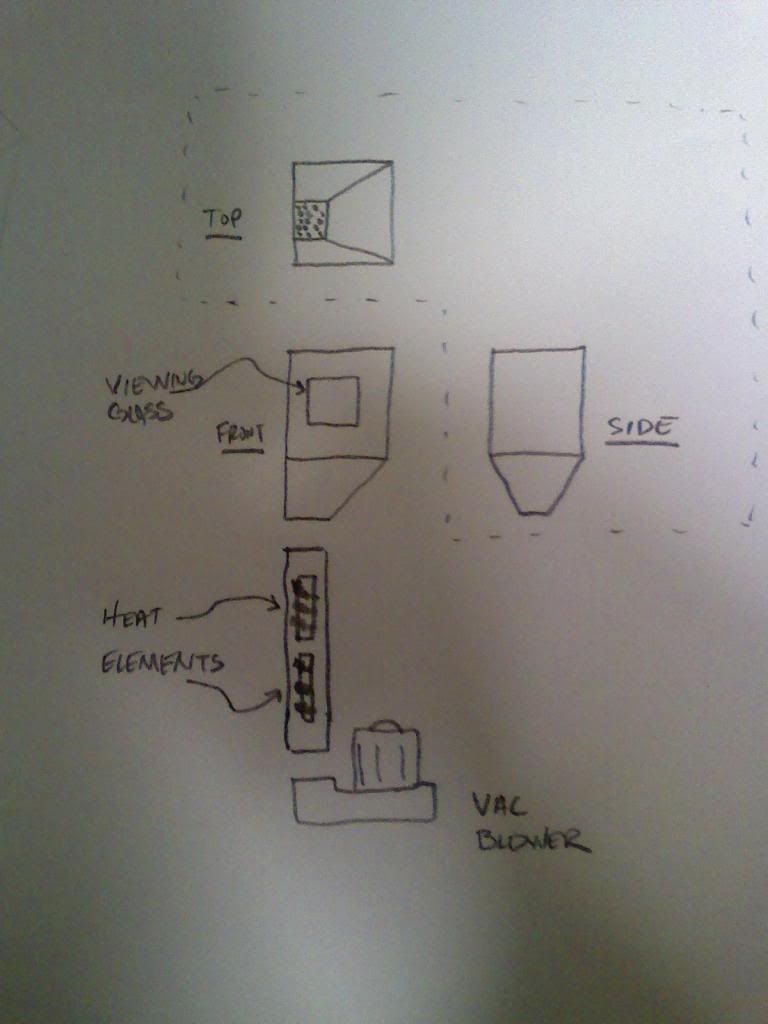

I have been on a bumbling mission to build an air roaster (in the spirit of Sivetz or RoasterRob) for pennies on the dollar. My first attempt showed some promise, but I couldn't bring it all together. This time? Who knows. GOALS 2# capacity - bonus if it can roast as little as 1/2 pound. Built-in cooling Vented to outdoors Electric - yes, electric Easy to load/unload Quiet enough to hear cracks Ability to view beans Cheap, cheap, cheap Easy, easy, easy GUTS Air pressure source: Aluminum Kirby vacuum motor ($10) Manual Air Control: Harbor Freight Router Speed Control ($10) Heat source: Two HG-751b Master Appliance heatgun elements (14.5A each) ($10/pair) Auto Heat Control: Fuji PVX3 Temperature Controller, 50A SSR, K-type TC ($50) Viewing Glass: Safety glass from Halogen shop lamp ($10) Ventilation: Fasco fireplace squirrel cage fan 180cfm ($30) DESIGN Working on that MATERIALS Cement Board Aluminum Flashing High-Temp silicone With all the guts in my possession, it's time to figure out a design. This is the very general idea:  One reason for the squarish design is to be able to mount a viewing glass, another reason is my noted lack of fabrication skills. I have yet to decide if the hopper will be removable for loading/unloading, or permanent with a load chute and unload chute. The sides will be made from cement board, the interior lined in aluminum flashing. Above the hopper will be the Fasco fan blowing the smoke/chaff outside. My first concern is that the beans might 'need' a conductive hopper to help retain heat. Now, to find spare time. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| jlyon10 |

Posted on 04/29/2010 10:44 AM

|

|

1/4 Pounder  Posts: 101 Joined: April 01, 2009 |

Good Luck Jim Lyon

Jim's Coffee Beans |

|

|

|

| JETROASTER |

Posted on 04/29/2010 11:54 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Looks like fun! I'm in the vacuum business. If that motor doesn't give you the results you want, let me know. You could well ventilate a closed system with just the one blower. Looking forward to your updates, Scott |

|

|

|

| seedlings |

Posted on 04/29/2010 1:06 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote freshbeans wrote: Looks like fun! I'm in the vacuum business. If that motor doesn't give you the results you want, let me know. You could well ventilate a closed system with just the one blower. Looking forward to your updates, Scott There may not be a complete seal between the top of the hopper and the bottom of the ventilation contraption, which may make the 1 blower not possible. BUT, thanks for bringing that up now since I can design it in. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| seedlings |

Posted on 04/30/2010 1:40 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

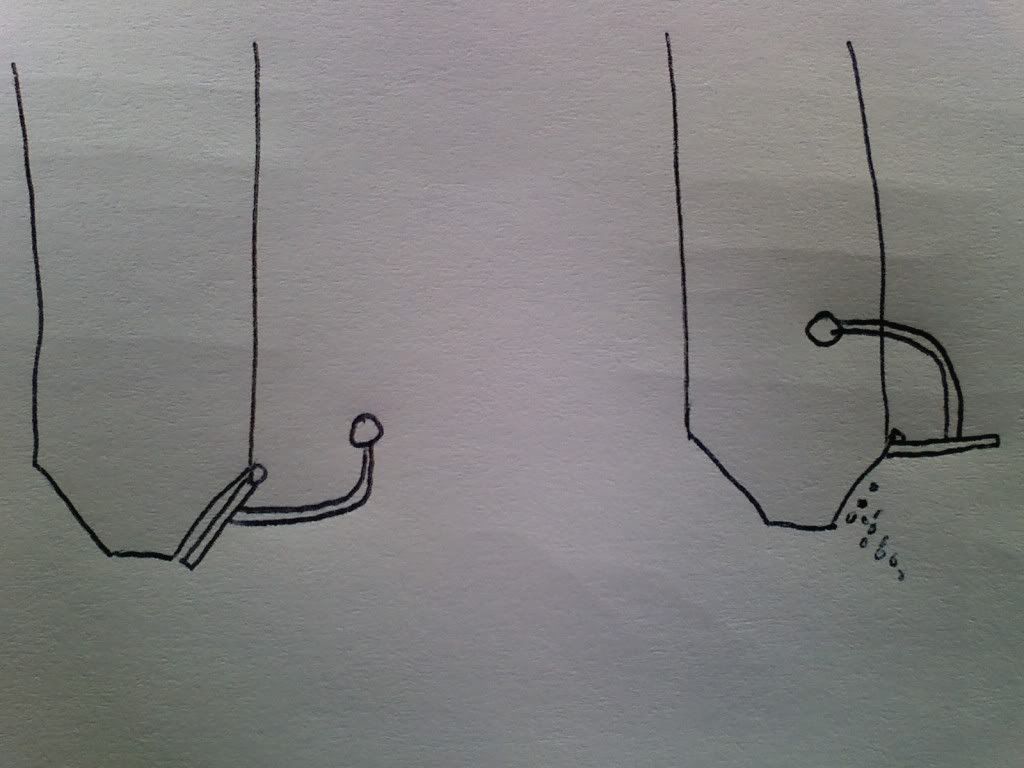

I'd like to employ something like this to unload the beans. What do you think about the weight of 2# of beans and the pressure in the hopper? There won't necessarily be much weight from the beans, but probably need a lot of weight to hold the door closed during operation because of the pressure. CHAD Edited by seedlings on 04/30/2010 1:43 PM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| JETROASTER |

Posted on 04/30/2010 4:25 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

If I may pry a bit... what sort of tools do you have at your disposal? Re-purposing some common items will require less raw fabrication. I have a design logic in mind that has already worked. (with propane) -Scott |

|

|

|

| seedlings |

Posted on 04/30/2010 9:46 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote freshbeans wrote: If I may pry a bit... what sort of tools do you have at your disposal? Re-purposing some common items will require less raw fabrication. I have a design logic in mind that has already worked. (with propane) -Scott Just the very basics... jigsaw, circular saw, drill, manual rivet gun, screwdrivers, pliers. No table saw, no drill press, no lathe, no welder. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Unta |

Posted on 05/01/2010 6:33 AM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

Quote seedlings wrote: I'd like to employ something like this to unload the beans. What do you think about the weight of 2# of beans and the pressure in the hopper? There won't necessarily be much weight from the beans, but probably need a lot of weight to hold the door closed during operation because of the pressure. I think a latch would be successfull.At that point the weight of the roasted beans would be a benefit opening the door after the latch is released. Edited by Unta on 05/01/2010 6:42 AM Sean Harrington

educate. |

|

|

|

| Unta |

Posted on 05/01/2010 8:02 AM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

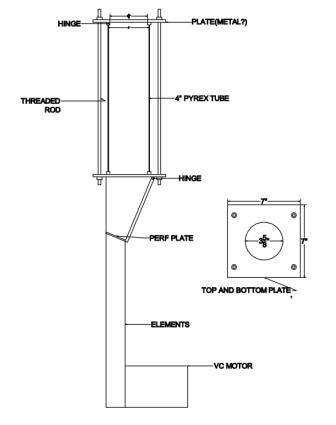

heres my take..The hinge would have to be worked out and so would the latch.The section between the perf plat and the VC could be smaller, depending on the size of the elements. OH and for scale the pyrex tube is 15" tall, neglected to annotate height. ;) VC motor not to scale! A link to a larger version of thebelow picture. http://www.facebo...1576066216

Unta attached the following image:

Edited by Unta on 05/01/2010 8:33 AM Sean Harrington

educate. |

|

|

|

| JETROASTER |

Posted on 05/01/2010 8:40 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Release door; Hinge at bottom, opens inward. As the door is pressed inward, existing airflow (from perf plate)assists in evacuating the RC up and over your door. During roasting, bean weight assists in keeping door shut. Tools: A dremel will be money well spent. Looks like fun! Scott |

|

|

|

| Unta |

Posted on 05/01/2010 12:20 PM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

it would have to be a pretty small door to open inward..I think you would also have some trapped beans. unless im not understadning. Pictures are worth a thousand words..

Sean Harrington

educate. |

|

|

|

| seedlings |

Posted on 05/01/2010 12:48 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Oh yeah, I do have a dremel. I understand what you're saying Scott, but thought about "trapping beans" like Sean said. Sivetz uses a 'guillotine' sliding damper and most beans dump out, then they use a tool to scrape the rest out. (clip courtesy of opus). I also thought about rotating the door open/closed - maybe with a channel to keep it closed tight. CHAD Edited by seedlings on 05/01/2010 12:54 PM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| JETROASTER |

Posted on 05/01/2010 12:52 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Size and shape are an issue. It has to be shaped to act as an airfoil. I skipped the dump door thing... seems more trouble than its worth. I did use vacuum evacuation in years ago. Currently use a 5lb. pump and dump. (removable RC) Roast it, cool it , dump it ,reload it. At 2 lbs, it's worth considering . Scott |

|

|

|

| seedlings |

Posted on 05/01/2010 1:02 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

If the roaster has a removable hopper, then it will be difficult to ventilate properly. I'd like to have the roaster fixed, with a chaff cyclone, vented outdoors, and probably partial recirculation. With all that it makes the hopper tough to move in/out... unless it slides straight in the front... hmmm... Then I'll probably drop it and break the glass. Lots of variables. Thanks for the input everyone, it helps to have different angles of thought. Scott, could you post some pictures of your roaster (in a dedicated thread)? CHAD Edited by seedlings on 05/01/2010 1:04 PM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Unta |

Posted on 05/01/2010 1:06 PM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

Quote seedlings wrote: Oh yeah, I do have a dremel. I understand what you're saying Scott, but thought about "trapping beans" like Sean said. Sivetz uses a 'guillotine' sliding damper and most beans dump out, then they use a tool to scrape the rest out. (clip courtesy of opus). I also thought about rotating the door open/closed - maybe with a channel to keep it closed tight. CHAD Blast gate might work also,though i was thinking that it might be harder to build then the hinge.. Sean Harrington

educate. |

|

|

|

| JETROASTER |

Posted on 05/01/2010 1:06 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

I'll get crackin' on some photos. -Scott |

|

|

|

| endlesscycles |

Posted on 05/01/2010 1:10 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

The bubble bed design might be best for recirculated heat, as the temp can be lower. btw: just launch the beans out. You know that will work. This can be done. -Marshall Hance

Asheville, NC |

|

|

|

| Koffee Kosmo |

Posted on 05/01/2010 6:57 PM

|

|

Administrator  Posts: 1621 Joined: December 31, 2008 |

Did you have a look at the post I put up http://forum.home...post_20826 Have a play with the interactive section for a Fluid Bed roaster Keep adding beans and see the reaction KK Edited by Koffee Kosmo on 05/01/2010 6:58 PM I home roast and I like it. Designer of the KKTO

Roaster Build information https://homeroast...ad_id=1142 https://docs.goog...lide=id.i0 Blog - http://koffeekosm...gspot.com/ Bezzera Strega, Mazzer Robur Grinder, Pullman Tamper Convex, (KKTO) Turbo Oven Home Roaster. |

|

|

|

| seedlings |

Posted on 05/01/2010 9:05 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

KK, that's a great presentation. We had a long thread some time back talking about probat's bowl roaster, and that presentation came up. I have yet to taste a drum roast that I preferred to an air roast, but I'm willing to be impressed. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| seedlings |

Posted on 05/03/2010 9:34 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Found out today that our scrap yard doesn't sell scrap any more... But I bought a length of 4" square steel tubing from a local metal fabricator, then enlisted a coworker (who thinks cutting and welding is fun to do in his spare time) and gave him some general instructions to what I wanted. I'll be excited to see what he comes up with. CHAD Edited by seedlings on 05/03/2010 2:12 PM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| seedlings |

Posted on 05/05/2010 10:13 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

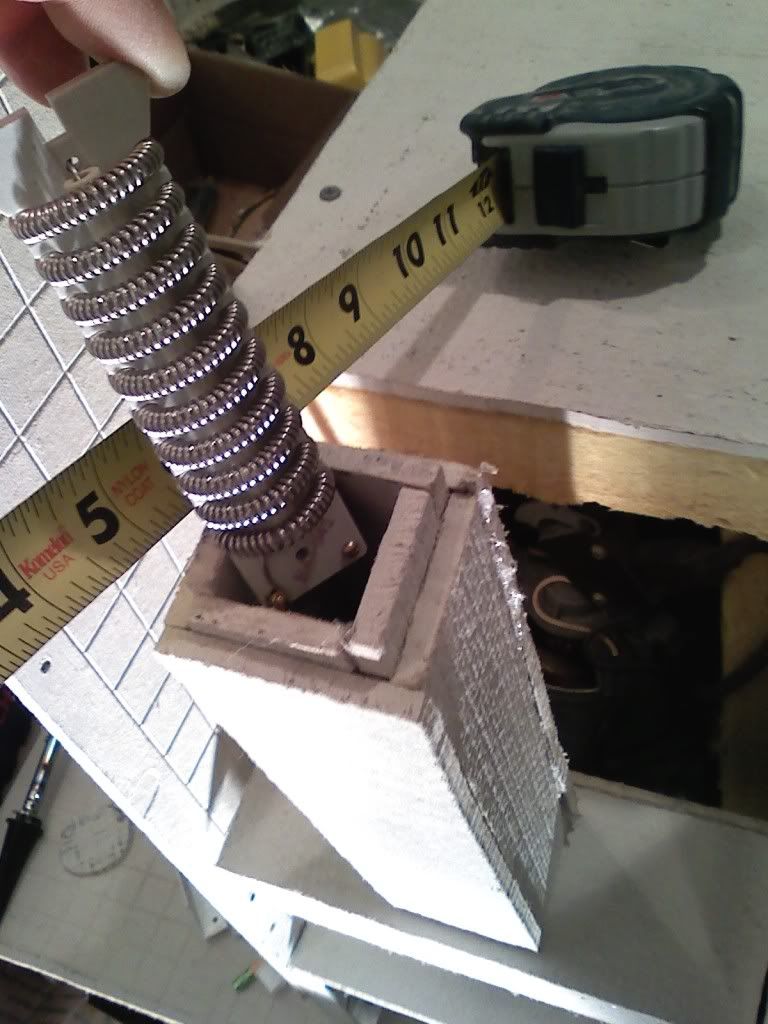

Here are a few pictures... I had to get the square peg (heat tube) to fit the round hole (blower outlet).     The elements will fit in this tube, and each element came with 2 sheets of mica:  I'm waiting to get the hopper back from a coworker doing some welding. Once the hopper is here, I will jigsaw puzzle some contraption together to join the heat tube to the hopper. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| JETROASTER |

Posted on 05/05/2010 10:29 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Hi Chad, This looks like a fun one. If that Kirby is old enough to have a metal fan, it could handle a small amount of recirc. Most of those also had a high speed option built into the safety switch(front of fan housing). Looking forward to your progress. Scott |

|

|

|

| seedlings |

Posted on 05/05/2010 10:38 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote freshbeans wrote: Hi Chad, This looks like a fun one. If that Kirby is old enough to have a metal fan, it could handle a small amount of recirc. Most of those also had a high speed option built into the safety switch(front of fan housing). Looking forward to your progress. Scott My previous attempt included recirculation, but I didn't have enough electric heat. I hoped to roast 2 pounds with 1800W element + recirculation. After reading more, I think my air-to-nichrome heat transfer was grossly inefficient. I did keep the recirc temps around 200F and the kirby just kept going. It really is a beast. There's even a heatslinger between the motor and the fan. http://forum.home...post_10094 CHAD Edited by seedlings on 05/05/2010 10:44 AM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| JETROASTER |

Posted on 05/05/2010 10:48 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Yup, that's good ol' fashioned American quality. Rebuilding all these vacuum motors is just part of the daily grind for me. If you need parts, drop a line. Scott |

|

|

|

| bvwelch |

Posted on 05/05/2010 11:27 AM

|

|

1 1/2 Pounder  Posts: 1064 Joined: December 27, 2007 |

CHAD - way to go! we're watching this project closely! I love the idea of using cement board too. Possibly stupid idea-- connect a hose or some such to move the noisy motor further away from the entire setup? |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman