Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

CoffeeAir II Roaster Build

|

|

| dja |

Posted on 12/10/2010 7:12 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Chad, Since the part numbers came from you thread I decided to post the question here. I picked up two coils like the ones you use except that the ones I got are 1000 watters. how did you supend the coils in the tubes in your roaster or do you have them just hanging in there, and what type of wire did you use to hook up with, wire with regular insulation, or wire intended for high temp applications??????????? I and going to shorten the heating section of my roaster and hopefully mount the coils open air like inside the heater section side by side, still have to go cabbage up some high temp wire, maybe trash one of the poppers I have or go to the thrift store for a toaster. on the coils, right now I am looking at milling out a bar with two slots for the wide end of the coil ceramic to fit into, them spreadind and supporting the other end with like 6/32 stainless steel all thread, or a road with threaded ends thru some small tubing with the road passign through a central support. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 12/10/2010 7:51 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

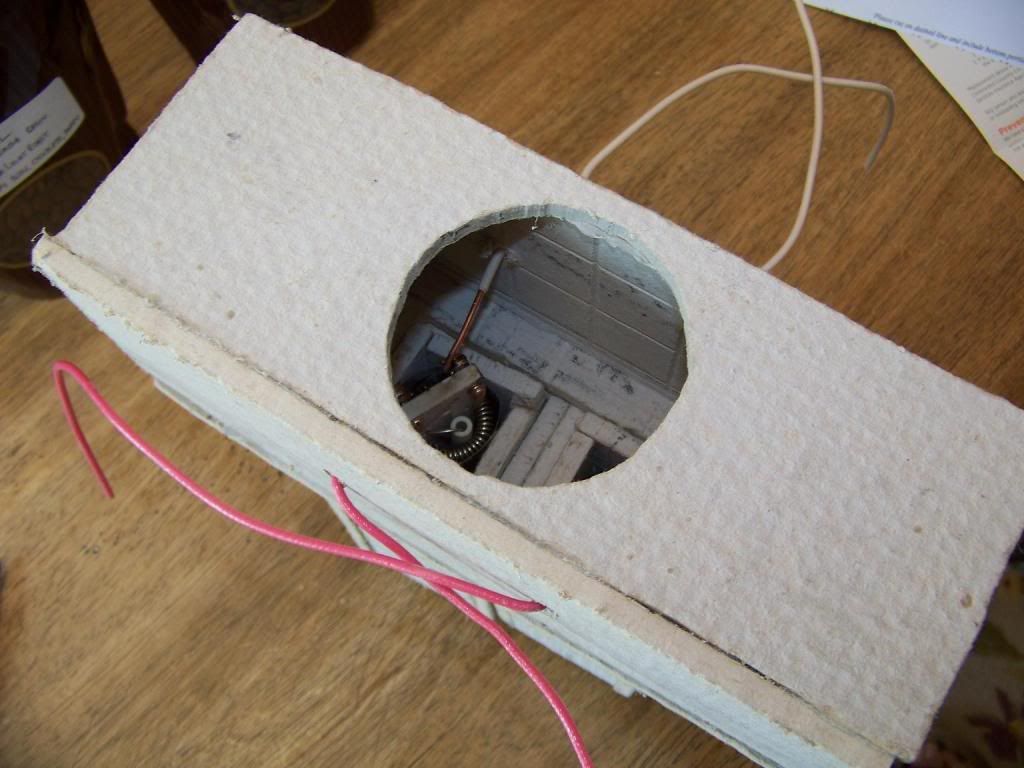

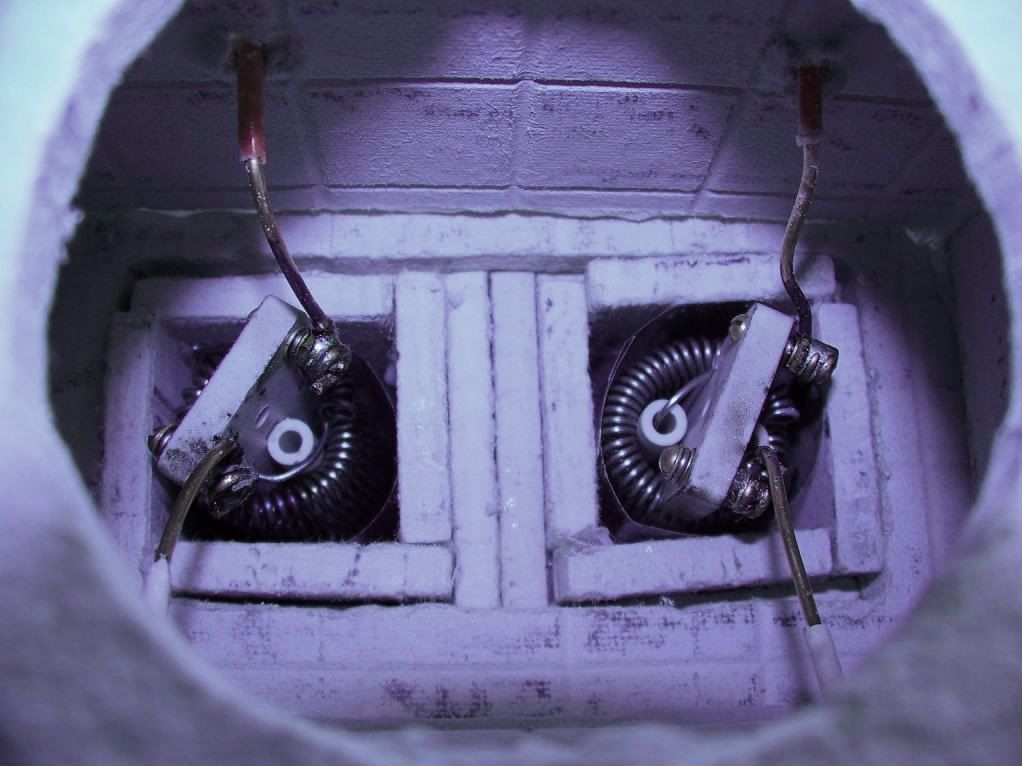

David, I soldered 12ga solid copper wire to the terminal leads, and that wire goes out either side of the chamber. Since it is stiff, it does suspend the coils up into the riser tubes. The only thing holding them there is wire and the fact that the clearance is tight and they can't go anywhere. Chamber:  Zoomed in on elements inside (this is the underneath/bottom where cool air enters):  These elements are 8 ohms each, wired in series. With 240V from the wall that's: P=(V^2)/R P=57600/16 P=3600W CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| dja |

Posted on 12/10/2010 12:59 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

the ones I got are suppose to be 1000 watts apeice, at 700 degrees is what they are suppose to put out, have you had any problems with the electrical solder getttign hot and soft?? Will post pictures when I get mine mounted. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 12/10/2010 1:28 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote dja wrote: the ones I got are suppose to be 1000 watts apeice, at 700 degrees is what they are suppose to put out, have you had any problems with the electrical solder getttign hot and soft?? Will post pictures when I get mine mounted. David Well, I haven't looked at the solder. I just figure it's on the cold air side of the heat. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| dja |

Posted on 12/10/2010 1:41 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

ok I may get away with using ire with regular insulation them my problem is I need soft wire with the way that I plan on mounting the coils.

I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 12/10/2010 1:45 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

I thought the coils you used from looking in Grangiers catalog were 700 watts each????

I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 12/11/2010 7:13 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

David- I have two replacement elements from this heatgun: http://www.graing...Pid=search CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| dja |

Posted on 12/12/2010 11:28 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

thats the same element that I plan on using, do you have your elements connected in parrallel or so that you can control them seperately? I plan to connect mine up in a straight 220 circuit, from the roast that I was able to do before the element shorted into where I had spliced it (grimped the two ends together in half a butt splice), I did no control of bean temp with the Heat all control was with air flow. I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| endlesscycles |

Posted on 12/12/2010 5:39 PM

|

|

Pounder  Posts: 420 Joined: April 11, 2009 |

Quote dja wrote: thats the same element that I plan on using, do you have your elements connected in parrallel or so that you can control them seperately? I plan to connect mine up in a straight 220 circuit,... Doubling voltage quadruples power. Let me know how that goes. I've got three of them that I plan to use in time. I suspect it is heat that fails nichrome, not total watts. I need to invest in some things before I can actually check it out, though. -Marshall Hance

Asheville, NC |

|

|

|

| seedlings |

Posted on 12/13/2010 9:32 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

David, if you put 220V across your element, I believe it would fail much sooner than the last element. Mine are in series, so each element gets it's designed 120V. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| dja |

Posted on 12/13/2010 12:01 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

thats what I'm thinking also, be nice to try it the element didn't cost so darn much. I got to work on the new holder that I am making yesterday, but this leg problem keeps me pretty much in a chair, when I need to be standing in front of the mill cutting out the part that I need to put my roasters heater back together with. I was lucky yesterday, my brother in Tulsa brought me a heater coil from a motel type heat and air unit, it has some nice high temp wire with ceramic tube insulation on it that I can scavange for my hook up wire. anxiously awaiting the arrivial of the new Brazialian Burbon Beans, this D@@N roaster better be back together by the time they arrive. OOOOH well its all in fun and caffine.

I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 12/14/2010 6:06 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Chad, I was finally able to get the new coils mounted in the roaster I connected them together in parrallel and checked the ohms on them, together they only pulled 17.5 ohms, so I went ahead and hooked up the power to them, surpise surpise when they build lots of heat in the heater section but very little coming out into the beans, guess I'm gonna have to open up the pref holes some to let the air flow better. I did have a beautiful spouting water fountain type air flow thru the beans though. I also plan on raising the elements closer to the air outlet (before final build I plan on cutting lower sections as short as possible) and I moved them closer to the rod that I have them mounted on, have not taken a pic yet but one will be forth coming this evening in my Air Roaster Thread. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 12/21/2010 12:07 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Just roasted 2 pounds 3 ounces in 38F weather! I went to weigh out 1.75 pounds, and only had a little left, so I just roasted all of it. I did have to use the heatgun on low for about 5 minutes of the roast from bean temp 350F through about 410F, but it can be done! CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 12/25/2010 7:19 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Well done! That's 2 pounds 3 ounces (1kg) with 3600W of heating? So my 4800W shouldn't have trouble doing 1kg with a 60F ambient temp. |

|

|

|

| seedlings |

Posted on 12/26/2010 8:30 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote greencardigan wrote: Well done! That's 2 pounds 3 ounces (1kg) with 3600W of heating? So my 4800W shouldn't have trouble doing 1kg with a 60F ambient temp. 4800W sounds perfect! Heatgun is something like 1600W, but I used low, held 16" or so from the vac inlet... so that was surely less than 1000W? CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| SteveN |

Posted on 12/26/2010 3:15 PM

|

|

1/4 Pounder  Posts: 127 Joined: March 16, 2010 |

Quote seedlings wrote: Quote greencardigan wrote: Well done! That's 2 pounds 3 ounces (1kg) with 3600W of heating? So my 4800W shouldn't have trouble doing 1kg with a 60F ambient temp. 4800W sounds perfect! Heatgun is something like 1600W, but I used low, held 16" or so from the vac inlet... so that was surely less than 1000W? CHAD Agreed, I've managed 1.2kg with my 5500W element and I still think I can squeeze more efficiency out of it. |

|

|

|

| seedlings |

Posted on 02/07/2011 8:45 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Finally got this ridiculously long video to load to youtube: [video]http://www.youtube.com/watch?v=i7t78rf0z5k[/video] CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 02/10/2011 4:36 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Thanks for the video! A video says a million words. I watched it at work with the sound low so I'll watch again later to hear what you're saying. You said previously that you only get minimal air leakage around the base of the RC. Is it leaking enough to feel the air coming out there? Also, what is the purpose of the wire around the HC? Edited by greencardigan on 02/10/2011 5:00 PM |

|

|

|

| seedlings |

Posted on 02/10/2011 10:24 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Yes I can feel hot air leaking out. If I could magically make the bottom plate differently, I would, but since it would take a re-weld (that I can't do) then it will stay this way. That wire held the cement board together while the silicone cured and I just never took it off. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| seedlings |

Posted on 04/13/2011 8:15 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

An order has been placed for a CoffeeAir roaster, so the build will begin again. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 04/13/2011 9:47 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Do you plan to make any changes from your last build? Cement board heat chamber again? |

|

|

|

| seedlings |

Posted on 04/15/2011 8:44 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote greencardigan wrote: Do you plan to make any changes from your last build? Cement board heat chamber again? I'll have a new, different blower to design around, but otherwise only slight modifications, especially how the hopper sits on the heater. The hopper will have a wider base and sit shallower in the roaster top. Other than that, pretty much the same. CHAD

seedlings attached the following image:

Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| seedlings |

Posted on 05/14/2011 10:03 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

The CoffeeAirII 2 build is underway.  CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| allenb |

Posted on 05/15/2011 11:02 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Looking good Chad! Whats the white plastic looking thing inside your enclosure? 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| seedlings |

Posted on 05/15/2011 3:23 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote allenb wrote: Looking good Chad! Whats the white plastic looking thing inside your enclosure? The vacuum motor came with a rubber 'shock' mount and a plastic cover. I figured it could help with reducing noise. The inside will be lined with 1.5" rigid industrial fiberglass. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman