Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 11

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

air roaster

|

|

| dja |

Posted on 03/30/2011 11:20 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

I will try and answer all three of your questions Chad. I run 100% heat until after first crack.... well, it's been winter for a long time. Maybe if 65F shows up someday the roaster won't need as much heat. David, do you have a chunk of 5" metal tubing to try out for fun? I wish that I did, because 5 inch is what I used on the bottom to house the blower and heating coils in, that way I could test with a smaller tube no reason to watch the beans move around we already know that they will in and orderly fashion. Unta I bet your trouble with heat will comedown to pressure, which may be remedied by a baffle or some change in the RC. The way that the air flowed in the narrow tube was far more restricted then it is now. Can you put another perf with less holes in the bottom, see if you can get a bit more pressure built up in the Furnace section? I think what your saying is the main problem that I have to overcome with this new tube, if you go backwards to my last couple of post you will see I have plans to not physically but mechanicly shorten the tube to find out if thats the problem. Endlesscycles: Nah, it's a bean bed depth problem. Going wider diameter for a given mass reduces efficiency, so you have to add more heat power. Endlesscycles no beating around the bush with you right up front and bold as day I think that you have also put you finger on one of the problems, the other tube even though I could put more in than I did the load was only 1.5 pounds in a very restrictive enviroment esspecially when they started swelling from the heat, thats the reason for all the jumping(basketballing/ jumping up and down) and YES, shame on anyone that builds this type roaster that you can't easiely remove the pref plate for modification, once I know it will work and someone else wants one it will be fixed in place probably casted into the funnel. I will probably/hopefully get something done today, the blockin gplate for the tube test won't take long to knock out, for a pref plate I want some 16 gauge stainless steel, lots of heat hits it and I need enough for a couple of plates new pref plate equals a new holder for it so maybe tomorrow will have to see. What I would really like to to get this roaster working in the 1.5 to 3 pound range, I know the air is there for 3 pounds as what is in the video is 2 lbs.13 ozs. So we can say that I have reached the goal of being able to handle them. Now on to heating them, If it gets down to it I will rebuild the heater section and if needed put in a third element, I don't think it will come to that but we don't know yet. I hope I have answered your questions and hope that I have generated more, this has been a very fun project, it has taken some time to build but I think that all will benifit from it even if its only the enjoyment of saying it won't work. It does work and I belive that there is a lot of be gained from it in the way the beans act in a round chamber with a funnel shaped bottom with perf plate centered in the bottom. One things for sure I learned that it doesn't take very much of an obstruction to stop the beans from circulateing poin in fact look at the edge of the funnel where the beans are just sitting in the video above. David J. Allen Edited by dja on 03/30/2011 11:59 AM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 04/02/2011 12:47 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Update, finally got around to working on the roaster this evening and re made the pref plate, I used the same hole pattern as in the 4 inch Roast Chamber setup, two things happened the temp went up not as much as I was hoping for, but it did go up. I didn't time how long I ran before shutting down but it was longer than what it should take to roast, I used the same beans that I have been using, no sense in wasting prefectly good beans to find out that its not going to get hot. I will cut a plate tomorrow since things have calmed down and I don't have any more doctors appointments for a while. If blocking off the top to make it shorter raises the temp up close to 500 degrees I will drop the load of beans from the close to 3 pounds down to 2 pounds and see if I can do and actual roast. one thing that I didn't mention at the first of this post was that the new pref plate did change the air flow, I had to increase the fan speed to almost max to get the beans to moving, but was able to lower it to about 50% mark for the rest of the trial. It was easy to recover the spouting action in the beans when I would increase the fan speed. I also checked again to make sure that both heating coils were working, after tring the new pref plate, with the top half off I ran the fan at about 50% and connected the power to the coils to see if they both were working, both coils came online read an ready to roast beans. I will post a picture tomorrow of the new pref plate to late to drag out a camera tonight. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| allenb |

Posted on 04/02/2011 9:56 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

David, please remind how many watts your running when on full heat? I'm hoping someone who has the info handy can post the KW per pound necessary for fluidbeds. Also, just for curiosity sake, what is the slope angle of your new RC bottom? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| dja |

Posted on 04/02/2011 1:23 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

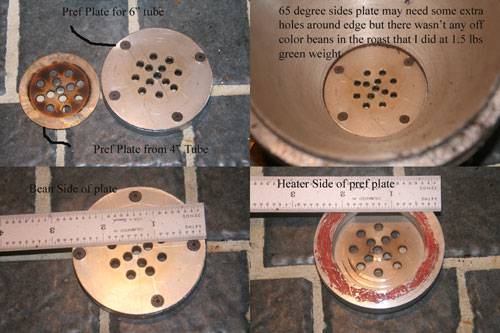

Wattage, minds running away with me there for a minute. Wattage I have the same elements in my roaster that Chad has in his. The angle isn't as steep in this funnel as it was in the four inch, meaning that the 4 inch tube had a set on a block that was approximately 4 inches high, and was carved out on the top at 3.75 to an opening in the bottom of 1.5 close enough really steep. The new one is 5.9 at the top is like 4 inches high and the bottom is 2.6 much flatter. the pref plate guess nows as good a time as any to take a picture it should be cool enough to get out of the roaster. 65 degrees on the side. I have attached a photo that shous the pref plate and the transition section inside with pref plate installed. I did a trial roast with green beans today using 1.5 lbs of Mexican beans oldest I had, also the one I had the least of. I have some video I will post. I tried to block the upper section of the tube off but due to air pressure and heat this was not a success. I will have to make a top with a variable opening in it. The ability to vary the opening on top can make our brake your flavor profile in this roaster. The roast today didn't last ten minutes, bean temp/ Air temp was at 530 degrees so I'm getting there. As soon as I use up the beans that I roasted today or give them away I will do a larger batch of 2 pounds of Nic Java that I have left.

dja attached the following image:

Edited by dja on 04/02/2011 1:32 PM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| Unta |

Posted on 04/02/2011 1:56 PM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

So you gained heat with just a change to the perf pattern?

Sean Harrington

educate. |

|

|

|

| dja |

Posted on 04/02/2011 3:48 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

and a lighter bean load, I am trying to get a video loaded onto U-Tube so I can post it here, it is of a 1.5 pound load of Mexican LaPluma that I have had for a spell. I wish that I could to a back to back roast with a larger bean mass sof two pounds, but sadly as I would like to I just can't waste anymore beans testing this thing, my first test was close to 21 dollars in beans that I poured into the yard today. Sorry Steven they were warm I would of shipped them to your dogs, but I didn't think that they would arrive warm. One thing that is appearant is that with a tube this large in diameter you don't need but about half the height in the tube that I have which is 16 inches tall. [video]http://www.youtube.com/watch?v=d75CwQ-Vbsg[/video] I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| greencardigan |

Posted on 04/02/2011 6:18 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote dja wrote: Sorry Steven they were warm I would of shipped them to your dogs, but I didn't think that they would arrive warm. Oh well, it's the thought that counts. And I'm Brad, not Steven. ;) What time did you get to second crack? 1st crack in 5 minutes suggests you've got plenty of heat. |

|

|

|

| dja |

Posted on 04/02/2011 7:14 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Brad sorry I had names mixed up. the beans reached second crack in about 10 miuntes, this was with about half the bean load that I had in the first time I tried to roast in the big tube, I'm really wishing that I could of gotten 5 inch tube instead of the 6, but I have what it is so I have to work with it. I will have to do a layout in can see about if there is room for a third heaing element, I also need to open the outlet from the heater section up some its only about 1,5 inches. I wish that I hadn't of thrown the old beans away, I could of used them and some rubber tubing around the blanking plate that I made to check the pressure in the bean mass at differant fan speeds. but that needs to be done during a real roast from green to done. David J Allen Edited by dja on 04/02/2011 7:15 PM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 04/03/2011 5:42 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

I'm running about 3400 watts with two 14.5A elements. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| dja |

Posted on 04/21/2011 8:39 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Been a while since I posted anything here, been kinda busy what with work and paying bills, guess we all got that problem. If anyone has any beans that they would like to get rid of cheap I need some to continue working on my roaster, this thing gets a little expensive when you start filling it up to what it will handle. Anyway I would like to find some that are like way to old or just plain junk for a 2 or 3 dollars a pound. I have been testing and really can't find why I won't get any hotter that what it does except that maybe its the 6 inch tube not holding the beans in tight enough for the heat to build. Anyway tonight I tried to roast a 1.5 pound batch and the thing just would not come up to temp. I opened up the air outlet in the top plate of the bottom section, hope this will help get the temp up, gonna run to town in a bit and get some small beans and see what happens. I also need to pick up a piece of aluminum plate to make a top with an adjustable damper in it, plus a some type of a door to load an unload the beans thru. Life is just so much fun in the land of coffee roaster. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| JETROASTER |

Posted on 04/21/2011 9:06 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Hi David, I was just wondering how the project was doing. Hope all is well. It sounds like cfm has increased. How much can you choke the exhaust, and still get a plume? -Scott |

|

|

|

| dja |

Posted on 04/21/2011 10:18 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

I had a pot lid in the top of the thing tonight acting as a top cover with a 1/8 inch welding rod being used as a stop to hold the lid up on one side while running the thing with 1.5 lbs of beans in it, circulation was no problem beans were spraying in a water fountain plume. I also checked the heating coils to make sure that both of them were working, with out the top on and placing the thermal couple directly in the air path of each coil I had over 700 degrees. would of regestered higher but that was the set point on the pid, I hope someone reads this that has some junk sour beans that they want to pawn off on a poor roaster builder that needs some testing material. wonder if Zyphers has some thats been sweep up off the floor????? I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 04/30/2011 4:01 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

heres a picture of the last two revisions of the pref plate that is in my roast chamber. the one on the right is the one in the roaster at the moment, it has I belive 13 1/8" diameter holes in it. to one on the left let too much air thru and would not let the roaster reach the temperatures that it is capable of.

dja attached the following image:

Edited by dja on 04/30/2011 4:03 PM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 05/08/2011 4:28 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

here's a little video of some Columbian beans that I purchased locally from an outfit that builds coffee roasting equipment here in OKC. This is the second roast since I installed the new pref plate that only has twenty three holes or is it 27 can't Remember. I have also added a top plate to the tube so that I don't have to keep hunting for something to block it off with, I have completed two of the rods that tie the top half together, have two left to make. I need to make an exhaust port on the top that has an adjustable damper blade in it, the door that I put in the top just isn't enought vent at the start of the roast. I always try to keep circulation as slow as I can with but to where the beans are still spouting. I don't see where beans that are flying all over the place contribute anything to the roasting process. Hope you enjoy the video, it seems that the more I work on this roaster the more it wants to act up on camera. [video]http://www.youtube.com/watch?v=MPXnOlc1eI8[/video] I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| allenb |

Posted on 05/08/2011 7:26 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Looks like you're achieving a decent spout with no launching to the top. Also looks like you're getting plenty of heat. It's too bad you can't cool the beans in the roast chamber. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| dja |

Posted on 05/08/2011 9:09 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Hi Allen, Glad that your liking what I have done with the Freak. And to answer your question. too much thermal mass in the bottom of the roast chamber and the top plate of the heater section, takes way to long to cool down, which works great if you are doing back to back batches. I have found some latches that will work for securing the two sections while roasting there is enough air pressure in the bottom section to almost launch the top half of this thing into low orbit. I have made a top plate that has a 2.5 X 1.5 inch door in it that helps to control the air but its either open or closed, and you will hit a spot in the air flow adjustment and it flutters, so thats no good. I have room behind the door to put in a small 2" diameter tube with a flat damper blade in it, this will give total control over the air. I have found that I get roast results that are just as good with running the air so that they are circulating smoothly instead of having them flying everywhere, that just waste energy = Heat. This roast today was one of the best I have done with this large tube, and I am gradually inceasing the amount that I roast each time. but some times I have to leave town so what this thing will roast in one batch is enough to keep me in coffee sometimes for a couple of weeks. But I do promise to get rid eventually of all the bungee cords so that it doesn't look so getto. I also am going to have to install a wider stance base plate from what I saw today, I do have one excuse for all the fumbling around. Oklahoma wind typical day wind blowing 4o MPH. I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| greencardigan |

Posted on 05/08/2011 11:13 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Thanks for the video. I think you are getting MUCH better efficiency than me with my erratic plume. What is the slope of roast chamber base? Can you hear the cracks easily over the blower noise? |

|

|

|

| dja |

Posted on 05/09/2011 8:27 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Matt, your name is Matt correct? if you look at post 257 you will see a shot of the inside of the bottom section of the roaster (top right quarter of that photo), the sides are sloped at a 60 degree included angle, or thirty degrees off of each side of the vertical center line. The pref plate is about 2.75 inches in diameter but you can see that I have the hole loosely grouped in the center of the plate. I did try one plate that was full of smaller holes (didn't work) and I tried one with larger but fewer holes (it didn't work either), the one in it now has thirteen holes size 29 I belive is what I drilled them with (this plate works), or anyway it seems to work. I am slowly working my way up the batch size ladder the first roast with this plate was with just a little over 1 pound of green, this roast roast was 1 lb 8 oz of green columbian as weighed on my postal scale. The problem I have in the testing department is I am the only one around my house that drinks coffee (looks around slowly, heck I'm the only one here) so it takes me a while to drink up some of my mistakes. I don't know how well you can see the circulation in the bean mass but they are rolling over pretty fast, an as long as they are doing that there's no reason in wasting heat trying to blow the beans all over the place. I was going to cut the tube in half but wa advised by the Seller not to as I would be taking a chance on the tube exploding on me while cutting it or at some point in the futher from the stresses created in the glass by the scratches left from using a regular wet saw for tile to cut it with. And I don't need that happening. David P.S. Cracks yes the cracks are very easy to here, and on some of the videos you can actually hear the cracks in the video's. If you have a noise problem, try lining the blower half of you heater section with egg crate style foam, that stuff they stick under patients in the hospital that has all the peaks on it, a craft hobby store should have some if nothing else use some regular foam rubber to absorbe some of the noise from the blower. you can also try using a (dryer vent) hose on the inlet to make it longer this will stop some of the screaming noise. It doesn't have to be very long say 2 feet, .5 Meter. Edited by dja on 05/09/2011 8:38 AM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 05/09/2011 12:58 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Local glass shop here can cut Pyrex. You're 'not supposed to be able to cut Pyrex'. Might look to a local glass shop. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Dan |

Posted on 05/09/2011 3:10 PM

|

|

1 1/2 Pounder  Posts: 1662 Joined: October 24, 2005 |

I used to cut glass for a summer job. Pyrex (borosilicate) is regularly used by glass blowers to make custom laboratory glassware. It works like a dream and, if memory serves, cuts just like silica glass used for home windows that I used to cut. Perhaps you are thinking of tempered glass? |

|

|

|

| dja |

Posted on 05/09/2011 3:30 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

I'm not to worried about it, other than the fact that with it that long its can hold probably four pounds roasted, I know the fan will move three pounds. but I'm the only one that gets to reap the rewards of my labors to build this Thing for want of a better name. Anyway I have changes planned for the near futher for this Thing. David Edited by dja on 05/09/2011 3:32 PM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| JETROASTER |

Posted on 05/11/2011 9:48 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Quote dja wrote: Anyway I have changes planned for the near futher for this Thing. David ...Smaller blower due in Thurs. Good luck, Thanks for the video. It occured to me that you could secure that whole thing together, then evacuate the beans with a vacuum set-up. It worked for me in the past. .....as if you don't have enough things to do! -Scott Edited by JETROASTER on 05/11/2011 9:51 AM |

|

|

|

| dja |

Posted on 05/12/2011 8:07 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

now that just might be an idea I get this thing working like it should I could have a second tube sitting along side the roaster when the roasting is done, just flip a switch and start sucking them little brown bits of gold out of the roaster and cool em off at the same time.

I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 05/17/2011 5:43 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

I received from FedEx a package today, inside was a bright and shiny new pyrex tube 5 inches in diameter and 6 inches long. One problem I have to leave town for a couple of days and run to Carson City Nevada so I won't be able to do any changing around till I get back. One thing that this tube will do is make the roaster more streamlined with it being the same size for the full length, I think that I can use the same pattern with some modification to it to make a new transition for the tube to mount on. there are also a couple other changes I want to make. 1 is to get some quality cord grips where the wires pass thru the wall of the 5 inch tube so that they will stop leaking air. I also want to re do the coil mount so that it is shorter and insulate it differantly then the way I have it leaks to much heat thruto the roaster shell. So changes are forth coming as soon as I get time to work on it, dang grass has to be mowed tomorrow before leaving for Carson City ad the bright lights and blackjack tables. David I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| dja |

Posted on 05/22/2011 8:40 AM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

Well back from Reno, and found a big mess from a storm that went thru here while I was gone. Roofs gone off the Shed, Molding Sand has about 600 % to much rain water in it, so it looks like I may be a couple days longer in getting the new 5 inch tube mounted and working, or I may just use the bottom section off the 6 inch tube and see what I can come up with. I am posting a photo on here of the three disserant Tubes that I have used so that people can have a size referance of what I am working with. The small one in front is 3.75 inches in OD ( real hard for me to get my hand thru it to clean the tube), the one in the middle is the new 5 inch tube that I received last week just before I had to run to Reno Nv, and the one in the back is the giant of the three it's 6 inches in Diameter and 16 inches tall. The 6" one will hold a ton of coffee and the fan that is installed at the moment will move (circulate) the beans vigorously without any problems. I had some problems with this 6" tube with the heat but was finally able to I think hit on a perf plate that would put enough back pressure in the heating section that I could heat the air and was working my way up in poundage when I found out that I would be able to aquire a tube in the 5 inch range which is what I was looking for when I found the 6 inch one. Ok enough with that, here's the picture, I gotta go see if I can cobble something together with this and roast some beans, and see what this 5 inch tube will do. PLUS I have one heck of a mess in the yard from the storm to clean up so if anyone would like to help feel free to stop by. Oh yea anyone on here tried the Brundi from Roast Master's cause I just ordered 5 pound of it. David

dja attached the following image:

Edited by dja on 05/22/2011 8:41 AM I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman