Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

My 1kg Electric Air Roaster build

|

|

| seedlings |

Posted on 02/16/2011 9:57 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

On mine the airflow is on one side, the TC measures bean temp on the opposite side. It reads 400F first crack and 440F second crack, so the temps are accurate. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 02/17/2011 5:10 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I added another row of holes in perforated floorplate tonight and drilled them all out to 1/8". I have a total of 48 holes. Bean circulation seems a bit better. I can circulate 1kg green with my air on 75%. I had lots of air escaping the roast chamber where the glass tube meets the lower aluminium tube. I've tried to seal the gap with silicon but it looks a bit nasty. Are there any issues with the roasting beans touching cured RTV silicon? Any fumes I need to be worried about? |

|

|

|

| greencardigan |

Posted on 02/17/2011 5:51 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote greencardigan wrote: Are there any issues with the roasting beans touching cured RTV silicon? Any fumes I need to be worried about? The MSDS says it can release small amounts of formaldehyde when heated above 150C. Hmmm??? http://www.myhenk...ealant.pdf And the MSDS for the clear stuff Chad used. http://www.itwcon...ds_184.pdf Edited by greencardigan on 02/17/2011 6:10 AM |

|

|

|

| seedlings |

Posted on 02/17/2011 8:16 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

I believe all of the MSDS info is for the product in the liquid (tube) state, the state it's transported and sold in. Cured, it's as inert your silicone oven baking sheets. To be sure, just don't have in in direct contact with the beans. CHAD Edited by seedlings on 02/17/2011 8:17 AM Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 02/20/2011 5:23 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

A few pics of some recent changes. I hope to attempt a 1st roast when I've used up my already roasted beans. Maybe next weekend or the following one. The current perforated plate with 48 1/8" holes drilled parallel to the roast chamber walls.  The trial perforated air diffuser located under the elements.  The flexible silicone gasket I've used to seal the RC to the HC. It seems to withstand the roasting temps.  And some more circulation tests with the above perforated plate. I'm wondering I if I still need more holes? 1kg [video]http://www.youtube.com/watch?v=ITPXbSVmSwI[/video] 750g [video]http://www.youtube.com/watch?v=cD5wEY1soyM[/video] 500g [video]http://www.youtube.com/watch?v=fPLLht-MrtI[/video] Edited by greencardigan on 02/20/2011 5:40 PM |

|

|

|

| dja |

Posted on 02/20/2011 9:26 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

how fast were you running your blower in the test???

I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| greencardigan |

Posted on 02/20/2011 9:32 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I had the blower running at approx 75%. |

|

|

|

| dja |

Posted on 02/20/2011 9:44 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

the bean mass is going to lighten up when you turn the heat on, and you don't really have any mass of metal that will suck the heat up like I have in mine, you might try, once you do a couple roast real time, dumping the beans in with the air running and the heat on that way you won't have to lift the whole mass to get it started flowing. Wish I could do that with mine but the tops to small. I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| seedlings |

Posted on 02/21/2011 12:31 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Nice videos. I think you're close, but not quite to the right kind of circulation, 750g to 1K were a bit slow to get the beans back down to the heat... BUT, that's just a visual observation. Could be more going on in the mass than we can observe from outside.... like Allen's Bubble Bed Roaster Did you run a test without the restricted baffle for comparison? Do you think it helps? CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 02/21/2011 6:09 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote seedlings wrote: Nice videos. I think you're close, but not quite to the right kind of circulation, 750g to 1K were a bit slow to get the beans back down to the heat... BUT, that's just a visual observation. Could be more going on in the mass than we can observe from outside.... like Allen's Bubble Bed Roaster Did you run a test without the restricted baffle for comparison? Do you think it helps? CHAD It looks like most of the bean mass is moving slowly back to the heat. Some of the beans close to the plume get drawn bak in quicker. Here's a quick vid showing the same setup but with the air on 100%. [video]http://www.youtube.com/watch?v=qOINb5ZA-ac[/video] I still have a fairly narrow plume. I almost feel like drilling another row of holes but that could be too much? That would be 60 holes. Rob used 36 holes on his 4" and 76 holes on his 6". Mine is 4.75" I can't remember if I tried the current perf without the air spreader baffle. However, I don't think it has much influence on the airflow volume and pressure. It's got plenty of open area. |

|

|

|

| greencardigan |

Posted on 02/21/2011 7:48 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I've just 'bean' thinking about the bean circulation in my RC. I'm wondering if my flatish sloped base is slowing down the return to the perf. |

|

|

|

| allenb |

Posted on 02/21/2011 8:08 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote greencardigan wrote: I've just 'bean' thinking about the bean circulation in my RC. I'm wondering if my flatish sloped base is slowing down the return to the perf. I've heard (somewhere) that the absolute minimum should be 45 degrees and steeper is probably better. The faster the slide, the more beans that can join the trip up the plume and with a resulting fat plume. OTOH, I've seen some roasters with a shallow angle pull it off with some creative perf areas but experimenting with the many possible variations could be a real time eater! Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Ringo |

Posted on 02/21/2011 8:48 PM

|

|

Pounder  Posts: 474 Joined: January 14, 2010 |

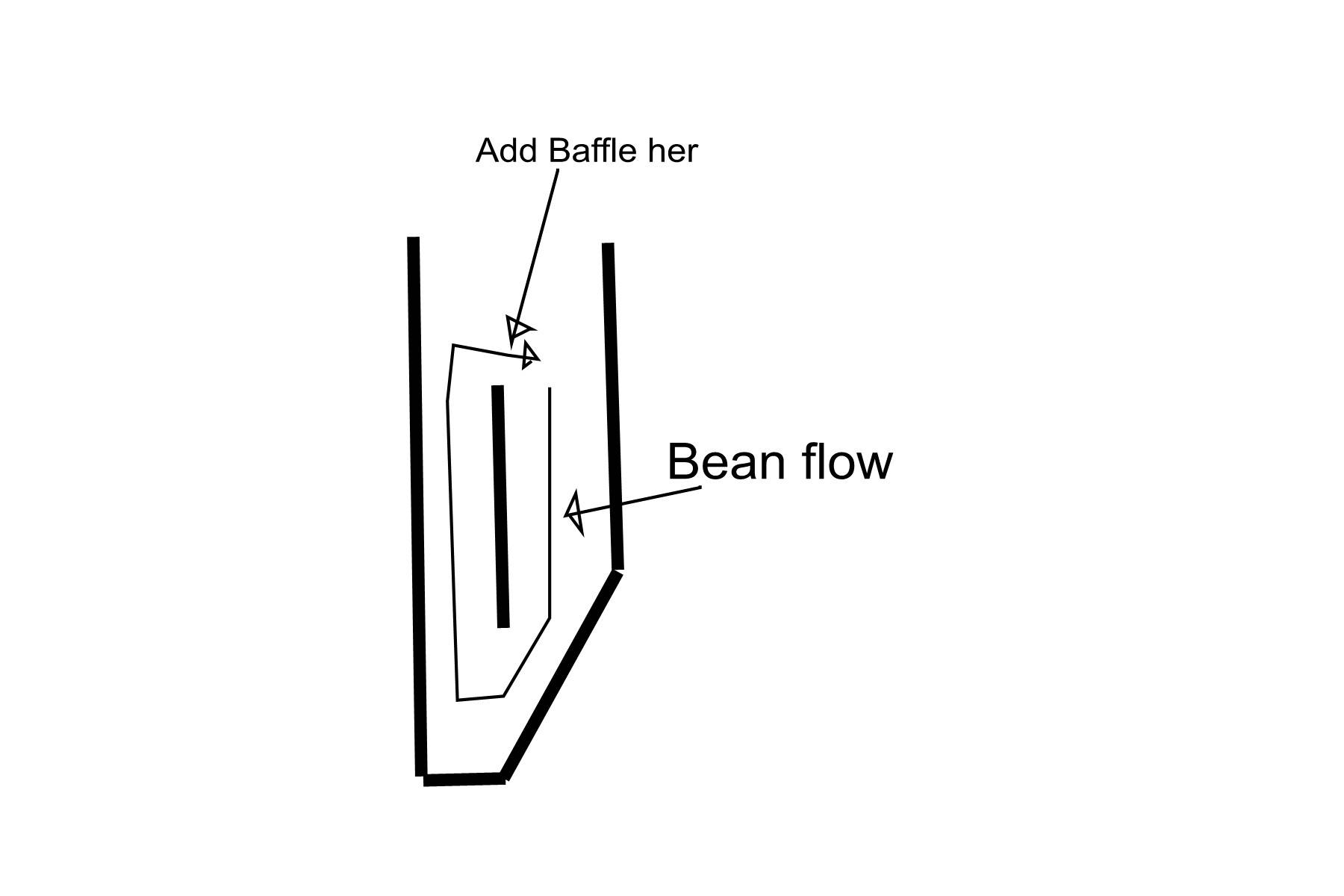

Throw out an idea, could you add a baffle inside the glass. the beans would fly up over the baffle and land on the other side. So all beans would see the same heat and maybe you could use less air becouse there would be less beans to loft at any one time.

Ringo attached the following image:

Edited by Ringo on 02/21/2011 8:51 PM All you need in life is ignorance and confidence, and then success is sure. Mark Twain

|

|

|

|

| Unta |

Posted on 02/21/2011 9:29 PM

|

|

1 1/2 Pounder  Posts: 788 Joined: January 26, 2010 |

Quote Ringo wrote: Throw out an idea, could you add a baffle inside the glass. the beans would fly up over the baffle and land on the other side. So all beans would see the same heat and maybe you could use less air becouse there would be less beans to loft at any one time. some chit chat about a baffel/wing here on page 3..http://forum.home...owstart=50 Marshals results of baffel/wing testing on page 4.. sean Edited by Unta on 02/21/2011 9:30 PM Sean Harrington

educate. |

|

|

|

| greencardigan |

Posted on 02/21/2011 9:29 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote allenb wrote: I've heard (somewhere) that the absolute minimum should be 45 degrees and steeper is probably better. The faster the slide, the more beans that can join the trip up the plume and with a resulting fat plume. OTOH, I've seen some roasters with a shallow angle pull it off with some creative perf areas but experimenting with the many possible variations could be a real time eater! Allen :| That's bad news! Mine is close to 20 degrees I think! What to do?? I could replace the slope and perf but I'd prefer to try a workaround first. I'm thinkg more holes is definitely on the agenda. |

|

|

|

| greencardigan |

Posted on 02/22/2011 5:48 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

After playing with the roaster tonight I suspect my blower has different performance characteristics than the blowers others are using. To get a continual plume, I need to have the blower on at least 70%. Any less than that and there's no plume and no circulation. |

|

|

|

| dja |

Posted on 02/23/2011 6:18 PM

|

|

1 1/2 Pounder  Posts: 701 Joined: November 07, 2008 |

running it at 70% actually makes it easier on the motor than like mine where I have to run it at less then 25 percent of rated speed even thou the motor has pleanty of air going thru it to keep it cool its hard on the carbon brushes because of the arcing. you might try to block off as much of the open space as you can, the more space you have the more air you will have to pump into it to build the pressure to lift the bean mass I pour Iron and roast Coffee Beans

If life seems normal your not going fast enough Mario Andrette |

|

|

|

| greencardigan |

Posted on 03/04/2011 7:03 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

:Clap: I've just done a reasonably successful first roast!!! The pics and will show most of the relevant details. This test has revealed a few issues though.    This short video clip was taken at what I think was 2nd crack. The roaster is a bit noisy and I'm currently trying to get over a bad cold which is affecting my hearing a bit. I think you can hear the cracks in the vid when the cam looks down the RC. [video]http://www.youtube.com/watch?v=gYMfc3xyRIo[/video] Anyway, the test roast has revealed the following. 1. Something is not right with my thermocouple measuring the air temp. It seems to be reading too low. 2. The blower need some sound insulation so the cracks are hearable. 3. Smoke at 2 minutes??? Not sure what's going on there. 4. Roast chamber is too short. Most of the roast I was losing the occasional bean. And lost quite a few trying to cool them post roast. 5. The neighbors will be sweeping up chaff for weeks  6. I seem to have ample heating power and air flow. I could have sped the initial stages of the roast up considerably I think. 7. Bean circulation was better than expected. A bit lumpy but there seemed to be more movement than my green tests. 8. A small amount of tipping occured. What temps does this usually start? 9. The beans look a lot lighter than my usual roasts??? I can't understand why. What next? Stainless gas roaster?

Edited by greencardigan on 03/04/2011 7:22 PM |

|

|

|

| RoasterRob |

Posted on 03/04/2011 8:35 PM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

1. I measure only the bean mass temp, works well for me. 2. Spa blowers are VC blowers with noise reduction (apparently) 3. Steam. At 2 minutes my bean mass temp is usually just over 100C. 4. This type of RC does need to be tall. 5. You wanna see chaff? Just got a new experimental RC which does 4kg loads. I prefer to roast in an easterly wind. 6. This type of RC is very efficient. My 4kg roasts are still with a 7KW burner. But definitely the limit of a 7KW burner. 7. Getting the perf plate right will sort the lumpiness. However getting it right for the start of the roast with green may not be right for the end of the roast when the beans are half the weight and nearly twice the size. 8. Don't know. Not necessarily the cause but compared to my roasts you are faster to 105C bean temp then slower from 145 to 1C. Close to my roast from 1C to 2C. 9. How different are you roast times to your usual roasts? Rob From the shaky city. Edited by RoasterRob on 03/04/2011 8:42 PM VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| allenb |

Posted on 03/04/2011 9:27 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote greencardigan wrote: :Clap: I've just done a reasonably successful first roast!!! 1. Something is not right with my thermocouple measuring the air temp. It seems to be reading too low. 3. Smoke at 2 minutes??? Not sure what's going on there. 7. Bean circulation was better than expected. A bit lumpy but there seemed to be more movement than my green tests. What next? Stainless gas roaster?  Wow, to get a first roast to come out as smooth as this is a testament of your abilities as a roaster builder. The first roasts of my builds produce flames and explosions until I go through rev's 9 and 10! #1 definitely need to find a different place for the TC. #3 Could there be things baking out from construction sealants etc? #7 With all the variables of a fluid bed to achieve what I'm seeing is perfection at this stage of the build. As Rob stated, it will take some playing around with the perf plate but you'll have to zero in on a preferred batch weight and fine tune. You'll never get a perfectly smooth bean movement at both start and at end of the roast. Keep the progress reports coming, Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| greencardigan |

Posted on 03/04/2011 9:42 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Thanks Rob and Allen for the info. I suspect the lumpiness of the bean flow actually helps my beans circulate faster. Or maybe I'm just imagining that. With my popper I had a similar length roast. But I've been using a 14 - 15 minute roast with my BM/HG setup. Rob, what time do you hit 200C? Edited by greencardigan on 03/04/2011 9:59 PM |

|

|

|

| greencardigan |

Posted on 03/04/2011 10:22 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote allenb wrote: Wow, to get a first roast to come out as smooth as this is a testament of your abilities as a roaster builder. The first roasts of my builds produce flames and explosions until I go through rev's 9 and 10! #3 Could there be things baking out from construction sealants etc? Allen I'm as surprised as you are. I was expecting the worst. I don't think the smoke/steam was anything to do with the sealants. I had already run the elements for 1/2 hr without any sign of smoke. Can anyone hear the cracks in the video? Do they sound like 1st or 2nd cracks? Edited by greencardigan on 03/04/2011 10:32 PM |

|

|

|

| greencardigan |

Posted on 03/05/2011 9:50 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I've just made a few cups from this roast with just over 24hr resting. I haven't had this bean before but it was a very nice cup. The occasional bean has a small oil spot. What level of roast does that suggest? I'm up to page 12 of the 4-channel TC meter thread. I might have to investigate these arduinos. Not sure what benefits they have over the picaxe type systems? |

|

|

|

| coffeeroastersclub |

Posted on 03/05/2011 10:08 PM

|

|

Pounder  Posts: 535 Joined: May 26, 2009 |

Quote greencardigan wrote: I've just made a few cups from this roast with just over 24hr resting. I haven't had this bean before but it was a very nice cup. The occasional bean has a small oil spot. What level of roast does that suggest? I'm up to page 12 of the 4-channel TC meter thread. I might have to investigate these arduinos. Not sure what benefits they have over the picaxe type systems? "The occasional bean has a small oil spot. What level of roast does that suggest?" Full city+ Len "If this is coffee, please bring me some tea but if this is tea, please bring me some coffee." ~Abraham Lincoln

|

|

|

|

| greencardigan |

Posted on 03/22/2011 6:32 AM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Just a quick update. I hope to do another roast this weekend and will try to get a full length video. This time I'm tempted to try a smaller load. Maybe 500g. It's taking me quite a while to get through the 900g batch! I have partially enclosed the base of the roaster to muffle some of the blower noise. Hopefully the cracks will be hearable this time. And one of JimG and bwelch's TC4 thermocouple boards arrived in the mail today. Once I get it up and running I hope to get this roaster automated. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman