Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [376] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 4

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

chaff collecting revisited

|

|

| dfluke |

Posted on 02/12/2012 11:22 AM

|

|

Newbie  Posts: 45 Joined: October 17, 2006 |

So I have a BMHG setup, and I'm using a blower as a sort of central air like setup to suck air through some 4" ducting, through my chaff collector, and back out to exhaust. It's worked okay, but no matter how hard I try, I seem to get chaff bits in the blower. I started with a 5 gallon bucket, then added a second one underneath it, but it's still sucking chaff out. I saw some dust collecting/chaff collecting threads here, and have looked into doing a bit of research to conversions of buckets. I found this: http://www.evenfa...zfz_l2Q0rU The concept looks great, but I'm worried that my already slightly warping buckets wouldn't hold up long term with this setup, given the Thien separator/baffle thing looks to need a decent unaltering shape. So, I thought about grabbing a metal bucket and creating the same thing but using metal parts instead. Hopefully this will stay under 40 to 50 bucks or so. Any thoughts or recommendations? Right now chaff collection and exhaust are my main issues with the roasting, other than wanting a five pound roaster. Edited by dfluke on 02/12/2012 11:36 AM |

|

|

|

| Koffee Kosmo |

Posted on 02/12/2012 5:06 PM

|

|

Administrator  Posts: 1621 Joined: December 31, 2008 |

It will probably work OK As long as you dont suck to much heat out of the roasting section Also I am in commercial cleaning and we use a simple system called a turbo dust filter Now if you can make one of these in steel and glass you will be on a winner  In plastic they cost around $25 KK Edited by Koffee Kosmo on 02/12/2012 5:09 PM I home roast and I like it. Designer of the KKTO

Roaster Build information https://homeroast...ad_id=1142 https://docs.goog...lide=id.i0 Blog - http://koffeekosm...gspot.com/ Bezzera Strega, Mazzer Robur Grinder, Pullman Tamper Convex, (KKTO) Turbo Oven Home Roaster. |

|

|

|

| oldgearhead |

Posted on 02/12/2012 10:38 PM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

The roaster that I built recycles up to 50% of the hot air that exists from the RC. Because it recycles hot air, I must keep the intake pretty clean. At first I used a baffle-separator, but I was only able to catch about 1/2 of the chaff in the collector. So, since then, I have been using a 200 mesh screen over the intake and a 30 mesh screen over the RC outlet. I just vacuum the chaff off the top of the beans after the roast is cooled....

oldgearhead attached the following image:

Edited by oldgearhead on 02/12/2012 10:41 PM No oil on my beans...

|

|

|

|

| dfluke |

Posted on 03/03/2012 12:44 PM

|

|

Newbie  Posts: 45 Joined: October 17, 2006 |

I settled on creating a thien baffle style 5 gallon bucket collector. Tried the first test yesterday and it works okay, but my blower is underpowered. I will post some pics and stuff when I get them downloaded. As for blowers, I was finding these things called draft inducers that look like they go on top of hot water heaters. I've never seen one in person, so does anyone know how much power they have? I'm guessing they are not very powerful, but I could be wrong. I'm going to try my Kirby motor on it when I get more 2 inch hose. |

|

|

|

| Dan |

Posted on 03/03/2012 1:19 PM

|

|

1 1/2 Pounder  Posts: 1662 Joined: October 24, 2005 |

Just in case the physics is new to some, here are the basics. The link in the original post makes what is called a cyclone separator. Cyclone separators are often used on drum roasters. They have been around for almost a hundred years. The principle is simple, use the dust collector's air velocity to create a cyclone in a container so that the centrifugal forces move the larger particles out toward the edge of the container where friction causes them to slow down and drop to the bottom. My shop central dust collector uses on as the primary filter followed by a bag filter for the final step. |

|

|

|

| allenb |

Posted on 03/18/2012 8:26 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

If anyone needs another option for a simple, non-conical cyclone that's simple to build and will not pass any chaff out the exhaust, folks should consider this: http://www.jarkma.../bench.htm You can use old pieces of ducting, trashcans etc and you don't need any fancy calculations at all. I wouldn't make the central uptake tube any larger in diameter than 1/2 the can's diameter. When I get a shop that's larger than a small closet (hopefully soon) I'm going to build one about the size of the one in the link. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 03/21/2012 4:26 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Without complicating things too much, the addition of a baffle maintains a high pressure zone up high. The chaff really gets spun out, then drops into the low pressure section below the baffle. It seems to be a pretty common design element in central vacs as well as all the bagless vacuums out there. Cheap and easy. -Scott

JETROASTER attached the following image:

|

|

|

|

| oldgearhead |

Posted on 03/21/2012 4:51 PM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Scott - Large grain handling facilities, even those with several fine dust cyclones and self-standing bag-houses will use a few 'baffle separators' near the front of the process.. No oil on my beans...

|

|

|

|

| seedlings |

Posted on 03/22/2012 7:55 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

De-mystifying the baffling. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| allenb |

Posted on 03/22/2012 8:45 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote freshbeans wrote: Without complicating things too much, the addition of a baffle maintains a high pressure zone up high. The chaff really gets spun out, then drops into the low pressure section below the baffle. It seems to be a pretty common design element in central vacs as well as all the bagless vacuums out there. Cheap and easy. -Scott Interesting. You would think the particles would lose some of their velocity once they dropped past the narrower opening between the baffle edge and drum and be more prone to being drawn back up the uptake tube. Is there any rule of thumb for a ratio of diameter of drum versus diameter of baffle? Or, is the outer baffle slot between baffle and drum dependent on cfm? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 03/22/2012 11:17 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

"You would think the particles would lose some of their velocity once they dropped past the narrower opening between the baffle edge and drum" -Allen Exactly. They lose the velocity and drop. What's more, they drop at the greatest distance from the exhaust port. The beauty of this arrangement is that overall, you don't lose much CFM . I'm not aware of a suggested ratio, but it seems common for the baffle to occupy roughly 80% of the drums diameter. I imagine a blower with a high pressure potential allows for a tighter fit. -Scott |

|

|

|

| JETROASTER |

Posted on 04/09/2012 9:45 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

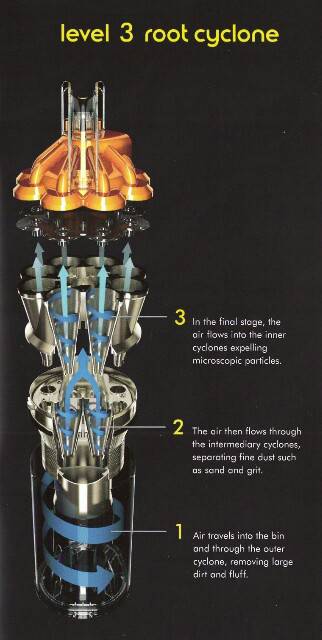

Dyson meets Sawzall. It's actually really nice design. Would it be overkill for for chaff? ...Or, is chaff/exhaust to 'sticky' for this design? -Scott

JETROASTER attached the following image:

|

|

|

|

| Dan |

Posted on 04/10/2012 4:04 AM

|

|

1 1/2 Pounder  Posts: 1662 Joined: October 24, 2005 |

Allen's link above shows a tangential inlet for a cylindrical cyclone. You don't have to get so fancy. You can use a radial inlet (set on the diameter, or perpendicular to the tangent) with a 45? baffle on the inside. The baffle is enough to get the cyclone spinning. That's how my home shop cyclone works. A 55-gallon drum makes a good shop shop container. Mount the centrifugal blower on top. |

|

|

|

| JETROASTER |

Posted on 04/10/2012 10:32 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Yeah, something simpler makes more sense! (sorry for the hijack dfluke) I actually did the autopsy just to get a better idea of what's going on, and to check some basic ratios. I had read that cyclone length being 1.64 times the cyclone diameter was a pretty good basic rule. The MH-1 needs a matching chaff collector, so I'm just nailing down some basics. I want to be as compact as possible. -Scott |

|

|

|

| allenb |

Posted on 04/13/2012 7:53 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I'm curious about how the dyson mini cyclones work. I'm assuming the air inlet on each cyclone enters on a tangent at the top of each one and the air leaving them goes up through the small white cylindrical units centered at the top of them. Are the cup handle looking ears at the top of each one the point of dirty air entry? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 04/13/2012 8:52 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

"Are the cup handle looking ears at the top of each one the point of dirty air entry?" The entry points are between the ears. The ears seem to focus the airflow toward the entry. I like the idea of a second stage, ....just not 6 of them. One secondary cyclone would be enough for me. -Scott

JETROASTER attached the following image:

|

|

|

|

| allenb |

Posted on 04/13/2012 10:05 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Got it, What constitutes the first stage in the Dyson? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 04/14/2012 8:31 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Hi Allen, This image illustrates a newer 3 stage design. The first stage is the large bin where air first enters. The bulk of large debris is left there. I'd like one more stage consisting of a single cyclone. I can't imagine needing a third stage for coffee...although it would be fun. Why not add an after-burner on top?  -Scott -Scott

JETROASTER attached the following image:

|

|

|

|

| allenb |

Posted on 04/14/2012 8:56 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

The drawing helps a lot! I didn't realize where the initial entry point was in the chain. Thanks 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman