Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Enhancing My HotTop (5 of 5) ? Advanced Modifications

|

|

| smico |

Posted on 03/20/2013 9:33 PM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

I would add two things to the list of mods to make your HT perfect: 1. Variac 2. Kill-a-watt I bought TECHNIPOWER VARIAC W30. I can keep voltage constant, and profiles track perfectly every time. Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| ciel-007 |

Posted on 03/24/2013 1:24 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote smico wrote: ... I would add two things to the list of mods to make your HT perfect: 1. Variac, 2. Kill-a-watt ... Miroslav, thanks for sharing; I'm glad to hear that you're enjoying the added control provided by the Variac and the K-W. It's hard for me to imagine that there's a better "home" roaster out there than the HT. However, in my opinion, the HT continues to fall short of the mark as the "perfect" roaster. In recent months, I have been experimenting with yet another modification that may possibly help nudge the HT closer to "Perfection". I have been attempting to resolve a fundamental design flaw in the HT. I consider my current experiment to be an "Extreme Mod", and I have tentatively called it the "RAF-1". I look forward to sharing my test results here at HRO... as soon as they reveal some evidence of success. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| snwcmpr |

Posted on 03/24/2013 3:42 PM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

Hint, Hint, Hint!!!!! Ken --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| rlb2444 |

Posted on 03/24/2013 3:44 PM

|

|

Newbie  Posts: 24 Joined: December 28, 2009 |

Ditto to the benefits of adding a Variac and Kill-a-watt. I also have thermocouples measuring bean and environmental temps. I have roasted as much as 10 oz but prefer to be around 9 oz. The weakest part of the HT in my opinion is the distribution of chaff throughout the roaster. I use a high pressure blower after a half dozen roasts and clean as best I can after each roasting session. Another thing that I use is a fan over the bean drop hole to speed up the cooling time between roasts. If I cut it off at around 161 by the time I insert the chaff tray and cover the bean drop opening it will go into pre heat. A minute or so the buzzer goes off and the timer starts counting down. While not perfect it works well for me. Looking forward to a larger capacity one. Faema Legend, Versalab, Robur-E, Monolith, Compak K10 Fresh, Hottop

|

|

|

|

| smico |

Posted on 03/28/2013 3:56 PM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

How about guess... Fundamental HT flaw is that exaust air heats motor. Are you moving drum motor or fan to the front. Or taking out the motor with flexible shaft. Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| snwcmpr |

Posted on 03/28/2013 5:00 PM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

Quote Fundamental HT flaw is that exhaust air heats motor. Ken in NC --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| smico |

Posted on 03/28/2013 6:04 PM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

I wrapped motor with thin silicone baking sheet. I had limited success, but heat buid was much slower. The same for cooling of the motor. Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| snwcmpr |

Posted on 03/29/2013 7:47 AM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

I agree with you Ginny. I have only modified mine to have a Bean Temp Probe. As to the cleaning, the smoke on the motor is part of the cleaning. I don't know much about other machines, but the exhaust fan blowing across the motor seems a flaw to me. Humbly by a newbee, Ken in NC --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| Randy G |

Posted on 03/29/2013 11:21 AM

|

|

1/2 Pounder  Posts: 398 Joined: February 17, 2010 |

Present models of the Hottop have vent slots in the rear cover (It is a relatively new modification. Whether that prolongs component life remains to be seen. From my experience, the heat affects the gear box on the motor and not the motor itself. To help that situation it is important to be sure that the drum moves freely and does not rub on the front or rear roast chamber areas causing added stress to the reduction gears. The silicone insulation may help, but a good amount of heat energy may be conducted through the shaft-coupling and through the cover of the gear box that faces the roast chamber. I would try insulating just that cover. Remember that insulation will also hold IN heat so I would not cover the entire motor. |

|

|

|

| smico |

Posted on 03/30/2013 6:35 AM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

Randy, Good point about heat of the gear box. My enclosure was like a sleeve all around the motor, not covering the motor's own air vents of course. And indeed, I could do two consecutive back to back roasts from the cool roaster, but later on I would end up needing similar time between roasts compared to the naked motor due to less efficiency of the cooling. Still, it was beneficial modification due to lower max temperatures. I removed the cover and started working on almost complete three sided silicone cover, and a tiny Teflon tube to supply fresh air for cooling within the enclosure with an old aquarium bubbler. I have few other ideas in my sleeves, but Ciel is not telling us much here... I hope that he is currently working on the related project... Cheers, Miroslav Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| snwcmpr |

Posted on 03/30/2013 8:14 PM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

Thanks Ginny. Like I said, all I have is a bean probe. I have hearing loss, so I rely on the temp. I measure (weigh) my beans for brewing, but that's about it. That gives me repeatability. I will say ... all I know about roasting, what little I do know, 90% I got here. Thanks, Ken --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| Barrie |

Posted on 03/30/2013 11:37 PM

|

|

Pounder  Posts: 504 Joined: April 10, 2012 |

Quote ginny wrote: I do not believe you need to mod the hell out of a roaster to get a great bean to brew.  Your point is well taken, Ginny, but there is a whole group of people who both enjoy coffee that they have brewed, and enjoy fiddling with machines and electronics. I don't think they are mutually exclusive but, then, perhaps that is what you just said.

Barrie (San Diego, CA)

"So much to learn, so little time." Hottop 2K+., Artisan, Jura Capresso ENA 3 (i.e. espresso). |

|

|

|

| ginny |

Posted on 03/31/2013 9:27 AM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

Barrie: There is nothing wrong with mods on anything, period. We have this site for anyone to post up their mods to help other users do the same... I am/was only suggesting that simply out of the box the Hot Top is a great little roaster. ginny

Edited by ginny on 11/16/2013 12:14 PM |

|

|

|

| RAG |

Posted on 11/16/2013 11:59 AM

|

|

1/4 Pounder  Posts: 60 Joined: September 22, 2013 |

Quote ginny wrote: ..... I am was only suggesting that simply out of the box the Hot Top is a great little roaster. ginny First and foremost I have to agree with ginny. Couple of things. The RAF mod is first. Not only does this prolong hottop life, it adds control to the roast process. Fan to heat control in FC becomes tweakable and more immediate along with the added benefit of removing heat, chaf, and goo from the electronics area. I added an insulated firewall to further isolate the chamber heat from the roaster internals (not sure this was needed). I added a diode just after the bean cooling fan so that I can switch the fan and bean rotor motor on without activating the main fan, but still allow the normal design function of both fans being on the same circuit for normal operation. So now I have a switch that turns on only the bean fan and motor by grounding the yellow wire (U2p5) and the bean tray fan. Normal operation is whenever the main unit fan is off, the bean tray fan is off. I figured if doing back to back, I may want to cool beans, while not activating main chamber fan. The 165 override I did with a DPDT switch between the regular thermocouple and some left over thermo wire I used to make a junction to monitor the motor area. This provides a very dangerous heater on switch. It also allows roasting to any level and a hard on heater at any point in the roast cycle, while monitoring internal temperatures. So roasting and these mods are not for the faint of heart. Thanks Ciel and others for the motivation. |

|

|

|

| snwcmpr |

Posted on 11/16/2013 3:13 PM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

Well, some people drive cars the way they are made. If they don't like them, they get another one. Others modify the car to make it what they want. No right or wrong, just different. All I did was add a temp probe to the HT. When I got another roaster, that I like better, I put the HT on the shelf. Ken in NC --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| ginny |

Posted on 11/17/2013 7:27 AM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

Share solution-oriented experience and learnings freely. the above is from our What We Are About on the front page and I am placing it here because I see a trend of machine bashing happening. not simply regarding Hot Tops but other roasters as well. many members take hours of time and energy posting their respective ideas and mods they have done on any given roaster for other members who want to venture down that road... while I have never been shy about saying that all of these home roasters are GREAT straight from the box I clearly respect anyone who does creative and cool things with their roasters... if anyone feels they must bash their roaster start your own thread and do it but please do not roaster bash in threads that are designed to help other move beyond stock. not fair to anyone. thanks in advance, ginny |

|

|

|

| turtle |

Posted on 11/17/2013 8:10 AM

|

|

1 1/2 Pounder  Posts: 652 Joined: November 06, 2013 |

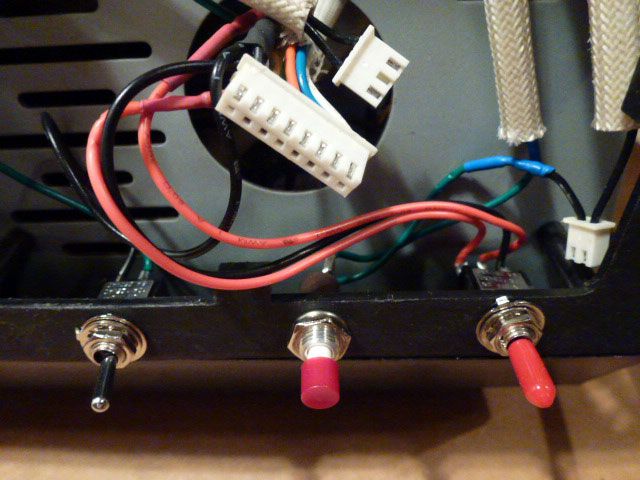

I wanted to thank Ciel for their time, for not only testing, but posting all of the mod and customization info that they have amassed about their Hottop home roaster. I know that I will be using many of their ideas. Last night I finished wiring in switches for the main fan and bean cooler motors as well as the temp sensor interrupt for "hot start" back to back roasts. I am sure that I will use these additional functions numerous times starting with today's roast.  |

|

|

|

| ciel-007 |

Posted on 05/10/2014 6:16 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Cracking the ?165F Barrier?: A FOLLOW-UP The modification, as described earlier, was designed to work on older Hottop models (i.e. KN8828B, KN8828P, KN8828B-2, KN8828P-2...) which have a large button shaped Temperature Sensor inside the roasting chamber. Given the nature of its design, that modification could theoretically be called the "OPEN CIRCUIT" method of tricking the Hottop Control Panel into reading "0"F at Startup. This Follow-Up is directed towards those who have attempted to "Crack the 165F Barrier" on the newer Hottop models (i.e. KN-8828P-2K and KN-8828B-2K) which have a thin K Thermocouple in the roasting chamber. I have two questions for you: (1)Would it be possible for 2K Hottop owners to tell us if the PHOTO that was used earlier (shown below) is representative of the manner in which the new K Thermocouple leads connect to the new 2K Hottop Control Panel? If not, would it be possible to post a photo that does? (2) More importantly, would it be possible for 2K Hottop owners to tell us if the electrical DIAGRAM that was used earlier (shown below) provides a circuit that actually works on the new 2K Hottop roasters? It is my understanding that thermocouples generate tiny changes in voltage (micro-volts) when the temperature varies. In that event, the OPEN CIRCUIT method (shown in that DIAGRAM) should theoretically be able to interrupt that tiny voltage flow, and thus trick the Control Panel into accepting that the temperature in the Hottop roaster is actually close to "0" F at startup. Alternately, it might also be theoretically possible to trick the new 2K Control Panel into reading 0 micro-volts by using a SHORT CIRCUIT method. That would involve using a Momentary Button Switch (that is normally open) and connecting it across the two K thermocouple leads; thus, when the button switch is pushed, the resulting short would reduce the micro-voltage to "O", and trick the Control Panel onto reading "0" F. Since I do not own a 2K roaster, I am unable to compare the Open Circuit and Short Circuit methods for Cracking the 165F Barrier on the new Hottops. Is there a 2K owner out there, who is brave enough to test both methods, and to tell us if one, both or neither of those methods work on the new Hottops? Ciel

ciel-007 attached the following images:

Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| JimG |

Posted on 05/10/2014 8:14 PM

|

|

1 1/2 Pounder  Posts: 834 Joined: October 23, 2008 |

I can confirm that the open circuit does not work. Like many other thermocouple instruments, the HT K control boards have open circuit detection. The board will shut down the roaster right away if open circuit is detected at power up. I don't know what happens in the event of open circuit detect at other times, but my guess is immediate shutdown (not good). Short circuit does work, however. I have never set up a switch to create the short, but a small loop of plain copper wire can be safely substituted for the thermocouple (done this several times). Electrically this is equivalent to closing a shorting switch. The result is that the HT believes the roasting chamber is the same temperature as the control board, essentially ambient temperature or a bit higher. I've used the wire loop trick several times for troubleshooting and testing on a P-2K board, and I am pretty sure it will work equally well on B-2K boards. Regarding switch installation details: if you add copper wire to extend the thermocouple leads there is likely to be some loss of accuracy in the temperature readings because you would be moving the "cold junction" away from the circuit board. Ideally one should use type K wire to extend the TC leads. The wires to the shorting switch can be copper. The caveats are: 1. While I have tested the effects of both open and short circuits on a P-2K board, I have never used this to break the 165F barrier. I have done the testing in a controlled test bench environment. 2. Why the heck do you want to do this anyway?  . I am perfectly happy to give the roaster a few minutes to rest between roasts. . I am perfectly happy to give the roaster a few minutes to rest between roasts.  Jim Edited by JimG on 05/10/2014 8:20 PM |

|

|

|

| ciel-007 |

Posted on 05/16/2014 10:57 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Cracking the ?165F Barrier?: A FOLLOW-UP Quote JimG wrote: I can confirm that the open circuit does not work... Short circuit does work, however. I have never set up a switch to create the short, but a small loop of plain copper wire can be safely substituted for the thermocouple... While I have tested the effects of both open and short circuits on a P-2K board, I have never used this to break the 165F barrier... Jim, thanks for this valuable follow-up. Recognizing your long standing expertise in the field of electronics, I welcome your explanation (and caveats) as to why the "Short Circuit" method should work on the new Hottop 2K models - in contrast to the "Open Circuit" method which works on earlier B and P Hottop models. I look forward to the day when a 2K Hottop owner will post photos of a modified roaster actually "Cracking the 165F Barrier" with the appropriate switch design. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| JimG |

Posted on 05/16/2014 11:22 AM

|

|

1 1/2 Pounder  Posts: 834 Joined: October 23, 2008 |

Quote ciel-007 wrote: ... I welcome your explanation (and caveats) as to why the "Short Circuit" method should work on the new Hottop 2K models - in contrast to the "Open Circuit" method which works on earlier B and P Hottop models. The earlier models use a thermistor. This is a sensor whose resistance changes with temperature. The relationship between resistance and temperature is known, so measuring the resistance is equivalent to measuring the temperature. To measure the resistance at any point in time, the circuitry on the control board passes a known current through the sensor and measures the resulting voltage drop. If you short circuit this sensor, you end up measuring 0 ohms resistance, which puts the temperature off the chart! Probably there is circuitry which limits the current in the event of a very low, i.e. 0, thermistor resistance. So I don't think there is too much risk of damaging the control board by shorting the pins on the P or B, but I would not try it just in case. The newer models (B-2K, P-2K) use thermocouple sensors. Instead of changing resistance with temperature, TC's actually generate small voltages, under 10 mV, when one end is hotter than the other end. The circuitry to read a thermocouple is entirely different. The control board has a very high input impedance op amp that reads and amplifies the very low mV voltages that are generated by a thermocouple. A reading of 0 mV, which is what you get with a shorting loop in place of a TC, simply means there is no voltage being generated by the sensor. This condition is not unusual and occurs whenever the sensing tip of the TC is at room temperature. Most thermocouple instruments also pass a very low current through the TC at all times and have circuitry that can tell if this current has been interrupted. The current is too small to generate even mV voltages across the TC leads, so it does not mess up the readings. But if the TC is broken or missing, then the current does not return to the instrument and it knows there is a problem. I am not sure why an open circuit does not cause a similar problem on the earlier models. Perhaps it would if you left the switch open for a long enough duration? Jim |

|

|

|

| ciel-007 |

Posted on 05/16/2014 12:40 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Cracking the ?165F Barrier?: A FOLLOW-UP Jim, I am grateful to you for taking the time to explain the evolution that has taken place in the complex Hottop thermal circuitry over the years - that's much appreciated! Quote JimG wrote: I am not sure why an open circuit does not cause a similar problem on the earlier models. Perhaps it would if you left the switch open for a long enough duration? Jim, I believe that you are correct (as usual) in your statement. In my attempts to "crack the 165F barrier", I conducted a number of experiments. In earlier trials, I used a toggle switch to open the thermal circuit. I was mystified by the fact that opening the circuit in that manner did not work consistenly. Jim, you have just now provided an explanation as to why it did not. During my experiments, I eventually realized that success with this tentative modification depended on my ability to activate the toggle switch very quickly. I thus abandoned the toggle switch in favor of an intermittent button switch; with an intermittent button switch, it is easy to open the circuit for only a brief moment, and thus successfully trick the thermal circuitry into allowing the roaster to start-up at higher temperatures. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| JimG |

Posted on 05/16/2014 3:11 PM

|

|

1 1/2 Pounder  Posts: 834 Joined: October 23, 2008 |

Another approach for the earlier thermistor-based boards would be to use a switch to swap in a resistor rather than leave it open circuit. To determine the correct size resistor, use a DMM to measure the resistance across the sensor leads with the sensor at room temperature and unplugged from the control board. This approach should eliminate the timing issue. Jim PS - I am still not sure I think that tricking the roaster this way is a good idea  |

|

|

|

| ciel-007 |

Posted on 05/17/2014 10:17 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Photos of the 2K Control Panels & Cables It is likely that some of the above mods for the older B and P Hottops may not work as originally intended on the newer roasters. In order to help identify which mods might possibly require some tweaking, additional information about the 2K roasters would be appreciated. Would it be possible for the owner of a KN-8828P-2K and the owner of a KN-8828B-2K roaster to post photos of the back of their Control Panel (including the Main Control Cable, the Chaff Tray Safety Switch Cable, and K Thermocouple Cable)? Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 05/23/2014 6:20 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Hottop Struggling - Variac Needed! Before deciding to buy a Hottop, I remember reading a number of claims made by the manufacturer. Here are two that specifically come to mind: -Hottop claimed that its roaster provides: "750 watts of roasting power" . -The manufacturer also claimed: " not sensitive to voltage, no variac needed ". If memory serves, the above claims may possibly date as far back as 2007 or so, when the B and P models were introduced. Those claims encouraged some Hottop re-sellers to advertise the roaster with words such as: "Not sensitive to the line voltage... no voltage regulator (such as a Variac) is needed... to maintain proper voltage" or perhaps words along the lines of: "these new Hottop models are voltage compensated". I had not given much thought to those claims until recently, when I read several posts by Miroslav (Smico). In his posts, Miroslav explains how he uses a Variac to improve the roasting performance of his Hottop. http://homeroaste...post_50479 http://homeroaste...post_49882 After reading Miroslav's posts, I thought it might be interesting to take a closer look at Hottop's claims. In order to do that, I first had to find my Variac (an old Superior Electric Powerstat - Spec BP57515) that had been quietly gathering dust in a remote corner of my workshop. Next I had to go out and buy a brand new Kill-A-Watt (model P4400) monitor. I was now ready to power up my faithful Hottop (KN-8828B-2) and to take a closer look at the manufacturer's claims. I normally use the same 120vac circuit when I roast in my workshop. During the week, this dedicated outlet undergoes typical voltage fluctuations that may range from 119vac to 123vac (with no load applied). That represents a relatively small (under 2%) voltage fluctuation from the mean. Given the above Hottop claims, one would not expect the roasting process to be affected in a meaningful way by those minor voltage fluctuations. Here is what my instruments revealed under two different roasting scenarios. Roasting on a High Voltage Day: There are days when the outlet I use to roast provides a voltage of 123vac. When the Hottop is set to roast at full power, the Kill-A-Watt monitor shows 121VAC under load, and the total power consumption appears as 735 watts. Roasting on a Low Voltage Day: There are days when the outlet I use to roast provides 119vac. When the Hottop is set up to roast at full power, the Kill-A-Watt monitor shows 118vac under load, and a total power consumption 711 watts. In order to force my Hottop to output the manufacturer's claimed roasting power 750 watts, I need to boost underload voltage to 122vac with the Variac. Conclusions: What might one to conclude from the above trials? 1.0 - One possible conclusion might be to reject the above results on the grounds of measurement error. In other words, my Hottop is roasting according to the manufacturer's claims, but that the Kill-A-Watt monitor I used gave me inaccurate readings. I am inclined to dismiss that tentative conclusion given the fact that tests conducted by Consumer Reports (and others) have stated that the P4400 monitor provides "accurate" results. 2.0 - A second conclusion might be that claims advanced by the manufacturer may be optimistic. I find this conclusion attractive for two reasons: 2.1 - In regard to the first claim, my KN-8828B-2 did not provide the manufacturer's advertised roasting power even on a High Voltage Day. On a high voltage day (121vac under load) when my outlet was actually exceeding the norm (120vac) for which my Hottop is designed, my roaster fell short of the claimed roasting power by 15 watts. 2.2 - More importantly, in regard to the second claim, I did not find any evidence that special circuitry might be at play to compensate for low outlet voltage. Quite to the contrary, a mere drop of two volts (118vac) below the norm (120vac) resulted in roasting power (711 watts) that was 35% below the manufacturer's claimed wattage. In other words, my Hottop roaster is sensitive to small voltage fluctuations. 3.0 - Given that the above results are based on a single, aging KN-8828B-2 roaster, I would encourage other Hottop owners to post their results following similar trials. It would be nice to document situations where Hottop roasters meet, or exceed, the manufacturer's claims in terms of roasting power and voltage compensation. Recommendation: Should the second conclusion above be confirmed by others, then a case might possibly be made for one further Hottop enhancement; perhaps a recommendation along the following lines: Hottop Struggling - Variac Needed! Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman