Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Enhancing My HotTop (5.1 of 5) ? Extreme Mods

|

|

| ciel-007 |

Posted on 11/02/2013 11:03 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

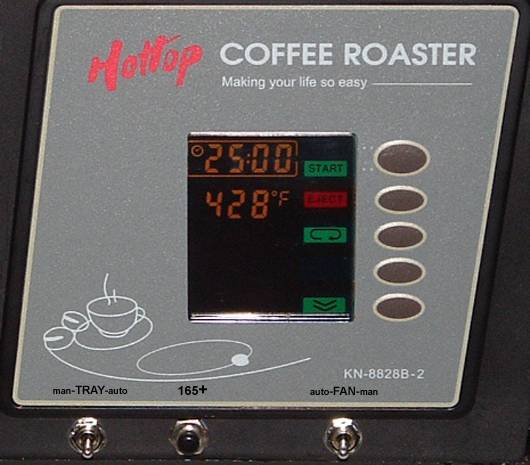

Quote Rag, I mounted the switches under the main control panel. That location makes it relatively easy to complete the modification, and very convenient to operate the switches during roasting. ciel

ciel-007 attached the following image:

Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 11/02/2013 11:05 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote Rag, I did not enjoy having to periodically dismantle the front cover to remove the unsightly chaff that gets wedged between the glass and the back steel panel. The high temperature silicone gasket works very well in preventing chaff from getting stuck, and reduces the need to remove the front cover to wash the glass. ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 11/02/2013 11:13 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote Miroslav, thank you for those kind words. As you can probably tell, I very much enjoy tinkering with the totally amazing Hottop home roasters. Further, I like to share the results of my experiments with other HT owners... hoping that it might help them explore new dimensions in roasting and possibly discover new levels of enjoyment... ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| RAG |

Posted on 11/03/2013 7:29 PM

|

|

1/4 Pounder  Posts: 60 Joined: September 22, 2013 |

Quote snwcmpr wrote: If a First Aid Kit works, would you consider a nice lunch box with the Cartoon Character of your choice? I see them all over the place. Ken in NC darn good idea. Would have loved a Road Runner or a Train. Miroslav, thank you for all the help and pointing me in the right direction again. Seems I need to search these forums better. Ciel, amazing as always. I tried the new mod quickly and you were right again Ciel about having to redo my profiles. The fan at 75% after first crack really stalled the roast. Great to have this new tool o control the roast. I am of course using the default fan in the new enclosure. I also put a charcoal & wire mesh filter inn da box. I plan on cleaning up this mod more and carrying on with the switches and internals. I hesitate on the switches as it will be my first real no going back mod and I am considering a touch screen instead. Thanks everyone for their help and support. Rich

RAG attached the following image:

|

|

|

|

| ciel-007 |

Posted on 11/05/2013 11:55 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Rich, I too was hesitant about permanently mounting the switches below the Control Panel. So, during several weeks of roasting trials, I allowed the switches to simply hang below the Control Panel (as seen in the photo below). It was not until I was satisfied with the performance of the switches, and the convenience of their location, that I proceeded to mount them permanently on the Side Panel of the Hottop. However, should I ever change my mind, and elect to remove the switches, I can always order a new replacement Side Panel (Part # P-24) which Hottop sells for about $10. ciel

ciel-007 attached the following image:

Edited by ginny on 11/06/2013 9:29 AM Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| RAG |

Posted on 11/10/2013 8:55 PM

|

|

1/4 Pounder  Posts: 60 Joined: September 22, 2013 |

Quote You gotta love hottop for that reason alone. Ok so I haven't drilled the hole yet but I put in a dpdt switch for switching from the built in thermocouple to one i made with left over wire located in the eletronics area. Two fold benefit. it works as a heater on switch and also allows monitoring of electronics. |

|

|

|

| RAG |

Posted on 11/10/2013 9:53 PM

|

|

1/4 Pounder  Posts: 60 Joined: September 22, 2013 |

If attempting back to back roasting, is there a way to get the chaf from above the tray, that sits in the well that falls out when you take off the front glass? I built a metal tube vacuum adapter that cleans the inside pretty well but this area seems stubborn. Thanks |

|

|

|

| ciel-007 |

Posted on 05/12/2014 12:58 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Venting the Plenum Cover After hundreds of roasts in the RAF-1 Extreme, I can report that the modified roaster performs very well. Although this roaster's appearance may seem novel, let me assure you that it continues to perform with the precision and reliability that has made the Hottop name legendary. However, I continue do seek ways to further enhance this singular design. Here is one tweak that I am experimenting with. It involves a small modification to the Plenum Cover. During roasting, the RAF-1 design encourages the rise of hot gases from the chamber into the extraction pipe above; concurrently, fresh air is naturally drawn into the chamber through the rear of the roaster. This spontaneous convection plays a useful role when the BMT exceeds 300F; that's the moment when the moisture inside the beans begins to escape, and the critical drying process begins. Those of you roasting with an RAF-1 modification will have noticed that this moisture finds it way into the Plenum, and may even spill out the back of the Plenum through the exhaust fan (even when the fan is OFF). Those hot gases may also coat the fan blades with residue (I do not use any filters in order to maximize fan efficiency). Typically, I leave the cooling fan OFF during this drying phase until the verge of first crack, when I turn the fan ON (level 1) to expel smoke and gain better control over ROR. I have been experimenting with a small modification to the Plenum Cover that reduces moisture accumulation and residue build-up. Take a look at the attached photos. The photos show: (1) that the knob atop the plenum cover actually conceals a vent opening (2) an ordinary sink stopper has been attached to the knob, and may be used to open and close the vent opening at will. (3) removing the knob to open the vent allows rather large amounts of moisture to naturally escape without any need to activate the main cooling fan. The vent works very well during the critical bean drying phase of the roast. Should you elect to try this tweak, don't forget to return the stopper to the vent opening before turning on the fan. Ciel

ciel-007 attached the following images:

Edited by ciel-007 on 05/12/2014 1:09 PM Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| snwcmpr |

Posted on 05/13/2014 9:08 AM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

Quote when the BMT exceeds 300F; that's the moment when the moisture inside the beans begins to escape Hmmm, I always thought that at 300F BT the moisture had already escaped and drying was complete, theoretically. Ken in NC --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| ciel-007 |

Posted on 05/14/2014 9:49 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote snwcmpr wrote: ... I always thought that at 300F BT the moisture had already escaped and drying was complete... Interesting... Care to share where the theory came from? Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 06/05/2014 4:26 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Bean Drying Phase in the RAF-1 Quote snwcmpr wrote: ... I always thought that at 300F BT the moisture had already escaped and drying was complete, theoretically... Ken, I was curious about the theoretical claim you advanced. That motivated me to do more reading about bean moisture content, and to conduct a few experimental "Bean Drying" trials with the RAF-1. So far, the articles I consulted suggest that the moisture content of green coffee is generally thought to be approximately 12%. Further, according to my understanding of Willem Boot's writings, the objective of the drying phase is to reduce that bean moisture content down to approximately 2%. In other words, during the critical drying phase, over three quarters of the moisture inside the bean must be "vaporized" away. Bean Drying Trials: Given the magnitude of moisture being vaporized within such little time, it should be possible to see evidence of this phenomenon as it happens. Under that assumption, I conducted several trials in the RAF-1 to document the BMT at which a perceptible amount of vapor would begin to rise from the roasting greens. I hypothesized that if Ken's "theory" was correct, then there should be visible signs of vapor escaping from the roaster before a BMT of 300F was reached. Some may fault me because the trials did not involve sophisticated measuring instruments. I employed simple visual cues; namely, I looked for the moment at which my eyes could detect a noticeable amount of vapor rising from the vent hole in the Plenum Top of my modified Hottop (RAF-1) via natural convection (fan turned OFF at all times). Findings: My observations found that little or no vapor was noticeable prior to BMT 290F. When vapors began to escape from the Plenum Top at BMT 290F, they were not sufficiently plentiful to be easily photographed. Photo 1 shows a more noticeable amount of vapor escaping at BMT 300F. The visible amount of vapor continued to increase as the BMT continued to rise. Photo 2 shows a even more dramatic amount of steam escaping at BMT 320F. Interpretation and conclusions: As BMT approaches 290F, the temperature of the moisture (and pressure) inside the beans is increasing; however, little humidity appears to be leaving the bean (possibly because of the hard outer shell of green beans), and little bean drying seems to be occurring at this time. However, once the BMT exceeds 290F, the rising gas pressure inside the beans would be such that vapor flares though the pores of softening cell walls, thus marking the beginning of the critical bean drying phase. The observations from several bean drying trials lead me to conclude that: (1) The RAF-1 mod makes it easy to spot the moment at which the critical bean drying phase begins (2) The design of the RAF-1 allows moisture to easily escape from the roasting chamber through simple natural convection (no need to cycle Hottop fan ON & OFF for drying) (3) Very little water vapor actually escapes from the beans prior to BMT 300F (4) When BMT 300F is reached, the critical bean drying phase (during which 75% of the water must be expelled from the beans) has just barely begun (5) The popular theory that the bean drying phase is complete by the time BMT reaches 300F would appear to be unfounded. Ciel

ciel-007 attached the following images:

Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 06/15/2014 9:55 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote turtle wrote: I am thinking of implementing your mid draft draw fan mod but I want to make the rear box out of sheet metal instead of wood. Not good at prototyping so dead in the water there. Do you have any measured drawings of your wooden box mod so that a "tin man" could use them to bend and fabricate a sheet metal box out of AC duct metal? Mick, Plenum dimensions of are not critical. The one in my photos measures 4"x7"x9". I used wood because it made it much easier for me to build various experimental boxes (RAF-Alpha, RAF-Beta, and finally RAF-1). If you prefer metal, you might also consider taking a look at RAG's alternative - the box from a First-Aid-Kit. http://homeroaste...post_46845 Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 06/17/2014 10:36 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote smico wrote: ... last weekend I have finally built an ad-hoc RAF... ... first roast was successful... ... I have some other mods that will be documented soon... Congrats Miroslav! I very much look forward to admiring you handiwork, and learning from your astute innovations. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| ciel-007 |

Posted on 06/22/2014 3:45 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Bean Drying Phase - A Follow-up Quote ciel-007 wrote: Interpretation and conclusions: As BMT approaches 290F, the temperature of the moisture inside the beans is increasing... once the BMT exceeds 290F, the rising gas pressure inside the beans would be such that vapor flares though the pores of softening cell walls.... The observations from several bean drying trials lead me to conclude that: ... (3) Very little water vapor actually escapes from the beans prior to BMT 300F (4) When BMT 300F is reached, the critical bean drying phase (during which 75% of the water must be expelled from the beans) has just barely begun (5) The popular theory that the bean drying phase is complete by the time BMT reaches 300F would appear to be unfounded. Quote oldgearhead wrote: ... the main problem, I have with the 'Bean Drying Phase in the RAF-1' is "perceptible amount of vapor"... was the vapor trapped and weighed? ... Following OGH's feedback, I elected to repeat the earlier bean drying trials using a more objective method. Follow-Up Bean Drying Trials: For the new bean drying trials, I used a digital scale to quantify the amount of moisture being lost during roasting. The trials involved roasting 300g of Columbian greens that were at an initial room temperature of 75F. The beans were roasted in accordance with the profile described at the following link: http://homeroaste...post_46459 After loading them into the roaster, the beans were allowed to reach a BMT of 300F; at that point, the beans were ejected, weighted, and then immediately returned to the hot chamber. At this point the beans were observed to weigh 292g on the digital scale. The method used to eject the beans, while maintaining the Hottop at full heat and roasting power is described in the following posts: http://homeroaste...post_40019 http://homeroaste...post_40020 Following their return to the roasting chamber, the beans were allowed to complete the cycle as described in the profile. At the end of the roast, the ejected beans were immediately placed on the digital scale and weighed again; the final weight was observed to be 258G. In order to ensure that this final weight was confined to measuring only moisture loss, the beans were weighed along with all the chaff that I was able to recover from the roaster. Follow-Up Findings: During the entire roasting cycle, the mass of the Columbian greens lost a total of 42g. The ratio of 42g/300g is equivalent to a 14% weight loss. That percentage is comparable to the moisture content frequently reported in green beans. More importantly, by the time the greens had reached a BMT of 300F, only 8g of the mass had been lost; the ratio of 8g/300g is equivalent to a 2.7% weight loss. The question that the trials were intended to address is this: How much of the entire bean drying process has actually occurred by the time the BMT reaches 300F? The answer is provided by the ratio 8g/42g, which is equivalent to 19%. In other words, by the time that BMT achieves 300F, less than 20% of the moisture has been removed from the roasting beans. These new empirical results actually concur with the earlier, albeit less objective trials, based on the vapor that was perceived to be escaping from the Plenum of the RAF-1 during roasting. FOLLOW-UP CONCLUSIONS: ... (3) Less than 20% of the moisture actually escapes from the beans prior to BMT 300F (4) When BMT 300F is reached, the critical bean drying phase (during which the remaining 80% of the moisture has yet to be expelled) is still at an early stage (5) The belief (still held by some roasters) that the bean drying phase is complete by the time BMT reaches 300F would appear to be misguided. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| Barrie |

Posted on 06/22/2014 5:03 PM

|

|

Pounder  Posts: 504 Joined: April 10, 2012 |

Good job, Fern! The chaff as a proportion of the total is still an unknown, and it would come off after the 300 mark, of course. Intuitively, it seems unlikely it would account for a large fraction of the total? Each of us who reads this report will have a different reaction. My career in the sciences induces respect for the methodology, given the limitations of your "laboratory." The homeroaster in me, with some established routines that do not include any change in settings once the drying/yellowing phase is over, encourages further approval.

Barrie (San Diego, CA)

"So much to learn, so little time." Hottop 2K+., Artisan, Jura Capresso ENA 3 (i.e. espresso). |

|

|

|

| Barrie |

Posted on 06/22/2014 7:25 PM

|

|

Pounder  Posts: 504 Joined: April 10, 2012 |

Just finished roasting two 232g batches of Happy Mug Peru Sol y Cafe. These beans are not big chaff producers (don't know the processing), but there was a fair amount in the chaff tray at the end of FC+ roasts. My scale measures to the nearest gram and the weight was ZERO! Incidentally, the beans are the prettiest I have seen. Good very uniform size, and textbook-perfect color changes during the roast. A really enjoyable experience. Barrie (San Diego, CA)

"So much to learn, so little time." Hottop 2K+., Artisan, Jura Capresso ENA 3 (i.e. espresso). |

|

|

|

| smico |

Posted on 06/29/2014 11:40 AM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

While waiting to find some time to build custom box, I picked up an old toolbox that I had laying around and spent a weekend building my ugly temporary RAF setup. 1. Pipe connection to the top filter I used Dremel to cut round hole in mesh of the top filter to fit end of the pipe in. Then I rolled two layers of aluminum foil around the filter mesh. High temperature silicone secures the end of pipe, and it makes the connection air tight. 2. Box Box is made air tight with layer of high temperature silicone on one edge. I could not find a cap so I used a hockey pack to close the top vent. I did just 4 roasts so far, and I have full control of the roasts, similar to the control of the original HT. I have to spend more time on temperature measurements of internal components during back to back roasts. So far so good. Ciel, thank you again for this gift. I will report further on usage details as I use the new setup more.

smico attached the following images:

Edited by smico on 06/29/2014 11:47 AM Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| frachlitz |

Posted on 06/30/2014 1:39 AM

|

|

Newbie  Posts: 16 Joined: March 26, 2014 |

Simco, thats looks promising! What kind of pipe did you use? |

|

|

|

| smico |

Posted on 06/30/2014 4:25 AM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

As per Ciel's instructions, I bough 1.25" chrome plated drain pipe kit for $20 in Home Hardware. Pipe is 12" long, and I did not have to cut it at all.

Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| Barrie |

Posted on 07/05/2014 5:14 PM

|

|

Pounder  Posts: 504 Joined: April 10, 2012 |

i see from the HB forum that Fern (Ciel-007) is moving on to a larger-capacity semi-pro roaster. He has made tremendous contributions to our information database as he has explored the possibilities with his HT, and I do hope we will continue to see his writings from time-to-time. Thank you so much for everything you have done for our hobby, Fern. I wonder if your new community of roasters know how fortunate they are?

Barrie (San Diego, CA)

"So much to learn, so little time." Hottop 2K+., Artisan, Jura Capresso ENA 3 (i.e. espresso). |

|

|

|

| ciel-007 |

Posted on 07/17/2014 11:19 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote smico wrote: ... While waiting to find some time to build custom box, I picked up an old toolbox that I had laying around and spent a weekend building my ... temporary RAF setup... Miroslav, I admire your creativity. Congratulations on a cool RAF mod! I look forward to hearing more about how the mod may have influenced your roasting experiences, and profiles. Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| okmed |

Posted on 09/07/2014 6:06 PM

|

|

Newbie  Posts: 42 Joined: August 23, 2014 |

First of all let me say that I'm a newbie to this site, and to roasting. Second let me say thanks to all the people that contribute here and the people that run this site. It was this site that helped me make my decision to purchase the Hottop. Special thanks to ciel-007 who's' work on "Enhancing My HotTop" mods impressed me so much I had to do them all. By the way Fern, I have the newer type K thermocouple and shorting it out works perfectly for the "Cracking the 165F Barrier" mod. The following attachments show my mods and the slight differences to accommodate my limited head room under my kitchen exhaust/microwave. I only had 15-1/2" under the exhaust/microwave so I made it 8-1/2" x 8-1/2" x 4". It should have been a little wider but I offset it towards the back to move the pipe over and create just enough room so that the charging funnel still fits. As you can see I used copper pipe and fittings to get more offset. Also due to the limited head room, I made the rear cover removable instead of the top . You can see the large flat top screws and cam plugs I found at Home Depot to facilitate that. I also made a simple cardboard chimney which works very well to direct the exhaust. I have two thermocouples and a TC4C kit (with RoastLogger software) on order and am looking forward to completing that final mod so I can better track and record my roast profiles. Thanks again to all who contribute here.

okmed attached the following images:

Edited by okmed on 09/07/2014 6:13 PM RAF-1 Extreme (modified B-2K) Hottop with HTC+TC4C, HG-One grinder, Bezzera Strega.

|

|

|

|

| allenb |

Posted on 09/09/2014 9:33 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Hi okmed, you've done some fantastic modding here. I especially love the copper plumbing work! Reminds me of vintage locomotive steampunk in some of your photos. How's your roasts turning out? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| okmed |

Posted on 09/09/2014 11:26 PM

|

|

Newbie  Posts: 42 Joined: August 23, 2014 |

Thanks Allen, as far as my roasts go I'm still on the learning curve. Have only done 8 roasts so far ( last one with the mods ) and none have been bad. Even the wife thinks they're pretty good. Just received my thermocouples and cables for the HTC/TC4C interface so I will be busy with the install but look forward to developing a RoastLogger data base to help with my learning curve. Milan RAF-1 Extreme (modified B-2K) Hottop with HTC+TC4C, HG-One grinder, Bezzera Strega.

|

|

|

|

| smico |

Posted on 09/16/2014 5:48 AM

|

|

1/2 Pounder  Posts: 262 Joined: December 17, 2011 |

Great job Milane. This is the nicest installation so far. I have to ask management to remove photos of my installation. Regards, Miroslav Hottop B2 + HTC, Cremina 83, OE Pharos, Brewtus IIIR, Baratza Vario

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman