Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Huky 500

|

|

| Vesteroid |

Posted on 06/22/2014 9:55 AM

|

|

Newbie  Posts: 2 Joined: June 22, 2014 |

I am a new huky owner and srill setting the unit up. From reading here the analog dial on the huky appears to be the drum temp(I assume that means air inside the drum) and the top digital probe must be the environmental temp, with the middle digital probe being the bean temp. I ordered it with the center 301 and have successfully gotten artisan to read both probes on my Mac laptop (that took some doing to find the serial to usb driver and get it working). My current issue is hooking up the supplied gas stove. It appears to simply have a .5 in not male nipple coming out of the stove. Does anyone have a recommendation on how to find a hose (or assemble parts) that will go from the propane tank to this nipple? Standard grill hoses have a different end on them with different threads and a rounded interior. This nipple is hollow with a brass fitting that is 90 degrees to the nipple wall inside that appears to make the transition to the .125 copper tubing. What I would really like to do is get a quick connect onto that nipple as I have a propane hose that has a quick connect female end on it already from a garage heater. Anyone have any ideas where I can source something like that? |

|

|

|

| Vesteroid |

Posted on 06/22/2014 12:53 PM

|

|

Newbie  Posts: 2 Joined: June 22, 2014 |

For reference I suppose I solved it (I think). I had a mr heater hose that went from my propane tank to my garage heater. It had a .25 mip fitting on the heater end. Through trial and error I discovered that what came on mr lis stove is a .375 mip fitting. I went to had and found a .375 fip coupling and a .25 fip to .375mip fitting that allowed me to make it all play nice. I need to go back and get some pipe dope as it has a bit of a leak but other than that I think it's solved. Now to learn how to use this monster . |

|

|

|

| Jeff Peters |

Posted on 07/21/2014 12:05 PM

|

|

Newbie  Posts: 3 Joined: June 17, 2014 |

This appears to be the official Huky 500 thread, so as a fellow Huky 500 owner I'm going to join in, giving advice where I can (which isn't much at this point) and seeking help when needed. First off, a big thanks to tamarian and frans for their detailed posts here, and to tarmarian for entertaining my many question on his setup (many aspects of which I used in mine) I bought a Huky 500 (my first roaster) about a month ago and have scouring forums all across the internet for build ideas. I'm an enginner by trade so I'm in the process of building the roaster into a sample roasting 'lab' setup. I just fired it up for the first time this week and have much to learn. Here's my garage sample roasting setup: Huky 500: Stock from the very friendly Khuano Li, with the Solid Drum and Extra MET thermocouple options detailed in the very thorough writeup at home-barista: http://www.home-barista.com/home-roasting/exploring-huky-500-coffee-roaster-part-ii-t20532.html Vent tube is mounted to a cyclone chaff separator with a 100 CFM high-temp blower, the output of which is then routed via dryer ducting to the outdoors. Instead of ordering of the infrared LP burner from My Li, I purchased a stand alone 15,000 BTU BBQ side burner, which I dropped into my stainless steel 'lab' table. I also dropped the cooling fan in the table so that the whole setup sits flush and looks clean. Cooling tray exhaust is routed to the outdoors as well via a separate dryer chute. As for burner control and the gas train in general, I built a gas manifold that has a manual 90 degree ball valve in parallel with a Clipper proporional valve (driven by their valve driver). This allows me to apply heat control manually, or automatically via the Fuji PXG PID that I have coming (thanks again tamarian and frans). Currently using Artisan to log (and eventually control) the roast profiles. A few notes about my setup and future upgrades for others that may follow: 1.) tamarian may be able to confirm this, but using a Clippard proportional valve (even the one with the largest orifice diameter of 0.060") may not be the best for low pressure (Natural Gas) use although using it with Propane shouldn't be a problem. While my 15,000 BTU burner is probably overkill for my setup, I approximate that I'm only getting about 200 BTU worth of flow out of it. I currently trying to fix this, but it's going to be a limiting factor in my setup and is going to limit the maximum rate of change of temperature I can induce. Currently looking at Kelly proportional valves that have about 3x the flow rate. More to follow. 2.) Having to detach the (extremely hot) vent tube to add the initial bean charge is defintely a 'kludge' (as others have put it) and requires welding gloves (and some speed) to accomplish without getting burned. While I eliminated 2nd the reconfiguration required at bean drop buy adding the additional cyclone/blower setup, this initial reconguration dance is a but anoying. However, I'm shopping around for a stainless T that I can install between the vent tube and the exhaust ducting so that I don't have to remove the vent tube to charge the setup. More to follow. Setup summarized, going to post some observations and questions in a separate post. |

|

|

|

| Jeff Peters |

Posted on 07/21/2014 12:32 PM

|

|

Newbie  Posts: 3 Joined: June 17, 2014 |

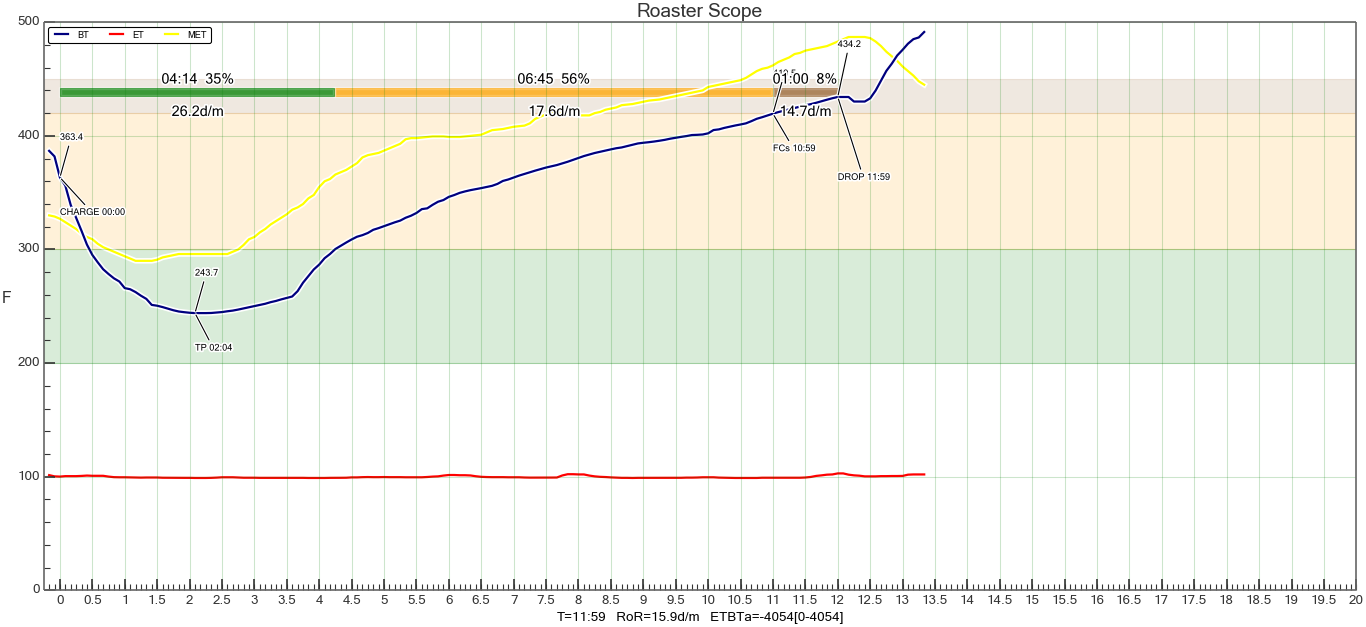

So I'm currently only 6 roasts into evaluating my setup, and have much to learn. For the time being, I'm roasting to characterize my system and the minimum/maximum levels of temperature rise rate that I can accomplish with my setup. At this point, I'm manually adjusting the gas flow to the burner but staying within the range of flow rates that the Clipper valve can achieve. As I mentioned in my previous post, the highest flow rate that the Clipper valve can achieve may be a limiting factor in my setup. My goals with this setup are two fold: first to have fun, and second to use it as a tool to learn how roast profile variation affects the flavor of the resulting coffee. A few things I've noticed immediately about roasting with the Huky 500 are: 1.) To get an accurate (and consistent) BT measurement, I've found that the charge weight probably needs to be 200g or larger. 2.) The amount of thermal energy that the (extremely solid) drum holds is pretty impressive. So as I embark on my journey of roasting exploration, I could use a bit of help from the folks here in the community and other who may also be using this model roaster. My first challenge is in establishing a charge weight, charge temp that results in a turnaround temperature in the ballpark of 200-210F (that is ideal right?) I'm just burning through some inexpensive green coffee at the moment but would like to keep the charge weights down to about 200 grams. Here's my first questions to the community. Other than concerns with tipping/scorching at high initial charge temperatures, does it really matter what this temperature is if the correct turnaround temperature is reached in a reasonable time? As an example, look at the attached profile...be nice, it's literally the third roast I've done in my life....ever (note that currently ET is measure ambient garage air temperature...yes, it's hot in the southwest). Real ET is coming soon once I replace the analog temperature gauge with another thermocouple. MET is the temperature outside of the drum within the roaster. Hopefully I got this nomenclature correct (feel free to correct me if I did not). Ignoring for a minute everything that happens after the turnaround point this appears to the fastest rate / lowest temperature drop I can get in my setup with 200 gram charge (I charged at 400F and turned the burner off entirely). Again, focusing just on the chage to turnaround time, would the suggest here be to lower my pre-heat/charge temperature to 40-50 degrees F to say 350 F? Thanks all for the help.

Jeff Peters attached the following image:

|

|

|

|

| az erik |

Posted on 07/21/2014 6:39 PM

|

|

Newbie  Posts: 43 Joined: January 25, 2013 |

100 degrees ET! You sir are in AZ!! I've never tried anything smaller than 400g's. Even with 525g's (I think it could go to 540g without being terrible temp management) I could still hit a ROR of 30degrees with the Iwanti 15k on 3/4 flame with 50% variac flow to the stock Huky fan. there seems to be a point where you can pull so much heat into the drum that you could possibly tip and scorch but so far I havn't managed to do that. Even when dropping at 550+ ET. I'm dropping 500g's at 430/440 now and getting a much better TP of 200 degrees. just about 5 min to 300BT. I can actually pull that even further down to 4 min if I step on the gas but the woodsy taste isn't very appealing in the cup. With the solid drum and open flame you can really mess around with this roaster to totally change the profile. I'll have to flip on the roaster laptop to get the latest profiles off it. I've experianced a world of difference in roast requirements just by changing beans on the Huky. The Guat I have is hard and doesn't absorb the heat like the same weight of Liquid amber or Monkey Spro. The requirement to bump my flame became obvious once my ROR leveled off at about 16deg between 300 to 375. In my case more fan (convection/air roast) up to 380, then I cut flame and ramp to 90% fan. This causes my ror to spike for a min to about 24-28deg ror. however the internal heat clears out quick and then I back down the fan to drum roast through 1c. Some roasts I just continue on drum heat (providing it's around 400deg or higher) some times I have to refire and drop the fan to about 30%. It's kind of a juggle. If I had a welder or welding skills for that matter, I'd have a different roasting bench for sure  Might just mod up a cart. A cyclone wouldn't hurt at all. Might just mod up a cart. A cyclone wouldn't hurt at all.Hows that for a super long answer  250G load, put the charge temp at 350, hold there until BT hits about 300, you can very easily ramp her but all it's going to take is a bump in ET to 400-450 to get through the rest of the roast. If my Huky didn't read 40C when I open the garage I'd say we should make a day of it and roast enough to drive the neighbors crazy  |

|

|

|

| allenb |

Posted on 07/21/2014 9:48 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote Jeff Peters wrote: 1.) tamarian may be able to confirm this, but using a Clippard proportional valve (even the one with the largest orifice diameter of 0.060") may not be the best for low pressure (Natural Gas) use although using it with Propane shouldn't be a problem. While my 15,000 BTU burner is probably overkill for my setup, I approximate that I'm only getting about 200 BTU worth of flow out of it. I currently trying to fix this, but it's going to be a limiting factor in my setup and is going to limit the maximum rate of change of temperature I can induce. Currently looking at Kelly proportional valves that have about 3x the flow rate. More to follow. Jeff, please place a new thread within this forum titled Huky 500 proportional gas valve or something similar. I'd like to keep this part of your inquiry separate since it might take up a bit of space and I think the discussion this will generate will be very helpful to other Huky 500 owners as well. Interesting topic! I've got a few questions to ask you once you've got the thread started that might allow us to drill down further on the lack of flow issue using low pressure natural gas. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| bean2friends |

Posted on 07/24/2014 8:55 AM

|

|

Newbie  Posts: 9 Joined: September 14, 2010 |

I ordered my Huky a week ago and hadn't heard from Mr. Li, so Yesterday I emailed him just to check to be sure he got my order. He responded immediately that he'd ship as soon as the cyclone passed. I said, Yikes. I don't watch the weather in Taiwan. Ship it when you can. He has been very responsive. I'm really looking forward to this. It's really like getting 2 roasters as I ordered both motors and both drums. I love my RK drum, but now I'll be able to roast in bad weather and also have more feed back on the progress if the roast. |

|

|

|

| Jarett |

Posted on 08/12/2014 4:08 AM

|

|

Newbie  Posts: 2 Joined: August 06, 2014 |

Hi Jeff, if you have time, I'd be intrigued to see some pics of your setup-- sounds fantastic. A couple of questions for you: 1.) Did you purchase your cyclone chaff separator, or did you build it? Can you provide some additional details/specs? 2.) Which model natural gas 15,000 BTU BBQ side burner did you pick up? Are you satisfied with its performance? I am purchasing a second fan for the Huky, and hence will be using one of the fans as a dedicated exhaust. As such, I've asked Mr. Li to fabricate a longer diversion pipe that will allow me to place the exhaust fan\filter behind the roaster (instead of alongside the unit). I'm rather excited to see how it turns out. Should provide for a cleaner operating environment when it comes time to managing the beans. I've also asked Mr. Li to place the Maximum Environmental Temperature (MET) thermocouple in the rear faceplate of the roaster (top-center). This should have the benefit of measuring the max temp (before the heat is drawn through the roasting chamber via the exhaust fan), and at the same time minimizing the clutter and cables sticking out of the front of the roaster. Does anyone have any thoughts as to why this positioning of the MET probe would be problematic? Thanks! --Jarett |

|

|

|

| Jarett |

Posted on 08/12/2014 4:13 AM

|

|

Newbie  Posts: 2 Joined: August 06, 2014 |

Also, what instrumentation are people using to measure their Variacs? I placed an order for a Phidget 4 port temperature monitor -- is there a similarly simple means of measuring fan speed\AC current? --Jarett |

|

|

|

| bean2friends |

Posted on 08/16/2014 4:27 PM

|

|

Newbie  Posts: 9 Joined: September 14, 2010 |

I have my new Huky up and running. I am controlling fan speed with a Variac and am using the Roastmaster app with a Bluetherm Duo which reads out on my ipad. Very cool, lots of information and at first the ipad, rather than the roaster, was demanding too much of my attention. Now, as I begin to understand Roastmaster better and the roaster better, I like it very much. I have 3 thermocouples hooked up, but with the perforated drum, I'm only using the ET and the BT. I also got the extra bowl exhaust hook up and have it hooked up to a Shop Vac hose. I got the stock infrared stove and am using lp gas. I've been roasting 8, 10 and 12 ounce charges. I have it set up in my garage on a card table for now. When the weather turns cold, I plan to move to the basement. Some of the folks here were very helpful in deciding what I needed to order. |

|

|

|

| whattodo |

Posted on 09/04/2014 5:27 AM

|

|

Newbie  Posts: 22 Joined: February 27, 2014 |

I am also interested in Huky. How long does it take to receive? Do you have problem at custom; delay, duty payment etc.? Thanks |

|

|

|

| bean2friends |

Posted on 09/04/2014 7:44 AM

|

|

Newbie  Posts: 9 Joined: September 14, 2010 |

Hi, Here's my experience ordering a Huky: I sent my first inquiry to Mr. Li on 5/28 and got an immediate response. Here it is: The price of Huky 500 is 1078 USD (not including choose appurtenance & shipping fee) Standard appurtenance  iversion pipe,fan,tray,funnel,AC adapter,tool (Attach picture) iversion pipe,fan,tray,funnel,AC adapter,tool (Attach picture)choose appurtenance: 1.Digit thermometer:Artisan supported devices: https://code.google.com/p/artisan/ a.Center 300 Thermometer(Single input)-----58 USD b.Center 301 Thermometer(Dual input)------70 USD c. USB cable(Connecting to a Computer for Win )---24 USD 2.Infrared stoves (with Needle valve & Gas Pressure gauge ) : 96USD 3.Exhaust hood(attach picture)-----------49 USD 4.Extra probe (MET)------------------------15 USD Most buyers choose. 5.Extra tray-----------------------------------14 USD 6.Extra fan------------------------------------40 USD 7.Extra funnel--------------------------------12 USD 8.Extra motor set(Motor,Box,Switch)----78 USD 9.Extra motor---------------------------------18 USD 10.Extra drum----------------------------------98 USD The freight charges By "Express Mail Service is "176 USD" (Can receive in about 4~7days ), You may pay by the wire transfer through banks or PayPal My Paypal account is: Li Kuanho (kuanho.li@gmail.com) After several e-mail exchanges - I was especially concerned about getting appropriate propane connecction - I ordered and sent paypal payment on 7/15. I received my Huky on 7/29 (They had a typhoon in Taiwan that slowed things down a bit). I recall it took about 5 days from the time he shipped to receive it. I did pay the express mail service charge - don't know if there's a cheaper alternative. I did have to sign for it when it came. But no special duties or anything like that. Very simple DickC |

|

|

|

| whattodo |

Posted on 09/04/2014 12:44 PM

|

|

Newbie  Posts: 22 Joined: February 27, 2014 |

Thanks DickC, you helped a lot. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman