Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Background Roast Iss...Skywalker roaster mods

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [374] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 3

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Blower review - does this sound OK?

|

|

| DANE J |

Posted on 03/06/2014 8:29 PM

|

|

Newbie  Posts: 39 Joined: December 15, 2013 |

Hi all I am the design phase of building my roaster and have been reading/posting on here a bit (mostly reading!). So thanks in advance for all your pearls of wisdom. So.. my roaster design (sorry, design diagrams are only scribbled on paper) is a 100mm diam SS roast chamber (I have sourced a 800mm length), and I have 2x2000W heatgun elements. Will control them with appropriate dimmers ("Electronic Thyristor Power Regulators").. not sure if I will mount in series or parallel yet. Regarding air flow, I am thinking a smallish centrifugal blower.. I understand from other threads on here that I'd need around 15-20CFM/pound of bean.. I have found a 64CFM one, but I am just not sure about pressure. I am wanting to roast 2 pounds max at a time, and have both heat and airflow adjustable - the blower I'm interested in has the following specs, does this sound about right?? Power: 57W Air Volume: 110m3/h (this equates to 64cfm if you are that way inclined) Type: Centrifugal Fan Voltage:220V Electric Current Type:AC Mounting  uct Fan uct FanBlade Material:aluminum alloy Current:0.29A Speed:2823 R/min Air volume(max):110m3/h Static pressure(max):880Pa Noise:70Db Weight:2.8Kg I was planning on using a 220V, 1500W garden leaf blower, but 1) it's insanely noisy, and b) it's very high wattage, I don't understand why.. (clearly I didn't pay enough attention to physics at school but I just can't understand why it's such a power hog). Anything else that springs to mind that I may be missing??? Thanks Dane |

|

|

|

| allenb |

Posted on 03/06/2014 9:25 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Hi Dane, Can you translate the static pressure value (880 Pa) to inches water column? This will be the big determining factor as to whether you will be able to loft 2 lbs of green. At .29 amp I'm fairly confident it will not meet the requirements by a large margin. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| DANE J |

Posted on 03/06/2014 9:54 PM

|

|

Newbie  Posts: 39 Joined: December 15, 2013 |

Hi Allen 880Pa = 3.53 Water Column (inch) How does that sound? I am also going to attempt to control the air flow, either with a electronic device ('dimmer' etc) or valve etc. Hoping with this much flexibility I'll be able to roast a wide range of loads. I originally anticipated regularly doing 1kg/2lb loads, but now I am roasting origin beans separately for blends, so probably my loads will be smaller, but nice to have the capacity should I require it  Cheers Dane |

|

|

|

| RoasterRob |

Posted on 03/07/2014 1:33 AM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

Simple answer No. JMO minimum usable pressure is 10" WG. Simple rule 1" per inch of bean mass height plus a few inches to get some loft height. Also remember that the max pressure of any blower is at the minimum flow and vice versa (more or less). If you want a blower that will definitely work use a vacuum cleaner motor. Lofting 2 pounds of green with a 1000 watt VC blower will draw no more than 400 watts because it will be dimmed down to about 40% at which point it's not actually that loud. Rob VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| oldgearhead |

Posted on 03/07/2014 8:17 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

You will need a two or three stage vc motor like this Amtek-Lamb: : http://www.ebay.c...41761c2fe4 ..although the side discharge may not work in you design... they are available in flow-through as well. |

|

|

|

| oldgearhead |

Posted on 03/07/2014 9:31 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

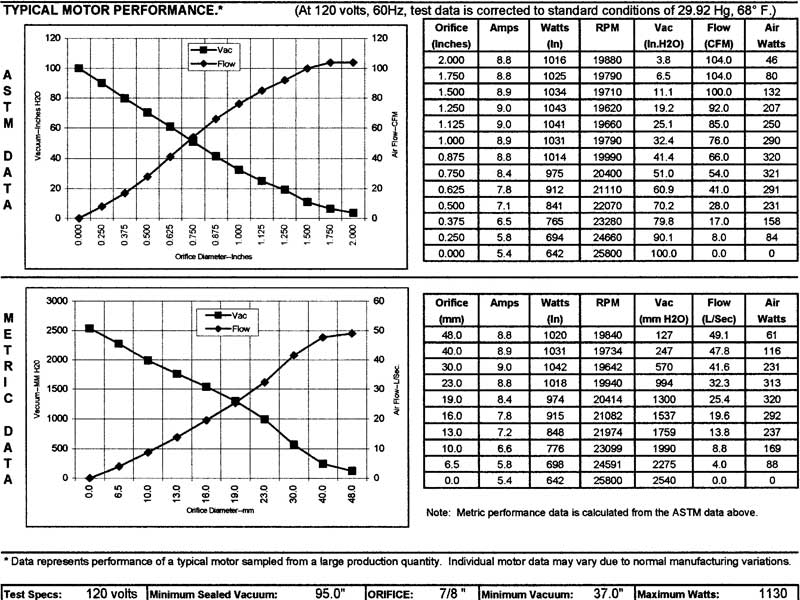

Here is a data sheet for a typical 120V, 2-stage, flow-through vc motor. Note, it's a 100 cfm x 100"H2O design, but as RoasterRob said, not at the same time....

oldgearhead attached the following image:

|

|

|

|

| allenb |

Posted on 03/07/2014 3:22 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote oldgearhead wrote: You will need a two or three stage vc motor like this Amtek-Lamb: : http://www.ebay.c...41761c2fe4 ..although the side discharge may not work in you design... they are available in flow-through as well. OGH, Did you find in practical experience that a single stage vac motor in at least a 5.7" impeller diameter would not be adequate for lofting a 2 lb charge? With my tests, I had to dial my 5.7" single stage down to around 30% for a 1lb charge so I can't understand why a 2 lb charge would cause it to be under powered. Allen Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| JETROASTER |

Posted on 03/07/2014 4:03 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Actually, you can move 2lbs nicely with a 3" single stage. Here's a clip of 2lbs...flowing nicely...with no heat yet! But I would say, the motor OGH posted is easy to work with. Good luck with your build!! -Scott |

|

|

|

| oldgearhead |

Posted on 03/07/2014 4:27 PM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Allen, The 120V, 5.7", 2-stage, flow-through data sheet that I posted is for a robust blower that has performed flawlessly for 33 months pumping 120-150?F air through a ported manifold, not the minimum possible blower for the task. |

|

|

|

| allenb |

Posted on 03/07/2014 4:56 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

You stated Quote You will need a two or three stage vc motor like this Amtek-Lamb: which can lead some to believe they must use something with not less than 2 stages. It's good to have clarity in case someone finds something laying around in a single stage that they might be able to include in their design. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| DANE J |

Posted on 03/09/2014 5:59 PM

|

|

Newbie  Posts: 39 Joined: December 15, 2013 |

thanks guys for the info. Glad I found out I was barking up the wrong tree before buying a motor. I have a spare vacuum cleaner here which I will pull apart and look at suitability. If not, will buy a replacement one such as OGH mentioned. Thanks all! |

|

|

|

| oldgearhead |

Posted on 03/10/2014 9:04 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

The two main reasons I need the large (5.7"/2-stage) vc motor: 1) Manifold is ported for higher RPM's. 2) Cooling is performed in the RC at 85% full vc motor speed. |

|

|

|

| DANE J |

Posted on 03/11/2014 2:02 AM

|

|

Newbie  Posts: 39 Joined: December 15, 2013 |

ok, I salvaged a motor out of our old vacuum cleaner (1500W) [img]http://postimg.org/image/wgbfqull9/[/img] (http://postimg.org/image/wgbfqull9 if the image doesn't show - and ahem.. apologies for the advertisements!) Now obviously the air enters at the top port in this picture. And from the research I've done it looks like these sorts of motors can't really be reversed. So would it be sufficient to just put it upside down and (ensuring everything's airtight), have this sit 'below' the heat gun elements? Will this create the sufficient pressure below the beans to cause them to loft?? It's taking a while for me to get my head around pressure vs just direct air flow. Or should I ditch this motor before investing too much timing building a manifold/bracket for it? Thanks Dane |

|

|

|

| oldgearhead |

Posted on 03/11/2014 8:32 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Dane, Yes, that is a normal single-stage, flow-through, vacuum motor/blower assy. No you don't need to reverse the motor. Just mount it in an enclosure that contains the air. I used a spa blower boot, but most just fab something..

oldgearhead attached the following image:

|

|

|

|

| RoasterRob |

Posted on 03/12/2014 4:23 AM

|

|

1/2 Pounder  Posts: 330 Joined: March 03, 2007 |

Quote So would it be sufficient to just put it upside down and (ensuring everything's airtight), have this sit 'below' the heat gun elements? Will this create the sufficient pressure below the beans to cause them to loft?? Sufficient flow and pressure to blow a kg of coffee into the rafters of your garage if you start it on full noise. I am lofting 6.5kg with one 1400watt VC blower. Yes that was Kgs. Rob VBM Minimax 2gp, 1gp Reneka Techno, 2 gp la Pavoni Pub, la Cimbali M28, SJ Maz, FB 6kg HM roaster and other stuff

|

|

|

|

| Thermobaric |

Posted on 03/13/2014 2:42 AM

|

|

Newbie  Posts: 2 Joined: March 07, 2014 |

Gents, Thanks for the info. I've been reading everything and posting nothing, but I've outgrown my Poppery II and am working on an AFB roaster. I managed to salvage an abandoned VC motor at 1440w, and it just seems sooooo tiny. 6.5KG is way more than I'll need anytime soon, so I thank you for your time and words. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman