Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

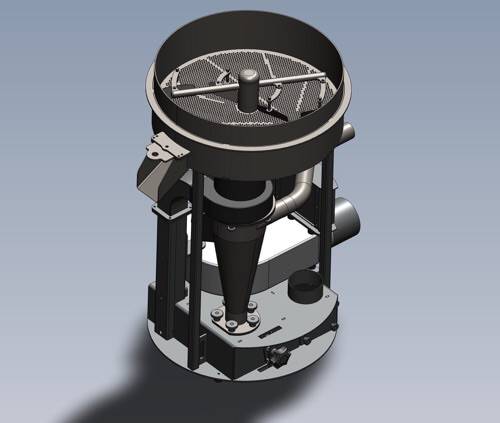

Cooling Tray attempt

|

|

| broeker |

Posted on 11/16/2014 4:17 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

So my parts have started arriving for my cooling tray & chaff collector........ So far so good.........

broeker attached the following images:

|

|

|

|

| chimpy74 |

Posted on 11/16/2014 5:15 AM

|

|

1/4 Pounder  Posts: 51 Joined: June 18, 2014 |

that's some pretty cool looking engineering!! |

|

|

|

| Omega |

Posted on 11/16/2014 10:53 PM

|

|

1/4 Pounder  Posts: 132 Joined: June 13, 2014 |

Wow! That's what I call top-shelf, excellent fabrication. Very impressive.  Barry |

|

|

|

| Mad Mac |

Posted on 11/17/2014 2:14 AM

|

|

1/4 Pounder  Posts: 55 Joined: October 25, 2014 |

Looks like excellent metal works. However I don't understand how it works or where it will be situated. |

|

|

|

| broeker |

Posted on 11/19/2014 4:31 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Thursday night update :-) Got the chaff cyclone tacked up :-)

broeker attached the following image:

|

|

|

|

| Lawnmowerman |

Posted on 11/19/2014 1:49 PM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

In reply to post from Mad Mac: this is a larger version.

Lawnmowerman attached the following image:

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

| broeker |

Posted on 11/20/2014 5:06 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Quote Exactly :-) mine will also have the chaff cyclone under it.... |

|

|

|

| broeker |

Posted on 11/20/2014 5:08 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

This shows a little more of my design :-)

broeker attached the following image:

|

|

|

|

| baysidedweller |

Posted on 11/23/2014 2:19 PM

|

|

Newbie  Posts: 20 Joined: August 15, 2013 |

broeker: cool contraption! I also looked into cyclone but decided to use the attached instead due to simplicity. The contraption I built is a bit amateurish but it works very well. I have attached a photo of the key parts only. The bean basket is slid-able and the reason why the suction head has so many holes and grooves is to control the bean flow into the basket, thus controlling the cooling while sucking the bean into the basket. The reason why there is a paper on the head is I drilled too many holes and the bean flow slows to a crawl. So I reduced the airflow from the sides and thus increases the bean flow. There is a post in home-barista about positive and negative air flow during roasting and I commented that I find cooling under negative pressure reduces the undesirable flavors.

baysidedweller attached the following image:

|

|

|

|

| broeker |

Posted on 11/24/2014 4:10 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Bay sided.... Your rig looks sweet!! Well fit for purpose:-)...... I need to collect chaff from 50-60 kg per day so hopefully have sized it properly... Fab is progressing.... Had to add a 4" butterfly valve I didn't count on :-(

broeker attached the following image:

|

|

|

|

| Lawnmowerman |

Posted on 11/24/2014 12:25 PM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

Breoker: this build is beautiful. It's inspired me to put a stirrer on my cooler. It really doesn't need it. But I wanted one anyway. I'm going to make it removeable and set on top of the cooling tray. For ease in building. Then,since I won't be able to dump the beans in with a can opener motor on top, I will install a hopper. It's gonna look weird, but so do ALL my roasting related contraptions.

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

| allenb |

Posted on 11/24/2014 7:24 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

If I was very well off financially I would seriously plead with you to build me a custom drum roaster. You are incredibly talented and do remarkable fabrication and machine work! Make sure to post photos of the whole setup when its all running as a package. Wait a minute, I just noticed something on your cooling tray. Is that a trailer hitch ball above the dump chute? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| broeker |

Posted on 12/03/2014 4:06 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Thank you Allen :-) Its more my location here in New Zealand that's a barrier than money :-) the sharing of ideas has been awesome... I now have it all running....... It's workes really well :-) some mods on the arms but now it rapidly cools 5kg and clean sweep all the beans down the chute. I'm working on the shroud now ( a crusty 44 gallon drum) (I'm purposefully making the cover "rustic" (I could make it super crispy & stainlesss if I wanted... I'm going for the rat rod look)) It is indeed a trailer hitch... If u pull on it the bean chute opens... One of my brothers has a forge so made two skull heads from hitch balls.... The other one is on the top on the dump handle on the roaster..... Going to run some bulk kg's through it tomorrow and evaluate things..... 2.0 is happening :-) |

|

|

|

| broeker |

Posted on 12/03/2014 4:08 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Update :-)

broeker attached the following images:

|

|

|

|

| broeker |

Posted on 05/16/2015 6:05 PM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Hey guys.... So in my setup I've got both combustion/air & chaff going up the chimney as well as cooled air being sucked down through the cooling tray...(when in use) My questions is..... How much chaff comes of the beans in the cooling tray? The reason I ask is I'm getting chaff coming out the chimney and am trying to decide if my cyclone isn't working (combustion side) or if I also need a cyclone on the cooling tray side....... What do u think? |

|

|

|

| allenb |

Posted on 05/16/2015 10:02 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I get a small amount of chaff through my cooling tray from each roast but it's not much. I guess after 10 or 20 roasts it could amount to a handful but I'm doing 1 lb roasts. Many commercial drum roasters run their cooling tray exhaust through the same cyclone as the drum exhaust to collect it all. Can you run both through your cyclone without major re-ducting? To test your cyclone as it's set up now, place a piece of window screen downstream of it to see if anything is getting past it. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Lawnmowerman |

Posted on 05/16/2015 10:21 PM

|

|

Pounder  Posts: 546 Joined: March 14, 2012 |

Broeker: the roaster where I buy most of my beans has just had installed, (thank you epa), a post -cooler cyclone. He has a 150 pounder I believe, but scale really doesn't matter, I think. If a big roaster let's some chaff past, it's to be expected that a smaller one would also, right? Ben.

Bad coffee prevails when good coffee roasters stand by and do nothing.

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman