Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 4

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

sinner7's 5-7kg Fluid-bed in the works...

|

|

| sinner7 |

Posted on 01/20/2015 11:05 PM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Hello all, I've been a forum lurker for a while now and have decided to document my 2nd roaster build. I've been roasting on my galloping gourmet for a few years and I'm ready for a bigger hobby. Another chimney fluid bed design similar to roaster rob's designs. Though mine is called the hexa- roaster for the shape of the chamber hexagon. Here is the chamber rough welded. I'm working with a local welder and fab shop to fab the steel parts. I'm buying and fabricating parts as I can afford it so it'll be a while to complete it. The picture of the roast chamber is upside down.

sinner7 attached the following image:

Edited by ginny on 04/06/2015 4:15 PM |

|

|

|

| sinner7 |

Posted on 01/20/2015 11:15 PM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

I've ordered the sievert 2941 and read that it's rated for 2bar pressure (30psi). Rob is stated he's maxing it out at 4bar (60psi) for 7kg. Anyone else blasting it that much? I could order a 2942 for cold weather MN, not sure if it's needed for 5-7kg. Also need to pick a vacuum motor to loft 5-7kg...thinking about these based on forum posts: AMETEK-LAMB-116765 - 3stage or Ametek-Lamb-115334 2stage Any thoughts on these moving 7kg? Thanks for the tips, I'll post some more pics soon. Aaron |

|

|

|

| JETROASTER |

Posted on 01/21/2015 8:39 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

I think you'll have better results from the 115334. Cheers, Scott |

|

|

|

| JETROASTER |

Posted on 01/21/2015 2:48 PM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

I've gone through both spec sheets. Generally, the 3 stage(w/5.7" fans) will provide higher pressure, the 2 stage (w/7.2" fans) will provide better flow. Given the design path it looks like you're taking, I feel the 7.2" will serve you better(at operating pressures below 28" H2O) If you start operating at back pressures above 28" of H2O, then the 3 stage starts to become more effective at maintaining airflow. I can send the specs if needed. Cheers, Scott |

|

|

|

| sinner7 |

Posted on 01/21/2015 3:21 PM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Thanks for the suggestions Scott. I haven't wrapped my brain around the water pressure spec yet. Is that force needed to lift certain amount of water 28"? My furnace chamber will have a rough diameter of 6" (hex shape) and roughly 30" height. The perf plate will be a hex shape too about 3" diameter. So...how many kg are you pushing with your chamber/perf size? You are using a 7.2" 2 stage correct? I'm planning to test different perf plates to find the sweet spot pressure/flow. I think Rob said his 6" furnace produced good pressure/flow. Has anyone tested a pressure gate versus a variac to adjust pressure? Maybe a balljoint valve release vent? Probably be a lot more noise, maybe a muffler would help. Be nice for simplicity if it was effective.

sinner7 attached the following image:

Edited by sinner7 on 01/21/2015 3:26 PM |

|

|

|

| JETROASTER |

Posted on 01/23/2015 10:50 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

Hello, Quote How many kg are you pushing with your chamber/perf size? 10lb (4.5k) Single jet, 1"diameter, w/ stainless mesh Quote You are using a 7.2" 2 stage correct? Yes, ametek 115334, in an enviroment that is likely more restricted than the design you're considering. Quote Has anyone tested a pressure gate versus a variac to adjust pressure? In the past I used a manual gate valve to dump extra pressure. Currently, my machine is very much "set it and forget it". Hope this helps. Cheers, Scott

JETROASTER attached the following image:

|

|

|

|

| sinner7 |

Posted on 01/27/2015 12:56 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Thanks for the info. I'll probably pick up 115334 too, does $124 shipped seem ok for a online price? Still considering the manual pressure valve. I've posted a video demo of my 2941 setup. I could only get 30psi (want to test 60) but it's a pretty nice torch. Can't imagine running it at twice the pressure in the video (rob said that's his max 4bar 60psi). Kind of like watching a techno campfire  On to the vacuum motor soon... |

|

|

|

| JETROASTER |

Posted on 01/27/2015 9:38 AM

|

|

Administrator  Posts: 1780 Joined: March 06, 2010 |

124.00 is a very good price. Before you order; Confirm that it is in stock. Beware of any wording that allows the vendor to use a "suitable replacement". Looking forward to your progress! Cheers, Scott |

|

|

|

| sinner7 |

Posted on 04/06/2015 10:16 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Ok, picked up my other stainless this weekend and started cutting parts for my furnace and base. The attached image shows the big parts stacked without the mounting plates between them or small pieces like feet etc. Hope to get the parts to the welder this week. This is my first big metal working project, fun but loud and messy. Up next, testing perf plates and bean cooler design.

sinner7 attached the following image:

|

|

|

|

| sinner7 |

Posted on 04/24/2015 10:27 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Well time for a few updates, I've been madly building my roaster and not documenting along the way. If people want to see something just ask. I removed my previous video because the crappy soldering didn't hold up, I had to have the torch head welded/brazed to a brass fitting. My welder (new friend) did an amazing job. I cut and prepped as many parts as grinder wheels would allow and had them welded and buffed everything at home. My grinder skills have increase to level 9 for sure  Originally I planned the hex chamber to be the bean hopper, that's where the 5-7 kilo number came from. After testing pinto bean lofting with the shopvac, I decided to flip the design and use the hex tube for the furnace section and 6" pipe (rob style) for a starter chamber. That way I'd have few surprises in performance and more manageable roast size. Here's a enhance smokey roaster portrait: Yes, it has handle bars  Too hot to ride though.. Too hot to ride though..

sinner7 attached the following images:

|

|

|

|

| sinner7 |

Posted on 04/24/2015 10:56 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Using green beans I could loft/roll 9lbs or 4kg with no problems except my bean chamber isn't tall enough to hold that much roasted! So that's a good problem. I roasted 5lbs green/4lb 5oz roasted last night at 3am after finishing my blower box. Only having a manual grill thermometer at this time, I had to establish a base line for gauging bean temp. I put the probe on the air side of the hopper. I'll probably add another to the opposite side too. My hope is to keep this roaster simple and manual and develop my site/smell/gauge skills to profile manually. So I dumped just after the 1st crack about 14:00min. I wanted to be closer to 2nd crack so I put them back in for another 2 mins and ramped the heat up. Relying on my grill therm I think the reading was a little low compared to actual bean temp. I'll use a little more heat next time. The roast was very even considering it was remnant beans of different orgins. My target is about 13 min to 2nd crack, I know it's possible because my first test was 1.2lbs and it was french in 3:30 hehe. Thanks to all those who shared their proven ideas especially roaster rob and the other fluid bed peeps. This setup is quite an upgrade from my galloping gourmet. I had to turn off my security flood lights when I went to bed because the smoke was still seeping from the garage door! Didn't want the neighbor to call the fire dept when he left for work ha. I'll have to let him know what I'm up to. Question: If the forced air is 300 degrees, can the bean mass exceed 300 degrees? Seems like it could if the mass holds the passing heat, not sure? |

|

|

|

| sinner7 |

Posted on 04/24/2015 11:02 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Now if they will just pass the MN cottage food amendment HF910 I'll be in business, I never felt so compelled to write my representatives that don't seem to represent. In the meantime my family and friends will have plenty of good beans to brew. good times, good coffee |

|

|

|

| sinner7 |

Posted on 05/31/2015 11:19 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

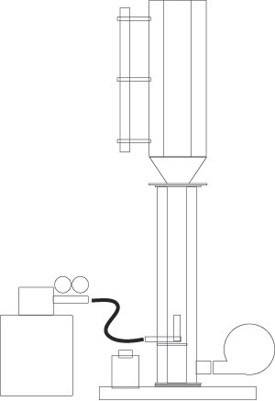

Here's a picture/diagram of the working roaster. I've roasted about 60 lbs so far and it works great. Starting to cup samples along the way learning the light and dark variation of flavors. I favor full city lately as most seem to enjoy a little darker. I know there is another side to lighter roast flavors. They seem enjoyable and sweet/sour in a good way. Still planning future innovations like chaff collector and maybe a trailer to house everything, thinking mobile. grind and brew.

sinner7 attached the following image:

|

|

|

|

| oldgearhead |

Posted on 06/02/2015 9:23 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Quote sinner7 wrote: >snip< Question: If the forced air is 300 degrees, can the bean mass exceed 300 degrees? Seems like it could if the mass holds the passing heat, not sure? The method I use to measure the heated air temperature is to set the blower voltage to one-third of the voltage required to loft the beans, then measure the temperature with no beans. Every test I've attempted with beans seem to be influenced too much by the beans. Another, more precise, way is to read the flow rate above a batch of fluid, slow-moving, beans, then set the 'no bean' blower voltage to achieve that flow rate...I control my fluid-bed roaster with blower speed only and I preset the heater based on ambient conditions, bean test weight (or %M), and bean type. My heated-air is normally in the 470-525 degree F range. No oil on my beans...

|

|

|

|

| allenb |

Posted on 06/02/2015 8:01 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote sinner7 wrote: Now if they will just pass the MN cottage food amendment HF910 I'll be in business, I never felt so compelled to write my representatives that don't seem to represent. In the meantime my family and friends will have plenty of good beans to brew. good times, good coffee I looked at some of the wording in the bill. Looks like they're looking to raise the max annual $ amount of sales to higher than $5K? Something I saw that seems like a real infringement if this is in the bill as passed: "(d) If the food is not prepared in a kitchen that is licensed or inspected, the seller must post a visible sign or placard stating that: "These products are homemade and not subject to state inspection." Do you know if other states have similar requirements? Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 06/02/2015 8:18 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

On the question of if the bean mass temp can exceed the incoming convection air temp? No it cannot unless the beans ignite. Its unfortunate that probe placement in fluidbeds is such a pain but such is the case with most and requires a lot of experimentation. I've found the best bean temp probe location in most of my builds to be around 1/4" from the side of the RC wall (opposite from the incoming air side) and either a few inches above the spouting level or slightly above the static green coffee level. Obviously this location would be based on a most-used batch weight. BTW, great looking build! Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| sinner7 |

Posted on 06/11/2015 10:22 PM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Yes the "cottage food bill" will increase the "non-potential hazardous food" sales from 5,000/yr to 18,000/yr. Currently only farmers markets and special events are legal venues for sales. The new bill will allow sales direct from home and internet orders (still have to deliver in person.) MN is one of the worst (restrictive) states about this crap. I'm not even sure the law will include roasted coffee yet but the dept of ag did confirm that roasted coffee is "non-potential hazardous food". The repro's are fighting about budget bills this week and the food bill is rolled into one that was vetoed but word is it will pass by the end of the month. Yet to order a digital temp probe, I really only need it to document an exact dump temp for profiles. Will post more updates then. My look, listen and smell profiles are producing very good coffee and several repeat drinkers  good times good times |

|

|

|

| allenb |

Posted on 06/13/2015 8:41 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

We'll keep our fingers crossed that it passes and that the commercial sellers don't have too much sway the other way. If it continues to go the wrong direction I can see a time coming where the little girl selling lemonade in our neighborhood gets surrounded by SWAT with bull horns and uzi's. Quote I'm not even sure the law will include roasted coffee yet but the dept of ag did confirm that roasted coffee is "non-potential hazardous food". Well, some coffee I had a few years ago at a local Starbucks could have qualified for a hazardous food designation! Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| casualsteve |

Posted on 07/05/2015 12:40 PM

|

|

Newbie  Posts: 1 Joined: March 31, 2015 |

This is a great looking build. I am working on one of my own that is of a similar design and will be using the same vacuum motor. What did you use for the hose to connect to your furnace? What did you use for that fitting as well? |

|

|

|

| sinner7 |

Posted on 03/23/2016 11:54 PM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Long time no post. The air hose is just a shop vac replacement hose from menards with rubber plumbing fittings. Roasting is going very well. I started my little side biz last sept 2015 and joined an indoor farmers market for the winter. I'm selling at the final market this sat. for the winter season. I'll be selling at two more markets on weds from may to oct 2016. I've sold about 400 lbs in 8 months or so. Here's my website: drogojoe.com I also had a story about my biz on cable access that will air in april 2016. That was pretty cool. I'll post some more pictures of my stuff soon. |

|

|

|

| sinner7 |

Posted on 03/24/2016 12:02 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

Some pics.

sinner7 attached the following image:

|

|

|

|

| sinner7 |

Posted on 03/24/2016 12:05 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

roaster and cooler tray.

sinner7 attached the following image:

|

|

|

|

| sinner7 |

Posted on 03/24/2016 12:06 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

gas feed

sinner7 attached the following image:

|

|

|

|

| sinner7 |

Posted on 03/24/2016 12:06 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

cooler tray. and coffee

sinner7 attached the following images:

|

|

|

|

| sinner7 |

Posted on 03/24/2016 12:08 AM

|

|

Newbie  Posts: 22 Joined: May 27, 2014 |

propane warmer. january in mn.

sinner7 attached the following images:

|

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman