Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 10

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

Anthony's Coffee Machine

|

|

| AnthonyD |

Posted on 03/22/2015 11:32 PM

|

|

1/4 Pounder  Posts: 79 Joined: March 16, 2013 |

Yea, I knew some types of tubing give that plastic taste, especially the cheap clear kind. I'll have to experiment with a few types to find one that works. I think my espresso machine uses John Guest tubing for the steam and water lines. |

|

|

|

| ginny |

Posted on 03/23/2015 9:38 AM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

looking great Anthony... nice work. ginny  |

|

|

|

| turtle |

Posted on 03/23/2015 4:29 PM

|

|

1 1/2 Pounder  Posts: 652 Joined: November 06, 2013 |

Looking good. stainless steel tubing with a flare connection would be your best bet for taste followed by copper and brass tubing (also flared). Mick - "Drinking in life one cup at a time"

"I'd rather be roasting coffee" Roaster 1: San Franciscan SF-1 Roaster 2: Hottop B-2K+ Roaster 3: 2 kilo Chinese drum Grinders: Mazzer Major - Forte BG (x3) Pour over: Hario - Bee House - Chemex - Kalita - Bodum Drip: Bunn CWTF15-1 & CW15-TC (commercials) Espresso: Pasquini Livia 90 auto Vacuum: Cona - Bodum Press: Frieling - Bodum Colombia |

|

|

|

| AnthonyD |

Posted on 03/29/2015 6:09 PM

|

|

1/4 Pounder  Posts: 79 Joined: March 16, 2013 |

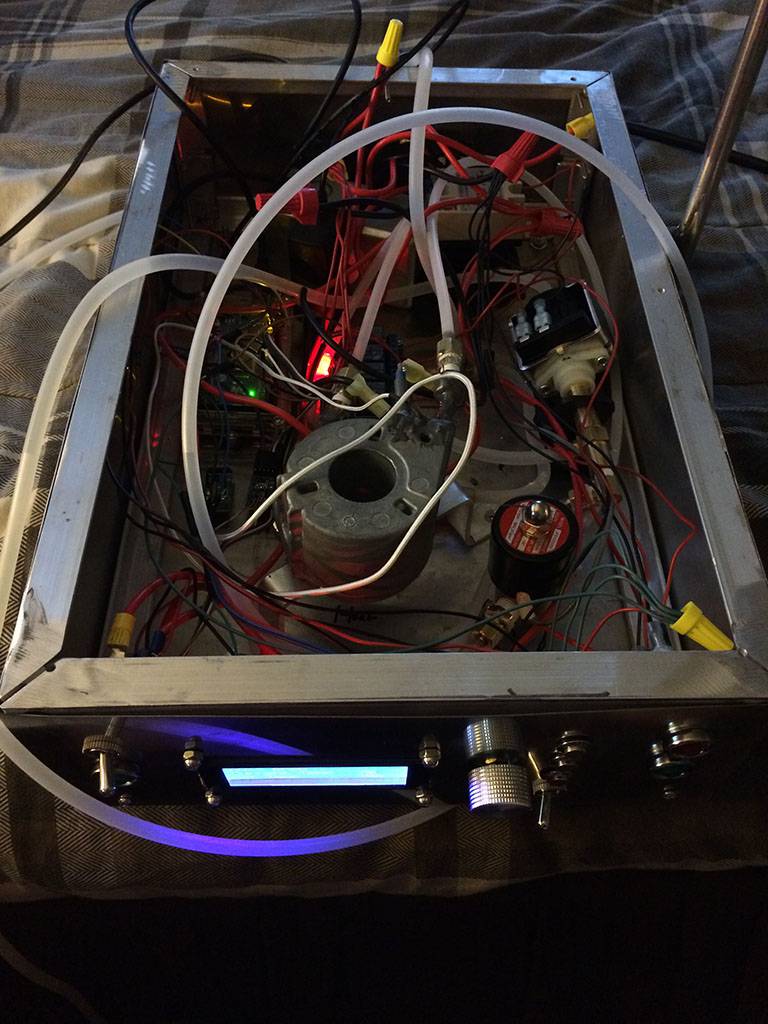

Update! I welded the basket mount this weekend, the 308L-16 electrodes worked pretty well for the stainless. My welding skills still need work, haven't welded since I built my roaster last year. When I welded the ring it slipped out of center. But it looks ok while the basket is in. Also did a pressure test today and had a couple of leaks so I resealed everything. Cracked the jb weld trying to tighten the fitting so I will have to wait till tomorrow to do another test. I ordered a tubing bender but it wont be in for another week. So I am using some copper and elbows for testing. When I was working a peacock, decided to visit. I never seen one around here before. I am using polyethylene pipe in the tubing. I decided to not run copper/brass/stainless pipe for the water line as advised for taste, because I am afraid I would lose to much heat. Cheers!

AnthonyD attached the following images:

Edited by AnthonyD on 03/29/2015 6:18 PM |

|

|

|

| AnthonyD |

Posted on 12/06/2016 12:34 AM

|

|

1/4 Pounder  Posts: 79 Joined: March 16, 2013 |

Hi Everyone! I finally got around to finishing my coffee machine! I was running into issues with how to handle pressure build up while heating the water. And it took me a while to source a normally open solenoid valve rated for the temperature (and within my budget). Now the output from the heater goes to a tee and then a normally open valve that goes back to the reservoir, and a normally closed valve that runs to the basket. I only have one thermocouple on it right now so I had to manually calibrate it so the water is ~205F while brewing. The heat coil cannot handle heating the water on the fly to brew temp so it brews in cycles. A link to the photos http://imgur.com/... And a quick vid of it brewing: https://www.youtu...LmUJTphgqI Well it's not quite done, I still have some adjustments to make and need to calibrate the flow rate for measuring the batch. Also need to bend the tube going to the the brew basket a bit more so its centered. I shimmed it for now. But it brews! Cheers!

AnthonyD attached the following images:

Edited by AnthonyD on 12/06/2016 12:49 AM |

|

|

|

| oldgearhead |

Posted on 12/07/2016 6:10 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

Wow! Nice job! It looks like you are using a commercial brew basket. Are you using a commercial spray head as well. I noticed a dramatic improvement when I replaced the shower head with the latest version. About the only thing I would change is the carafe. I have learned to like the glass-lined air-pot type of carafe, because they are very good at keeping the product hot for hours... No oil on my beans...

|

|

|

|

| AnthonyD |

Posted on 12/07/2016 3:12 PM

|

|

1/4 Pounder  Posts: 79 Joined: March 16, 2013 |

Yes, I am using a commercial basket and spray head as recommended by everyone earlier in the thread. Spray head: https://www.amazo...00HNQ91U4/ Basket: https://www.amazo...008DVGJGC/ (found it cheap on ebay) I was thinking about switching to one of those vacuum carafes. I originally went with glass so I could watch it brew. I could also raise the heater to contact the top panel to keep it warm. I also forgot to mention I originally had issues connecting to the heater because of the metric threads. So cut them off and flared them so I could connect a silicone tube with a hose clamp. I got the flaring tool cheap from harbor freight. It was a cheap fix with no leaks. |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman