Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Help Mod'ing thermocouples/temp readings

|

|

| Turingalad |

Posted on 06/20/2015 11:36 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

I've got a Mastech 6514 with basic K-type Thermocouple (TC) wires (exposed, no shield, just whatever wrap comes with). Main concern: ...after one roast, my TCs looked severely charred. My drum roaster ET gets above 650?F (working on vent system to possibly decrease ET), is this a problem? Wondering if I can DIY a heat shield/wire insulation/convert the naked wires to a probe. If so, what materials should I use? I've thought about copper (I have copper tubing and sheets). Would aluminum/tin foil tape just melt off? Do I need to worry about my TC making contact with other metals (copper, aluminum, steel)--will this affect temp reading or cause other electrical issues? (Last resort) Should I just buy a shielded probe, and if so--Advise on best bang for the buck? |

|

|

|

| ginny |

Posted on 06/21/2015 8:13 AM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

for me I would always use shielded probe. just makes more sense and typically you would have zero worry. ginny let us know,  |

|

|

|

| turtle |

Posted on 06/21/2015 9:06 AM

|

|

1 1/2 Pounder  Posts: 652 Joined: November 06, 2013 |

What type of roaster? A photo of your installed probes would help. I've always used shielded cable probes but depending on your installation it may not be necessary (i.e. the cables are external to the roaster)

Mick - "Drinking in life one cup at a time"

"I'd rather be roasting coffee" Roaster 1: San Franciscan SF-1 Roaster 2: Hottop B-2K+ Roaster 3: 2 kilo Chinese drum Grinders: Mazzer Major - Forte BG (x3) Pour over: Hario - Bee House - Chemex - Kalita - Bodum Drip: Bunn CWTF15-1 & CW15-TC (commercials) Espresso: Pasquini Livia 90 auto Vacuum: Cona - Bodum Press: Frieling - Bodum Colombia |

|

|

|

| Turingalad |

Posted on 06/21/2015 7:05 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

I'm about to test a couple homemade shields/probes to cover the exposed wires. Hoping to take a manual BBQ thermometer, cut off the top, and use the long, pointy sheath to cover my wire. I'm hoping for great things, but expecting interference. I read somewhere that additional metal shielding needs to be "grounded". I guess we'll see. I'm also going to play with copper tubing , without interfering too much with response times/accuracy. I'll provide photos after testing. If someone reading this within the next couple hours wants to warn me against any of this, please do so. I'm no electrician and have no idea what will happen. |

|

|

|

| Turingalad |

Posted on 06/23/2015 12:01 AM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Last night?s roasts were? rough. Very short story: I?ve had to make vent system, roaster mods, etc, completely from scratch that I find on a friend?s property? which is like a junk-yard meets Habitat For Humanity? on steroids. Hoping to soon have the means to do a more legitimate job. Meanwhile, what works works. Short story: - My BT probe was getting decent reading (roughly >20?F than what the actual internal BT is during roast?according to Sweet Maria?s https://www.sweet...gree-roast ) - Probably just need to invest in a couple good quality TC probes for my Mastech? advice that won?t break the bank? - Advice on controlling RoR with a vent, manually controlled flame, and (apparently) sensitive TCs? (My Artisan graphs are all over the place.) Is there a way to keep flame even and control heat/RoR strictly from the vent, or vice versa? Is there a rule of thumb on keeping steady rise when adjusting vent and/or flame? Long story: I used the sheaths/probes of a couple manual BBQ thermometers (like this https://images.du...pg&f=1) ?broke off top and stuck my TC wires in them. The steel that my machine is made of is pretty thick and gets extremely hot, because there?s only one layer to my machine and the outside walls are in direct contact with the ET inside. No heat-shield buffer. Should I make one?? I placed the BT probe in the bean chute (like most roasters). I bent it to get down in the drum without hitting the mixing fins. ET is in the back, top-left corner (same placement as the manual thermometer on the front, that was already installed in my machine when I got it.) ET reads >200?F higher on my TC probe in the back of the machine VS. manual thermometer on front (see pics). Both are in same place. The difference is it?s making contact with the machine itself, thus heating the sheath from both internal temp AND the metal of the machine?? Add?l issue: In some cases during roast when I crank up my vent fan to full speed, the BT increases while ET decreases. At least for a bit, before everything starts to cool. Is this normal? Another thing I need to do ASAP is get a T joint with cut off valve so I don?t have to physically replace the bean chute funnel with the vent tube every time. Pics link: https://drive.goo...authuser=0 Notes on pics A? I forgot to turn on vent, so no airflow, and the reason why the RoR looks decent. B? I remembered to turn on vent. Couldn?t seem to get a steady rise. The 1C straggled, with occasional pops for about 6 minutes (9:30-15:30), then 2C suddenly came on hard. C? after one test roast, my wire looked like this. Is that normal/will it affect reading? D/E/Ee? yes, my vent system is hokey! But very much Beta phase. Now that I know it works, I?ll invest in more legitimate venting. I like my cone/dog bowl/blower though  Eee. My vent control only has 3 working settings: Full (+/- 3200rpm), less than half, and barely on at all?advice on getting a good control for blower? G/H? Advice on probe placement? I/Ii? manual temp vs auto temp readings (+/- 200?F) J. Why is there spiking? Luckily Artisan smooths this out after roast, but still?? Zzzzz. Companion. :-) |

|

|

|

| Turingalad |

Posted on 11/02/2015 11:55 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

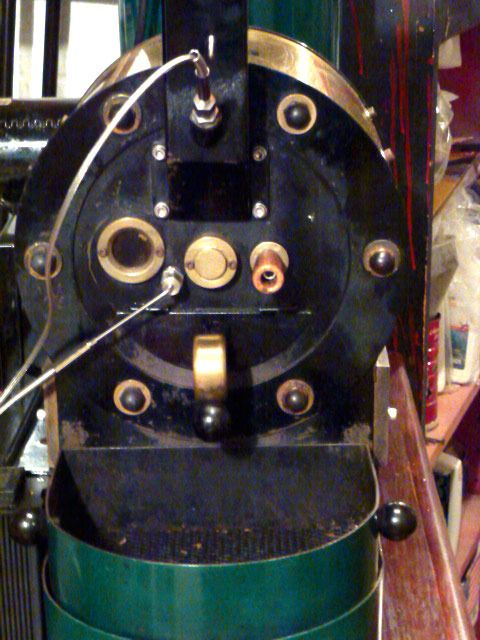

It's been a while, and I've since built a chaff collector/air flow vent, and purchased new thermocouple probes (just arrived in the mail today! WAHOO!!) Needing assistance installing the new probes in the most efficient place, and calibrating (is that the right term?) their readings to create a more accurate curve. My K-type probes are... 5mm diameter 5cm long 6.7mm thread Grounded 5mm diameter 10cm long 13 mm thread Ungrounded Not sure if it's gonna be a problem that one is grounded and the other isn't . (I understand that grounded reads more erratic, and ungrounded is more slow-and-steady.) Since these probes were cheap, I was hoping to get a feel for the 2 different types, and play with interchanging them between BT and ET to see which gives better results. Anyway, I'm looking for advice on where to place them, and which length/type (5cm grounded vs 10 cm ungrounded) is better suited for which reading (BT vs ET). Turtle, My machine: Custom/home-made (not by me) 1k capacity, stainless solid steel drum with mesh back. It's pretty much a thick, square metal box--like a heavy duty smoker) (Pics/details about my machine are in my older post above.) I mentioned to a roaster friend that my current ET thermometer is at the far top corner of my machine (see pics) and they said it may not be reading a true Environment Temp. Any thoughts there? Should I be trying to get closer to the back of my drum where the heat enters? Also, when I get a negative ("-") reading, does this mean I hooked the wires up backwards? ...I'm gonna go reverse them and see if this changes. Thanks! Having trouble attaching photos. Until then, here's a link to some photos https://drive.goo...=drive_web |

|

|

|

| ginny |

Posted on 11/03/2015 2:16 PM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

curious, did you get help with your first questions and problems?? just curious... ginny  |

|

|

|

| Turingalad |

Posted on 11/03/2015 3:11 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Ginny, Not here, I did some research and talked with a roaster friend who said I needed to just get any metal probes to start. So I got the ones listed above, sold by uxcell on amazon for $8-$9/ea. I tesyed them last night and found that the red wires are actually positive (at least on my datalogger) contrary to all the research I did which said red is negative. Oh well? :-P Hoping that when I install them I'll get more accurate readings on the Artisan roasting software. Still seeking help with probe placement. Should I but BT close to the shaft? It's a 5 CM length, with little to no room for adjustment. And ET is too long (10cm) to stick in straight, so I think I'll have to angle it if I want it close to the back of drum. Is this optimal placement? I also want to find a way to manually input my gas/heat adjustments, as well as airflow adjustments, mid roast. May need an Artisan expert to help...? It would be great is I could create buttons to click as I manually adjust these factors. |

|

|

|

| ginny |

Posted on 11/03/2015 4:05 PM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

great, I just like to follow up with members to see if they got the help they needed, from HRO or from other forums. we try to help all of our members and I appreciate your taking the time to respond. it is important to me, and all admins, that we do our job. not that it's just some job but that we help if we can. we are here to help. that is the reason I asked if you got some help and if we were able to be of service. HRO has a great membership with knowledge in so many areas. thanks for your membership and for returning... warmest regards, ginny  |

|

|

|

| ciel-007 |

Posted on 11/03/2015 5:50 PM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Quote Turingalad, there is a thread in the Hottop section about temperature probe installations. You may find it helpful. Here is the link: http://homeroaste...post_37936 Proper placement of the thermocouple is essential in order to accurately and reliably measure BMT. For example, the BMT probe should: - be mounted on the side of the drum that is rotating the beans in an upward direction - be completely submerged in the bean mass at all times - extend into the bean mass at a depth that is equal to 10 times the diameter of the probe - etc? The above pointers are based on an article published by Davis and Ribich. In their opinion, ? no tool has had as profound an effect on the advancement and growth in coffee roasting as temperature probes?. Here is a link to the complete article: http://www.teaand...coffee.htm Enjoy! Ciel Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| Turingalad |

Posted on 11/03/2015 6:08 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Ciel, Thanks so much! I'm glad I was patient/haven't had time yet to do the install. I never would have thought about the BMT probe needing to be on any particar side of the drum circulation. Almost made that mistake! I'm also glad that 10 x 5mm = 5 cm. This means I ordered the right length probe ;-) Will post updates when I get a chance to install. |

|

|

|

| Turingalad |

Posted on 11/03/2015 7:13 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Ciel, From reading the materials you gave me, I'm gathering that I need to have my ET probe IN my drum, is this correct? My probe is second probe is 10cm x 5mm. I'm not sure how to get it in there without hitting the bean mass. Do you think I could go through the back of my machine and get it really close to the back of my drum? (The only way to get IN the drum is through the front wall.) Or perhaps try to run close to the drum shaft inside the drum? |

|

|

|

| ciel-007 |

Posted on 11/04/2015 8:21 AM

|

|

1 1/2 Pounder  Posts: 651 Joined: April 03, 2012 |

Turingalad, it may not be possible for you to receive the best advice from HRO members unless you first provide diagrams (front view, side view, back view) of the roasting chamber and drum. Ciel

Ciel... seeking Heaven in my cup with ................................................................................................................. EXPOBAR Brewtus II - MAZZER Mini E - MAHLK?NIG Vario - GeneCafe - RAF-1 Extreme (Modified B-2 HOTTOP) - BellaTaiwan XJ-101

|

|

|

|

| Turingalad |

Posted on 11/14/2015 9:53 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Quote ciel-007 wrote: Turingalad, it may not be possible for you to receive the best advice from HRO members unless you first provide diagrams (front view, side view, back view) of the roasting chamber and drum. Ciel I finally got around to taking photos and gathering measurements. Here are photos (let me know if the link works) https://drive.goo...=drive_web Drum Measurements - diameter: 8 1/8? (20.6cm) - depth: 15 cm (5.6in) - space between cross beam and front wall of roaster: 9cm - thickness of drum walls: 5 mm - vein height: 1? (aprx.) Current probes - both: 5mm diam. - one 5cm long (grounded) - one 10cm long (ungrounded) Area inside roaster (measured from outside the 3mm walls? so, subtract 6mm from each of these for near precise measurements of inside area of machine. .) - 17? High - 10 3/8? Deep - 12 1/8? Wide Other: - Shaft 12mm - Bean chute 1.5in. Diameter ET probe: In my research, I found some who place this through the bean chute, as close to the opening into the drum. Some place it close to center (along shaft), and one big name roasting company said it should be at the "2 O'clock" position (if the shaft sticking out the face were like the center of a clock) Some even place it through the back, getting close to the back side of the drum/metal mesh. Should I base/adjust my ET probe after first solidifying my BT probe, or vice versa? How does one know when the BT probe is reading as close to accurate as possible? When it reads a certain temp at a certain point during roast, e.g. "first crack always occurs at/between xxx/xxx degrees C/F? Is it like gauging a thermometer's accuracy based on water "always reaches boiling temp at 214F (depending on elevation)"? Edited by JackH on 11/15/2015 4:52 PM |

|

|

|

| JackH |

Posted on 11/15/2015 3:36 AM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

Your link does not seem to be working. I think you have to create a public folder in google drive to be able to display on a site.

---Jack

KKTO Roaster. |

|

|

|

| Turingalad |

Posted on 11/15/2015 11:06 AM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Also, I got a few more measurements... - Space between back of drum and back wall is <10cm - Area within drum to avoid veins is (safely) 15cm Diam. by 9cm deep (I found an old Folgers tin can lying around that happened to fit perfectly? convenient.) - Vein hight 2.3cm+/- This tells me I?ve got, roughly, a 7.5cm radius to work with for probe placements. I?ve seen some people use the bean-chute screw-holes for probes. I tested this and the holes are nearly exactly 5mm (the size of my probes). The bottom left hole, closest to center, is 3.7cm +/- from center of shaft. Wondering if this isn?t just convenience? The bottom right chute-hole is really close to the veins? pretty sure a probe would be directly in the flow of beans. I would consider this for BT, but someone said ideally BT probes go on the up-turn of the drum?mine turns clockwise, which leaves me with about 9 to 12 O?clock and 7.5cm?? I?m willing to drill wherever. This machine is a hunk of metal, meant to be an experiment. edit for dead link Edited by ginny on 12/10/2015 8:09 AM |

|

|

|

| JackH |

Posted on 11/15/2015 4:54 PM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

It works fine now. I corrected the original link in your earlier post.

---Jack

KKTO Roaster. |

|

|

|

| Turingalad |

Posted on 11/18/2015 3:14 AM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

Thanks Jack! I added a couple photos that may help... Drum with dimensions... https://drive.goo...cslist_api Roaster face with dimensions... (It's not precise, but gets the point across, I hope.) https://drive.goo...cslist_api Still needing to find where to place ET and BT probes. |

|

|

|

| Turingalad |

Posted on 12/09/2015 1:23 PM

|

|

Newbie  Posts: 30 Joined: November 18, 2014 |

I'm about to start drilling holes and doing test roasts. Perhaps this is the best way for me to figure out where my probes need to be. I did a test roast with my probes places in pre-drilled holes https://drive.goo...cslist_api Pics of graphs and more here: https://drive.goo...VKSU0/edit |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman