Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Looking for plans...

|

|

| Etr005 |

Posted on 02/25/2016 10:55 AM

|

|

Newbie  Posts: 3 Joined: February 25, 2016 |

Hello all! I'm looking into building a 2.2kg or bigger roaster and was wondering if anyone had any plans with parts list and dimensions etc. for a build. Or a good recommendation for a build thread with good details. Not looking to design a roaster from the ground up necessarily just want to do the build. Thanks! |

|

|

|

| ginny |

Posted on 02/25/2016 11:00 AM

|

|

Founder  Posts: 3476 Joined: October 24, 2005 |

Hello: go into the Building a Roaster forum, Drum and you will find what you need, link below... http://forum.home...rum_id=137 not way for a member to list threads here as we do not know what you want or how much you want to do yourself. so your homework is to go through the builds in that forum. ginny  hope this helps. |

|

|

|

| Etr005 |

Posted on 02/25/2016 11:07 AM

|

|

Newbie  Posts: 3 Joined: February 25, 2016 |

I am looking to build it from the ground up including fabrication of metal etc. I was just looking for some good build recommendations is all. Sorry for the vagueness... |

|

|

|

| dmccallum |

Posted on 02/25/2016 11:44 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

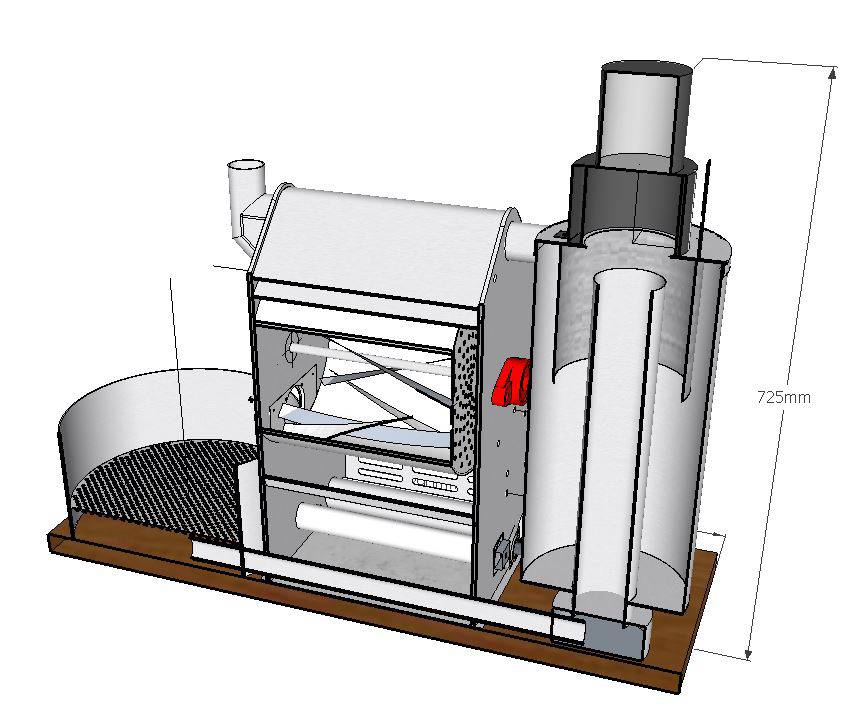

As per thread http://forum.home...ad_id=4811, I said I'd be happy to share the design of my 2kg drum machine http://forum.home...ad_id=4802. I am taking advice here on the design and it's not proven of course, but going on similar threads it seems to be heading in the right direction. Still doing 3d model and will post an update shortly, but then to transpose to 2d for cutting so might have to be a little patient if it looks like it might suit your purposes and you want to avoid the design effort.

dmccallum attached the following images:

Edited by dmccallum on 02/25/2016 11:55 AM |

|

|

|

| broeker |

Posted on 02/26/2016 5:45 AM

|

|

1/4 Pounder  Posts: 75 Joined: June 23, 2014 |

Nice work :-) it looks pretty cool.. I would pay plenty of attention to your drum, particularly to the diameter of the perforations that appear on the back plate of the inner drum, in my experience the volume of chaff / smoke released will very quickly block holes & crevices when you start doing a bit of roasting. I wouldn't rely on the vacuum of your fan to pull the chaff through the holes..... It won't for long :-) Are you going to have a valve of sorts on the cooling tray? Or is your fan sized to have enough pressure to drive the cyclone and cooling tray simultanously? It's good to have some adjustment on one of your main shaft bearings, so any inaccuracys in your fabrication can still be adjusted out to ensure your drum and your front plate run parallel (even gap) Think access / easy dissembly for cleaning, coffee roasting is a dirty smoky oily process.... How are you going to empty your cyclone? Good to see the polidoro burners there, I've had great success using them..... Is the model you have chosen pretty small? looks like two of them in there) I have a single one of them in my roasters (4kg) and can turn beans to carbon in minutes if I give it full burn...... |

|

|

|

| allenb |

Posted on 02/26/2016 10:06 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote Broeker stated: Good to see the polidoro burners there, I've had great success using them..... Is the model you have chosen pretty small? looks like two of them in there) I have a single one of them in my roasters (4kg) and can turn beans to carbon in minutes if I give it full burn...... Unfortunately, the US rep for Polidoro will not sell retail but only to OEM or non-end users. I spoke to them recently and they explained that it's not practical for them to stock the various models of burners for sale individually. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Etr005 |

Posted on 02/26/2016 9:23 PM

|

|

Newbie  Posts: 3 Joined: February 25, 2016 |

Thanks a lot dmaccallam for the response! lots of great info and pretty much exactly what I am looking to do... your images/models are top notch. Im now looking into components and was wondering what all you thought about this motor for the drum. Debating on putting a 30:1 gear reducer to put it in at 57.5 rpm or follow suit and set it up with sprockets and a chain drive. http://www.surplu...0-3004.axd as far as steel is concerned too, what kind of steel is ideal for the drum? I was thinking 12 gauge for thickness but didnt want to wind up with anything with residue or too much expansion/contracting This was the blower I had picked out per other threads: http://www.ebay.c...0573233180 cheaper/better options? Thanks again! Edited by JackH on 02/27/2016 3:07 PM |

|

|

|

| hbboyd |

Posted on 02/27/2016 2:52 PM

|

|

Newbie  Posts: 30 Joined: May 26, 2015 |

Not sure on the motor, off the top of my head that seems pretty over powered but not sure. My drum was 10 gauge and performs wonderfully. I used that exact fan and it has tons of extra power, technically speaking I don't think its supposed to be speed controlled but I just a variac on it and it appears to be happy. |

|

|

|

| dmccallum |

Posted on 02/29/2016 6:31 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

Re the drum motor I am using a 35W c-face induction motor/gearbox sourced from UK. Someone here detailed the following US Dayton 1/20hp equivalent, although there's a wide range of c-face mount standards, so you'd have to get a steel cut to mount your specific one. http://www.ebay.c...0373333454 On the blower I'm thinking the Dayton [url]3FRG2, http://www.electricmotorwarehouse.com/dayton-high-temperature-blower-129-cfm-3050-rpm-230-volts-60-50hz-model-3frg2/[/url], but only because the San Franciscan SF-1 uses a 130CFM blower. Will look at it again.. |

|

|

|

| dmccallum |

Posted on 02/29/2016 7:23 AM

|

|

1/4 Pounder  Posts: 93 Joined: November 24, 2015 |

Quote broeker wrote: I would pay plenty of attention to your drum, particularly to the diameter of the perforations that appear on the back plate of the inner drum, in my experience the volume of chaff / smoke released will very quickly block holes & crevices when you start doing a bit of roasting. ---That rear plate is indicative only. I may use a mesh, although any steer appreciated. Quote Are you going to have a valve of sorts on the cooling tray? Or is your fan sized to have enough pressure to drive the cyclone and cooling tray simultanously? --- No, just haven't detailed yet how I'll switch between drum and tray. I'm assuming the machine will not handle roasting and cooling at the same time with the way I've configure it at the moment - 1 blower for drum and cooling, and one motor driving the drum and cooling tray arm Quote Think access / easy dissembly for cleaning, coffee roasting is a dirty smoky oily process.... How are you going to empty your cyclone? --- I'll put a door in the side most likely much like the San Franciscan SF-1 Quote Good to see the polidoro burners there, I've had great success using them..... Is the model you have chosen pretty small? looks like two of them in there) I have a single one of them in my roasters (4kg) and can turn beans to carbon in minutes if I give it full burn...... -- Only one burner (the other tube will be one of two going to the cooling tray. I haven't yet contacted the UK Polidoro but expect they won't be doing retail. I've an alternative route via a large UK catering parts supplier who hold many Polidoro burners for various catering appliances but selecting/sizing will not be straightforward. Currently doing bean hopper, trier, temp probe orientation and also need to get some clarity on the burner size one way or another. After that I'll start doing 2D files for cutting (Solid Edge 2D Drafting - it's free and supports AutoCad exports). |

|

|

|

| hbboyd |

Posted on 02/29/2016 6:26 PM

|

|

Newbie  Posts: 30 Joined: May 26, 2015 |

Just an fyi for everyone thinking about burners, I have found a company willing to sell me the indiviual burners that are found in Mill City's roasters as seen in the below image. They put out ~4k btu each by my calcualtions for $20+ship. Now they will require a manifold be built, I am going to grab a couple then report back. |

|

|

|

| eschlukebir |

Posted on 10/11/2016 8:13 PM

|

|

Newbie  Posts: 22 Joined: October 06, 2016 |

any follow up on this? |

|

|

|

| JSA Coffee |

Posted on 11/09/2016 3:10 PM

|

|

1/4 Pounder  Posts: 90 Joined: June 11, 2016 |

I would like to know about any follow up too. What's the source for the burners? |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman