Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

What do you think about this Pyrex roasting chamber idea?

|

|

| Cheekius Geekus |

Posted on 08/17/2016 10:03 AM

|

|

Newbie  Posts: 10 Joined: March 30, 2015 |

Greetings all, I've been an air popper roaster (off and on) for many years. I've got the stuff to do a TurboCrazy, but I'm already thinking about going bigger. I really like the fluid bed concept and my plans are influenced by two major things so far: 1) seedlings CoffeeAir II build (thread here: http://forum.home...post_60499 and YouTube videos here: https://www.youtu...=coffeeair ) and 2) The Neuhaus Neotec Shop Roaster http://www.blanch...221627.pdf My design build goals are: ? 110V (hopefully on one circuit) ? 1-2 kg of green capacity ? electric heat (probably twin heat gun elements, separately switchable) ? Kirby vac motor blower on a Router Speed Controller (capable of stalling the roast by overpowering the heat elements) ? A transparent roasting chamber, but closed (or semi-closed design to prevent beans from being ejected out the top ? Considering building this on a two-wheel cart for easily rolling around/transporting ? I'd like to be able to roast year-round, but I live in Nebraska where we (normally) have extreme air temps in both summer and winter. So I'm thinking of doing some sort of "preheated air chamber" for the blower to draw from in cold weather months. I will normally be roasting outside or in a non-heated outdoor structure ? I'd like to make use of Artisan software and twin thermocouples for creating roasting profiles. I've got one of these Artisan-compatible units on the way: http://www.ebay.c...1911569443 Comments on any of the above is appreciated, but I'm mainly here to see what you think of this roasting chamber idea. (It is probably not original, but I have not yet had time to read ALL of the great Fluid Build threads here to know for sure.) My thought is to get a Pyrex tube that will sit in a stainless steel funnel. The funnel spout will be where the blower gets hooked up. The tapered bottom of the funnel will provide for bean circulation as the sides feed down to the "blow hole" where they are blown/agitated up to the top. The top of the Pyrex tube will be a closed or partially closed design to keep beans from being ejected and to facilitate chaff removal (via a separate cyclonic chaff collector, ala the Neotech design). My plan is to hold the Pyrex tube, top and funnel together using a piece that looks like the attached 3-tab funnel base. The closed top would also have this three tab system and threaded rod and nuts would hold the top and bottom together. You can see my rudimentary idea here: http://www.antiqu...erBase.gif I'd like to figure out how to make this chamber dumpable - right into a cooler, as in the Neotec design. The funnel I'm looking at has a top diameter of 5-3/4" so I'm looking at a 5" diameter pyrex tube of either 10" or 12" height. I'm not quite sure how much capacity/coffee i can actually roast in that size of a cylinder/roasting chamber. Any ideas? Thanks, in advance, for sharing any thoughts you might have. |

|

|

|

| Cheekius Geekus |

Posted on 08/17/2016 10:13 AM

|

|

Newbie  Posts: 10 Joined: March 30, 2015 |

Tell me if I'm doing this right: a 5" pyrex tube has a 2-1/2" radius (I know i'm right at least that far)  If I put in green beans to a depth of 2-1/2" that should be about 49 cubic inches. Then using this calculator: http://www.thecal...coffee.php and their default value of density for green beans (561 kg/m3) That would be .45 kg of green beans. (This is not allowing for the extra amount in the lower taper of the funnel. So to reach my 1 kg batch goal, I would actually have to fill the tube to a depth of more like 5". That sounds like too much to be able to effectively circulate with the blower (but you tell me)! |

|

|

|

| seedlings |

Posted on 08/17/2016 12:49 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Hello there Cheekius Geekus - I like your style. First, I'm sure you've read up on Roaster Rob's designs. If you choose a cylindrical roast chamber, he has it down to an art. http://forum.home...rowstart=0 2nd, I'm in MO, and I've roasted in temps as low as 15F. If I need to, I point a heat gun at the air intake to preheat the air. You could not do this unless your blower motor has no plastic parts (why I chose a used Kirby) - so preheating the air is a good idea. To push that idea further, and what I originally wanted to do, re-circulate the hot air. It would be fairly simple to employ an air return that filters the chaff, and lets the hot air back into the blower. I just haven't worked on the task. I will tell you that the very first time you make a hopper fully or partially out of glass, you'll drop it. Guaranteed. I did. Totally broken two, and my current CoffeeAir II has chipped corners on the pyrex view glass. I believe that happened within the first couple of roasts... Roast chamber. It looks like you want to make a bean bed where the air comes up the center of the bean mass, throwing the beans out to the perimeter. CLICK --> I have done this <-- and it can work. I believe the asymmetrical style of Roaster Rob is more efficient (or at least more often employed at a larger scale). What kind of materials are you looking at to build the main blower/heater chamber? CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Cheekius Geekus |

Posted on 08/17/2016 2:00 PM

|

|

Newbie  Posts: 10 Joined: March 30, 2015 |

Hey there, Chad! Thanks for the reply. I didn't realize you were an Admin here! We had a short email conversation (8/9-8/11) from my work email address.  Geez I'd hate to drop that Pyrex. That is almost the most expensive part of the build! I have not read up on Roaster Rob's asymmetrical design. I guess I liked the symmetrical design because it made sense to me and could be made with off-the-shelf parts, like the funnel. (By the way, the spout on the one I'm looking at has a 9/16" spout diameter. Can the Kirby blower be usable at that small of an opening?). I'm open to any kind of adjustment right now, since it is almost all only on paper. I did get the Kirby G5 bought for $20.00 and see that there is a "Kirby G5 tear-down" video on YouTube. Haven't watched it yet, or got the tear-down started, but I'm curious to see what that motor looks like. I was thinking of housing it in some sort of styrofoam cooler (to help with noise?) and just have cut-outs for the intake/outflow. No plans on the materials for the heat gun element chamber yet. I'm all ears if anyone has plans or suggestions. It should NOT be terribly important to have the blower motor some distance from the heat elements (should it?). I would think having the heat elements close to the roasting chamber would be important, but as long as the air also gets there, it seems to me that the blower motor could be in the bottom of the machine. (Correct me, if I'm wrong.) As far as the chassis for this whole thing, I've got some 80/20 and I think your cement board could be cut into pieces that slip right down into the slots of that 80/20 .... sort of like a rail and stile cabinet door panel. The bottom panels could be cement board and the top could be plexiglass (or even open). If I can find a suitably larger funnel, I might scale this whole thing up to use an even larger diameter pyrex tube. It seems to me that I could build this using substitute materials for the roasting chamber (like a big 'ol roll of aluminum flashing) for a proof-of-concept and then order the Pyrex tube once one knows the proper dimensions for the quantity that one wants to roast. |

|

|

|

| seedlings |

Posted on 08/17/2016 2:47 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

I would not be confident with a 9/16" concentrated hot air blast to heat all your beans well - look at something like 20% of the area for the hot air flow. If you read through that first Roster Rob post where I put together many of his findings, you'll read: Quote Initially I came to the conclussion that you would need to go conical over 6" dia. But after getting 6kg lofting in an 8" asymmetrical RC I don't know if there is an upper limit. I do believe there is an advantage using the asymmetrical design in minimizing bean to bean friction. I tried something random the other day. had 5kg of green in the conical RC, it wouldn't loft with the blower on full noise so i pushed a 2" ss pipe down the middle of the RC to about an inch or so from the perf plate, the beans started to flow up and spout out of the pipe. Seems the pipe directed the air flow and cut down the friction/engulfment of the surrounding beans. The perforated area should be related to the total area of the RC say 20%. Hole size and distribution is linked to the pressure and air flow. Too many holes for a given area and the you lose pressure & velocity and get a random bean flow and bean bed height is limited. If the holes are too small (or too few for a given area) again your bean bed height will be limited. Greater pressure can over come this but is probably not an option due to limited options for blowers. Also heat/air density will no doubt be affected. Your bean height is affected by air pressure. If your air pressure is 18" of water, beans weigh approx 70% of water so you should be able lift more than an 18" column of beans. However because the beans don't form a tight seal in a pipe you get alot of slippage (airflowing past the beans). Plus you need surplus airflow to throw the beans around. The only potential down side of having the blower separated from the roaster via PVC tubing is it could cause the beans to bounce a little bit. Most likely not any big deal at all. I don't think styrofoam would help much, and could possibly cause resonance at particular frequencies that would worsen the problem. If you want it close by, make the container walls very, very dense. Then, you could PVC the intake from a distance away. That would probably be the best function to reduce motor noise: 1) dense, heavy, thick walls, and 2) putting the inlet some distance away. Heat elements as close as possible to the chamber, check. For approx 1kg loads, you WILL NEED two 1500W heat elements. The ability to switch one off will not be beneficial. I need 100% heat for the first 6 or 7 minutes of the roast. If you want to roast more, then you will need a 3rd heat element or need to increase inlet air temp. CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| Cheekius Geekus |

Posted on 08/17/2016 6:01 PM

|

|

Newbie  Posts: 10 Joined: March 30, 2015 |

Well, I've tried to read that link but I can't make heads or tails out of most of it. Is there a guide to the acronyms used around here? I can gather that RC = Roasting Chamber but beyond that... good grief. (everything is simple, once explained) |

|

|

|

| seedlings |

Posted on 08/17/2016 6:39 PM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

Quote Cheekius Geekus wrote: Well, I've tried to read that link but I can't make heads or tails out of most of it. Is there a guide to the acronyms used around here? I can gather that RC = Roasting Chamber but beyond that... good grief. (everything is simple, once explained) Haha- good point. I read through most of it again just now and didn't see too many acronyms though. There is a sense that you're reading a different language with familiar words. Slow and steady! CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 08/17/2016 6:55 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Hi, I've got a symmetrical air roaster that can successfully circulate 1kg green. Here's link where I tried a 1kg roast with a full roast video. I think I concluded that 1kg was a bit too much for my 2 x 1800W elements with no heat recirculation. http://forum.home...post_30790 |

|

|

|

| btreichel |

Posted on 08/18/2016 1:37 AM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

I found a limit of around 300 grams with a 1800 watt heater. After that I figured that you needed heat re-circ and that's a whole different animal. |

|

|

|

| Cheekius Geekus |

Posted on 08/18/2016 7:53 AM

|

|

Newbie  Posts: 10 Joined: March 30, 2015 |

Quote greencardigan wrote: Hi, I've got a symmetrical air roaster that can successfully circulate 1kg green. Here's link where I tried a 1kg roast with a full roast video. I think I concluded that 1kg was a bit too much for my 2 x 1800W elements with no heat recirculation. http://forum.home...post_30790 Thank you for sharing that! Nice ideas there, especially using a Coleman lantern globe as the sight glass and using aluminum for the rest of the roast chamber. Very low cost solution. If one wanted to go to a full glass tube after one had the design worked out, one could (but there is still the fragility issue - Less so if one could make the roast chamber FIXED and use a dump valve on the bottom. Hmmmm.) So that Coleman globe is about (what?) 4-1/4" in INSIDE diameter? What is the diameter of the "blow hole" in the bottom? Good info about your capacities vs heat elements also. Much appreciated! |

|

|

|

| seedlings |

Posted on 08/18/2016 8:16 AM

|

|

1 1/2 Pounder  Posts: 4226 Joined: June 27, 2007 |

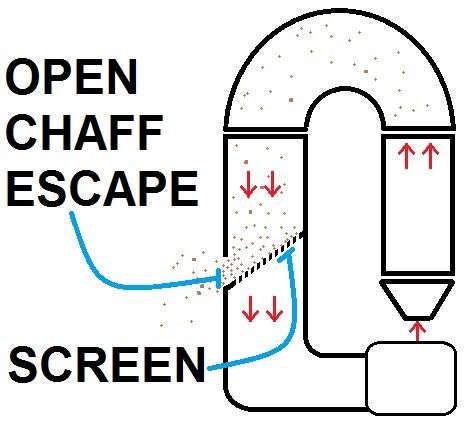

Good points greencardigan and btreichel. Also, Cheekius Geekus, something to keep in mind. I decided against the single 120V circuit. You'd need 3500 watts to run two elements at 14 amps each and a 5-amp motor. On 120V, that would require at least a 40-amp breaker, and at least #6 gauge (nonstandard) wire. So, either way, you'd need (an electrician) to install that new circuit. You'd be better off with a 30A 220V circuit, which is what I use. Most standard 120V circuits in a house or apartment are 15-amp or 20-amp if you're lucky. You'll need 3000W of heat for 2 pounds without hot air re-circulation. This is the basic, simple plan I had to re-circulate. Pretty easy to implement.  CHAD Roaster: CoffeeAir II 2# DIY air roaster

Grinder: Vintage Grindmaster 500 Brewers: Vintage Cory DCU DCL, Aeropress, Press, Osaka Titanium pourover |

|

|

|

| greencardigan |

Posted on 08/18/2016 7:52 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

Quote Cheekius Geekus wrote: So that Coleman globe is about (what?) 4-1/4" in INSIDE diameter? What is the diameter of the "blow hole" in the bottom? The pyrex tube (Coleman globe) I used had the approximate dimension below. 119mm ID = closer to 4-3/4" 125mm OD 136mm tall The base of my roast chamber's funnel has a sink strainer used as a perforated plate. I can't remember, but it's probably around 2 1/2" diameter. |

|

|

|

| oldgearhead |

Posted on 08/19/2016 9:04 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

I use a system similar to the drawing posted by Chad. With today's ambient temperature (77DF) I roasted 2-500 gram loads with 1200 watts. I use an un-insulated (in summer) Bake-A-Round tube. Because I cool and collect chaff in the roast chamber, I cannot use anything smaller. My system has been in constant use (at least 2x per week) since the summer of 2010. No oil on my beans...

|

|

|

|

| alexcampbell |

Posted on 08/19/2016 2:21 PM

|

|

Newbie  Posts: 42 Joined: December 16, 2013 |

The bake-a-round tube can be a severely limiting factor in this type of design. My build is here http://forum.home...post_56148 A bake around tube is fairly small diameter, and they are not all the same diameter, which can be a problem. The problem is that you require a lot of air pressure to circulate beans at the depth that they are at when green. This, of course, lessens as the beans gain volume and get lighter. With the airflow requirements to loft one pound of beans, you will require a lot of heat. I use a 3300W 240V plastic welding element in mine. This element frequently runs at 80-100% duty cycle. Two 1500W heat gun elements would require about 12 amps each, which could not be supported on one circuit, however 3300W is only 14 amps at 240V. Another issue is the sheer volume of the cylinder. I can roast 1lb of green coffee, but no more. One thing to consider is that Bake-a-Rounds are honestly not the ideal roast chamber. There are many on-line sources for large borosilicate tubes, and often you could have one cut and delivered for not much more that a bake-a-round. Ideally, if I were to build another roaster, I would make a metal roast chamber as it is much easier to work with, but they sure don't look as cool. |

|

|

|

| oldgearhead |

Posted on 08/21/2016 5:43 AM

|

|

1 1/2 Pounder  Posts: 1128 Joined: February 10, 2011 |

I think the Pyrex Bake-A-Round tube is the best thing going for a home roaster to start with, and the build is here: 120 volt, 1000-1500 watt, 500 gram, hot air reclaiming, coffee roaster: forum.homeroaster...ad_id=2207 Edited by oldgearhead on 08/21/2016 5:49 AM No oil on my beans...

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman