Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

P1 Group Build?

|

|

| btreichel |

Posted on 09/22/2016 8:12 AM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

My p1 has a outer lip and base / shelf that it might fit into. Normally, the glass is just a tad big. A use a small bead of silicone rtv to seal the two. Food safe and good to 500f. Basically like the adapter you are building. |

|

|

|

| walt_in_hawaii |

Posted on 09/22/2016 3:19 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Hmmmmmmmmm. Now you've got me thinking. I hate to see the glass from Menard's go to waste, and it would be a VERY simple operation to machine a simple, very short aluminum 'sleeve' that would go over the outside lip of the lantern glass, then slide over the top of the roast chamber/fan... you could rtv/silicone it to the glass, which is cooler, then just use a friction fit to the roaster/base and it wouldn't be this huge contraption I have here which only Frankenstein (and me) could love... I'll go and see if the bay has any aluminum pipe that is close in size. It would be a very simple project, and then these 3 glass globes would not go to waste. |

|

|

|

| walt_in_hawaii |

Posted on 09/22/2016 3:21 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Ha! in fact, I think I might get by with just a simple piece of turbo silicon hose coupling, it slides over a 3" pipe just fine and should accommodate the popper and the glass perfectly... these are used by speed shops for intercooler piping and very common. I'll call a couple shops down here and see if I can scrounge a small piece for a trial fitting.... |

|

|

|

| walt_in_hawaii |

Posted on 09/23/2016 3:03 AM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

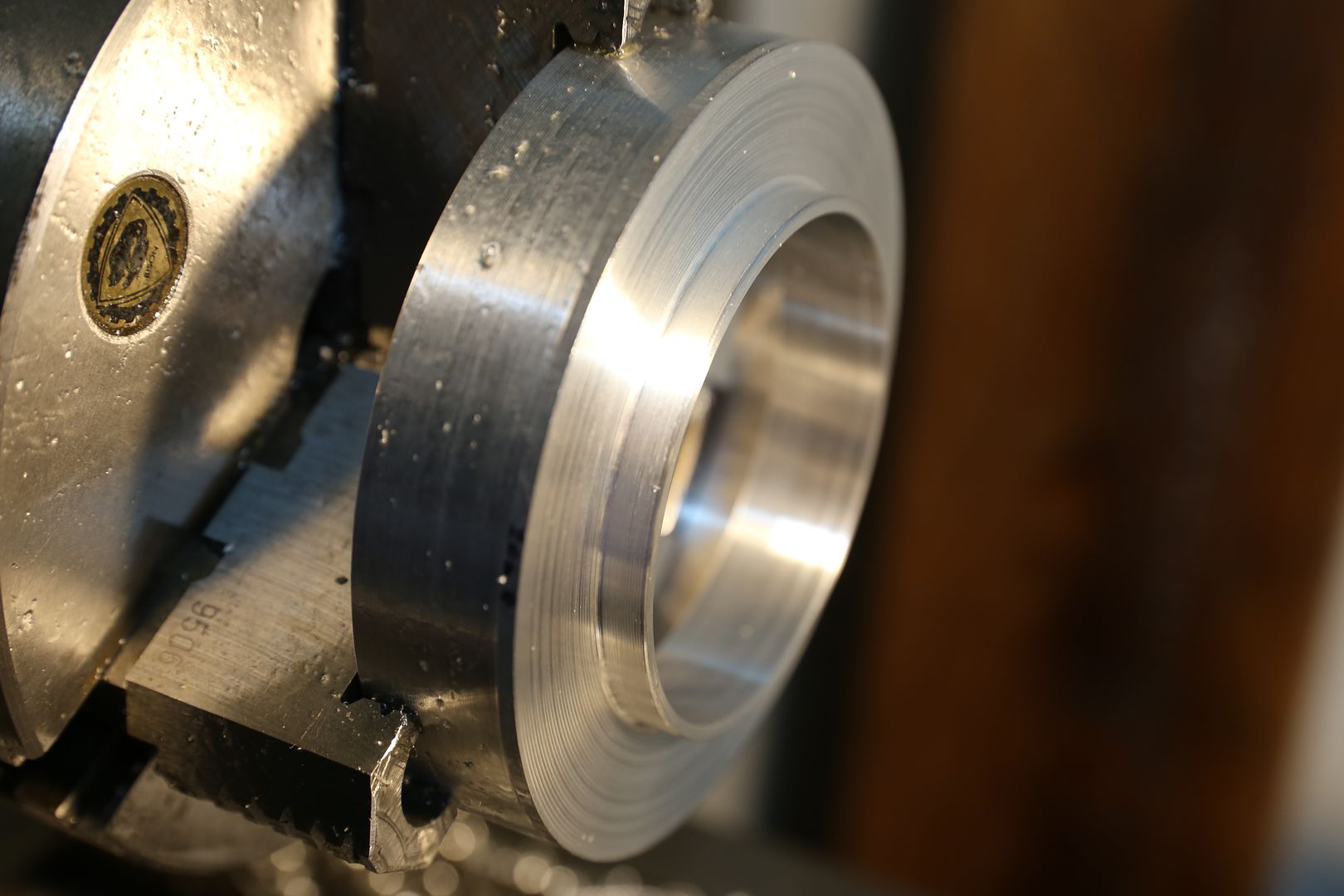

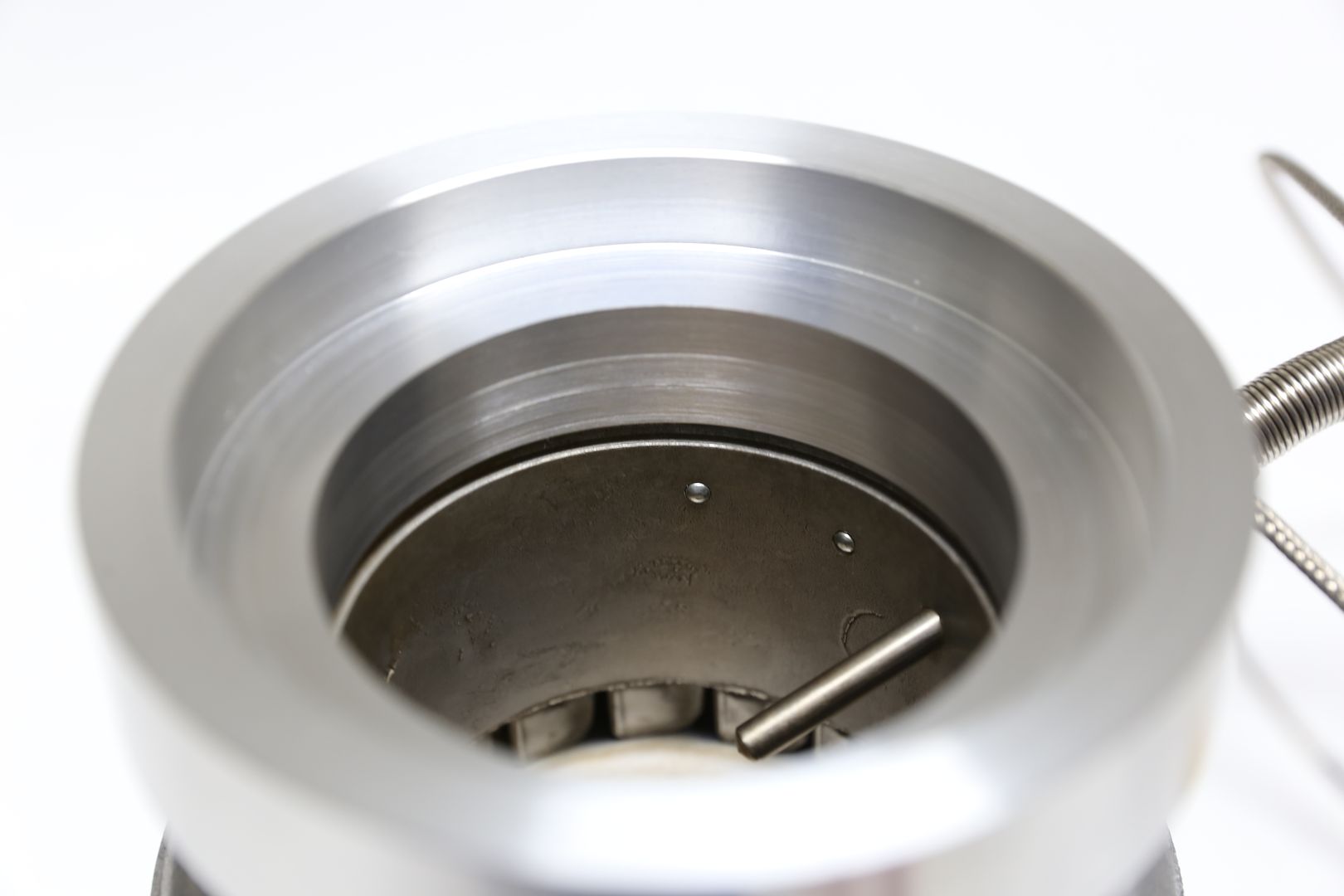

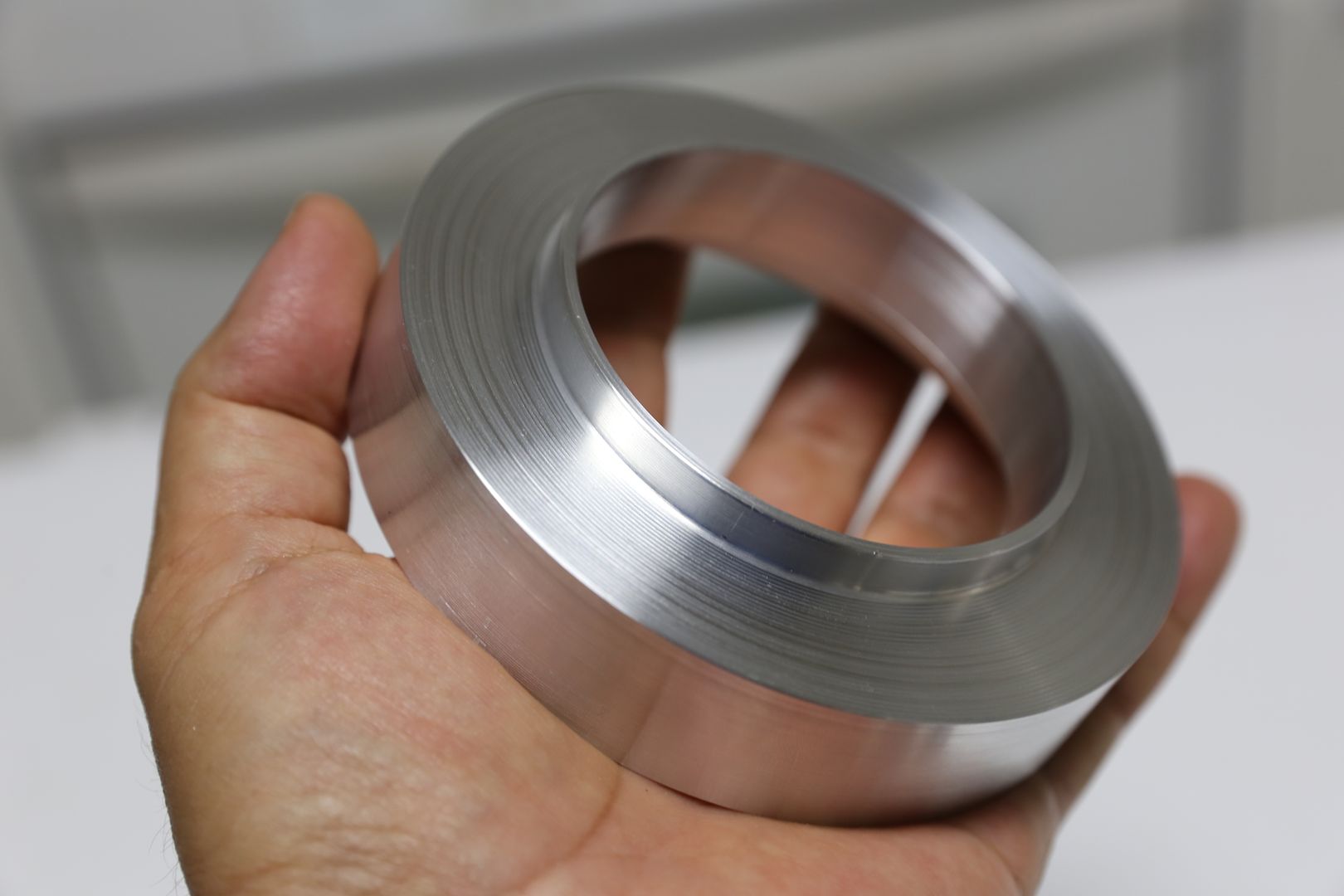

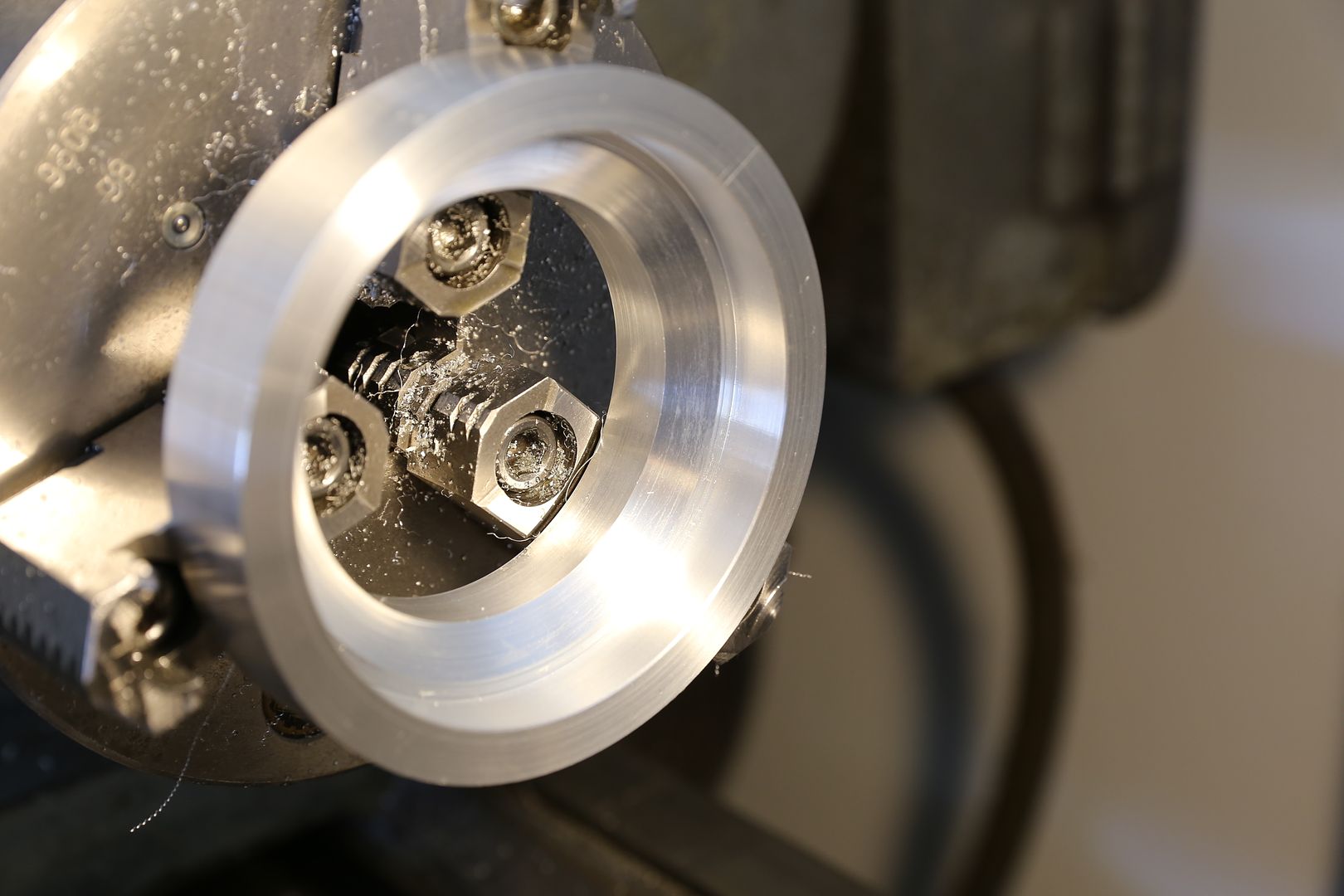

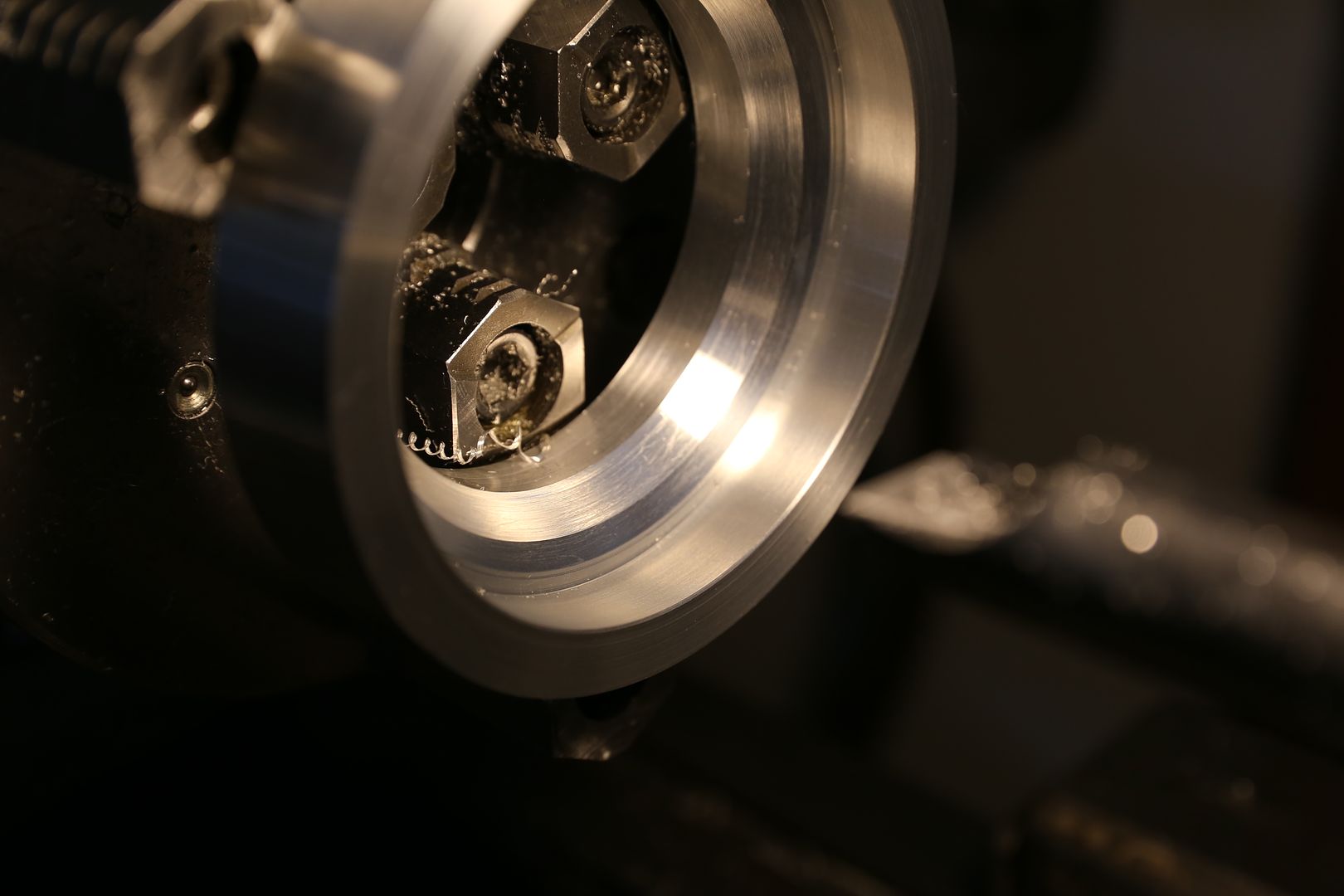

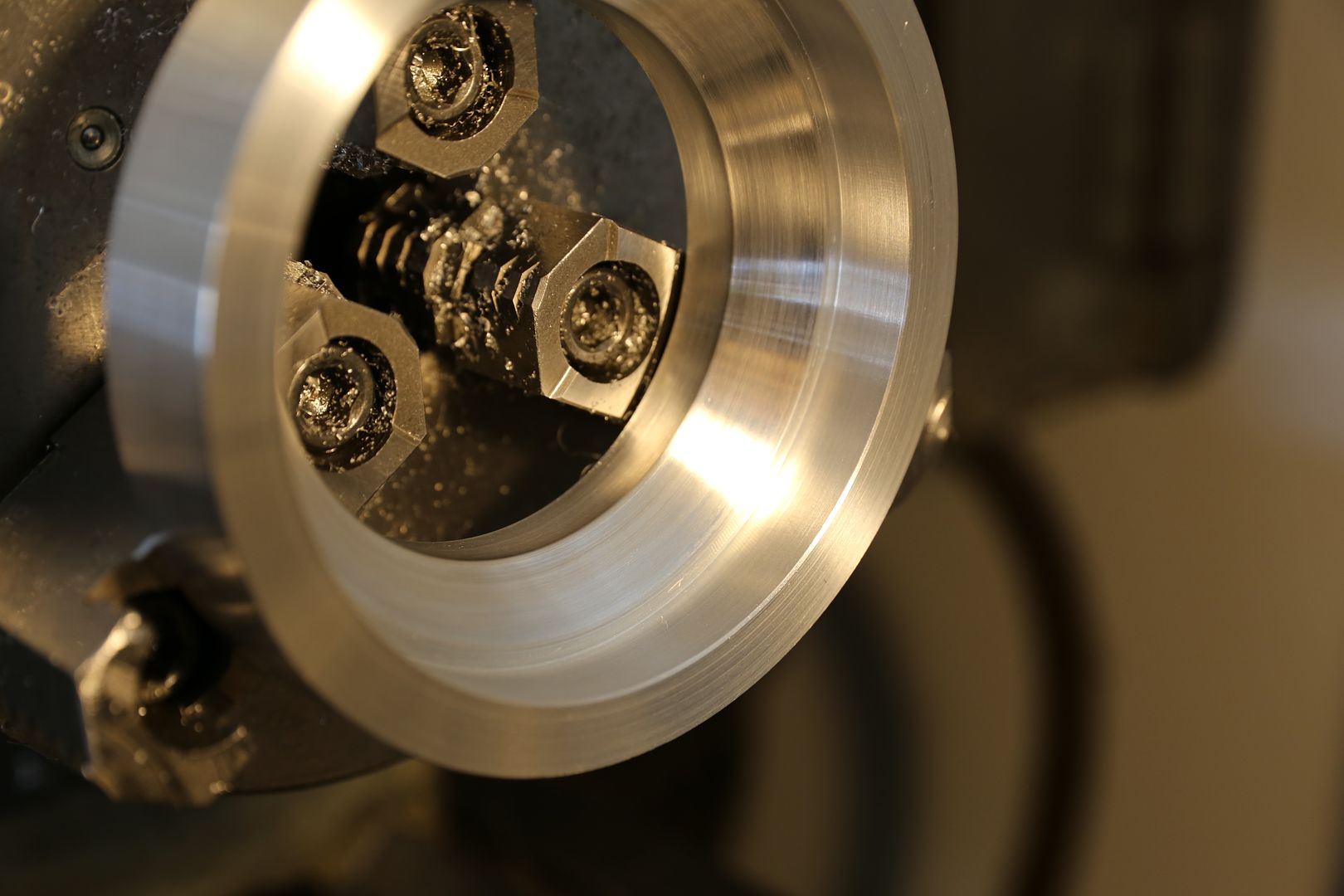

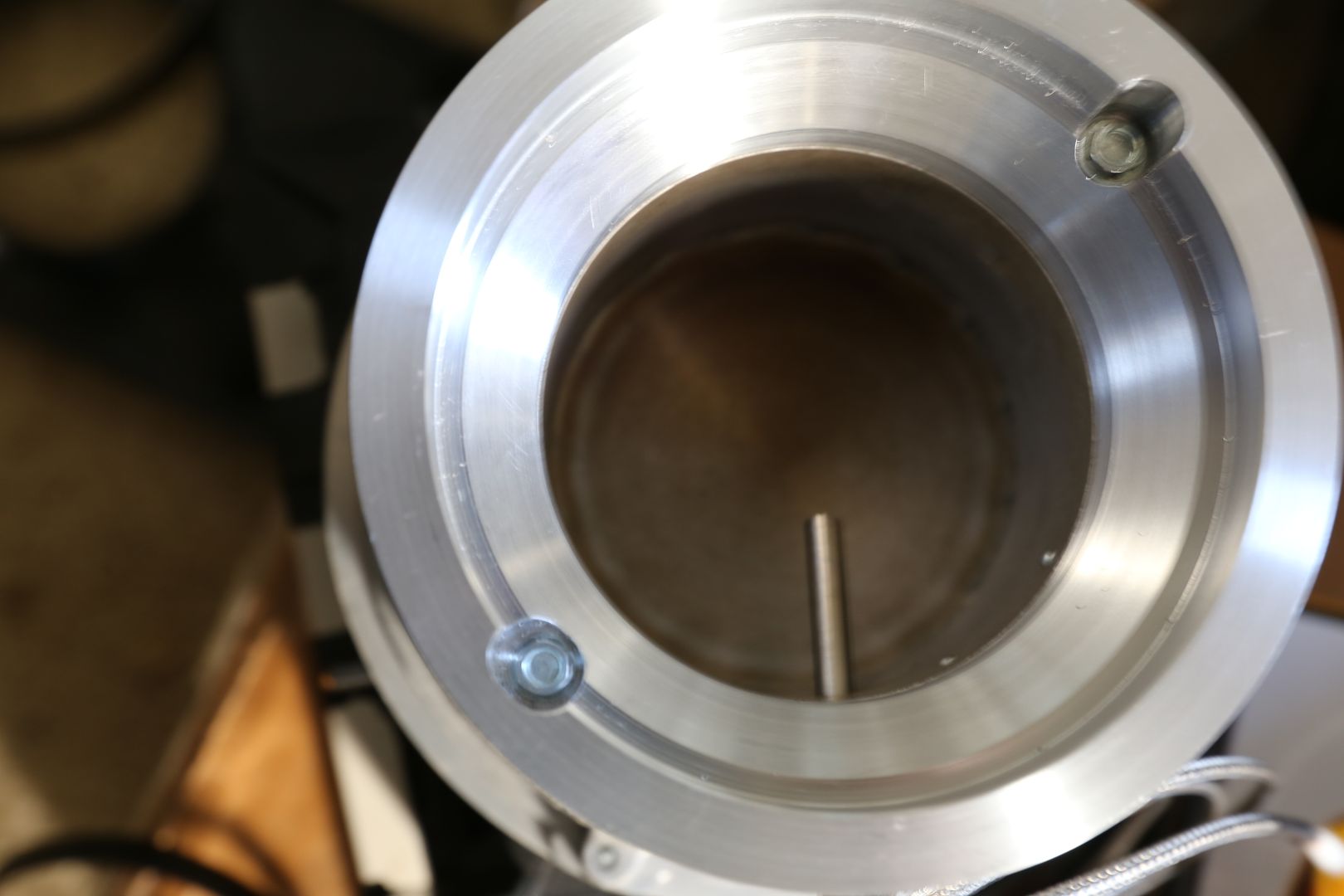

OK, so the top of the adapter ring is pretty much done; tonight I finished up the bottom by removing most of the metal and leaving a small ring next to the internal diameter: Trial fitting... it fits perfectly into the top of the roast chamber, BUT... I didn't read the dials correctly, and the 'lip' is too shallow, by exactly .100" ...  Bottom fits fine, I'll have to figure out a way to bolt it to the original bosses.  But for now I have to put this back into the lathe and cut a bit deeper to make the lip extend out another .100"  |

|

|

|

| BenKeith |

Posted on 09/23/2016 7:41 AM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

You will probably need to put a taper on the inside of your adapter to keep beans from just sitting on the lip. |

|

|

|

| walt_in_hawaii |

Posted on 09/23/2016 12:00 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

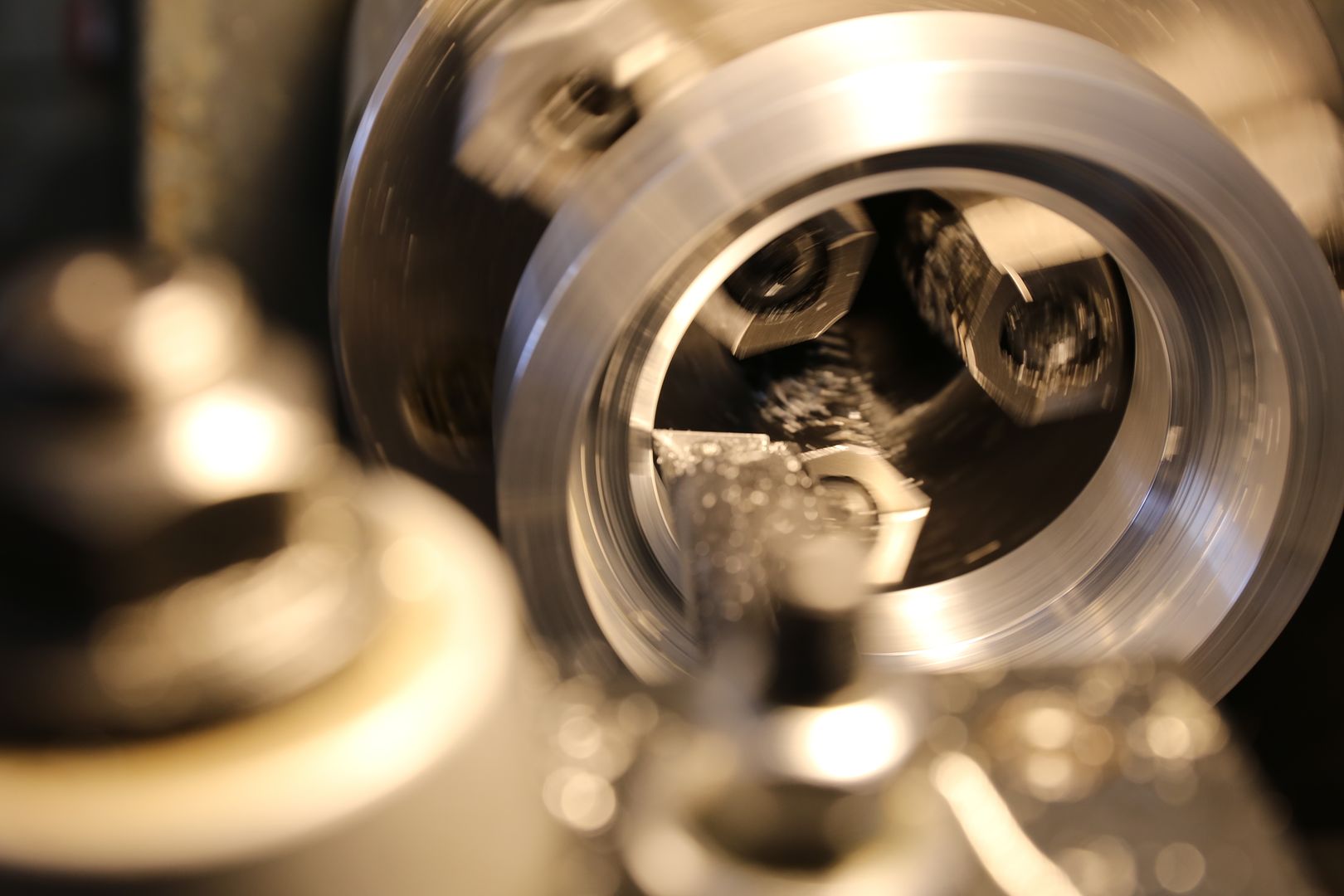

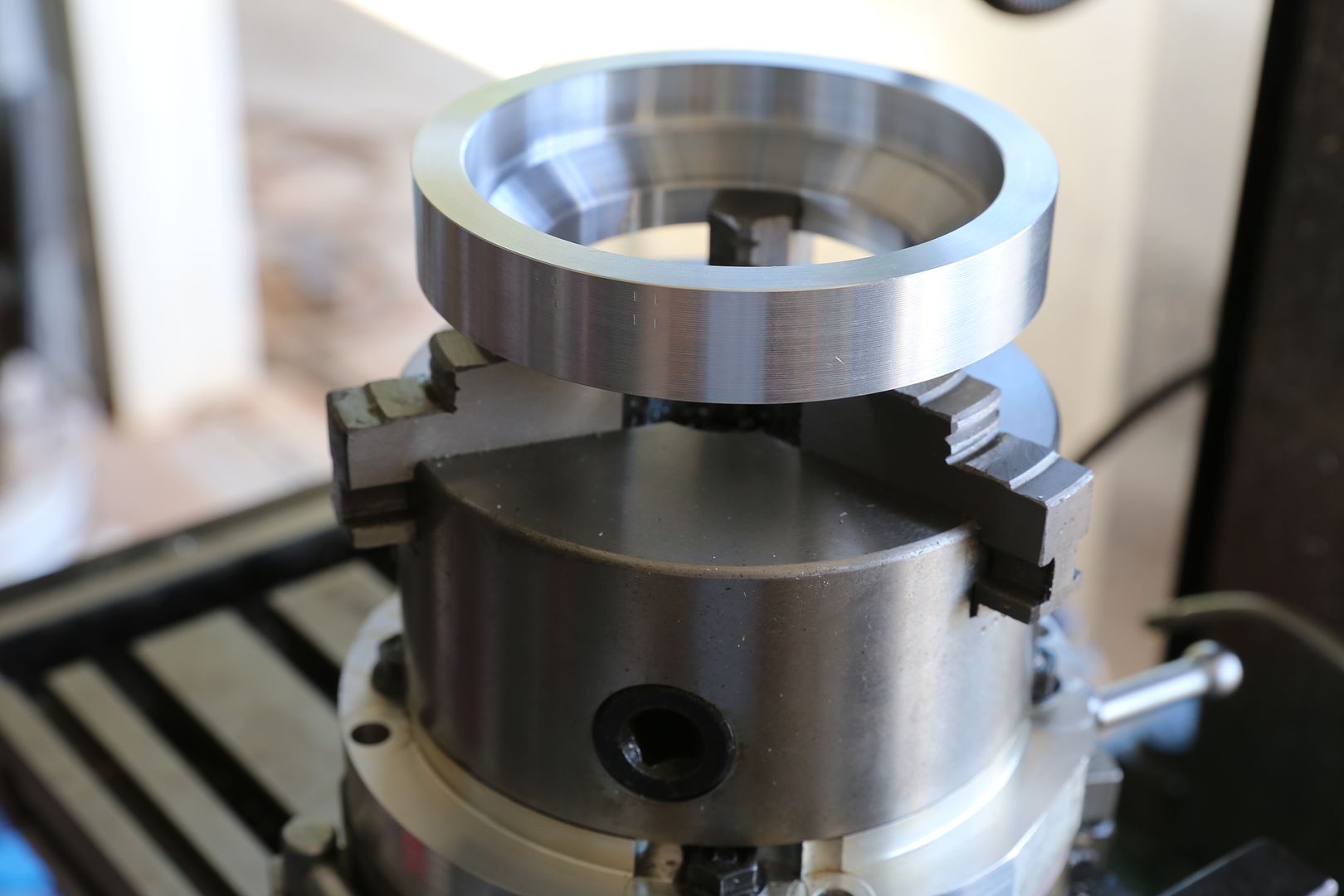

Hi Benkeith. Yes, there will be a taper on the inside, to go from the roast chamber dimension to the inside of the bake a round chamber dimension, and it should be a very shallow taper to allow the beans to move freely from one to the other. I'm still juggling that part in my head, because once you cut the taper you can no longer hold the workpiece by the insides (you can only tension a straight cylinder), and I think I might have to hold it from the insides to cut the outside to make the mounting boss... trying to figure out a way around that, not sure yet. |

|

|

|

| BenKeith |

Posted on 09/23/2016 12:41 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

I would just throw in in my three jaw chuck and make shallow cuts to keep from loading the piece and having walk or slip in the jaws. That few thousandths out will never be noticed. You might have a little line in three places where the jaws were but if you don't over tighten it, they probably won't be noticeable. |

|

|

|

| walt_in_hawaii |

Posted on 09/24/2016 11:59 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

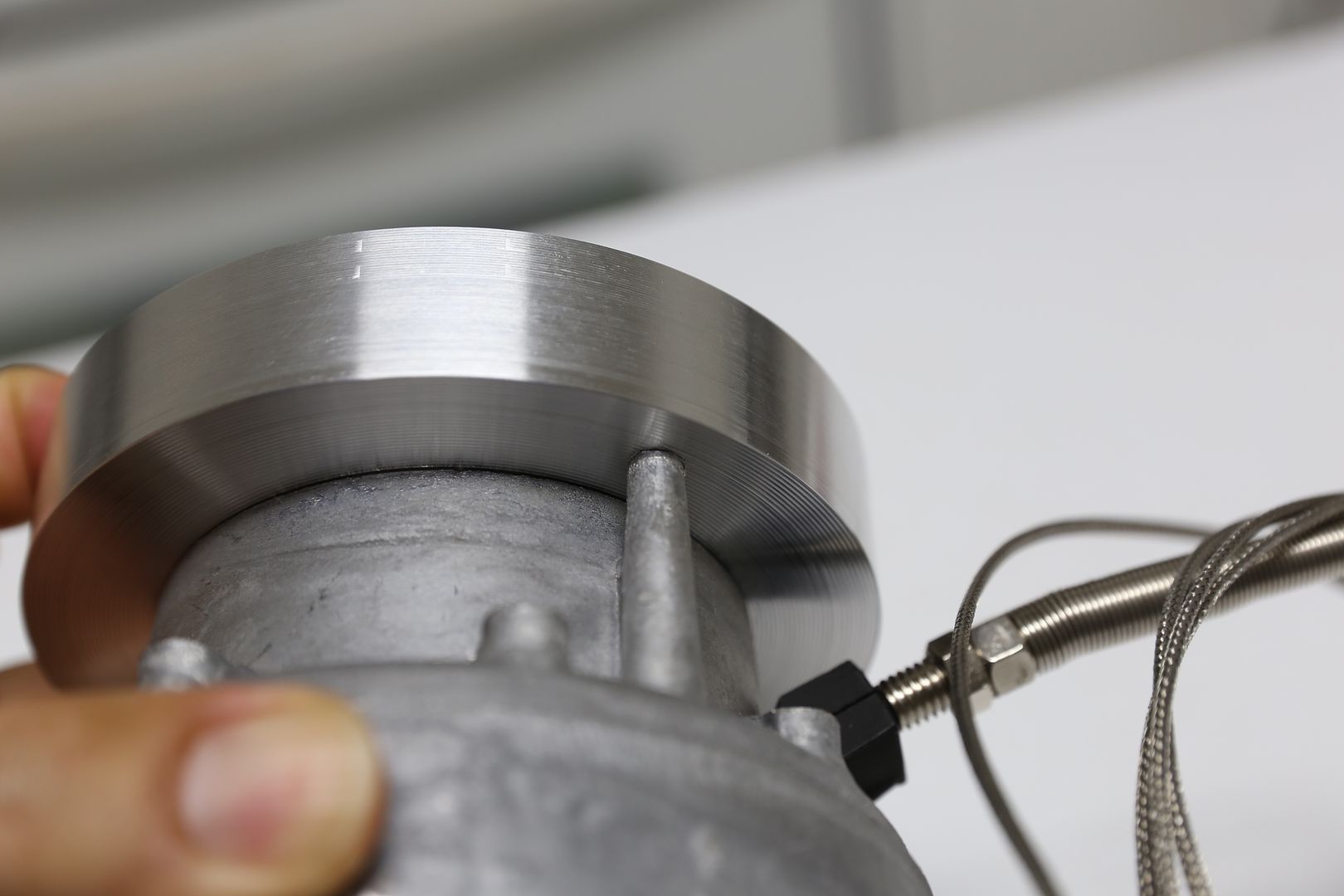

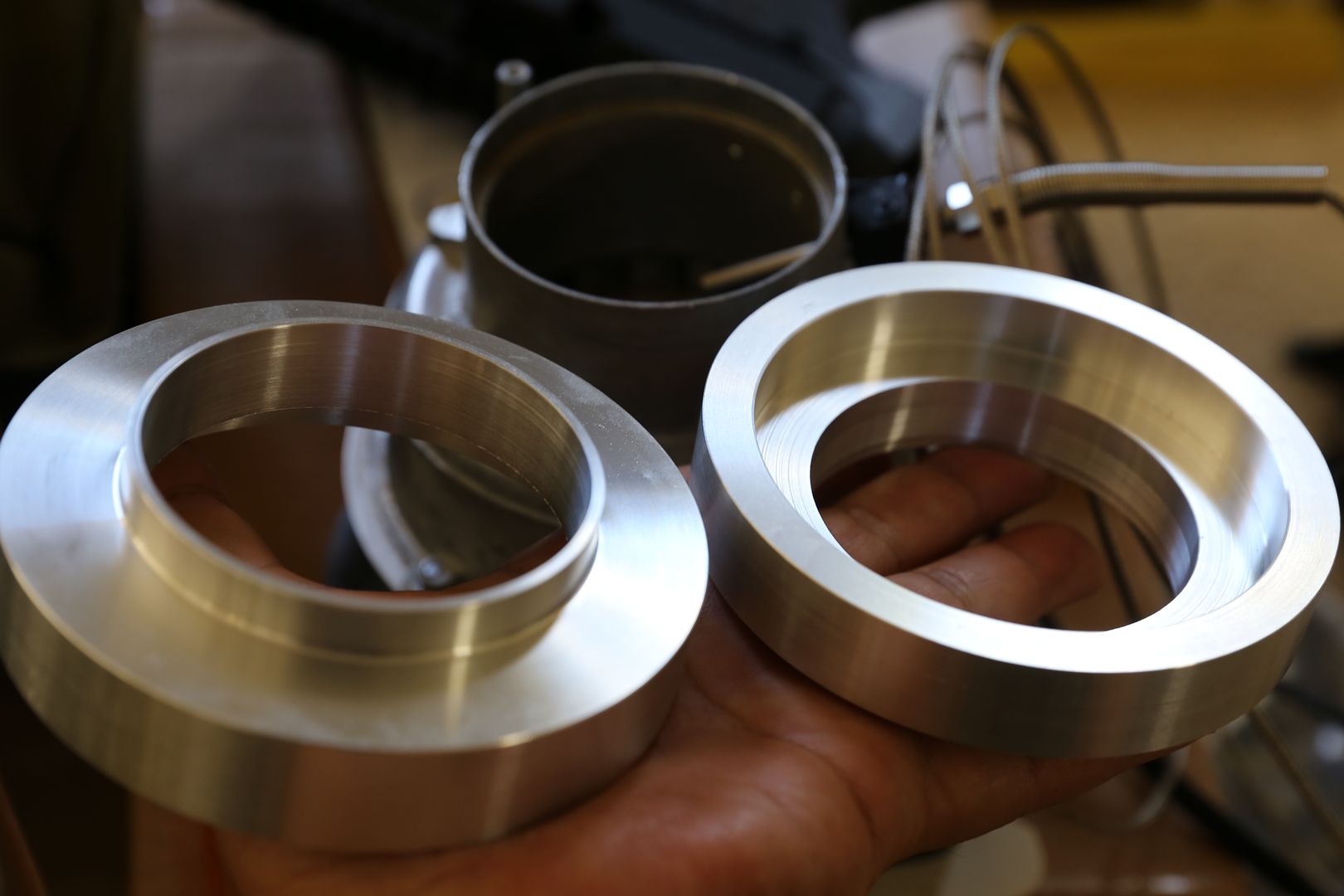

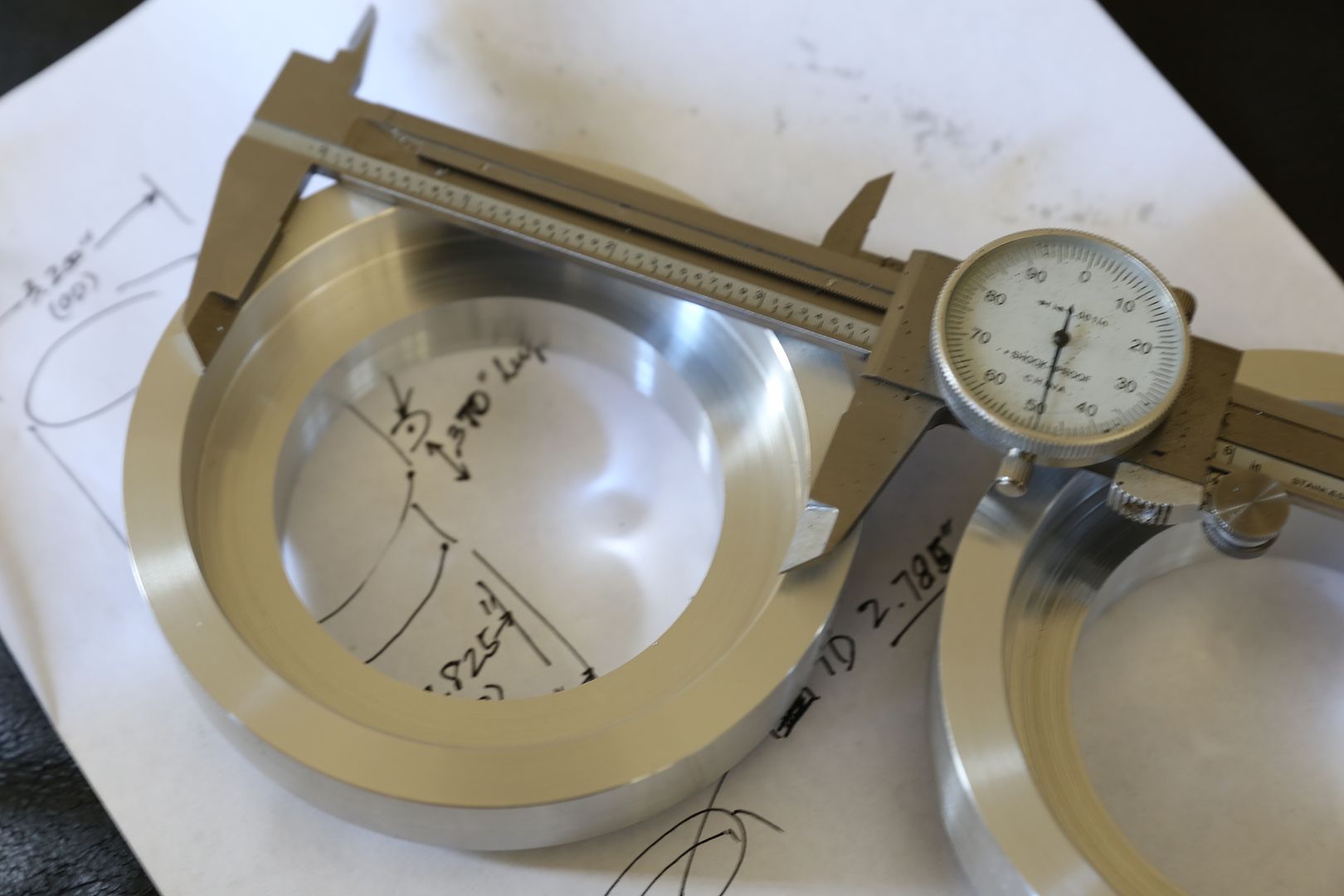

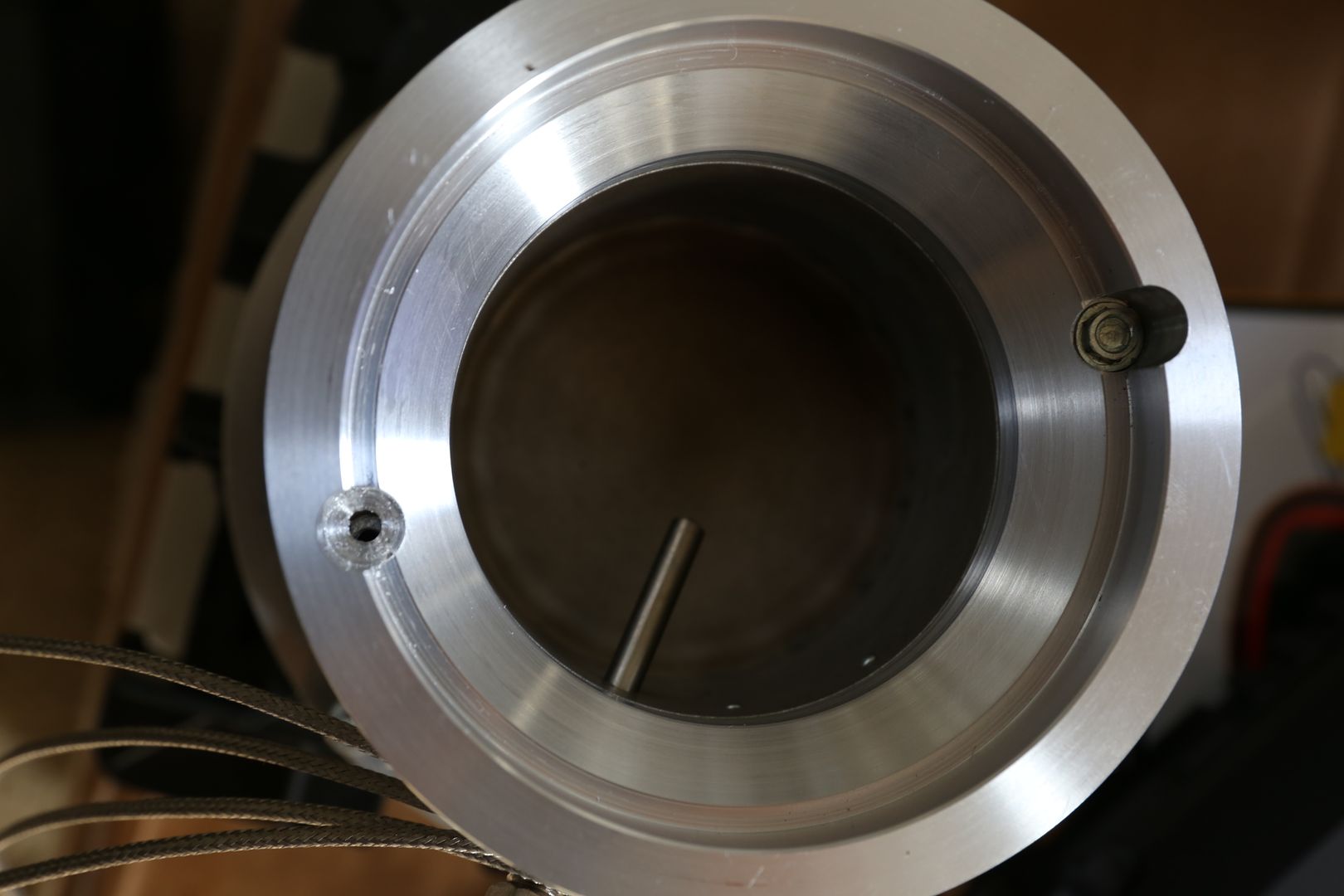

OK, I've fixed the 'short' lip... both adapters are the same (one for a backup P1): Now I have to cut a taper to 'blend' the diameter from the roast chamber up to the bake a round. I picked 29 degrees because the lathe is already set up at 29 degrees for cutting SAE threads:  It is obvious the 29 degree is too shallow, the taper does not reach down far enough:  So, next I try 50 degrees and take another cut:  It is obvious that this cut is too steep; I need something about in the middle of those 2 angles, so I pick 42.5 degrees and take another cut:  Just right. Now I have to mount it to the P1. The calipers show the exact spacing between the mounting holes (3.750" center to center):  and, as you can see, this bolt spacing is right in the middle of the transition area in the spacer, so I can't do separate mounting point under the flange, which is what I was originally planning. I decide to just cut straight into the top. Here is the adapter mounted into a dividing head, which can spin the unit clockwise or counter clockwise an exact number of degrees, so I can rotate it 180 degrees and drill another hole exactly opposite the first:  After 2 holes are drilled, I bolt up one side; the other side is OFF slightly, by about half a hole's diameter:  I'm not sure where the inaccuracy is coming from, the original mounting boss may not be exactly 180 degrees from the other? So I end up cutting one of the holes slightly sideways to let the mounting bolt move sideways slightly:  P1 now has the adapter plate mounted securely. Now I put the pyrex tube into the adapter; I have to find some insulating material to soften the contact between the plate and the glass so it doesn't crack. Also, the hose clamps I ordered are the WRONG size:  |

|

|

|

| BenKeith |

Posted on 09/25/2016 6:57 AM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

Wow, you had to machine a new piece. That was expensive. If your design requires being able to lift the glass off, I would look at cutting a couple O-ring groves and fit O-rings in it to give it a slight friction fit. If it's a permanent fit, they sell food grade, high temp silicone, but most you find is red. I just noticed your mounting holes, that's going to make cutting O-ring groves a pain. Not sure the purpose of the clamp Edited by BenKeith on 09/25/2016 7:07 AM |

|

|

|

| walt_in_hawaii |

Posted on 09/25/2016 12:18 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Benkeith, the clamp is going to be used like on the original post indicated. I want to be able to take the glass off for washing, so siliconing it in place is not an option (although would be the easiest thing to do by far). The clamp will have to be modified slightly, I'll have to weld little ears or tabs onto it so I can drill/tap the mount to attach it to the plate. O rings are a great idea! ....too bad I can't do that, I've machined O ring grooves for other projects, and the fit has to be fairly close. In this project I allowed for a rather large space between the glass and the plate, and no O ring exists that can fill that gap, I would have had to plan on it from the start and made only a small gap... but great idea, wish I had thought of it! |

|

|

|

| walt_in_hawaii |

Posted on 09/26/2016 11:54 AM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Quote BenKeith wrote: Wow, you had to machine a new piece. That was expensive. Benkeith, there were 2 adapters, I didn't have to start over on a 2nd. Since the roundstock that I started on was longer than I needed, I decided to just cut it in half and make 2 of the adapter plates at the same time for only a little more labor time involved since each machine had already been set up for the prior operation on the first plate. There is a show coming up this weekend, so people need a lot of stuff done this week. I'll get back to this probably over the weekend... the oversized hoseclamps need to be cut and a small section taken out, then re-welded back at the correct length. And I have to find some sort of cushioning material between the plate and the glass... Edited by JackH on 09/26/2016 3:27 PM |

|

|

|

| BenKeith |

Posted on 09/26/2016 1:03 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

Well, my next suggestion would be to visit a local hydraulic shop and find a lip seal that fits what you have and cut groves for one or two of those. Problem there is the get dam proud of those things sometimes. Another option, if you have an automatic transmission shop around, they use a lot of different types of rubber lip seals in their clutch packs and you can just cut one to length to fit, those are fairly cheap but not as stiff as hydraulic if you have a huge gap. |

|

|

|

| walt_in_hawaii |

Posted on 10/01/2016 7:06 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

I have a few extra parts now... the top black bezel on the stock unit, and also the black bakelite chimney will be useless in a little while. If anyone needs these parts, please contact me off list, they are free if you pay shipping to where ever you are (US only please). If you are on Oahu we can meet somewhere, no shipping. aloha, walt |

|

|

|

| walt_in_hawaii |

Posted on 10/07/2016 1:39 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

The only update I have is, the top of the plate has been drilled and tapped 1/4-20 for three screw holes at 120 degree intervals to hold down either 3 long studs to hold the cap and pyrex tube in place, or else 3 hold down studs (short) for a clamp type arrangement on the pyrex tube. I opted for 3 because we have 3 degrees of freedom; x, y, and z wherein the pyrex tube can shift. (4 actually, if you count a torsional rotation) Yesterday, I just held the pyrex tube in place and did a bean airlift test (with cold air and green beans), to see how much bean movement I could get, and what my max roast size would be.... Arrrrghhh, the results were less than stellar, very disappointing. it seems my sample size would be limited to 175g ish... looks doable, but 200g BARELY moves. This is with green beans, of course; so after a little drying 200g or even slightly more might be a possibility. But this is still very disappointing... I was hoping for 220g-250g. I'm being limited by the basic design and airflow of the original P1, and if I want more I am pretty sure I'll have to start sourcing parts and going with my own design, like the other people here who have done similar work. :( I did take some video, but I don't think I need to post it here... everyone knows what slowly moving beans looks like. Building from scratch does not sound that difficult to do, but what's holding me back is the roast size has diminishing returns and that point appears to be JUST about near the 200g mark.... bigger than that, I won't need (very often), and smaller than that, I can still make up (and have been doing so) by doing multiple roasts of the same bean if necessary. Hmmmph. Let me stew on this awhile. Its hard to jump ship when you've already collected 3 P1's in the garage... the pyrex tubes can be used in the new design, but machining new tops and bottoms would be a lot more work. aloha, walt |

|

|

|

| btreichel |

Posted on 10/07/2016 6:46 PM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

Have you put about a 15 degree tilt to it? |

|

|

|

| walt_in_hawaii |

Posted on 10/08/2016 10:13 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Yes, I've experimented with about 5 to around 20 degrees, a little over 10 degrees seems pretty good... but there isn't enough air, especially with coffee that has larger, heavier beans like ka'u, which has the largest beans I've seen. Ethiopians seem to work best, they have tiny beans; but even then I can still do only 200g max, I think. This will work, but I think I'll look for an old vacuum cleaner that someone doesn't want to do some tests.... |

|

|

|

| btreichel |

Posted on 10/08/2016 10:48 PM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

Are you boosting the voltage? It took me about 140 volts to get to 28o grams |

|

|

|

| walt_in_hawaii |

Posted on 10/09/2016 3:16 AM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Haven't measured my voltage with a dmm, but yes, I'm using a variac which goes to 140v. I hear the P1s vary in their airflow quite a bit, though; I think I will try one of my other ones and see if it is able to lift more beans than the current one I'm using. |

|

|

|

| btreichel |

Posted on 10/09/2016 10:29 AM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

The other thing I note ( working with my new one) is that it's takes more voltage to get the bed moving, than keeping moving. Try stiring / moving the beans a bit to get motion going. PS, didn't do this with my old p1. |

|

|

|

| walt_in_hawaii |

Posted on 10/10/2016 7:35 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

UGHHHH! I opened up one of the other P1s and although the owner says it has almost no use on it, there are problems with stuff that people just don't use very often... in this case, there are layers of cockroach egg casings bunched up in the nooks and crannies of the black bakelite lower portion. I was so disgusted I ran the unit under the faucet while scrubbing with a stiff brush (sparingly near the motor)! and its drying out in the sun right now, I want to leave it a few days in the sun before running any current through it... |

|

|

|

| walt_in_hawaii |

Posted on 10/10/2016 7:44 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

*SIGH* I've sort of resigned myself to just building another roaster at this point. The only thing that will be salvageable from this project are the pyrex bake a round tubes... to be used just above the new roast chamber so I can easily see what the beans are doing. I guess I can also use the aluminum adapter plate upside down as a top 'hat' on top of the pyrex tube... have to make a new bottom, though, so the pyrex can be joined to the yet-to-be-designed-and-made roast chamber (probably stainless?). P1 will still be around as my backup roaster, though, in case something happens to the primary, but the sample size will be limited to 150g-175g ish. I'll just use them with the menard's hurricane lantern glass and see if the 'belly' in the glass helps to toss around more beans. |

|

|

|

| walt_in_hawaii |

Posted on 10/14/2016 5:31 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

my 3" turbo intercooler coupling hose has arrived, I nearly lost a couple fingers trying to use a large knife to cut it into 3x 1" sections as the 3" section was way too long. Silicon can be cut with a knife, but it ain't fun and my knife is SHARP. test roast of a couple batches of around 175g-200g turned out so-so with the lantern glass. I had to use more tilt than before, nearly 20 degrees? to get the beans circulating and they aren't going around and around so much as over-under near the top of the tilted portion. P1 does a credible job... but a bit small on the batch size. Will have to make another roaster. |

|

|

|

| Airhan |

Posted on 10/23/2016 11:44 AM

|

|

1/2 Pounder  Posts: 228 Joined: September 29, 2013 |

Quote walt_in_hawaii wrote: P1 now has the adapter plate mounted securely. Now I put the pyrex tube into the adapter; I have to find some insulating material to soften the contact between the plate and the glass so it doesn't crack. Also, the hose clamps I ordered are the WRONG size:  I wouldn't worry about the pyrex cracking, in my poppery 1 I have a tube held in place with nothing but a pipe clamp. borosilicate glass undergoes such little thermal expansion that so long as your clamp isn't way too tight, you shouldn't have any problems. For your reference: http://forum.home...post_54374 Aaron

"Grind it like it did you some great injustice!"D.L.Clark |

|

|

|

| walt_in_hawaii |

Posted on 10/28/2016 4:35 PM

|

|

1/4 Pounder  Posts: 133 Joined: August 24, 2016 |

Sorry, have to post a pic when I get home, but I've been using the silicone intercooler sleeve with the Menard's hurricane glass and getting reasonable results with my old P1. I'm roasting 150g consistently, and I think I can go to 175g, given the amount of agitation I'm getting, but I'm still experimenting. I have been using the normal 'router speed control' in the black plastic case which is sold by several different vendors on amazon, I got mine for around $18. It worked fine with the P2, but with the P1 (which uses around 250 more watts) it started to 'time out'.... it would click off in the middle of a roast. I'm running into a thermal barrier of some sort, I think it is rated at 15A. It would take 3-4 minutes to cool down and reset, and gets very hot to the touch. I ordered the 'heavy duty' router speed control for around $35 or a tad more, and have been experimenting; its takes getting used to, this one doesn't go from 0-100%, it only goes from 0-60% roughly so its hard to get it into 1C, I have to flip it to 'full' and do away with the knob... so early part of roast its incremental knob adjustment, then from about 3 minutes I just flip it to 'full' and have to use the fan control to stall the heater a little and come up gradually. My stainless rods have come in, so I'll start to put together the chamber assembly for the new roaster which will have a little more capacity than the P1. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman