Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

First roasting

|

|

| BenKeith |

Posted on 11/19/2016 2:06 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

Ok, here's what I come up with and would do if I was going to change it. First, you will need: a Hand full of thermal fuses. a Small 18ga power cord to run the fan after mod a 600W dimmer a 2000W dimmer a 220VAC Primary 36VAC 2 or 3 amp secondary transformer A small wire nut or crimp butt connector. A soldering Iron and Resin Core solder Electrical tape or heat shrink Understand also, if you do any modifications on that roaster, that's all on you. I was just saying if it was MINE, this is how I would try to modify it. I'm not saying it's safe, or it's something you should try to do to yours. I take absolutely no responsibility for anything you do with anything you read on here. Take the white wire that goes from the heater to the motor board off the motor board. For now, tape up the end so the bare wire is not exposed but when done and it works you can cut it out all together. Solder one wire from the transformer secondary to the motor board where you disconnected the white wire. Take the Blue and Black wire off the motor board and use the wire nut or butt connector and connect both of those ends together and tape it up so no bare wire is exposed.\ Solder the other wire from the transformer secondary to the motor board where you took the Blue and Black wire off. Connect the 600W dimmer to the primary of the transformer. Connect the 2000W dimmer to the poppers AC power cord. Now this will let you separately control the fan and the heater. Just understand, having the fan on a separate control, if you forget to turn it on or turn it down too slow, you will blow your thermal fuse and trust me, that is going to happen, more than once. Also notice, I meant to say a 36VAC transformer, that's what it's going to take to run that roaster, a 24VAC will make the fan too slow. Let me know when you get ready to do this, I will be checking the news for some Italian that burned his house down or fried himself messing with coffee roaster. |

|

|

|

| allenb |

Posted on 11/19/2016 5:40 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote BenKeith posted "Connect the 600W dimmer to the primary of the transformer. So, there's not an issue feeding a stepdown transformer with the dimmer's sawtooth waveform output? I remember blowing up a perfectly good 600 watt dimmer feeding a transformer years ago. This was with no load on the secondary. On the other hand, I've seen many seemingly operational circuits posted here with standard light dimmers in conjunction with transformers and I haven't heard of meltdowns. Quote Also notice, I meant to say a 36VAC transformer, that's what it's going to take to run that roaster, a 24VAC will make the fan too slow. Are you aware that some poppers fans are getting anywhere from 18 volts max to 24? Feeding a popper fan that's meant for a max of 18 V could fry or have a short life span at anything over 24. Allen Edited by allenb on 11/19/2016 5:45 PM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| BenKeith |

Posted on 11/19/2016 8:49 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

It's entirely possible you may be right. I did it 16 years ago on my first Poppery I started with and didn't have a problem. However, instead of a dimmer, I used a triac circuit I built, but I think most dimmers use a triac. Then again, I might be thinking when I shouldn't be and it may go off like a Fourth of July fireworks display. For right now, I think he needs to just chase one rabbit at the time. Connect the fan to run when the unit is turned on and not try adjusting the speed until he's more comfortable with it. Right now, I'm willing to bet a dollar to a doughnut he blows his thermal fuse where he forgets to turn the fan on. As for the fan voltage, all I have to go by is the readings he gave me off the heater coils. They are being used as a voltage divider and doing the math, it shows the rectifier is being fed with almost 36VAC from the heaters. The only way to tell for sure would be to do actual voltage measurements across the white wire from the heater and the Blue and Black junction on the fan motor board. Ohms law says it's going to be 31 to 35VAC. Also note, those two black cylinder pieces between the rectifier and motor appear to be wire wound resistors. Not knowing the value of those, the fan itself may be running 18 - 24 VDC at the negative and positive terminals on the board. Again, that would require measuring. Measuring voltages in this thing is something I'm not comfortable with having him doing, so I'm having to base everything off what he has provided me and doing the math. Edited by BenKeith on 11/19/2016 8:54 PM |

|

|

|

| allenb |

Posted on 11/20/2016 7:36 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote ChicagoJohn posted: To replace the power to the blower motor, I used a 50VA 24VAC transformer. While I used a single pole dimmer switch on the primary of the transformer to control the output and thus control the motor speed, I now realize that is not necessary and if I were to do it again, I would just run the motor at full speed and not use the dimmer switch. On my popper, the motor draws about 2.5 amps at 24 VAC so this is why I used a 50VA transformer. With a lower VA rating I tried, the transformer quickly overheated. The transformer case temperature should not exceed 170F (80C). Your system operates at 240 V I think you said. So all of the values will be different but similar principles should apply -- you will have to research that yourself. I went back over John's previous post and see that there shouldn't be an issue feeding pandiani's transformer with a standard dimmer and as you stated "However, instead of a dimmer, I used a triac circuit I built, but I think most dimmers use a triac" they should be built from the same type of circuit structure. John included the dropping resistive element to ensure all of the original heat capacity was replicated when he made his mods. How many watts is that one good for? And, should he include it in this mod? I agree, it would be best if someone could take some as-is state voltage measurements to know for sure what voltage to feed the fan if he decides to forego the fan controller. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| BenKeith |

Posted on 11/20/2016 9:49 AM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

It's not changing the heating element. It will still be using both coils. However, Yes, it will loose the small amount of load the fan circuit is using but have no way of knowing what the parallel resistance is the motor circuit has so it might see some loss in heating power. I'm thinking (doing that again when not used to it) since it's connected to the bridge rectifier it would be 600 ohms or so, which would make minimal difference across that 41.5 ohm winding. That one will have to be determined. If I was doing it, I would just wind me a new 2000W heating element and stick it in there. It's also possible to regain any loss and add even additional power by shorting out windings on the higher resistance element. Again though, if he's not comfortable with making the changes he want's and can't afford to buy another replacement popper if things go south with this one, he should not be making any changes. |

|

|

|

| pandiani |

Posted on 11/20/2016 1:57 PM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

wow Recap So two of those that are coming to me, you do not need me anymore, is that correct? https://www.amazo...dp_summary Then, a section of cable 18 thermal fuses, 250V 10A is ok? 2 dimmer, 600 and 2000 W, A 220 VAC 2 or 3A. And here I ask you, can I do the test with my 220VAC 2A? Welder, small cap, duct tape. I do nothing. Here we are only 😉 hypothesis. This to see if I understood all of the materials, then calmly read all the steps, and before you do I will ask confirmation. This is a change that you probably would do in 20 minutes. I hopefully will employ weeks :-). The news is if you want to follow in Italy, specifically in Rome, but I hope you just read a new home roaster :-) |

|

|

|

| pandiani |

Posted on 11/20/2016 2:51 PM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

Sorry in english it' s better https://www.amazo...B0197MKV0K I believed that these controllers, instead of dimmer could be fine |

|

|

|

| BenKeith |

Posted on 11/20/2016 4:29 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

They are way over kill but they should work. SF214E SEFUSE Cutoffs NEC Thermal Fuse 216?C 10A 250V. This is the same fuse you have in the roaster now. No Duct tape, electrical tape or heat shrink. Not sure what you meant by your welder. A 45 watt pencil type soldering iron and resin core solder is needed. If you have the knowledge, you would probably want to verify the voltage the transformer needs to be. |

|

|

|

| allenb |

Posted on 11/20/2016 7:44 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote So two of those that are coming to me, you do not need me anymore, is that correct? https://www.amazo...dp_summary Yes, you still need these two controllers. A 2000 watt dimmer is very expensive compared to the controller you're planning on buying. Quote They are way over kill but they should work. Actually, they are advertised as being able to handle 4kw but due to insufficient heat sinking they're probably only able to handle a little over 1800 watts without cutting their life expectancy down quite a bit unless one adds forced air cooling. Allen 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| BenKeith |

Posted on 11/20/2016 9:23 PM

|

|

Pounder  Posts: 485 Joined: April 21, 2014 |

Ok, I think I've gone about as far as I can go with how you can possibly modify your popper. I think these guys can help you more. I'm sure they have more experience at modifying them than me since I've never done but one and that was 16 years ago and I've never gotten into using dimmers. They are just what they say they are and I buy or build controls designed for the application I want. I'm sure ya'll can get it worked out. |

|

|

|

| pandiani |

Posted on 11/21/2016 4:14 AM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

I have mistranslated, electrical tape, and I have soldering iron, and I also resin-core solder. I just have to buy the thermal fuses these: ?https://www.amazo...B00H4WX2DY And understand, the controllers are fine? or I have to buy the dimmer? The 2000W dimmer as Allenb said, it is expensive, but if the controller does not go well, then purchase the dimmer. Last thing, the transformer 220VAC ok, but, 24V or 36V secondary? 2 or 3 A.? The thing I want to know is if trying this with my 24 I would have the only problem I could go more slowly, and that's it, or it could burn anything? in that case I would purchase the secondary 36A immediately. |

|

|

|

| pandiani |

Posted on 11/21/2016 10:00 AM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

however, not easy to find a transformer 220Vac / 36V 3Amp I'm looking on the internet and I find only Chinese, shipping time 1 month |

|

|

|

| pandiani |

Posted on 11/21/2016 11:45 AM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

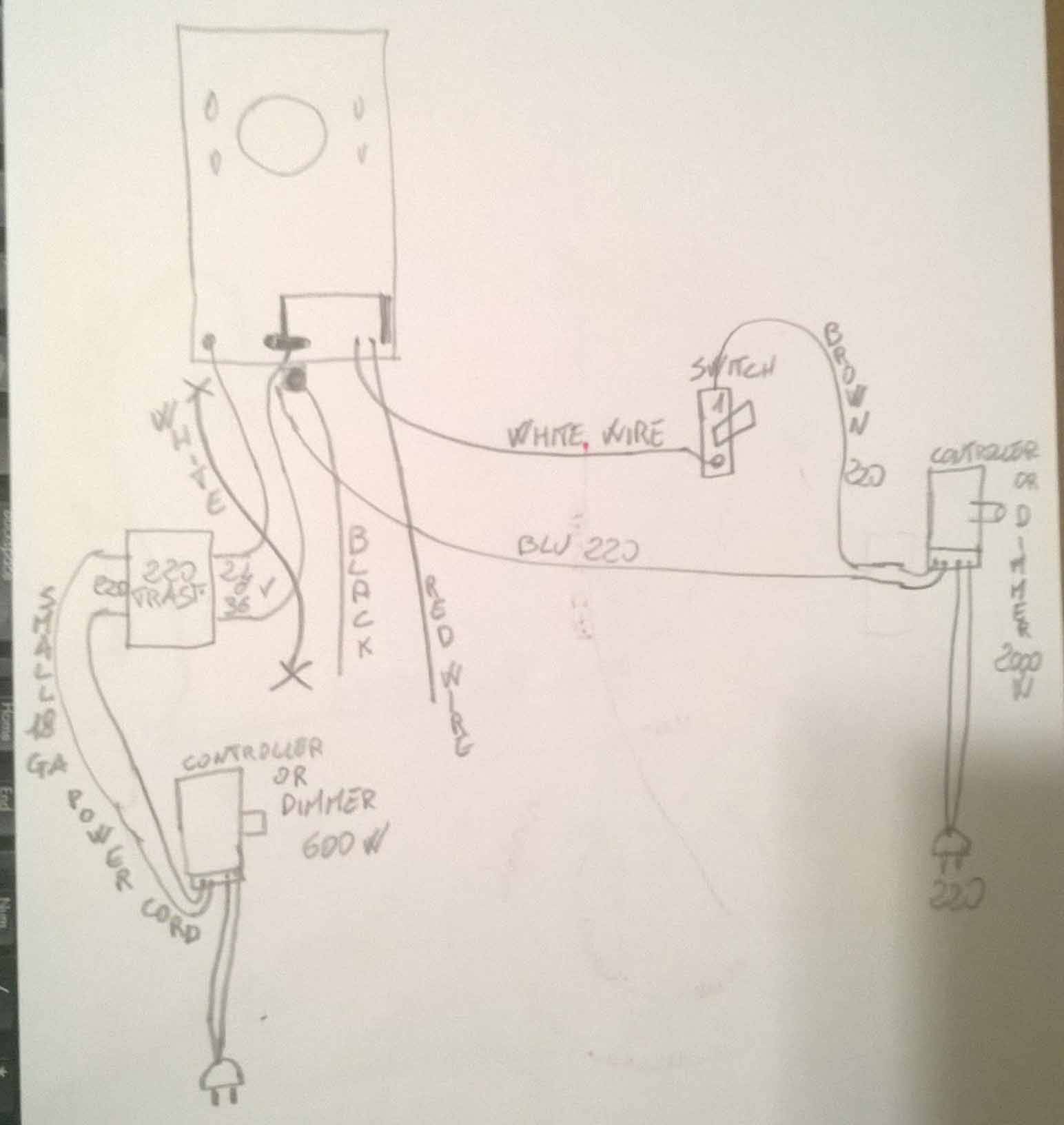

This is what I understand, very simple scheme. A question, I can remove the switch, connect the white wire and brown wire, and possibly put a switch between the power cord and the controller or dimmer?

pandiani attached the following image:

|

|

|

|

| pandiani |

Posted on 11/23/2016 5:26 AM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

Hello everyone, I wanted to inform you that the controllers arrived yesterday, ahead of schedule, and I assembled everything and now .... EVERYTHING WORKS I would like to thank all of you, that you have been precious for me, especially BenKeith. Now I just have to put everything in a box, to make a clean job Soon I will post a video on youtube Thank you all, magnificent forum, attended by wonderful people, who have allowed me to realize a small dream. I am very satisfied. Thank you |

|

|

|

| pandiani |

Posted on 11/30/2016 11:16 AM

|

|

1/4 Pounder  Posts: 74 Joined: November 05, 2016 |

Going forward, and doing various roasting tests, there are the first technical questions. I realized that if I put 100 grams of beans, and turn on the air, they do not move, if I tilt a few degrees popper, move, but little. If I put 60 gr. no problem. If you start with the heat and 100 grams, then with beans that do not move (at least at first, because they have much, humidity inside) risk of burn? Or the beans will begin to move after a few seconds and you do not burn? Essentially I wonder if there is a solution to roaster 100 or maybe 150 grams of beans. Or my popper has a low ventilation, and I can not roast more than 60 gr at a time? |

|

|

|

| btreichel |

Posted on 11/30/2016 3:10 PM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

tilt and stir. they will lighten and expand. as along as you keep your heat within the guidelines discussed, no problem. Try 150, you wil find out. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman