Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 9

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

Using a TC4 with Artisan Roaster Scope

|

|

| renatoa |

Posted on 10/02/2021 3:21 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

A reason of the above issue could be how is the board cased/vented, related to the cold junction compensation. https://www.omega...principles If using a closed enclosure, heat can accumulate inside, and shift the AT sensor value from the real ambient value. In an ideal world, the AT sensor should be placed stuck to the TC connection terminal block, if possible even to the screw metal, because that is the point what we call "cold junction". This terminal block usually is exposed to open air, so could be considered closer to ambient temperature than the AT sensor, which is located inside the case. We can see in the data above there is a 1.6-1.7 degrees (23.8-22.2) difference between AT and TC values. This is the temperature difference between the TC connector and the sensor location, some cm away on the board. Even if this difference can be compensated in the software, if the enclosure is not well vented, will shift in time. |

|

|

|

| TheHobo |

Posted on 10/04/2021 7:57 PM

|

|

Newbie  Posts: 16 Joined: September 14, 2021 |

So it was set up on my desk in an enclosure that was open. Next to no heat sources or anything like that. Didn't realise the TC had an ambient sensor on board - that's good to know. I did receive my TC's but currently away from home this week - looking forward to trying some roasts this weekend! Thanks again |

|

|

|

| TheHobo |

Posted on 10/10/2021 10:41 PM

|

|

Newbie  Posts: 16 Joined: September 14, 2021 |

So I did 2 roasts the other day - First was an Indian Elephant Hills followed by an Ethiopian Sundried Gambella The Elephant Hills was first, and way too fast. I preheated to 120C and dropped - had temp then set to 450C on the heat gun. Dropped around 210C - whole roast only took 6:45 Tried the Ethiopian Sundried next, didn't preheat and started at 380C, but dropped it and moved it around a little bit during the roast. Still too fast, i'll start at 350C this time around. These were my second and third roasts ever - and first since I have had thermocouples. Both roasts were 400g I'll be doing another Elephant Hills later today - any tips/suggestions (apart from further reducing temps)? Not sure if this would be better suited in another thread Thanks! https://i.ibb.co/8PWfhBn/9-Oct-Ethiopian-Gambella-Sundried.png https://i.ibb.co/vsNDxxC/9-Oct-indian-elephant-hills.png |

|

|

|

| davsvatos |

Posted on 05/07/2022 1:17 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

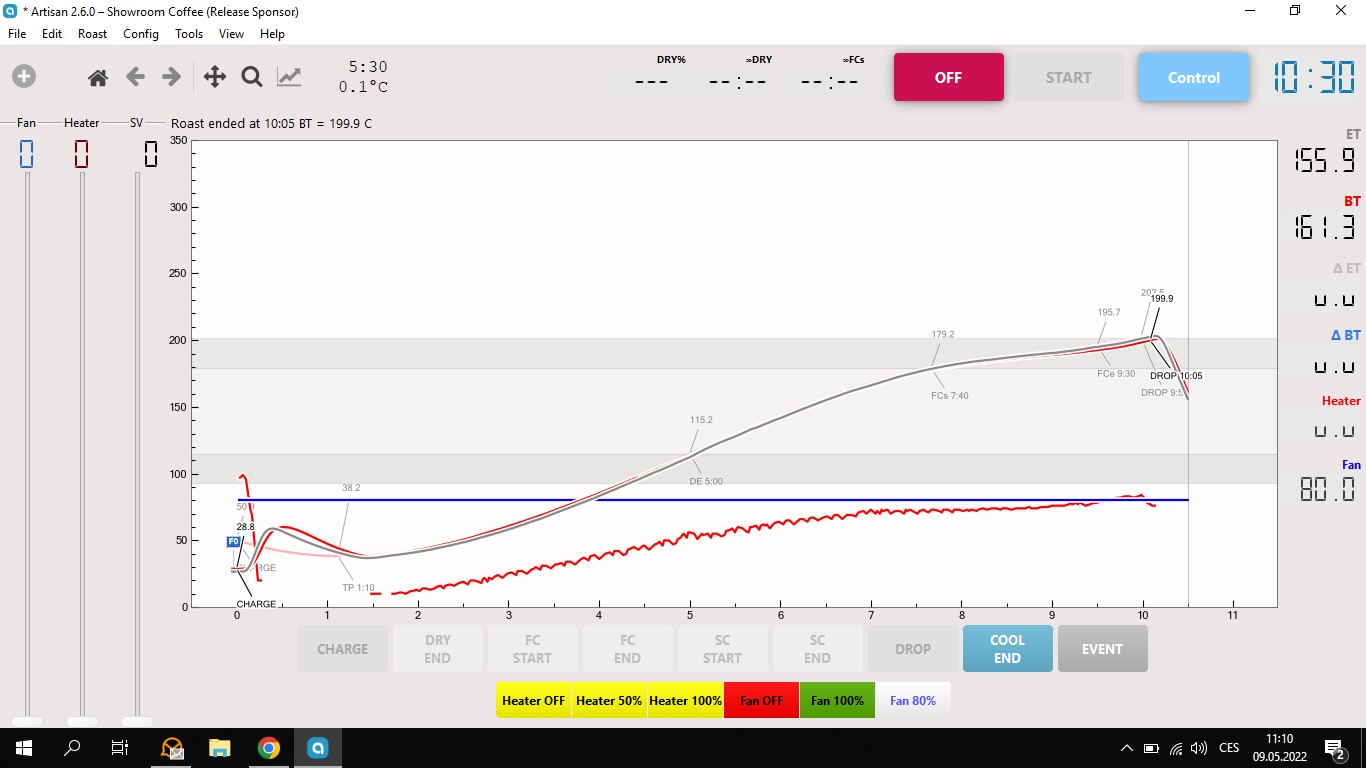

Hi, Do you know someone why on this temperature is PID regulation turn off, set "DROP"and the heater is switched on to 100%? It is each roasting. I still have to tune the fluctuations of the curve, but that's not the subject now. thank you for the advice!

davsvatos attached the following image:

|

|

|

|

| renatoa |

Posted on 05/07/2022 2:20 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Because PID;OFF command just stop profile following, keeping the last power level unchanged. You should use PID;STOP command on DROP, for complete heater cut off. I am using PID;OFF in the first crack, to allow me drive the roast during development. Also during charge, and some time after turning point, the soak period, the PID is disengaged. Edited by renatoa on 05/07/2022 2:23 AM |

|

|

|

| davsvatos |

Posted on 05/07/2022 2:22 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

Quote renatoa wrote: Because PID;OFF command just stop profile following, but not turn off the heater. You should use PID;STOP command on DROP, for complete heater cut off. Yes, I know. But it stopped by itself, the PID was supposed to run to the end of the profile. It will never finish the profile and it will end like this + - at the same point. I didn't find where I was making a mistake. |

|

|

|

| renatoa |

Posted on 05/07/2022 2:30 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Are you using a background profile following ? If true, and the background profile has a drop event at some point, the profile is finished abruptly when reaching that point, whatever is temperature or the previous events evolution. For this reason the drop event of the profile should be better placed much farther than it normally occurs, just for safety, to have a roast finish always, if you aren't around, or you are disturbed by an unexpected event. And drop manually, with the button. If you don't use a background profile following, please explain what is your roasting routine. As a side note, I am puzzled why your power is 100% all the time... how you control the roast ? |

|

|

|

| davsvatos |

Posted on 05/07/2022 6:50 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

Quote renatoa wrote: Are you using a background profile following ? If true, and the background profile has a drop event at some point, the profile is finished abruptly when reaching that point, whatever is temperature or the previous events evolution. For this reason the drop event of the profile should be better placed much farther than it normally occurs, just for safety, to have a roast finish always, if you aren't around, or you are disturbed by an unexpected event. And drop manually, with the button. If you don't use a background profile following, please explain what is your roasting routine. As a side note, I am puzzled why your power is 100% all the time... how you control the roast ? Yes, I'm using a background profile following. I only start the roasting process and the PID regulation follow the background profile. And +- at the same place, PID regulation stop by itself. On the screen you can see my settings. On 100% is set only FAN (blue). Heater is the red curve.

davsvatos attached the following image:

|

|

|

|

| renatoa |

Posted on 05/07/2022 7:03 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

What you mean by +-, is about fan adjustment ? If you have a HTR_CUTOFF_FAN_VAL value of 50, in user.h, then any +/- of the fan slider around this value, will cut or reinstate the heater power. Move the slider to 49 and heater will be cut, move it to 51 and it is back heating. This behavior could look to you as a PID stop, but actually PID continue to work, only the heater is switched on/off, as an overheat protection for fluid bed machines. What about the drop event I wrote above, do you have such event mark in the profile file ? Can you post here attached the profile file, for an analysis ? |

|

|

|

| davsvatos |

Posted on 05/07/2022 8:02 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

Quote renatoa wrote: What you mean by +-, is about fan adjustment ? If you have a HTR_CUTOFF_FAN_VAL value of 50, in user.h, then any +/- of the fan slider around this value, will cut or reinstate the heater power. Move the slider to 49 and heater will be cut, move it to 51 and it is back heating. This behavior could look to you as a PID stop, but actually PID continue to work, only the heater is switched on/off, as an overheat protection for fluid bed machines. What about the drop event I wrote above, do you have such event mark in the profile file ? Can you post here attached the profile file, for an analysis ? no no, "+-" I mean "around" - around the time 7:10 is the PID regulation stopped by itself...and further like I wrote before. DROP I have in the roasting profile on the end in 9:59. Here is the profile: https://drive.goo...sp=sharing Edited by renatoa on 05/07/2022 8:21 AM |

|

|

|

| renatoa |

Posted on 05/07/2022 9:19 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Nothing suspicious in your profile... except the unusual values and allure  I am using a tool like this: https://freeseria..., when I want to diagnose a suspicious Artisan to TC4 traffic. Give it a try and see what commands are sent in the moment of PID drop. |

|

|

|

| davsvatos |

Posted on 05/08/2022 8:22 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

Quote renatoa wrote: Nothing suspicious in your profile... except the unusual values and allure  I am using a tool like this: https://freeseria..., when I want to diagnose a suspicious Artisan to TC4 traffic. Give it a try and see what commands are sent in the moment of PID drop. Do you have some short tutorial on this app for diagnosis the TC4? Because I don't know the app. Thank you for help so much! |

|

|

|

| davsvatos |

Posted on 05/09/2022 2:11 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

Quote renatoa wrote: Nothing suspicious in your profile... except the unusual values and allure :D I am using a tool like this: https://freeseria..., when I want to diagnose a suspicious Artisan to TC4 traffic. Give it a try and see what commands are sent in the moment of PID drop. Sorry, this app doesn? work on my PC. But I try another app for serial monitor and I have this. It is from the time of the end of PID. After this event PID doesn't work and the heater work on 100 %. Code Download source READ Code Download source [09/05/2022 08:39:45] Read data (COM4) I see that It set in the time max SV temperature, so the PID is not inactive. But regulatio doesn't work. I can make video what is it do. |

|

|

|

| renatoa |

Posted on 05/09/2022 2:45 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

This jump, from 175 to 210 degrees, of requested setpoint, definitely is not right, and looks like an Artisan issue. Would contact the author on this subject. First reason, the jump is too big, and out of profile values sequence. As I read in the .alog file you sent, the sequence should be: Code Download source ... 174.44961933, 174.72832279, 175.00409465, 175.27691517, 175.5467646, 175.8136232, 176.07747123, ... ... and second, there is no 210 degrees point in the profile, it ends at 202 ! Code Download source 200.88538913, 201.15199614, 201.42259643, 201.69724434, 201.97599418, 202.25890029, 202.54601701], Is this 210 value something set elsewhere in Artisan, maybe a (wrong) command on a button ? In the .alog file the value exists only as a timex marker, the 210 seconds moment of profile, i.e. 3:30 Edited by renatoa on 05/09/2022 3:01 AM |

|

|

|

| davsvatos |

Posted on 05/09/2022 5:49 AM

|

|

Newbie  Posts: 9 Joined: April 21, 2022 |

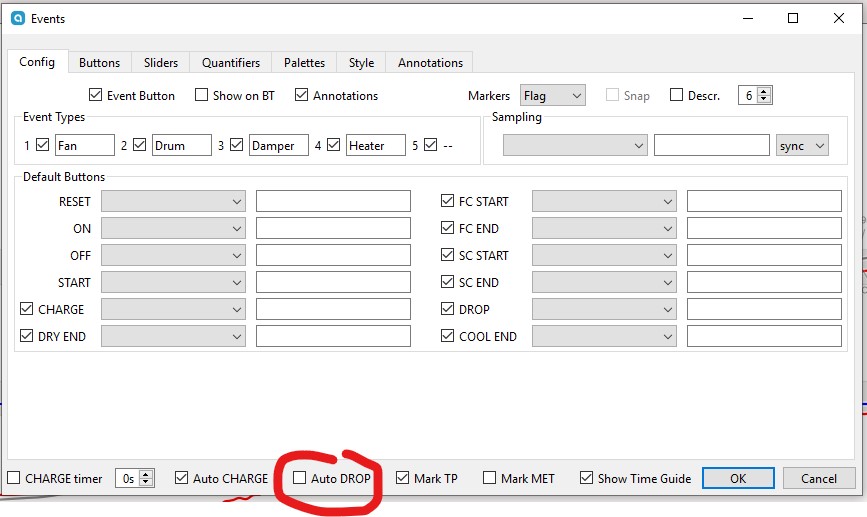

Quote renatoa wrote: This jump, from 175 to 210 degrees, of requested setpoint, definitely is not right, and looks like an Artisan issue. Would contact the author on this subject. First reason, the jump is too big, and out of profile values sequence. As I read in the .alog file you sent, the sequence should be: Code Download source ... 174.44961933, 174.72832279, 175.00409465, 175.27691517, 175.5467646, 175.8136232, 176.07747123, ... ... and second, there is no 210 degrees point in the profile, it ends at 202 ! Code Download source 200.88538913, 201.15199614, 201.42259643, 201.69724434, 201.97599418, 202.25890029, 202.54601701], Is this 210 value something set elsewhere in Artisan, maybe a (wrong) command on a button ? In the .alog file the value exists only as a timex marker, the 210 seconds moment of profile, i.e. 3:30 I found it! It was in this checkbox "auto drop". If I turned off this function It was OK. At least I boast with PID settings, now It is good :) Thanks a lot for help.

davsvatos attached the following images:

|

|

|

|

| renatoa |

Posted on 05/09/2022 12:06 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Make sense, and coupled with your noisy BT... as mentioned in this thread: https://homeroast...ad_id=5699 ... will trigger a false drop. |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman