Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Another DIY Drum roaster

|

|

| groucho |

Posted on 03/10/2018 1:03 PM

|

|

Newbie  Posts: 14 Joined: March 10, 2018 |

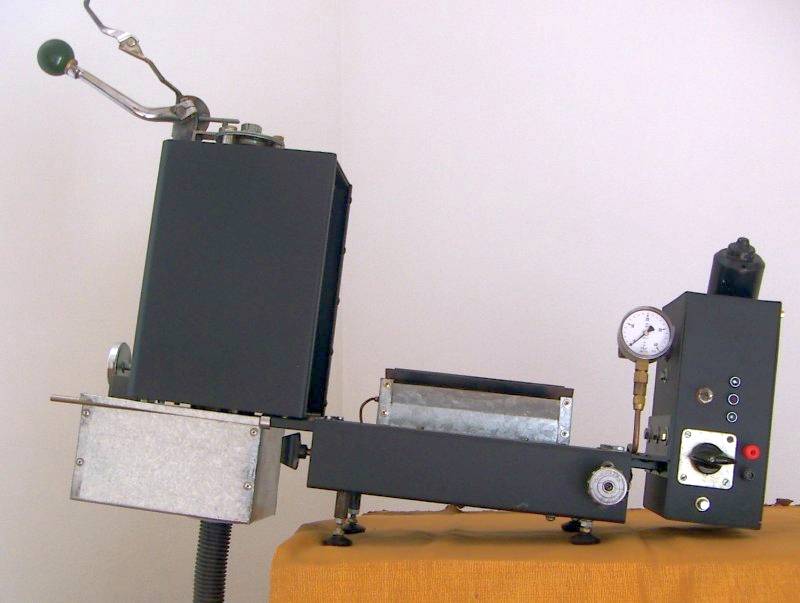

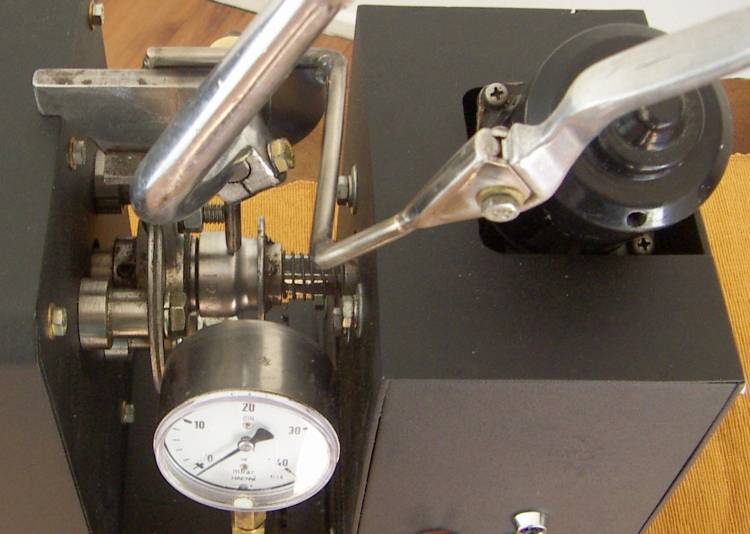

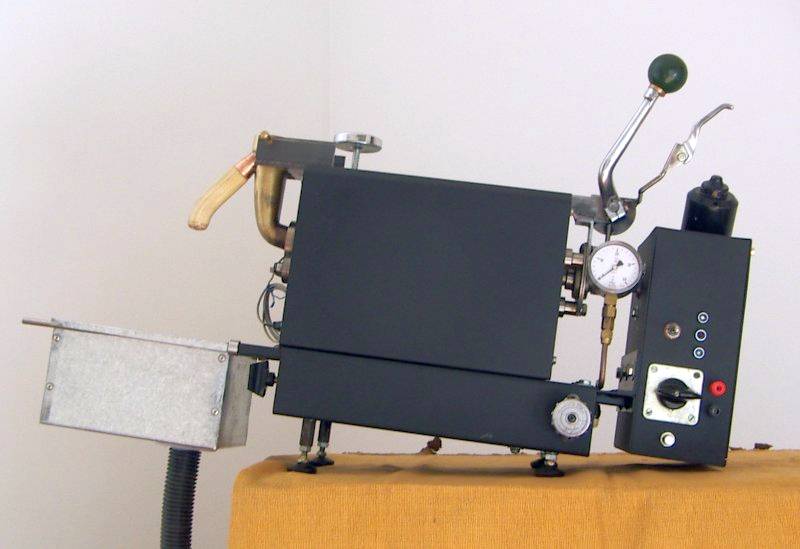

Hello: New memeber, usually posting at Home Barista. I had meant to post it here at the same time but forgot ... =^/ So here it is. --- I finally managed to put the finishing touches on a roaster I've been working on for the longest while. It's a three speed gas fired solid drum design (based on the simplest Jabez Burns sample roaster, from the end of the 19th. century) open end, no trap door (tilt to empty) which runs on a 12V high discharge battery. Knowing I could (very!) easily get carried away with my spending, when I started the project I decided it had to be simple, as much DIY and inexpensive as possible, using as many recycled/discarded parts from whatever source was suitable and built at home in the reduced space available in my apartment to keep external (=$) intervention in check. The inevitable rolling, bending, welding and lathe work also had to be kept at a minimum. Because of all this, in the end it made for a rather long and drawn out process, with more interruptions than I care to remember. The photos sort of speak for themselves: it's just another drum roaster, of the simplest kind but most importantly it is effective enough for my needs, around 600 grams/session without much ado. I make an effort to roast with my sight/nose/ears plus the use of a two channel temperature logger (Mastech MS6514) to feed the Artisan software running on an Asus 1000HE netbook and a single channel Tenmars TM-712D (to replace the pizza oven thermometer seen in the photos) to monitor the box temperature. Unfortunately, this last one does not work with Artisan and I was not able to convince the autors to write a driver for this RS-232 meter. Just for fun, this is more or less the list of the parts I used in the building, all of them found discarded/binned/had or obtained for small cash on the local fleabay sites: - a crankshaft pulley from a 1994 Renault 18 sedan - a set of burners from a discarded gas fired water heater - a gas valve and safety control device from a discarded IR room heater - the old set of bearings from my Cimbali Max Jr. - an auto-centering bearing from a stripped chemical lab machine - a wiper motor from a 1990 Suzuki Swift - a 12v battery from a burnt out server room UPS - assorted rotary cam switch parts to make a 'working' one - adjustable leg ends from discarded office chairs - a small 250cc motorbike kick start - a bowls game ball, leftover form a tamper project - a discarded bicycle brake lever - a pair of stainless steel rods discarded by a Xerox machine repair guy - a brass bathtub faucet part from an apartment renovation - short piece 1/2" leftover copper pipe - a piece of a small stainless steel Chinese colander - a piece of processed bamboo handle from a cheap umbrella found on the street - switches, cabling, terminals, pilot lamps as well as screws, bolts and washers came from my various bins - a rechargeable 2kg. camping propane tank And this is more or less the list of the parts purchased new: - 1.5 mm sheet steel - 0.9 mm galvanized sheet steel - a 15/16" hex socket - aftermarket freon charge valve for a split AC unit - replacement igniter parts for a gas fired convection room heater - heavy duty steel weld-on door hinge - automotive fuse holder and fuse - propane tank regulator and hose - 40 mBar gas manometer - 350? C pizza oven thermometer - SS braided J thermocouple wires - screws, bolts and washers I did not have at hand - electrostatic epoxy paint job (a last minute decision) In use, some light coloured chaff from the initial drying phase ends up exiting through the holes at the rear end of the drum, where I just clean up afterwards. Not the best solution but it's easy and quite simple, no complex tubes and funnels. Roasting smoke is taken care of with the kitchen extraction mechanism and the bean cooling and post roast chaff collection with an old Toshiba vacuum cleaner connected to the bottom of the collector tray at dump time, very efficient. With the manufacturer's instructions (+ the usual caveats) and a change of the burner's gicleurs, I tricked out the gas regulator so as to get about 30/35 mBars pressure with the valve open at 100% and this allowed me more firepower with the use a set of four burners instead of the original two you see in the photos. It also gave me a wider regulation range (0-35 vs. 0-24). The freon charge valve's original stem was replaced by a different one turned to my specs so as to be able to be able to regulate the gas flow as finely as I wanted and improve security with a tighter o'ring. As you may guess, I now have absolutely no idea where the original burner rating has gone. The four position cam switch at the front allows the use of three different drum speeds (42/52/62 rpm) and the two +/- posts at the front are to be able to top the battery's charge before roasting. I had planned to add an elementary electronic circuit to flash one of the LEDs at front when the battery went low but have since dropped the idea. As time went by and work progressed very slowly, I ended up losing track of the parts/expenses list but my guess is that the whole thing set me back roughly between US$450/US$550, a fair part of which went to spending on what could be alloted to R&D, non-working designs, wrong choices in materials, etc. And that's about it. Ahhh ... Yes, the photos. I have attached eight *.jpg files of the roaster and a batch. (Finally got it right) Cheers, G.

groucho attached the following images:

Edited by groucho on 03/11/2018 8:02 AM |

|

|

|

| renatoa |

Posted on 03/10/2018 1:52 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Is the Tenmars TM-712D protocol known ? If Yes, I can write for you a small piece of code to gather signals from Mastech and Tenmars and output them as a virtual TC4 to Android, code already done, without the Tenmars part. Roasters: DIY: TO based IR 200-640g

Commercial, moded: Skywalker, Dieckmann RoestMeister, Nesco, popper(s). Electronics: TC4ESP (author), MS6514, USB/Artisan/Apps (contributor), PID controllers Grinders: Potu ghost burrs, Arco, Xeoleo ghost burrs, Krinder, vintage PeDe Dienes, MBK Feldgrind, Kinu M38 Brew/presso: ALM pour over, Arin lever, Staresso Mirage, Hario Cafeor dripper, Flair Signature, Kompresso, Aeropress, Gaggia Mini |

|

|

|

| groucho |

Posted on 03/10/2018 3:30 PM

|

|

Newbie  Posts: 14 Joined: March 10, 2018 |

Hello: Quote renatoa wrote: Is the Tenmars TM-712D protocol known ? Yes. When the authors of Artisan told me that they needed it, I sent a couple of emails to the people at Tenmars (I had been corresponding with them for some time) and they were very kind to send me the code. Quote renatoa wrote: If Yes, I can write for you a small piece of code to gather signals from Mastech and Tenmars and output them as a virtual TC4 to Android, code already done, without the Tenmars part. [/quote] That's really very nice of you. =-) My netbook still has W98SE (my other hardware was migrated to Linux long ago) as I also use it at the office for minor stuff and runs the WinTel version of Artisan. How would this work? Cheers, G.

groucho attached the following file:

Edited by groucho on 03/11/2018 3:28 PM |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman