Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 4

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 2 guest(s)

|

TC4+ Arduino coffee roaster shield (TC4-compatible)

|

|

| AlexMunt |

Posted on 03/25/2019 4:39 AM

|

|

Newbie  Posts: 9 Joined: February 01, 2019 |

Quote Yes, of course, it should be a PWM, correct me if I'm wromg. |

|

|

|

| mg512 |

Posted on 03/25/2019 5:19 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote AlexMunt wrote: Yes, of course, it should be a PWM, correct me if I'm wromg. OK, that is strange. Should indeed be PWM. Let's narrow it down: Try removing the TC4+ altogether, and measure on the Arduino's IO3 pin. That would rule out the TC4+. And, try the sketch in CONFIG_PWM and CONFIG_PAC2_IO3HTR mode and see if it makes any difference. That would rule out a hardware issue. Also, can you post your user.h, or email it to me? |

|

|

|

| AlexMunt |

Posted on 03/25/2019 5:24 PM

|

|

Newbie  Posts: 9 Joined: February 01, 2019 |

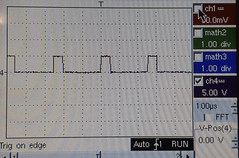

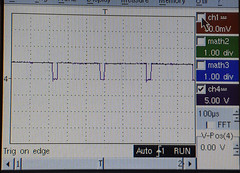

Quote mg512 wrote: Quote AlexMunt wrote: Yes, of course, it should be a PWM, correct me if I'm wromg. OK, that is strange. Should indeed be PWM. Let's narrow it down: Try removing the TC4+ altogether, and measure on the Arduino's IO3 pin. That would rule out the TC4+. And, try the sketch in CONFIG_PWM and CONFIG_PAC2_IO3HTR mode and see if it makes any difference. That would rule out a hardware issue. Also, can you post your user.h, or email it to me? Ok that's it, It was a loose contact, I think. Now I have the signal on IO3 ( 20% on the first photo and 90% on the second). I took off the TC4+ shield, and tested the continuity of the soldered pins, everything was fine. I measured the signal on the Arduino pin 4 and GND and the signal was OK. I plug in again the TC4+ shield and measured. Everything was OK. For that reason I think it was a loose. [img]  20190325_224416 by Alexandru Bogdan Munteanu, en Flickr[/img] 20190325_224416 by Alexandru Bogdan Munteanu, en Flickr[/img][img]  20190325_224354 by Alexandru Bogdan Munteanu, en Flickr[/img] 20190325_224354 by Alexandru Bogdan Munteanu, en Flickr[/img]Thanks again, mg512, a lot, for helping me to solve the ishue. P.S.:The user.h file is atatched.

AlexMunt attached the following file:

|

|

|

|

| mg512 |

Posted on 03/26/2019 5:31 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Ah, haha, it's always the simplest low-tech things that don't even occur to you! Glad you sorted it out.  |

|

|

|

| Ilovehash |

Posted on 03/27/2019 1:47 AM

|

|

Newbie  Posts: 4 Joined: January 03, 2019 |

Placed an order of TC4+. Got the shipment and have it setup. The DC motor control works fine. My UNO did not reset itself with TC4+. I had UNO reset issue when I use DIY IRF540 circuit to drive the FAN. Really happy with TC4+ DC Fan control. The thermal couple however is very sensitive to noise and I got jumpy readings. The same TC installed on MAX6675 are very stable. Once it is installed on TC4+, the temperature reading became very unstable. Moved TC4+ to different room in my house the outcome would vary. In some room it produces stable reading. Other rooms would not reliably read the temperature. Is it an EMI issue? Any good solution to it? |

|

|

|

| mg512 |

Posted on 03/27/2019 4:26 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Interesting about the DC fan and reset - happy to hear it's working well with the TC4+. About EM noise, that sounds strange, especially it being different in different rooms. A few questions: * How unstable is unstable +- 1C, 2C, 5C? Does it happen just when trying to measure the ambient temperature? * Does it make a difference if the fan is on? Does it happen when the fan is completely off? If it makes a difference, what kind of fan is it, and do you have any capacitors and/or inductors on the fan? * Same for the heater - does it still happen when everything is off? * How is the TC4+ and the fan powered - what kind of power supply? Arduino via the TC4+ on-board voltage regulator? How is it connected to your computer (USB or Bluetooth)? Is the computer plugged into the mains, or on battery? (If you connect via USB, try the computer on battery - does that make a difference?) |

|

|

|

| Wiz Kalita |

Posted on 03/27/2019 11:01 AM

|

|

Newbie  Posts: 49 Joined: August 06, 2018 |

I recently eliminated most of the noise in my thermocouples by wrapping the leads in aluminium foil. The other cables in my setup are able to induce enough of a current in them to give several tenths of degrees of noise. The rest of the noise I got rid of by isolating the TC4+ from electrical noise. The fan is now switched on and off through an SSR connected to OT2, and my laptop runs on battery. All these things helped a lot. |

|

|

|

| Ilovehash |

Posted on 03/27/2019 11:11 PM

|

|

Newbie  Posts: 4 Joined: January 03, 2019 |

I wonder if TC4+ provides any warranty. I just got the board for 3 days but it looks like the temperature reading now is totally none responsive. Both ET and BT reading stays at 27. I only connected to channel one but both channel 1 and 2 stays at 27 degree. Applying heat did not give me any change on temperature reading any more. It started with temperature fluctuation about +-10 degree celsius for the first two days of operation before it fails. |

|

|

|

| mg512 |

Posted on 03/28/2019 5:07 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote Ilovehash wrote: I wonder if TC4+ provides any warranty. I just got the board for 3 days but it looks like the temperature reading now is totally none responsive. Both ET and BT reading stays at 27. I only connected to channel one but both channel 1 and 2 stays at 27 degree. Applying heat did not give me any change on temperature reading any more. It started with temperature fluctuation about +-10 degree celsius for the first two days of operation before it fails. Yes, of course! Email me with the details ( coffee@gerstgrasser.net ) and we'll sort it out. |

|

|

|

| Shamu1023 |

Posted on 04/19/2019 9:07 PM

|

|

Newbie  Posts: 2 Joined: April 19, 2019 |

How can I use this on my Hottop B2K? Any install instructions? Do I need something called an HTC board too? Seems theres lots of threads about this, but I cant seem to get a straight answer. Thanks |

|

|

|

| mg512 |

Posted on 04/20/2019 5:10 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote Shamu1023 wrote: How can I use this on my Hottop B2K? Any install instructions? Do I need something called an HTC board too? Seems theres lots of threads about this, but I cant seem to get a straight answer. Thanks Ah, good question. Short answer: It depends. If you are looking for a plug-and-play solution this isn't available anymore. If you're looking for a DIY project, the TC4+ can interface with a hottop as with any other roaster, and no special Hottop board is needed. Longer answer: I think the HTC board you have read about most likely refers to tge "Hottop Roaster Interface" board that was made by Jim, who also made the original TC4. As far as I can tell from what information about it is still available, this board plugged directly into a proprietary control interface in the Hottop roasters. This would probably have made installation very easy. But, unfortunately, this isn't available anymore. I can't find much information on that Hottop control interface, nor do I have access to a Hottop roaster to try to reverse-engineer it, so there is no way I could come up with a new reimplementation of this. (Unless someone wanted to gift me a Hottop. ;)) That said, you can of course still use the TC4+ with a Hottop as you would with any other roaster, by wiring the TC4+ directly to the heater, fan and drum motor. It's a bit more work, you should be qualified to work with mains electricity, and you'd essentially replace the electronics in the roaster with the TC4+. There isn't any instructions specifically for the Hottop roaster, but do have a look at the manual and I've also just made a quick-start guide available here: https://coffee.ge..._start.pdf |

|

|

|

| Shamu1023 |

Posted on 04/20/2019 7:14 AM

|

|

Newbie  Posts: 2 Joined: April 19, 2019 |

I think I get it now. The old TC4 is basically getting TC output to PC, then HTShield would allow Artisan to control heat and fan. The TC4+ "could" do all of the above, albeit with a bit more wiring, and not connector compatible to the Hottop, as the HTsheild was... HTsheild used a hottop 7 or 8 pin wire to keep the original machine unedited. |

|

|

|

| mg512 |

Posted on 04/20/2019 8:55 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Yes, that's essentially it. Technically it's not so much to do with TC4 vs TC4+, more that the HT board isn't available more. In theory you could probably use both the TC4 and the TC4+ with or without a HT board. But the bottom line is the same, of course: Still possible, just a little more wiring as you say and you'll need a solid state relay and a few other bits and pieces. |

|

|

|

| RoastingBen |

Posted on 05/02/2019 4:15 AM

|

|

Newbie  Posts: 5 Joined: May 01, 2018 |

Quote renatoa wrote: You can save significant amounts of memory commenting out the unused thermocouple types in the TC code. For example if your TC type is K, then the code dealing with J and T types is simply occupying memory without never being used. And is a lot if bytes... hundreds. Already did this, PM me for the files if you want to test. Hello community, with regard to the gain in memory for aArtisanQ_PID to run smoother or to have room to implement extra hardware management or calculation, we are left with two options :

Did anyone had any success with one of these 2 options? I would prefer the portability to another Arduino board (leave more room for improvement), but it seems complicated by the different adressing across the various boards. Any feedback would be much appreciated. RoastingBen |

|

|

|

| renatoa |

Posted on 05/02/2019 4:26 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Just announced yesterday a project that partially match what is described as your second option, check here: https://forum.hom...ad_id=5913 |

|

|

|

| RoastingBen |

Posted on 05/02/2019 6:49 AM

|

|

Newbie  Posts: 5 Joined: May 01, 2018 |

Quote renatoa wrote: Just announced yesterday a project that partially match what is described as your second option, check here: https://forum.hom...ad_id=5913 Nice Job Renato :-) I wish there would be some adaptator to connect the NodeMCU board to the CR3 shield of Matthias. This would be a nice integration to avoid fiddeling with lots of extra subboards to get same functionality. RoastingBen |

|

|

|

| renatoa |

Posted on 05/02/2019 7:25 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

It was been explained elsewhere that reproducing the pin logic of an Arduino for other platform would be a task without great chances, even in the frame of the Atmel family of boards, to use another Atmel chip with more memory. |

|

|

|

| mg512 |

Posted on 05/02/2019 9:19 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote RoastingBen wrote: Quote renatoa wrote: You can save significant amounts of memory commenting out the unused thermocouple types in the TC code. For example if your TC type is K, then the code dealing with J and T types is simply occupying memory without never being used. And is a lot if bytes... hundreds. Already did this, PM me for the files if you want to test. Hello community, with regard to the gain in memory for aArtisanQ_PID to run smoother or to have room to implement extra hardware management or calculation, we are left with two options :

Did anyone had any success with one of these 2 options? I would prefer the portability to another Arduino board (leave more room for improvement), but it seems complicated by the different adressing across the various boards. Any feedback would be much appreciated. RoastingBen Those are essentially the two options you have, but there is a lot more specifics to consider in each case: 1. Removing unused code, you could either 1a. as you say, remove code from aArtisanQ_PID, like unused thermocouple types. 1b. you could try aArtisan (without the Q_PID) instead of aArtisanQ_PID. Fewer features, but also smaller memory footprint, and smaller codebase (easier to modify or add features). I've been using plain aArtisan myself, and have never missed anything. 2. For porting to a different platform, it really depends on the platform. 2a. You could go with a different Atmel-based Arduino platform, like an Arduino MEGA. That's relatively similar to an UNO. You would have to connect the I2C pins with a jumper cable, but otherwise the pinout is the same as on an UNO. On the software side, aArtisan and aArtisanQ_PID both use a timer register specific to the UNO to implement the 'slow PWM' on the SSR drivers; you would have to modify that to work on the MEGA. 2b. You could go with something different altogether, like an ESP8266 as renatoa suggested. Much more powerful, but the downside is that it's an entirely different platform and you'd essentially be starting from scratch. You might be able to connect an ESP to the TC4+ with jumper wires, but I'm not 100% sure if the different voltage level would be an issue with any of the hardware. You'd still have to change quite a bit on the software side. The bottom line is, if you do need extra memory, try plain aArtisan - if it has all the features you need and leaves enough memory free, then that's the easiest option. Failing that, you could try a MEGA. There is some work needed to port the slow PWM timer code, but it should be doable. Pinout is close enough to an UNO that you should only need a couple of extra wires. More importantly though, what do you need extra memory for? Just running low on memory is fine, and won't make any difference. It's not like a PC where if you run low on memory it might swap things to the hard drive and run slower. The only situation where you should seriously think about any of this is if you actually run out of memory. This doesn't happen with any of the current sketches, I think. And you would know - it would crash consistently, or not even compile in the first place. I've had a few people ask about this recently though. Is there some new development that I'm not aware of, that actually needs more memory than a UNO has? |

|

|

|

| renatoa |

Posted on 05/02/2019 10:19 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote mg512 wrote: .., Is there some new development that I'm not aware of, that actually needs more memory than a UNO has? There isn't development because Uno is at its limits. When you have plenty of memory, then it is development... all you need is ideas :D Below is what Arduino IDE reports at the end of compile, on the TC4ESP platform.: Quote Sketch uses 276404 bytes (26%) of program storage space. Maximum is 1044464 bytes. Global variables use 36032 bytes (43%) of dynamic memory, leaving 45888 bytes for local variables. Maximum is 81920 bytes. Memory demand that even a MEGA256 can't fulfill... |

|

|

|

| mg512 |

Posted on 05/02/2019 10:37 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote Oh, of course, no argument there. I was just curious if there was something limited specifically by memory, as opposed to the platform as a whole. |

|

|

|

| Jeanknotts |

Posted on 05/03/2019 6:53 AM

|

|

Newbie  Posts: 1 Joined: May 03, 2019 |

But, how to connect SSR? |

|

|

|

| mg512 |

Posted on 05/03/2019 10:41 AM

|

|

1/4 Pounder  Posts: 189 Joined: March 04, 2018 |

Quote There are two screw terminals on the TC4+ specifically for it, OT1 and OT2. Simply connect one of those to the DC side of the SSR with two wires. Plain wires work, you can just strip a few millimetres off the insulation and screw the bare wire into the screw terminal. The SSR will usually also have a screw terminal that can hold the bare wire. Or you could crimp ring connectors onto the wires on the SSR side for an even better connection. Does that make sense? Let us know if anything is unclear.  |

|

|

|

| JackH |

Posted on 05/03/2019 3:46 PM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

Quote mg512 wrote: Quote Oh, of course, no argument there. I was just curious if there was something limited specifically by memory, as opposed to the platform as a whole. It seems to perform it's original roaster/controller function. Would more memory really make a difference? ---Jack

KKTO Roaster. |

|

|

|

| renatoa |

Posted on 05/04/2019 2:48 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

If someone want to replicate a TC4 and nothing else, Uno board is enough. This sub-thread started from the RoastingBen post #89 about advancing to other level. However, from programmer point of view, managing a software of such complexity in such small amount of memory is atrocious. If this would be a real business, you save nothing in processor cost continuing to go with this '90s technology, conversely, programmers able to handle such restrictions would cost you more. Edited by renatoa on 05/04/2019 2:53 AM |

|

|

|

| JackH |

Posted on 05/04/2019 6:19 AM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

This is not business, just people roasting at home. The Arduino is simple and does the job. If someone wants to complicate the roasting process then they can go the engineering route.

---Jack

KKTO Roaster. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman