Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Fluidbed Roaster project

|

|

| cdrake39 |

Posted on 11/05/2019 9:48 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Hi everyone, I've been browsing this forum for quiet some time now and have finally decided to take the plunge and build my own roaster. I have posted regarding "fan/blower sizing" on the r/roasting subreddit, but was directed here as this forum is quite active. Here was my post: I'm looking into building a small, benchtop coffee roaster capable of roasting batches of approximately 200 grams. It will be a fluid bed design utilizing an 1800W heat gun element paired with a 12VDC fan. Ultimately, the fan and heat source will be controlled via the TC4+ Arduino shield. Since I would like to keep the design as small as possible, I am on the lookout for a compact fan with a sufficient static pressure and airflow to loft the beans during roasting. I came across this particular fan ( https://www.digikey.ca/product-detail/en/sanyo-denki-america-inc/9HV0612P1J001/1688-2189-ND/8285336 ) and was hoping to get some feedback on it's suitability? It has a small 60mm x 60 mm footprint, 7"H2O static pressure, and 66.4CFM flow rate. I was informed that the fan I had selected likely would not work, and a vacuum motor/blower would be more suitable. So I am now on the hunt for a compact (ideally less than 100mm x 100mm) fan that can be used in a 250g fluid bed roaster and was hoping to find some answers via this forum. I found a Dyson DC16 handheld vacuum in a local buy and sell for $40, which may meet my criteria in terms of size, but I'm unsure about air flow... This is my first project of this type and I am looking forward to learning from the expertise in this forum. Thanks in advance for your feedback! |

|

|

|

| CharcoalRoaster |

Posted on 11/06/2019 9:12 AM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

Vac motor is definitely the way to go as it will have the necessary CFM to circulate your beans. Look on eBay as I've had luck finding really great motors that have already been excised from their vacuums for the same price range. Both of mine are bypass not flow thru types |

|

|

|

| cdrake39 |

Posted on 11/06/2019 9:45 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Thanks for the advice! The more I read, the more I understand why people opt for vacuum motors. I guess my next question would be, would a 24V vacuum motor work? I ask for two reasons - Firstly, the TC4+ is designed for DC fans and this would make control a little easier (no need for a dimmer switch). Secondly, I am looking at the following motor (https://www.ebay....3830540125) as it is fairly compact. It comes from this vacuum -https://www.rowen...2210018532

Edited by cdrake39 on 11/06/2019 3:47 PM |

|

|

|

| JackH |

Posted on 11/06/2019 3:08 PM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

Love those links....

---Jack

KKTO Roaster. |

|

|

|

| cdrake39 |

Posted on 11/06/2019 3:47 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

My bad, just fixed them so they are clickable. |

|

|

|

| JackH |

Posted on 11/06/2019 4:10 PM

|

|

Administrator  Posts: 1809 Joined: May 10, 2011 |

Thanks, it just makes it easier for everyone.

---Jack

KKTO Roaster. |

|

|

|

| cdrake39 |

Posted on 11/07/2019 8:31 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

So I opted for this fan (https://www.aliex...b201603_52). I read about another roaster who had great success with this particular fan, so I figured I'd go for it. I have a few other details to sort out, so I didn't mind the long shipping time. Once parts begin to arrive I'll make a post regarding progress. |

|

|

|

| renatoa |

Posted on 11/07/2019 8:56 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Sourced the control board too ? |

|

|

|

| cdrake39 |

Posted on 11/07/2019 9:03 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Yep, got that as well! |

|

|

|

| pisanoal |

Posted on 11/07/2019 9:51 AM

|

|

1/4 Pounder  Posts: 97 Joined: October 11, 2019 |

Where did you source the control board from? |

|

|

|

| cdrake39 |

Posted on 11/07/2019 9:54 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

There are two options on the Aliexpress link - with and without the control board. Or are you referring to the TC4+ board? In that case it was sourced from here: https://www.tindi...-tc4-plus/ |

|

|

|

| renatoa |

Posted on 11/07/2019 11:51 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Nope, motor control board. Noticed it in the pictures, but not the option to buy. Now I see the seller notes. |

|

|

|

| cdrake39 |

Posted on 01/20/2020 1:24 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

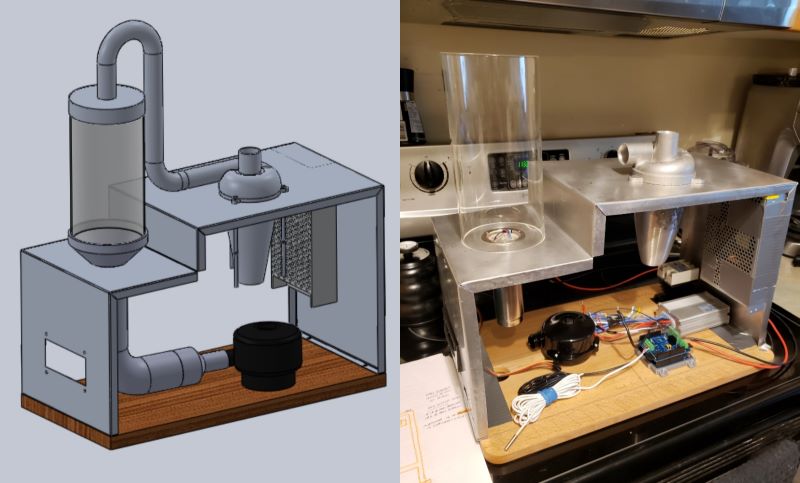

Hey everyone, rather than start a new thread I thought it would be best to continue off of this one. I have all the parts (aside from the top and bottom pieces which will ultimately enclose the glass roast chamber) and I am just about ready to start building the roaster -but I am wondering the best way to 'seal' the glass RC within the funnel. The first funnel I bought was a little too small (see pics), so I have ordered another that is 4.25" diameter. My RC is 4" diameter so this should give me room for a 1/8" thick gasket of sorts. Due to the design of my roaster, I need to be able to remove the glass chamber for cleaning, so a permanent seal isn't ideal and would require some design changes. I had an idea of using something like a bbq gasket (https://www.amazo...NrPXRydWU=) around the inner diameter of the funnel so the glass RC will fit snug up against it when inserted. Does anyone see any issues with this? Will there be a problem with thermal expansion if a non-rubberized gasket is used? And will the adhesive on this bbq gasket hold up to the temps? Any help on the matter is greatly appreciated. Also attached a pic of the rough design - duct tape connections to assess space within the enclosure lol

cdrake39 attached the following images:

Edited by cdrake39 on 01/20/2020 2:17 PM |

|

|

|

| greencardigan |

Posted on 01/20/2020 3:51 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

On my small roaster, I just have the glass sitting inside the funnel without any gasket or seal. It's held in place by the upper roast chamber but is free to move a little bit. My larger roaster has a small bead of RTV silicon on the base of the glass tube. So there's essentially a gasket between the base of the tube and the funnel but again, it's just sitting in the funnel not attached. |

|

|

|

| CharcoalRoaster |

Posted on 01/20/2020 6:37 PM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

Nice compact design! I dig it. What's the capacity? |

|

|

|

| cdrake39 |

Posted on 01/20/2020 7:38 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Quote greencardigan wrote: On my small roaster, I just have the glass sitting inside the funnel without any gasket or seal. It's held in place by the upper roast chamber but is free to move a little bit. My larger roaster has a small bead of RTV silicon on the base of the glass tube. So there's essentially a gasket between the base of the tube and the funnel but again, it's just sitting in the funnel not attached. Ok, good to know! I wasn't sure how important the seal between the glass and funnel would need to be in terms of air flow. I may design a custom gasket mold (3d print) and cast a gasket with RTV silicon. I guess to 400F stuff works just fine? Edit: Found this food safe RTV silicone good to 500F. Should do the trick? https://www.amazo...&psc=1 Edited by cdrake39 on 01/20/2020 8:30 PM |

|

|

|

| cdrake39 |

Posted on 01/20/2020 7:40 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Quote Thanks! That was the goal from the beginning, something 'counter top' size. The blower motor can loft 350g+ but I'm thinking my limiting factor will be the heating element. I may entertain the idea of dual in-line elements down the road if I ever want to increase the capacity. I'm hoping to do 250g batches with this current design. |

|

|

|

| CK |

Posted on 01/20/2020 9:17 PM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

Quote cdrake39 wrote: Ok, good to know! I wasn't sure how important the seal between the glass and funnel would need to be in terms of air flow. I may design a custom gasket mold (3d print) and cast a gasket with RTV silicon. I guess to 400F stuff works just fine? Edit: Found this food safe RTV silicone good to 500F. Should do the trick? https://www.amazo...&psc=1 Good silicone to use. Here's a link to a technique that works well. https://www.instr...nd-tubing/ |

|

|

|

| cdrake39 |

Posted on 01/20/2020 10:39 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Quote CK wrote: Quote cdrake39 wrote: Ok, good to know! I wasn't sure how important the seal between the glass and funnel would need to be in terms of air flow. I may design a custom gasket mold (3d print) and cast a gasket with RTV silicon. I guess to 400F stuff works just fine? Edit: Found this food safe RTV silicone good to 500F. Should do the trick? https://www.amazo...&psc=1 Good silicone to use. Here's a link to a technique that works well. https://www.instr...nd-tubing/ Very cool technique! Thanks for the tip |

|

|

|

| CharcoalRoaster |

Posted on 01/21/2020 8:17 AM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

Quote CK wrote: Quote cdrake39 wrote: Ok, good to know! I wasn't sure how important the seal between the glass and funnel would need to be in terms of air flow. I may design a custom gasket mold (3d print) and cast a gasket with RTV silicon. I guess to 400F stuff works just fine? Edit: Found this food safe RTV silicone good to 500F. Should do the trick? https://www.amazo...&psc=1 Good silicone to use. Here's a link to a technique that works well. https://www.instr...nd-tubing/ Now that's dope  |

|

|

|

| jbrux4 |

Posted on 01/21/2020 8:55 AM

|

|

1/4 Pounder  Posts: 139 Joined: October 26, 2019 |

Quote CK wrote: Good silicone to use. Here's a link to a technique that works well. https://www.instr...nd-tubing/ Thanks for this great find. It will come in very handy in many situations. R/

Jared |

|

|

|

| snwcmpr |

Posted on 01/26/2020 3:36 PM

|

|

1 1/2 Pounder  Posts: 925 Joined: March 03, 2011 |

I found this high temp sealer. https://www.amazo...G69RC?th=1 Up to 600 degrees. Edited by snwcmpr on 01/28/2020 12:05 PM --------------

Backwoods Roaster "I wish I could taste as well as I wish I could roast." As Abraham Lincoln said "Do not trust everything you read on the internet". |

|

|

|

| cdrake39 |

Posted on 02/02/2020 11:20 PM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Well, after some contemplation (and convincing from another user - thanks jbrux4!) I decided to use tri clamp fittings in my design. The primary reasons for this change are ease of cleaning, modular setup which allows for easier upgrades in the future, and aesthetics. The photo shows the concept for this design. Lots of design details to work out, but I'll have a better idea of how to tackle them when the parts arrive. I'm hoping to permanently affix a mesh gasket to the bottom of the 4" sight glass so I can remove that section (without having beans fall everywhere) to remove the beans when roasted.

cdrake39 attached the following image:

|

|

|

|

| renatoa |

Posted on 02/03/2020 1:09 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Is there any reason to lower the level of cyclone so much ? Is the heater in the picture, or outside the box ? |

|

|

|

| cdrake39 |

Posted on 02/03/2020 8:31 AM

|

|

1/4 Pounder  Posts: 83 Joined: August 08, 2019 |

Quote renatoa wrote: Is there any reason to lower the level of cyclone so much ? Is the heater in the picture, or outside the box ? No reason at all. Do you see any disadvantages with this design? It may be too late for me to change anything on this design, but I'm open to ideas for improvements! The heating element will be in the straight section of piping just below the roast chamber. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman