Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 10

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

New (to me) 1kg DIY roaster - Suggestions?

|

|

| jscott14 |

Posted on 02/20/2020 8:55 AM

|

|

Newbie  Posts: 28 Joined: February 20, 2020 |

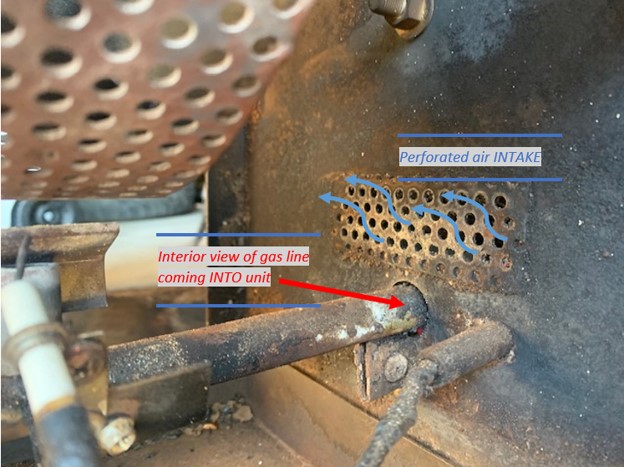

First, I want to say that I posted this in the home roaster section of another popular coffee forum (which strongly warned against cross-posting). Yet the only response I received suggested that i post the question here! So, please forgive the corss-post.. I'm simply following orders.  I am somewhat new to home roasting (having cut my teeth on the original Behmor 1600), but recently found what I perceived to be a good deal on a custom-built drum roaster. This roaster was built for a coffee shop who roasted their own beans for a few years with it, but they finally outgrew it. It is a well-built, heavy machine, and was advertised as a 1kg unit. Based on the info I found here regarding bean quantity (0.1 x volume), that appears to be quite low. The drum is 15" (L) x 9" (D). By the formula, that equates to about 6 lbs, or at least 2.5 kg! I think I got an even better deal on this than I thought! The unit is a propane/natural gas burner. It's lit electronically by a RobertShaw pilot light re-light system. The drum is driven by a 110v Dayton shaded pole 1/20hp gearmotor turning at 30 RPM. I've posted pictures to help illustrate the unit, but as I've read other posts, the main drawback of, say, an RK drum set up on a BBQ grill is the LACK OF AIRFLOW. The design of this unit does not have a fan, but rather convection-based air movement... cold air intake low on one side of the unit, then a chimney up high on the other side. I can't post pictures in-line here, but i've attached some photos that show several views of the roaster... some with labels/verbiage for clarity. Hopefully the pictures help paint a visual image of the main design aspects of the roaster. The perforated air intake is below the motor-mounting plate, and it does NOT allow for adjusting the air intake. Inside the unit, there is about 4" of "dead space" or free space between the wall of the roaster and the drum. Put another way, the drum is 4" narrower than the oven it spins in. It has a simple chaff tray below the drum. To the front panel of the roaster, I will be adding a BT and ET probe that feeds into a Phidget/Artisan. I MIGHT also add a probe for exhaust temp and/or flame temp, but I'm not sure that those will be as valuable. My main question is rather open-ended: is there any "low hanging fruit" that could improve the design of this? For instance, would the addition of a fan help this unit out, and if so, where should that fan be placed? I have a convection fan from a full-sized oven that I could use to simply introduce air MOVEMENT into the roaster... but that wouldn't pull in more CFM of air. It would simply move around the air that already naturally flows through the unit. That 4" of "dead space"... is there something that this space could be used for? A fan? A larger drum? Or is it perhaps a design element that helps mix/equalize the cool outside air coming in from the perforations? Is there a fan/vacuum chaff collection system that could somehow be added to this setup? I DO have a "dust deputy" type cyclone vacuum system already, but I have no idea how that could be utilized on my design to incorporate it. Based on the striping of the drum unit, it looks like there has been some inefficient combustion, so I will tune the air mixing of the gas supply to remedy that. With the flame tips touching the drum, are the hot "stripes" along the drum acceptable? The drum is made of quite heavy material... I believe 1/8" steel, but I'll measure tonight to be sure. I think this will help buffer the heat from the flames. I'm basically hoping that someone had experience with roasters SIMILAR in design to this who might be able to give me advice. I'm thinking that this design must be based off a commercial design of some type, but I don't know what that would be. Any comments/suggestions from the collective knowledge base here? Thanks in advance! I've already found incredibly useful information on this forum!

jscott14 attached the following images:

Edited by jscott14 on 02/20/2020 10:59 AM |

|

|

|

| baldheadracing |

Posted on 02/25/2020 1:29 PM

|

|

Newbie  Posts: 48 Joined: November 06, 2015 |

You're okay on the x-post; the rule is for people who make the same post simultaneously on multiple forums. Asking on H-B and then, after not getting a response for a few days, asking here - is a different thing. Sorry but I can't address any of your questions (which is why I didn't answer on H-B ...). I do have a perforated drum roaster that was re-designed to use convection airflow (no fan) right up to yellowing, but I didn't build it - see the "Enhancing my HotTop" series of posts here by Ciel-007 if you're interested ( https://forum.hom...rowstart=0 ). I do know that he spent quite a bit of effort (and roasts, and prototypes) getting the no-fan airflow just right for the roast capacity that he wanted to use. Good luck! |

|

|

|

| jscott14 |

Posted on 02/25/2020 4:05 PM

|

|

Newbie  Posts: 28 Joined: February 20, 2020 |

I appreciate that link... thank you! I'm starting to see more commecial roasters that have similarities to mine, but also some differences regarding airflow. I'll probably be adding a fan at the chimney/bean hopper to introduce some negative pressure to the roasting chamber. I know this will reduce my ET, so it will be a balancing act between flame and negative air pressure, but I'm at least on the right mental track. |

|

|

|

| baldheadracing |

Posted on 02/26/2020 12:03 PM

|

|

Newbie  Posts: 48 Joined: November 06, 2015 |

A good summary of airflow, albeit for 'traditional' solid drum roasters https://www.perfe...ontrol-it/ |

|

|

|

| jscott14 |

Posted on 02/26/2020 3:21 PM

|

|

Newbie  Posts: 28 Joined: February 20, 2020 |

That is also really helpful! I'm curious, based on your screen name... are you Don? (The article interviewed Don from "Bald Guy Brew", and you're "baldheadracing"... coincidence?)  My takeaway here is: 1) A certain amount of airflow is desireable (and necessary) 2) Nobody will be able to definitively tell me "how" or "how much" 3) Try, try again until I'm happy with the results! I'm thinking that a variable fan (or damper) in conjunction with a pressure monitor Phidget feeding into Artisan should help me quantify airflow. That way, I can get an idea of how x amount of airflow (negative pressure) impacts environmental temps, then adjust from there. |

|

|

|

| mkane |

Posted on 02/26/2020 3:30 PM

|

|

1/4 Pounder  Posts: 151 Joined: October 23, 2017 |

And if for no other reason to expel chaff.

Always learning

|

|

|

|

| jscott14 |

Posted on 02/26/2020 3:56 PM

|

|

Newbie  Posts: 28 Joined: February 20, 2020 |

Yeah, the current design just has a chaff tray beneath the drum... gravity alone. I would imagine that a small amount of negative pressure could easily lift that away. |

|

|

|

| baldheadracing |

Posted on 02/27/2020 1:31 AM

|

|

Newbie  Posts: 48 Joined: November 06, 2015 |

Quote jscott14 wrote:... I'm curious, based on your screen name... are you Don? (The article interviewed Don from "Bald Guy Brew", and you're "baldheadracing"... coincidence?)  LoL. Nope. BaldHeadRacing was just the name of my old (car) rally team :-) |

|

|

|

| renatoa |

Posted on 02/27/2020 2:28 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote And don't forget smoke... me want peaty flavours in whisky only  |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman