Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Bubble Bed roaster by Typhoon Roasters

|

|

| allenb |

Posted on 11/02/2020 6:11 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Wasn't aware anyone besides Nepro was offering bubblebed roasters of their own design. Looks to be an interesting variant of the bubblebed concept but uses continuous row spouts instead of individual single spouts. Skip to minute 3:35 in this video for viewing the bean movement. Edited by allenb on 04/06/2023 8:14 AM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 11/03/2020 2:51 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

So is not a a drum, as the misleading shape could make someone believe at first sight... |

|

|

|

| CharcoalRoaster |

Posted on 11/03/2020 2:35 PM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

Is the fluidized bed of a bubble roaster air driven or agitated like with an auger or something? |

|

|

|

| allenb |

Posted on 11/03/2020 6:27 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

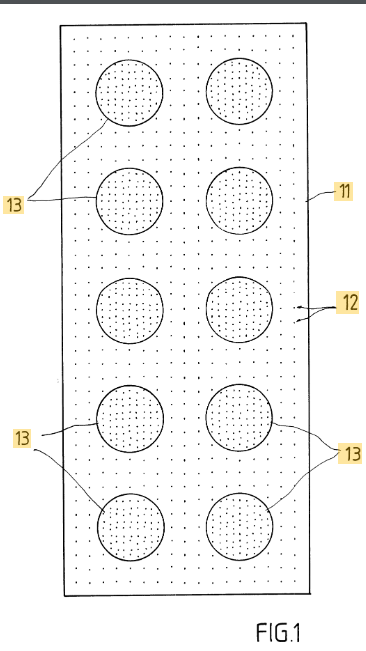

Quote Is the fluidized bed of a bubble roaster air driven or agitated like with an auger or something? Air driven. Imagine multiple perf plate areas on a single plate and each high density perf area surrounded by very low density areas. So, air is coming from the whole plate but each area where you see a bubbling low spout of beans, directly below that spout is a higher density perf area. The purpose of the low density perforated areas is to keep the whole bed fluid allowing the high density areas beans to easily flow into the adjacent areas. Here's a repeating moving image of bubble bed spouting action from the Nepro site: http://www.nepro-...hneAni.gif If you look at the Typhoon video in the first post at 3:32 and 5:20 you will see the low spouting action in multiple areas in the bed. Edited by allenb on 11/03/2020 6:36 PM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| allenb |

Posted on 11/04/2020 7:19 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote renatoa wrote: So is not a a drum, as the misleading shape could make someone believe at first sight... Hi Ren, yes, definitely looks like it should be a glass fronted drum roaster. I thought it should have a coin and bill slot mechanism and a place for detergent before I took a closer look. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 11/04/2020 7:57 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Coffee laundromat, lol The powder drawer to be filled with greens... |

|

|

|

| allenb |

Posted on 11/04/2020 10:40 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Here's an image of the patent Mr. Zoellner made of the bubble bed perf plate. The details of the percentage of high density to low density perforations are described within the patent doc. https://patents.g...38303B1/en

allenb attached the following image:

Edited by allenb on 11/04/2020 10:46 AM 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| CharcoalRoaster |

Posted on 11/04/2020 1:35 PM

|

|

1 1/2 Pounder  Posts: 640 Joined: April 13, 2012 |

Thanks Allen -- this is really helpful for me to understanding how they function. I dig it! Anyone ever tasted bubblebed roasted coffee before? |

|

|

|

| allenb |

Posted on 11/05/2020 9:07 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

No one to my knowledge. Their usage has mainly been for flash roasting for large commercial roasting in under 4 minutes. Folgers and the like. Nepro was the first company I know of who developed a real shop roaster using the bubblebed technology and was able to be programmed to do normal roast times. I don't recall ever seeing any cupping comparisons between the Nepro Vortex shop roaster and drum roasters. The main claimed advantage is the ability to roast at lower environment temperatures since there is a major increase in heat distribution per unit area of been mass. Lower ET will obviously lessen bean cell wall damage and should create a much cleaner roast. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jkoll42 |

Posted on 11/07/2020 9:18 PM

|

|

1 1/2 Pounder  Posts: 860 Joined: February 14, 2011 |

Well, looks like I'm going to be having flashbacks in my dreams of drilling lots and lots and lots of holes in various LP/HP variations  That was a fun project that I just rediscovered in the depths of the crawlspace -Jon

Honey badger 1k, Bunn LPG-2E, Technivorm, Cimbali Max Hybrid, Vibiemme Double Domo V3 |

|

|

|

| allenb |

Posted on 11/09/2020 6:08 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote jkoll42 wrote: Well, looks like I'm going to be having flashbacks in my dreams of drilling lots and lots and lots of holes in various LP/HP variations  That was a fun project that I just rediscovered in the depths of the crawlspace Hi Jon. I had almost forgotten all of your hard work trying to develop a working bubblebed back in 2011. You poured your heart and soul into it! It ticks me off when I see someone like Typhoon able to pull off a good, stable bed action and it be so difficult for us. Maybe the rectangular chamber is the key if a rotating bed is not sought? I may try some experiments with a rectangular bubblebed in the not too distant future as I would love to be able to once and for all be able to cup the same greens in a normal fluidbed and a properly performing bubblebed for comparison. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 11/10/2020 1:25 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

What if, instead drilling a lot of holes in the high density spots, make a big hole there, and weld a mesh/grid ? Or use a properly drilled sink strainer. |

|

|

|

| allenb |

Posted on 11/10/2020 3:54 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

If I'm not mistaken, I seem to remember Jon trying that during his experimentation but all reports I've heard is that the key to getting true "bubble" action where you have rising and collapsing spouts, you must lay out your plate very close to the perf proportions prescribed by Zoellner in his patent otherwise it ends up a mess.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| jkoll42 |

Posted on 11/11/2020 8:18 PM

|

|

1 1/2 Pounder  Posts: 860 Joined: February 14, 2011 |

Quote allenb wrote: Quote jkoll42 wrote: Well, looks like I'm going to be having flashbacks in my dreams of drilling lots and lots and lots of holes in various LP/HP variations  That was a fun project that I just rediscovered in the depths of the crawlspace Hi Jon. I had almost forgotten all of your hard work trying to develop a working bubblebed back in 2011. You poured your heart and soul into it! It ticks me off when I see someone like Typhoon able to pull off a good, stable bed action and it be so difficult for us. Maybe the rectangular chamber is the key if a rotating bed is not sought? I may try some experiments with a rectangular bubblebed in the not too distant future as I would love to be able to once and for all be able to cup the same greens in a normal fluidbed and a properly performing bubblebed for comparison. From all the experiments I ran it's a few things. First, yes a rectangular bed would be much easier to get a uniform looking bubbling fluidized bed. It would be easier to get the LP fields to fully border the HP areas. Second, bubbling fluidized is really giving the design more credit than is due. It's really a field of spouting areas to break up the fluidized areas enough so you don't get the chugging of beans nesting and then releasing pressure. The last and biggest issue is the purpose it was designed for vs. what our roasting goals are. The whole design was to take low quality beans and transfer heat into them on an industrial scale as quickly as possible while still maintaining some degree of evenness through the bean. The biggest issue I had was that the bed is so picky about the volume of air needed to maintain a calm bed of beans that when we (I) as a roasted who is looking to his a particular ROR curve over a 12ish minute roast just the volume flow of air changing from heat levels was enough to upset the bed. On an industrial scale though they were just going to be hit with a few different temp zones the beans would convey over during a course of a few minutes so airflow could be static. Sorry for the long post! I would love to see a uncut drop to dump video of that smaller roasters bean bed with TC data overlaid! -Jon

Honey badger 1k, Bunn LPG-2E, Technivorm, Cimbali Max Hybrid, Vibiemme Double Domo V3 |

|

|

|

| jkoll42 |

Posted on 11/11/2020 8:21 PM

|

|

1 1/2 Pounder  Posts: 860 Joined: February 14, 2011 |

Quote renatoa wrote: What if, instead drilling a lot of holes in the high density spots, make a big hole there, and weld a mesh/grid ? Or use a properly drilled sink strainer. Like Alan said, it's a very finicky plate and indeed needs the ratio ranges in the patent. Hole size mattered on both the HP/LP sections in addition to the ratios. I tried mesh initially but it ends up blowing huge spouts and basically having the rest of the bed dead. I will say it is a very cool feeling when you get the air flow perfect on a cold test to be able to just float your fingers through the bean bed -Jon

Honey badger 1k, Bunn LPG-2E, Technivorm, Cimbali Max Hybrid, Vibiemme Double Domo V3 |

|

|

|

| allenb |

Posted on 11/12/2020 7:03 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote Second, bubbling fluidized is really giving the design more credit than is due. It's really a field of spouting areas to break up the fluidized areas enough so you don't get the chugging of beans nesting and then releasing pressure. From additional reading on the design from Zoellner, there's a little more going on with the bed for why the term bubble bed. In boiling water, you have rising pockets of steam with surrounding water being drawn in behind it to fill the void as it rises which necessarily causes fairly effective stirring action preventing any given area of water to remain in one zone. This is replicated to a degree with coffee being the medium due to surrounding, non spouting beans being continually drawn towards the spouting locations. The sketch of his rectangular bed perforated plate shows a linear array of high density areas along the length of the plate versus a staggered pattern. The reason this design was used in Nepro's large roasters was due to them being a conveyer type continuous roaster which would naturally end up with more thorough mixing without the need for a staggered pattern. If you look at Thyphoon's video, they placed high density areas near or at the perimeter of the bed versus being inset as in the Zoellner sketch. This would be good to do for a batch roaster. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 06/07/2021 11:12 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

New 10 kg model https://typhoon.c...-kg-hybrid ... and another guys pretending that by lowering airflow you get "conductive" roasting... oh, well...  They now seems to roast into a great pan similar with the trays used for cooling, but pushing air upwards, instead exhaust. Edited by allenb on 04/06/2023 8:25 AM |

|

|

|

| allenb |

Posted on 06/07/2021 2:33 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Got to love their sales department's creativity! The hype sounded very convincing!

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman