Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Background Roast Iss...Skywalker roaster mods

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [374] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 3

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Testing Arduino UNO with bitwisetech / popc and MAX6675

|

|

| zamunda |

Posted on 09/27/2021 8:36 AM

|

|

1/4 Pounder  Posts: 173 Joined: November 17, 2020 |

Hello, I just recently how to work with Arduino and how to change baudrates of the HC-06 so I am not that experienced but this video helped me a lot In short, you have to connect the RX and TX-pins of the HC-06 to the TX and RX-pin of the Arduino. Then go to the serial monitor of the IDE and send fe the command 'AT'...it should respond with 'OK' If you do not get a response you have to tweak settings: - set baudrate of serial monitor to '9600' if you have not changed initital rate of HC-06 - set "No line ending" in the serial monitor as well - interchange RX and TX connection cables from HC-06 to Arduino and try again... Once you get an 'OK' you can change baudrate with command 'AT+BAUD5' if I recall well. As said, the mentioned video was very helpfull for me. Hope this helps! Regards |

|

|

|

| miyankizu |

Posted on 09/27/2021 9:23 AM

|

|

Newbie  Posts: 10 Joined: August 10, 2021 |

Quote zamunda wrote: Hello, I just recently how to work with Arduino and how to change baudrates of the HC-06 so I am not that experienced but this video helped me a lot In short, you have to connect the RX and TX-pins of the HC-06 to the TX and RX-pin of the Arduino. Then go to the serial monitor of the IDE and send fe the command 'AT'...it should respond with 'OK' If you do not get a response you have to tweak settings: - set baudrate of serial monitor to '9600' if you have not changed initital rate of HC-06 - set "No line ending" in the serial monitor as well - interchange RX and TX connection cables from HC-06 to Arduino and try again... Once you get an 'OK' you can change baudrate with command 'AT+BAUD5' if I recall well. As said, the mentioned video was very helpfull for me. Hope this helps! Regards thank you very much , I will check and if I found which works for me , I will update this topic |

|

|

|

| miyankizu |

Posted on 09/27/2021 9:26 AM

|

|

Newbie  Posts: 10 Joined: August 10, 2021 |

Updated info : I changed my skecth again 19200 to 9600 and make same updates on MODBUS connection also in Artisan. And changed jumper cables in case of any problem. Now it works it reads values well. I haven't test it with popper , till now it goes good. Thanks to zamunda and renatoa  |

|

|

|

| zamunda |

Posted on 10/06/2021 12:34 PM

|

|

1/4 Pounder  Posts: 173 Joined: November 17, 2020 |

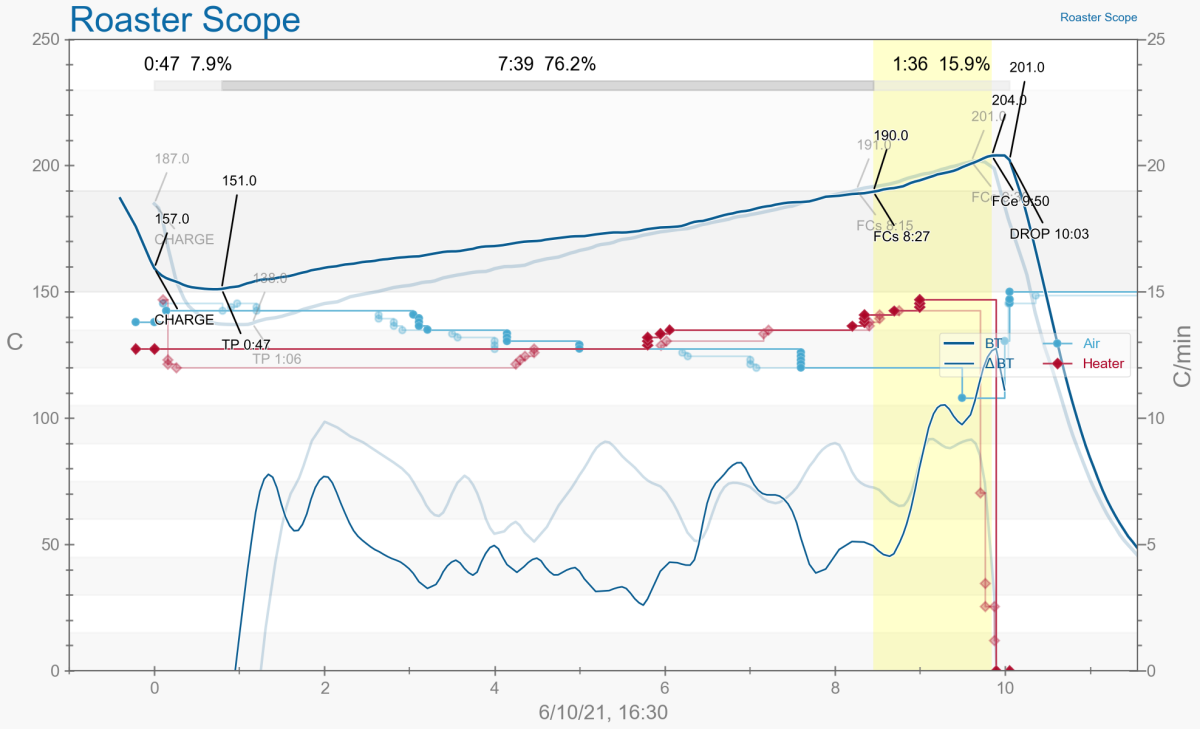

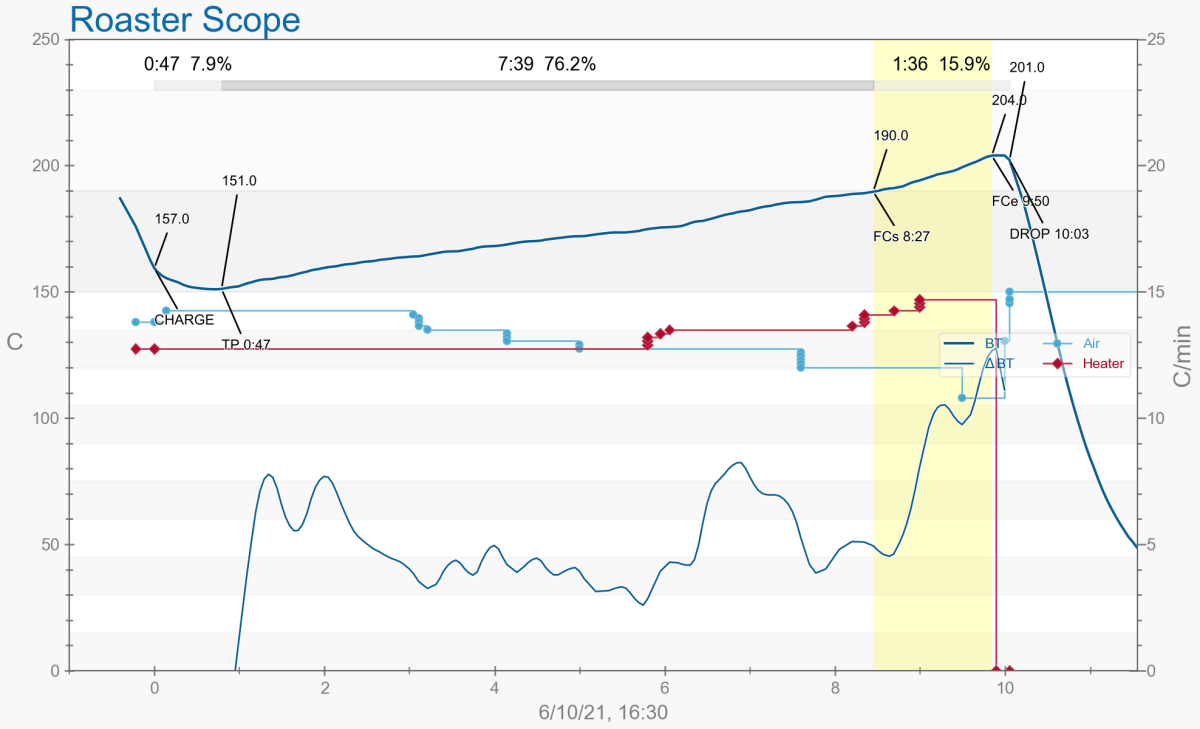

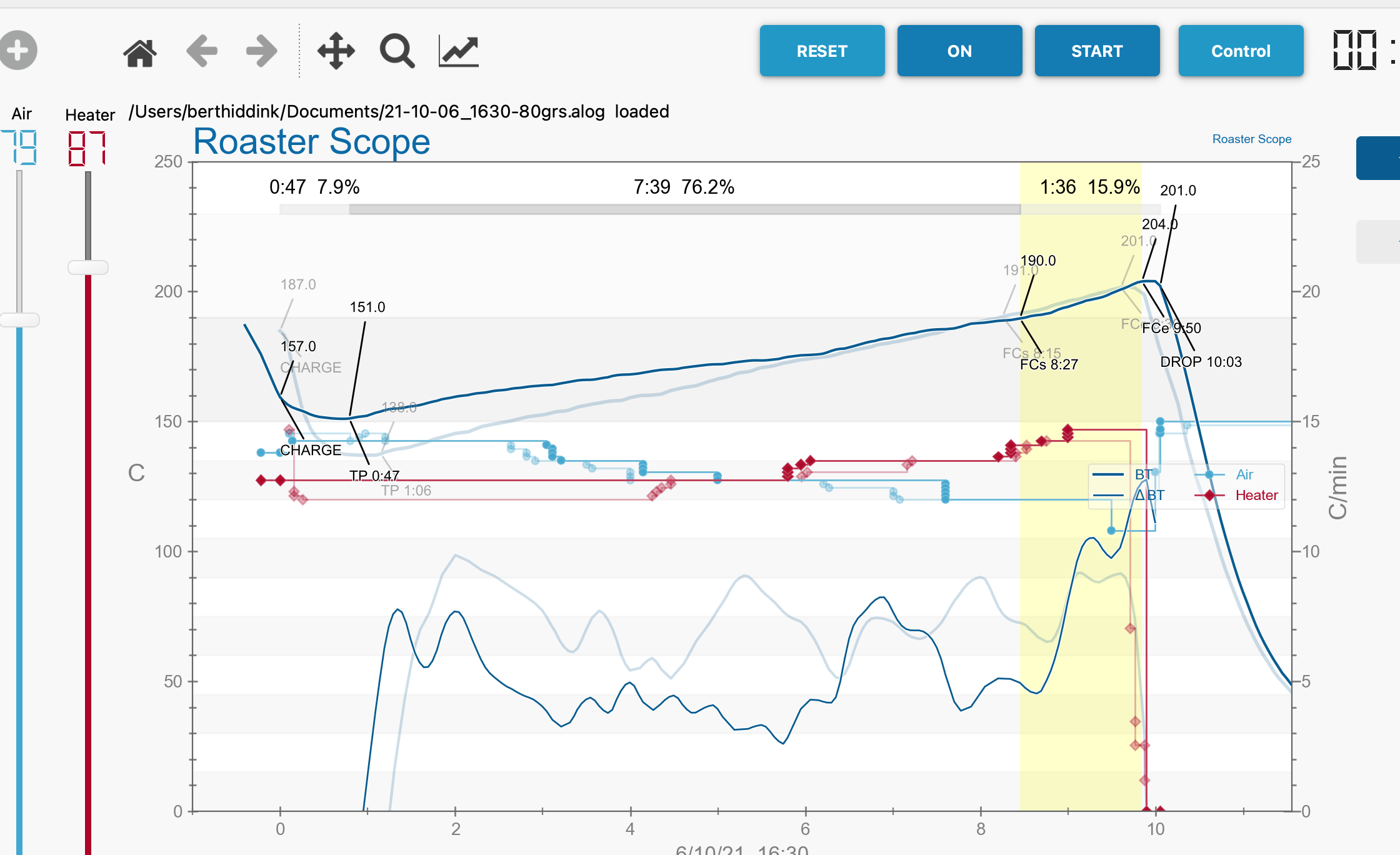

Hello, Showing some results from Artisan.... I roasted 80grs and 100 grs today playing with Air and Heater...works quite well technically I think...Normally I start with full air and 80% heat and after 3-4 minutes I lower the air a bit and increase some heat. Depending on ambiente temperature, I get first crack at 6-8 minutes, then leave the beans a minute after FC and finally cool them down in the roaster, cooling down to 30-40 degrees goes quite fast (< 1min). Happy with the result so far...Any comments are highly appreciated! Did a quick test with PID control but got quite confused with so many parameters to set, in fact, do not know how to start there... The settings shown in the image copied them from another project without really understanding how it works  Could some of you help me a bit in explaining the basic concept of PID-control? Thanks!

zamunda attached the following images:

Edited by zamunda on 10/06/2021 12:42 PM |

|

|

|

| miyankizu |

Posted on 10/07/2021 1:46 AM

|

|

Newbie  Posts: 10 Joined: August 10, 2021 |

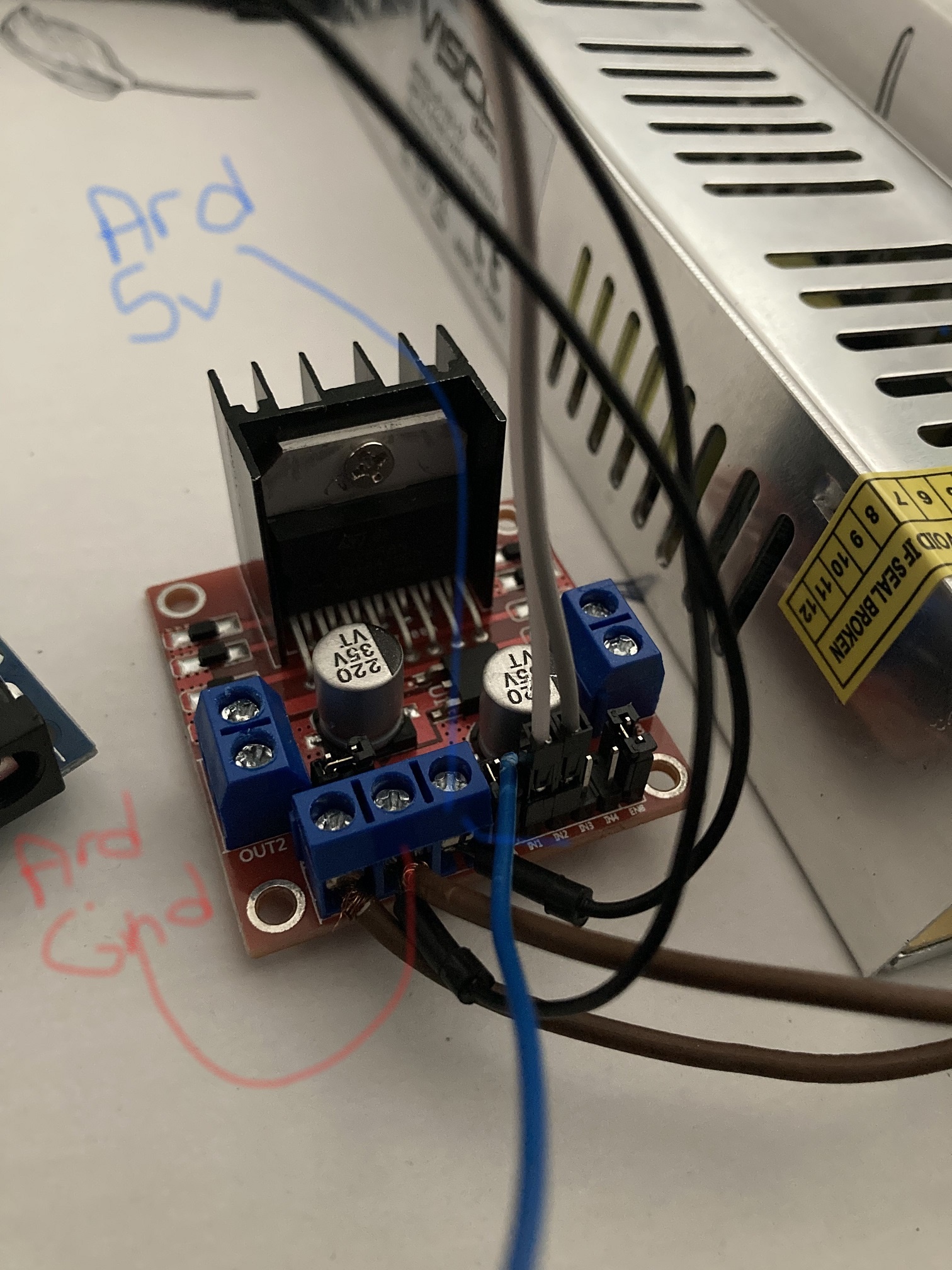

It is nice to hear that well done  I think you can roast more grams by chaning your power supply of fan. Also adding a tin can at the top of chamber. Because I can swirl 150 grams in my system with 24v 5A. I think you can roast more grams by chaning your power supply of fan. Also adding a tin can at the top of chamber. Because I can swirl 150 grams in my system with 24v 5A.By the way I built up your system. I can read temperature , but I'm not able to give a control from Artisan. I'm not sure that I can send the data to L298N from Arduino. Can you please share your circuit connection. I try to make my connections over your sketch and picture as I can see  Here is my circuit. Quote zamunda wrote: Hello, Showing some results from Artisan.... I roasted 80grs and 100 grs today playing with Air and Heater...works quite well technically I think...Normally I start with full air and 80% heat and after 3-4 minutes I lower the air a bit and increase some heat. Depending on ambiente temperature, I get first crack at 6-8 minutes, then leave the beans a minute after FC and finally cool them down in the roaster, cooling down to 30-40 degrees goes quite fast (< 1min). Happy with the result so far...Any comments are highly appreciated! Did a quick test with PID control but got quite confused with so many parameters to set, in fact, do not know how to start there... The settings shown in the image copied them from another project without really understanding how it works  Could some of you help me a bit in explaining the basic concept of PID-control? Thanks!

miyankizu attached the following images:

|

|

|

|

| zamunda |

Posted on 10/07/2021 4:32 AM

|

|

1/4 Pounder  Posts: 173 Joined: November 17, 2020 |

Hello Yesterday I created a project on Github to make sharing easier: https://github.co...daroaster/ Haven't uploaded a circuit though but will try to do that shortly. What is it that you can not control from Artisan? Have you created a slider for both heater and air? Maybe you could download the settings from the Artisan folder and load these into yours and see how I have configured things (obviously adjust it according your setup, USB or BT, etc): https://github.co...in/artisan Hope this helps for now... |

|

|

|

| zamunda |

Posted on 12/04/2021 5:47 PM

|

|

1/4 Pounder  Posts: 173 Joined: November 17, 2020 |

Hello, Updated the sketch for this project (with a big help of a friend) since I felt this could be done more efficiently within the loop separating controls for air, temperature and heater. Within the previous version, delays for air and temperature depended on the heater-delay. Did some roasts with this setup and there is evidently less delay in response when moving sliders within Artisan for air, also temp changes are shown at a higher frequency. https://github.co...Heater.ino Please let me know if you have any comments. Regards, Bert ########################

### A lot can happen over coffee ### ######################## |

|

|

|

| zamunda |

Posted on 12/05/2021 8:16 AM

|

|

1/4 Pounder  Posts: 173 Joined: November 17, 2020 |

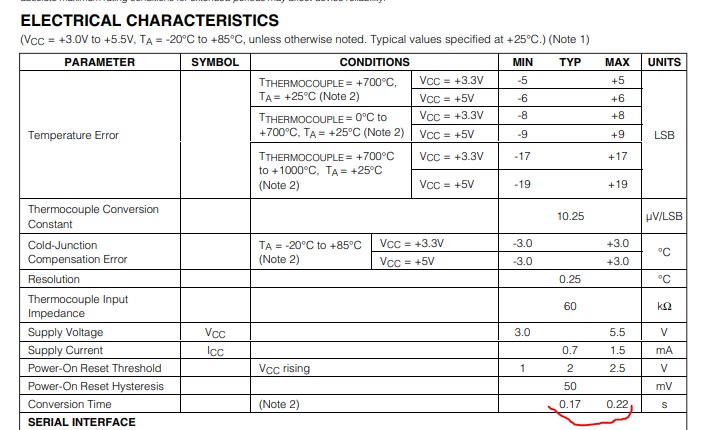

Hello, In order to test the minimal 'delay' (=conversion time) for the MAX6675 to be set within the loop, I added a temporary slider within Artisan. Its value is send to Arduino, this way I could determine by increasing/diminishing airflow that using '200ms' is still ok, '150ms' freezes the temperature showing within Artisan... '20' = 200ms '15' = 150ms etc.

zamunda attached the following image:

Edited by zamunda on 12/05/2021 8:24 AM ########################

### A lot can happen over coffee ### ######################## |

|

|

|

| renatoa |

Posted on 12/05/2021 8:31 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Chip specs say 250 ms, better stay on the safe side. |

|

|

|

| Golfkung |

Posted on 04/11/2023 8:46 AM

|

|

Newbie  Posts: 4 Joined: April 08, 2023 |

Help me please. I follow coding reference below. and I big thank first. But I found problem from this .Please refer tu attached figure for my problem. Quote zamunda wrote: Hello Renatoa, Thanks for explaining how to work with the fan and MODBUS. I did a quick test with a separate fan and this works... Only thing I noticed is that the fan reacts only after 2-3 seconds when moving the air slider... This is the sketch I have used right now (see below), tomorrow I will test it with a roaster... Also will try to look into the TC4 code regarding the big current issue. A big thanks again and I'll keep you posted! Code Download source #include <max6675.h> Edited by Golfkung on 04/11/2023 9:08 AM |

|

|

|

| renatoa |

Posted on 04/11/2023 8:48 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Which figure ? You only quoted a post... |

|

|

|

| Golfkung |

Posted on 04/11/2023 9:19 AM

|

|

Newbie  Posts: 4 Joined: April 08, 2023 |

Quote I have alreaady attached picture. |

|

|

|

| Golfkung |

Posted on 04/11/2023 10:06 AM

|

|

Newbie  Posts: 4 Joined: April 08, 2023 |

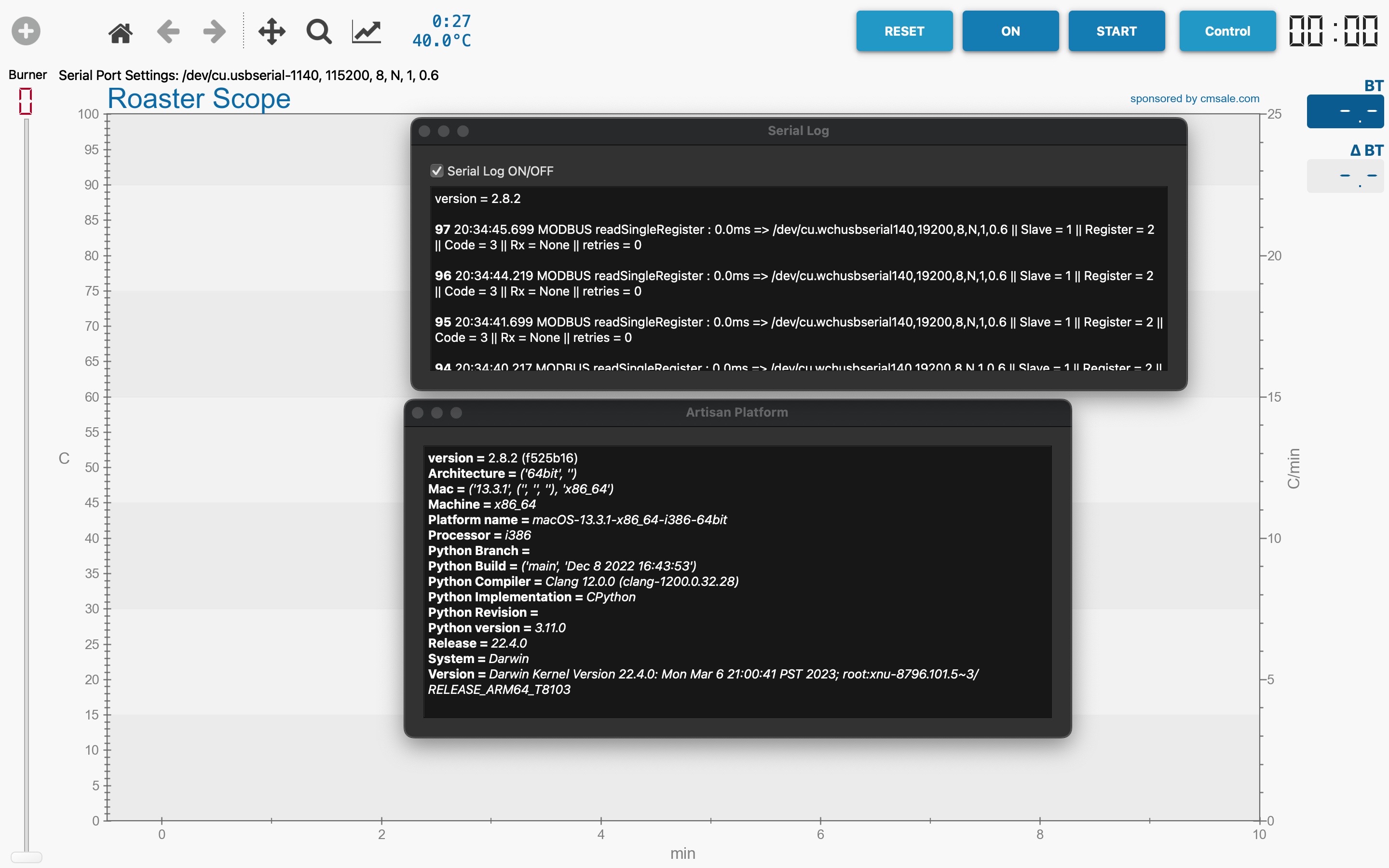

Quote For serial log====> version = 2.8.2 24 22:02:29.027 MODBUS readSingleRegister : 0.0ms => /dev/cu.wchusbserial140,19200,8,N,1,0.6 || Slave = 1 || Register = 2 || Code = 3 || Rx = None || retries = 0 ================================================================================f For Artisan platdorm version = 2.8.2 (f525b16) Architecture = ('64bit', '') Mac = ('13.3.1', ('', '', ''), 'x86_64') Machine = x86_64 Platform name = macOS-13.3.1-x86_64-i386-64bit Processor = i386 Python Branch = Python Build = ('main', 'Dec 8 2022 16:43:53') Python Compiler = Clang 12.0.0 (clang-1200.0.32.28) Python Implementation = CPython Python Revision = Python version = 3.11.0 Release = 22.4.0 System = Darwin Version = Darwin Kernel Version 22.4.0: Mon Mar 6 21:00:41 PST 2023; root:xnu-8796.101.5~3/RELEASE_ARM64_T8103 |

|

|

|

| Golfkung |

Posted on 04/11/2023 11:21 PM

|

|

Newbie  Posts: 4 Joined: April 08, 2023 |

Quote Golfkung wrote: Quote For serial log====> version = 2.8.2 24 22:02:29.027 MODBUS readSingleRegister : 0.0ms => /dev/cu.wchusbserial140,19200,8,N,1,0.6 || Slave = 1 || Register = 2 || Code = 3 || Rx = None || retries = 0 ================================================================================f For Artisan platdorm version = 2.8.2 (f525b16) Architecture = ('64bit', '') Mac = ('13.3.1', ('', '', ''), 'x86_64') Machine = x86_64 Platform name = macOS-13.3.1-x86_64-i386-64bit Processor = i386 Python Branch = Python Build = ('main', 'Dec 8 2022 16:43:53') Python Compiler = Clang 12.0.0 (clang-1200.0.32.28) Python Implementation = CPython Python Revision = Python version = 3.11.0 Release = 22.4.0 System = Darwin Version = Darwin Kernel Version 22.4.0: Mon Mar 6 21:00:41 PST 2023; root:xnu-8796.101.5~3/RELEASE_ARM64_T8103 Sorry for many tiom. I would like re attach picture.

Golfkung attached the following image:

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman