Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 8

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

Some questions to start right to mod a roaster with TC4

|

|

| iPa |

Posted on 12/23/2021 8:04 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Hi all, I thinking to mod my hot air roaster, to replace all the electronic control by a tc4. I already have made a lot a search, but many dead link or very old thread, and I am still confuse on some points. Heater AC 3000W Blower AC 200W 1) First question: Two boards TC4 V7.0 and a TC4+, TC4+ seems to be an improvement only for DC blower, and analogue inputs for potentiometer seem missing, correct ? 2) Do I need a PWM dimmer module for the blower or just a SSR ? 3) Is it the correct link for arduino source code ? https://github.co...TC4-shield Thank you |

|

|

|

| renatoa |

Posted on 12/23/2021 9:54 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The link seems right, but his thread contains even more accurate info: https://homeroast...post_43360 Heater usually is driven by an instant fire SSR, (CONFIG_PAC2 // phase angle control using ICC on OT1 (heater) and OT2 (fan); IO2 used to read the ZCD) Blower depends on motor build: with brushes or async (cage) A dimmer is ok for the first case, brushed, or universal motor. The dimmer is PWM (MOSFET) for low voltages only, for mains A/C the dimmer will use phase control and a triac (or instant fire SSR) For an async motor the options are very limited and costly, read more about VFD drivers. It's only me who feel the need for a glossary about motor control terminology and techniques ?  |

|

|

|

| allenb |

Posted on 12/23/2021 12:21 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote renatoa wrote: It's only me who feel the need for a glossary about motor control terminology and techniques ?  I think it's a great idea. You're right that with the multitude of different motor types and each having a different requirement for powering them for variable speed, it is most likely overwhelming for folks who haven't been previously immersed in how to control them and very easily can lead to disaster if wrong control method is used. Sounds like quite the undertaking though. Maybe see if anyone of our members who is blessed with this knowledge might contribute to the project?

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| iPa |

Posted on 12/23/2021 7:23 PM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

The original controller for the blower is just a dimmer triac/diac So I should need mode CONFIG_PAC2 in aArtisan_PID Is that correct ? Thank you

iPa attached the following images:

Edited by iPa on 12/23/2021 11:20 PM |

|

|

|

| renatoa |

Posted on 12/24/2021 1:20 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Wait a bit ! Now the things are becoming more interesting...  Before starting investing money into electronics, and time into education, please ensure you are able to open that machine ! I am saying this because I am right now in the middle of modding a similar machine, and the access to the innards of mine were impossible without a partial destruction of the bottom of the case. It is so absurdly built, by welding all the corners, and sealed, that literally you are in the front of a meat can, without any opening tool ! Edited by renatoa on 12/24/2021 1:29 AM |

|

|

|

| iPa |

Posted on 12/24/2021 2:36 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote renatoa wrote: Before starting investing money into electronics, and time into education, please ensure you are able to open that machine ! No access issue, I have already made some mods, added a thermocouple connector, replaced the dimmer potentiometer,… Only the blower could be a challenge to get it out. More picture here |

|

|

|

| iPa |

Posted on 12/24/2021 4:36 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

|

|

|

|

| renatoa |

Posted on 12/24/2021 7:04 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The last picture shows the same controller for fan as in my roaster. This is a typical dimmer using phase angle control. Mine is coupled with an A/C digital panel voltmeter, model hks-ac56, allowing the roaster precisely setting a fan flow, not relying on a potentiometer knob position, which is not so precise, nor reproducible. This dimmer can be modded to be controlled externally by a TC4. The bigger board though, seems a much more integrated solution, thermocouple+display+heater control... needs more detailed colse-up pictures, to decide if anything can be used for a computer controlled setup. Edited by renatoa on 12/24/2021 7:12 AM |

|

|

|

| iPa |

Posted on 12/24/2021 7:38 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

No, it cannot be connected (information from the manufacture). I have already made search with some numbers and labels I found on boards, but nothing. That why I am thinking to go to the TC4 (v7.0), the idea is to keep everything in place, and add an external box with the TC4 and all needed components, just need to out blower and heater wires, beans sensor is already external, still need to add an air sensor. I agree with the digital voltmeter for the fan, it’s one of my complaints about this roaster. |

|

|

|

| renatoa |

Posted on 12/24/2021 9:06 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

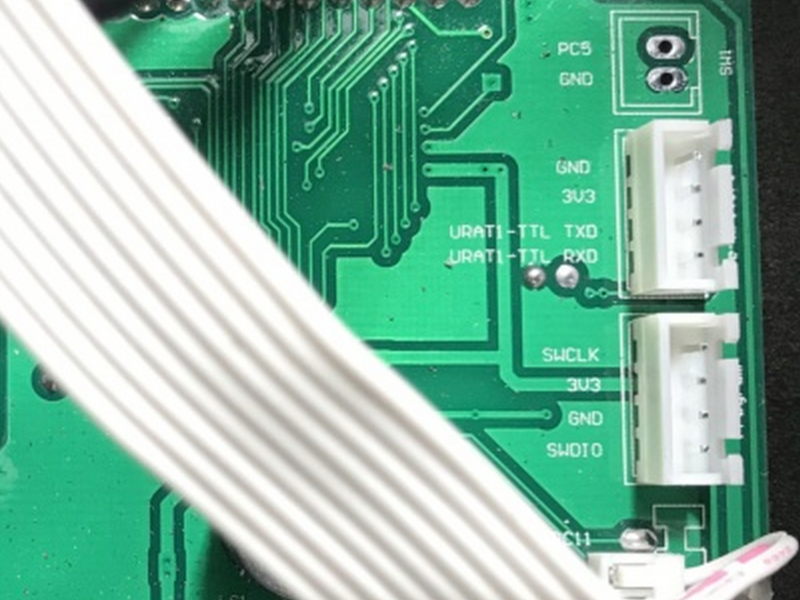

Very likely can't be connected as is now, but this is not what I meant... On that board can be seen pretty clear delimited a thermocouple processing area, a power control area... these can be repurposed for a smart roasting solution. Also, no need to place the electronics outside the roaster case, there is plenty of space inside, I did custom TC4 builds in a much crowded space. Later Edit: it seems that we have a comm line on this board... I would give it a try listening what's boiling there... ...

renatoa attached the following image:

Edited by renatoa on 12/24/2021 12:15 PM |

|

|

|

| iPa |

Posted on 12/24/2021 8:37 PM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

I tried this morning, but no data, tested at every standard baudrate. |

|

|

|

| iPa |

Posted on 12/28/2021 8:17 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote renatoa wrote: Mine is coupled with an A/C digital panel voltmeter, model hks-ac56 , allowing the roaster precisely setting a fan flow, not relying on a potentiometer knob position, which is not so precise, nor reproducible. Thx, that gave me an idea, I saw this volmeter module fews time ago on a web shop, just a round hole to mount it.  |

|

|

|

| renatoa |

Posted on 12/28/2021 8:38 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Or, replace the potentiometer knob with a multiturn version, you have 10x more precise dialing, and setting locking, for some models. https://www.tme.e...-passives/ LE: just figured you already did the mod... so the 67V is fan voltage  |

|

|

|

| iPa |

Posted on 12/28/2021 5:01 PM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote Yes I did  |

|

|

|

| iPa |

Posted on 01/20/2022 12:27 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

I now have all the parts to make the new electrical control based on the TC4 shield, buil is on the way. I red a lot of things, and I have some open questions: - What differences to use artisan's PID vs TC4 PID control, or what are the advantages or disadvantages of one or the other? - is it a good precaution to install an emergency stop in case the arduino crashes with the heater on and the fan off? - any advice for PID values to start (fluid bed)? - I have adjusted the fan minimum value ( #define MIN_OT2 30 ) based on my actual dimmer, is there some other important change to make for fluid bed roaster ? - any tips or advice for the first run are welcome

Edited by iPa on 01/20/2022 7:25 AM |

|

|

|

| iPa |

Posted on 01/21/2022 8:19 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote renatoa wrote: …I am right now in the middle of modding a similar machine … What’s about your machine mods ? Are you installing a TC4/Arduino ? |

|

|

|

| renatoa |

Posted on 01/21/2022 9:02 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

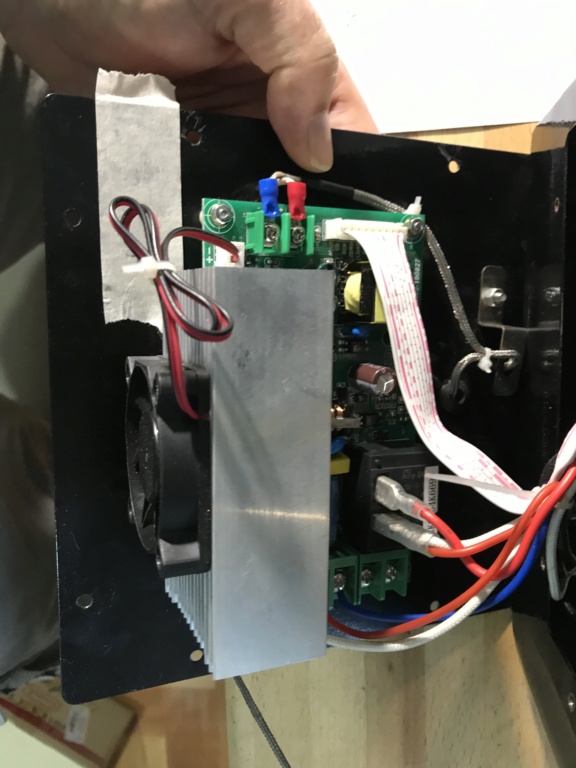

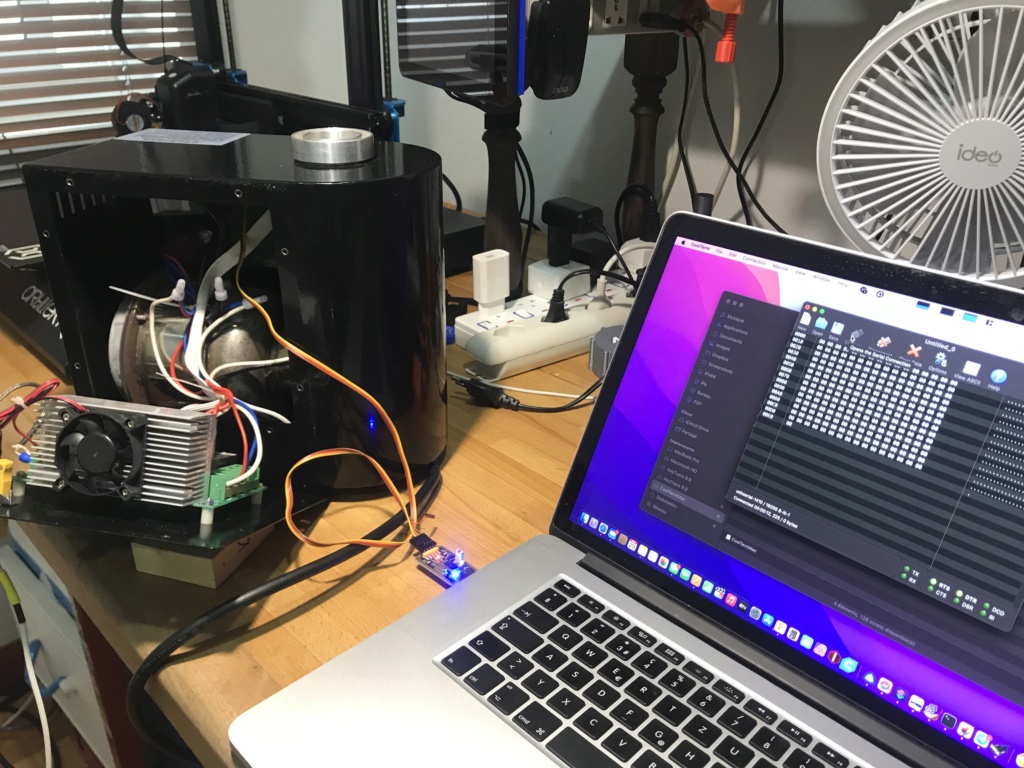

This is the machine I slaughtered: https://www.aliex...83209.html Installing a lighter, no UI, version of my TC4ESP hardware, basically performing one temperature acquisition and heater control. Fan will remain unchanged as was from the factory, manual with a pot, same control board as yours, with the associated voltage display, no changes here. |

|

|

|

| renatoa |

Posted on 01/21/2022 9:10 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote - What differences to use artisan's PID vs TC4 PID control, or what are the advantages or disadvantages of one or the other? Embedded PID always works better than a remote software PID, faster response and easier to tune - is it a good precaution to install an emergency stop in case the arduino crashes with the heater on and the fan off? Is mandatory ! At least an switched extension cord, with the breaker switch as handy as possible - any advice for PID values to start (fluid bed)? P = 2, I = 0.08, D = 0 - any tips or advice for the first run are welcome  I would spend more time with the machine as is, to know better its behavior... The computer will not roast for you, there is no AI inside to take decisions for you, it's just an events recorder and logger. |

|

|

|

| Adam_M@au |

Posted on 01/21/2022 9:40 AM

|

|

Newbie  Posts: 8 Joined: January 21, 2022 |

Quote hi @iPa saw your pics, though our roasters are slightly different (mine had the removable side panel with filter), it looks like the internals may be identical. how far have you got on setting up the tc4 ? a couple of questions on your machine, is it the 300gram model ? have you measured the power draw ? mine was marketed with a 2800W heater. how powerful is the blower in your model ? i can evacuate the glass chamber by turning the blower up to full. |

|

|

|

| iPa |

Posted on 01/21/2022 8:15 PM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote renatoa wrote: I would spend more time with the machine as is, to know better its behavior... Yes I totally agree with your point of vue, that why I used it not modified from 1,5 year. And now last 4 roasts and few next only monitored by Artisan ( Mastech MS-6514 ). @Renatoa Thank you for all shared informations |

|

|

|

| iPa |

Posted on 01/21/2022 9:04 PM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

Quote Adam_M@au wrote: hi @iPa saw your pics, though our roasters are slightly different (mine had the removable side panel with filter), it looks like the internals may be identical. how far have you got on setting up the tc4 ? I am at the middle of assembling all elements. Arduino board is ready with some settings mod and PID value shared by renatoa. Quote a couple of questions on your machine, is it the 300gram model ? It’s the D350G given at 300gr, with a light roast, you can slightly increase the amount at 350gr Quote have you measured the power draw ? mine was marketed with a 2800W heater. Only ones time with a 300gr batch, duration 17minutes, target beans temperature 206°C, heater target temperature on last stage 212°C, maximum power was 2200W (214V 10,3A), energy for the full process 0.550kWh. Quote how powerful is the blower in your model ? i can evacuate the glass chamber by turning the blower up to full. 200W |

|

|

|

| iPa |

Posted on 01/26/2022 8:01 AM

|

|

Newbie  Posts: 44 Joined: December 22, 2021 |

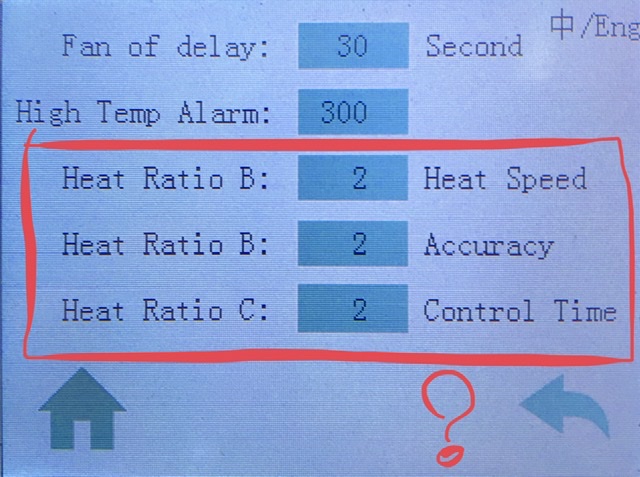

Quote hi @iPa saw your pics, though our roasters are slightly different (mine had the removable side panel with filter), it looks like the internals may be identical. Hi @Adam_M could tell me values of this settings on your roaster ? Thx  |

|

|

|

| Adam_M@au |

Posted on 01/28/2022 10:03 PM

|

|

Newbie  Posts: 8 Joined: January 21, 2022 |

hi @iPa sure, apologies i've been busy tearing the roaster apart to check out some hardware. lots of Silicone  interesting, the translation is different on my model (newer model i think) Fan of Delay: 30 Second High Temp Alarm: 350 The next three are labelled differently, Heat Mode: 2 (does not show Heat Speed) Temp Correct: 10 (does not show Accuracy) Temp Diff: 2 (does not show Control Time) I suspect those last three are PID values used by the controller. |

|

|

|

| Adam_M@au |

Posted on 01/28/2022 10:31 PM

|

|

Newbie  Posts: 8 Joined: January 21, 2022 |

while pulling it apart I found the controller is a STM32F103RB chip (64 pin LQFP package), I wonder if it can be reprogrammed. there is a main electronics board which appears to be driven by the controller, outputting the thermocouple via SPI and what I suspect is a zero cross signal back to the controller. I need to attach a scope to verify, I suspect the main heater is controlled via a PWM signal to the triac, there is a signal pin for the FAN which I believe turns on a relay powering the fan. the heater coil I measured at ~19.5 ohms, as I understand it, that equates to over 2800W heater on my mains (240V) |

|

|

|

| renatoa |

Posted on 01/29/2022 12:58 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

If not fused against unauthorized reprogramming... it could. The general schematic you described, sounds logical, is the typical way how these things works. That's why I asked at the beginning of thread about such details, to suggest attaching an existing solution to the main entry points of such electronics: temperature and power control. |

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman