Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [376] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Heating elements

|

|

| jake415 |

Posted on 02/15/2022 3:54 AM

|

|

Newbie  Posts: 26 Joined: January 18, 2022 |

Hi Homeroasters,. Any advice for attaching a heating element to the inside of a stainless steel pipes? I heard people talking about inserts, but can't find enough info to figure it out. I've been thinking of drilling in rods to hold up the thing but it isn't an elegant solution. For reference, I have a common 1600W ceramic heating element which is a hot air gun replacement part and 2" Stainless steel tube. https://www.amazo...N&th=1 Sorry if this was answered before, but I have a few more questions that I couldn't find info on: Is silicone insulation okay to connect to the heating elements or are people using nickel plated stuff? Also, Is it best to place it closer to the blower or the roasting chamber, or does it not matter? Any general advice around setting up heating element would be great. Thanks |

|

|

|

| jordo_99 |

Posted on 02/15/2022 8:16 AM

|

|

Newbie  Posts: 5 Joined: September 27, 2020 |

I used the actual heat gun housing in mine which is 1.5" and then just wrapped it tight with high temp insulation (mica or fiberglass...don't recall which) to fill the void between the 1.5" housing and 2" tube it sits in. The insulation is packed in there well enough that everything just stays in place. |

|

|

|

| renatoa |

Posted on 02/15/2022 8:47 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote Look at these cake tin patterns, image attached. Now imagine something done manually by you, having outer tips the size of tube inner diameter, and the inner tips arranged to support your heater.

renatoa attached the following image:

|

|

|

|

| jake415 |

Posted on 02/20/2022 4:43 AM

|

|

Newbie  Posts: 26 Joined: January 18, 2022 |

I tried the mica wrapping method and it worked great. I'll have to see if it effects airflow but it definitely is an easy way to install the heating element into the pipe. The star tin patterns is definitely a creative solution, good to know there are a lot of ways to figure this out. Less airflow resistance which is good. Thanks for the good ideas |

|

|

|

| exer31337 |

Posted on 09/25/2022 10:15 PM

|

|

Newbie  Posts: 49 Joined: September 12, 2022 |

I am confused why people don't use the 4.4KW or 6 KW etc... heating elements off of aliexpress for 1kg fluid bed roasters. Can someone tell me what I am missing? Thank you. https://www.aliex...94037.html Edited by renatoa on 09/26/2022 4:00 AM |

|

|

|

| renatoa |

Posted on 09/26/2022 4:00 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Too many choices... too little time... and money  to test everything... to test everything...If you know that "people don't use" these elements... what is using people actually for 1 kg FB machines ? For 1 kg maybe gas could be more economical ? Edited by renatoa on 09/27/2022 2:10 AM |

|

|

|

| exer31337 |

Posted on 10/03/2022 1:24 PM

|

|

Newbie  Posts: 49 Joined: September 12, 2022 |

I am sure gas is more economical I am just better at wiring than gas and I don't want a fireball to the face. I've seen people using two heating elements to get the same amount of KW as that one, so I am confused why they just don't use that one. More so wondering if I am missing something. Thanks. |

|

|

|

| allenb |

Posted on 10/03/2022 6:03 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I pulled up the heating element you linked to and it appears to be one that would work well for the task and, as you stated, prevents having to use two heaters trying to achieve the needed wattage. Many have attempted to utilize this style of heater in the lower wattage range but they have a significantly smaller diameter with corresponding small opening area. Due to this issue, they prevent being able to flow enough cfm even at very high static pressures. It appears that the 4.4 kw or higher wattage ceramic heaters don't have this shortcoming and it's great that you have posted a link to it as I've never seen this one before.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 10/04/2022 1:23 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Is 4.4kW enough for 1 Kg FB ? For smaller models the rule seems to be 1 kW for 100 grams...  |

|

|

|

| allenb |

Posted on 10/04/2022 5:42 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Watts per grams ratio drops as roaster batch size capability increases. Not sure if there are any relationship charts available but would be nice to have. I have been able to roast 500 grams in a fluidbed with 2500 watts so the ratio change happens fairly quickly.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 10/04/2022 7:32 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

I guess the cylinder ratio plays a role... bigger diameter favor less pressure to create the movement, thus less power consumed for both bubbling and heating. |

|

|

|

| progen |

Posted on 10/05/2022 4:57 AM

|

|

1/4 Pounder  Posts: 82 Joined: December 17, 2019 |

Quote renatoa wrote: Is 4.4kW enough for 1 Kg FB ? For smaller models the rule seems to be 1 kW for 100 grams...  Yes, it's enough even for a fairly inefficient heating chamber design where 70% of the air passed through the center column and the left and right columns were glowing red. That's if you don't play around with infused beans like me. I need much more power because of that. |

|

|

|

| greencardigan |

Posted on 10/09/2022 6:09 PM

|

|

1 1/2 Pounder  Posts: 1185 Joined: November 21, 2010 |

I typically roast 1.2kg green in my 5.4kW (3 x 1800W heatgun elements) air roaster with a bit of power to spare. I think 1kg green with 4.4kW is probably fine with the right roast chamber design. |

|

|

|

| hillelposner |

Posted on 03/19/2023 10:14 PM

|

|

Newbie  Posts: 8 Joined: March 13, 2023 |

I recently bought one of those heating elements. My first attempt was to run it off the tc4+ shield. It light up red right away, the shield was "pulsing it" through the relay and then POP, it shorted out... I was running it without any airflow.. I am assuming that is what killed it? I am about to order another one, but I am curious 1) is that what killed it or?? 2) Did you build yours around it? I am plugging it in to a 20 amp 220 outlet. I plan on putting it into a 1.5" diameter stainless tube and hook it up to an HVLP blower (used for paint spraying)... Any suggestions / Help? At least I got the arduino and the tc4 shield working with artisian..that took a while. Also, for now I am going to manually control the airflow (with a router speed controller). But eventually I would like to hook it up to the tc4. Anybody have an idea for this? It draws 12 amps at max load. Oh... Also, any suggestions for fuse / thermal protection on the heating element? Thanks!!! I am a newbie, but I've been reading a lot. Any help would be super appreciative... |

|

|

|

| renatoa |

Posted on 03/20/2023 3:39 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

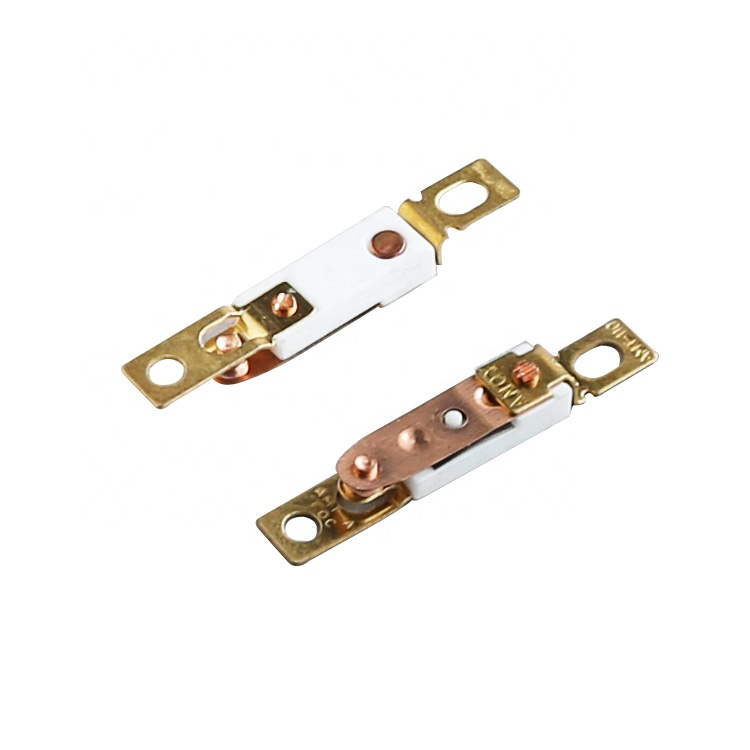

Some smaller power heaters are provided with built-in bi-metal protectors, that usually trips around 270. The most known example is the popcorn machine heater. See attached image. No idea where you can find these for sale, and how many amps are rated. The wire should be pale red at its best efficiency heating point. Any sign of turning to orange-yellow, and you should cut the power. Not sure if your unit "shorted", or melted... Short is usually associated with mains breaker popping. Does yours ? When heaters are overheated, due to low or missing airflow, the wire melts. A self destructive form of protecting owner goods  If the melting point is accessible, you can repair the heater, by twisting and crimping the two pieces where the melting occurred. And don't power without airflow next time

renatoa attached the following image:

|

|

|

|

| Piotrkurak |

Posted on 03/21/2023 9:40 AM

|

|

1/4 Pounder  Posts: 82 Joined: March 01, 2023 |

Place down in Carson City Nv called thermalfuse that does one shot elements that fuse at specific tempratures, bi-metallic resettable I haven't seen available to the consumer but haven't looked at ALIBABA. However for the $20 usd it cost last I bought one, a Sweet Marias popcorn popper has all the pieces parts |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman