Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

Grinder black hole??

|

|

| allenb |

Posted on 12/22/2022 10:24 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

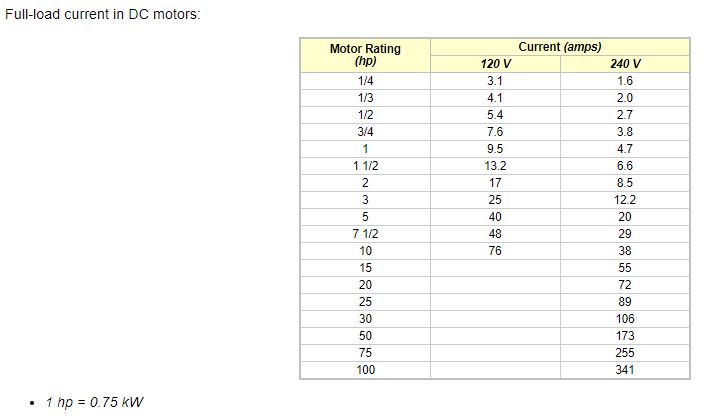

My assumption is that these starting current values in the chart are for regular induction motors. Brushed DC and permanent magnet motors do not have that kind of current inrush.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| CK |

Posted on 12/22/2022 5:09 PM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

The chart mentioned for post #24 is attached here.

CK attached the following image:

|

|

|

|

| renatoa |

Posted on 12/23/2022 1:20 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

This table is a pure math HP=Watts conversion, based on 750W/HP ratio. More exactly should be 745.7 Has nothing to do with real motors currents, which depends of load. |

|

|

|

| CK |

Posted on 02/17/2023 7:18 PM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

Here's the modified Urbanic grinder as it is today... has been working well with the updated mods. No more static or retention problems on this build, and the small bellows is just right for a final blowout.

CK attached the following image:

|

|

|

|

| allenb |

Posted on 02/18/2023 9:42 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Looks like your hard work and engineering skills paid off! This looks to be one that the main stream grinder makers will need to use as a model for a benchmark to try and beat.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| CK |

Posted on 02/19/2023 10:02 AM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

In case someone wants to make something similar, or play around with brushed DC motors, here is the video/channel I learned from. Everything you could want to know on how to use an SCR controller for speed control... correctly. |

|

|

|

| walaycow |

Posted on 03/12/2024 9:43 PM

|

|

Newbie  Posts: 1 Joined: March 10, 2024 |

Hi CK, I saw your mod and wanted to see if you can share your 3d print file or design drawings and to know more about how you end up to adjust the grinder speed. I just bought the exact same grinder and your modifications looks awesome and would like to do the same. Quote CK wrote: Here's the modified Urbanic grinder as it is today... has been working well with the updated mods. No more static or retention problems on this build, and the small bellows is just right for a final blowout. |

|

|

|

| CK |

Posted on 03/13/2024 6:46 PM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

I'll see what I can do for you when time permits. |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman