Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Presentation of my first Drum Roaster

|

|

| msantillan |

Posted on 11/30/2022 7:14 AM

|

|

Newbie  Posts: 8 Joined: April 01, 2022 |

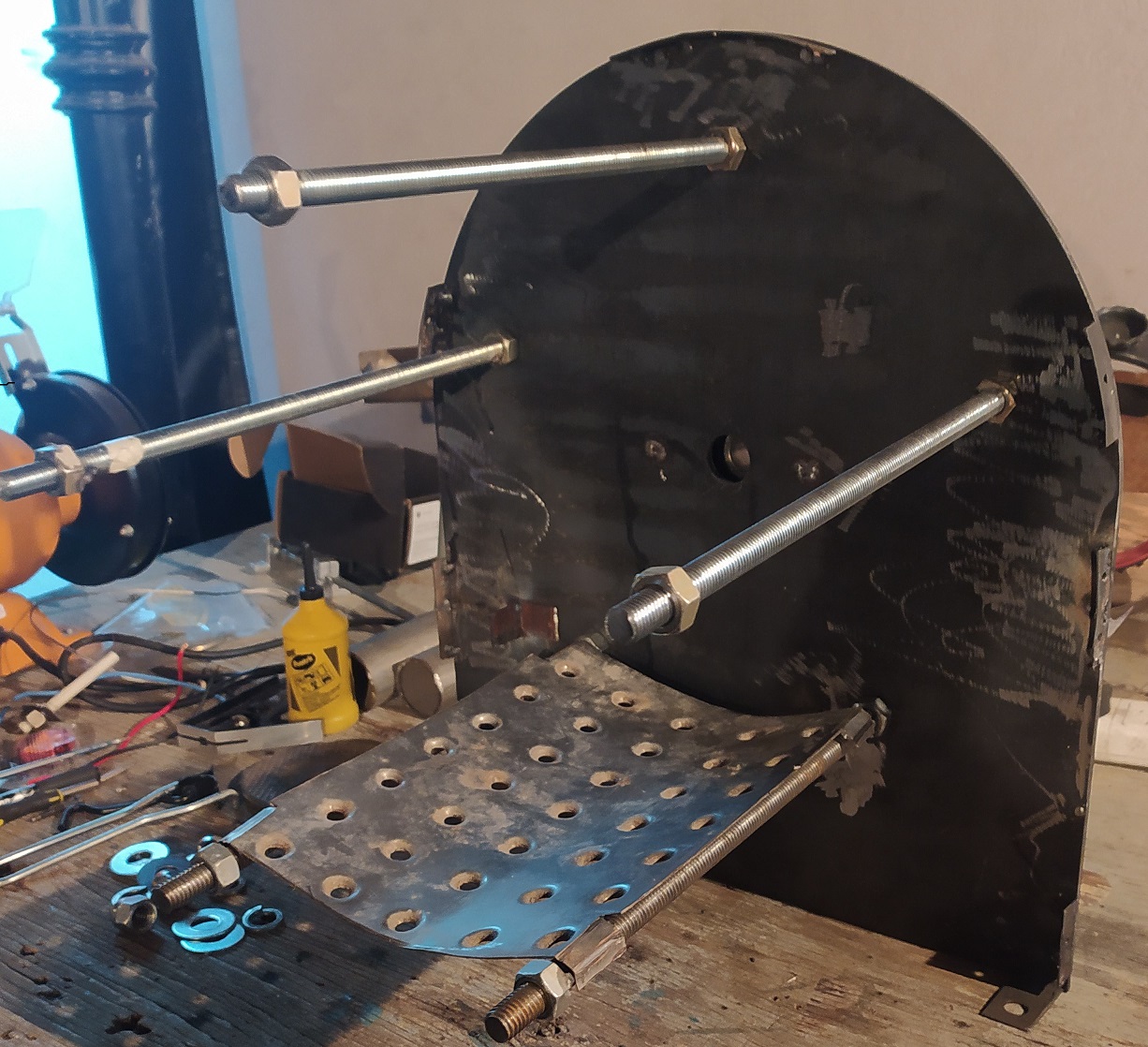

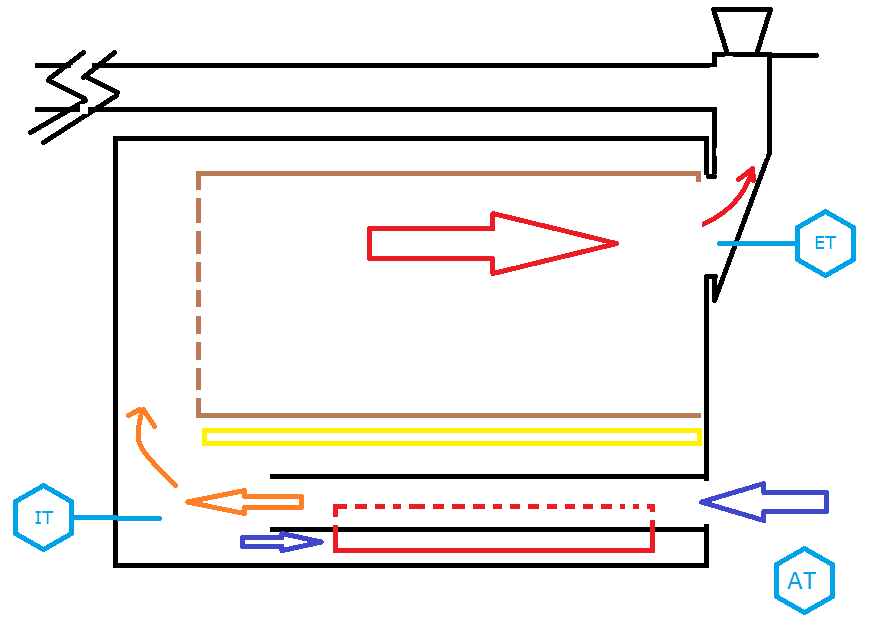

Dear colleagues, first of all I apologize for my English. In recent times I have been a regular reader of the forum and I have taken your experience as a school. The world of coffee has caught my attention and I have channeled this energy into the project of a drum roaster, all without gaving any experience as a roaster. I share with you some of my experience and I leave you some questions. Some information about my roaster. Type Drum Roaster Single Layer (SAE1010) + heat shield Capacity 1,2 kg (12 Lts) Tubular burner 3000Kcal/h Motor 50W 24Vcc Transmission by chain Variable Drum RPM Air blower 750 m3/h Bean temperature, exhaust temperature, inlet temperature, RPM, Rate of rise indication based on Arduino. Hace 6 meses I have been on the project of building a roaster for 6 months, now apparently this project is coming to an end. I attach some pictures, I hope you like them. To formulate my query I will first define two air circuits, one main and other secondary. Main air: air forced by the blower (750m3/h) Secondary air: air that mixes with the gas and feeds the burner. I would like to discuss the main air circuit, as I am not sure how hot it should enter the drum. In my machine the air is ducted through 2 Ø 50mm pipes that are on the sides of the burner. These pipes are heated by the burner, my idea was to prevent the forced air from influencing the burner flame. The question is the following: At what temperature should this air enter the drum to cook the grains by convection?. Because I have the suspicion that instead of cooking the grains it is cooling them. I did not have the opportunity to see the detail of a commercial machine to see what the air circuit is like. 02/12/2022 I have added a schematic to clarify the air path. In the first hot tests I did I discovered that the air from the main circuit influenced the burner flame, to avoid this I placed two tubes of 50 mm in diameter achieving to channel the inlet air and thus avoiding turbulence on the flame. In this machine both the combustion gases and the forced air are conducted through the drum. In the diagram I have detailed where are the temperature measurements of the air system. AT: ambient temperature IT: Inlet temperature ET: Exhaust temperature. Mariano Argentina

msantillan attached the following images:

Edited by msantillan on 12/02/2022 6:07 AM |

|

|

|

| renatoa |

Posted on 11/30/2022 10:30 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

750 m3/hour equates to about 440 cfm per minute, too much by known machine standards. For example the Bella Taiwan 800N use a 95CFM blower. This could be a reason why the airflow cools the machine, it is too powerful. The typical drum machines aren't using forced convection to roast the beans, i.e. hot air intake. They are using just natural convection, i.e. air extracting heat from drum walls, and heating the beans. For a true convection drum machine, check the Loring machines build, it's a bit different that you think/know. The maximum air temperature should be in the 250-260 C ballpark, for any roasting methods, if roasting under normal atmospheric pressure. When roasting in the mountains, over 2000 meters high, or using a pressurized roast chamber... things change a bit  |

|

|

|

| allenb |

Posted on 11/30/2022 5:11 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Hi msantillan, as renatoa mentioned, if your actual air throughput is that high, it's way too much. Or, is that air flow quantity only the blower's maximum output at zero static pressure? For us to better analyze your roaster, shoot us a sketch or detailed description of the airflow path. This will allow us to better understand a few things as: Does heat from your gas burner only contact your two 50 mm heat exchanger tubes or does it also end up heating the drum surface before exiting the roaster? How does the heated air pass from the outlet of the two tubes into the back end of the roaster drum? You've build a very attractive drum roaster to say the least! 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| goat4hooves |

Posted on 11/30/2022 10:05 PM

|

|

Newbie  Posts: 17 Joined: June 04, 2020 |

Your hard work has created a fine looking roaster. Congrats on your accomplishment. |

|

|

|

| renatoa |

Posted on 12/01/2022 4:16 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Looking again next day, after a good cup of coffee  starting to understand his airflow... starting to understand his airflow... - the blue arrows shows the cool air admission... - the pipes are heated by the burners... creating hot air inside... - the orange arrow shows this air coming in the bottom of the drum/oven, which probably is perforated, the drum back panel I mean - from there it is supposed the hot air enters inside the drum, due to the suction of the exhaust opening, and perform the roast. If I am right, probably he should find a burner/airflow setting where exhausted air reads 175-200C, a reasonable range for beans loading. Would be useful to have graphics plotted of exhaust temperature versus airflow, of empty machine, for at least 4 gas and 4 airflow levels, to figure more exactly the machine thermo-dynamics. At least, that's what I would do before trying the first roast. Edited by renatoa on 12/01/2022 3:10 PM |

|

|

|

| msantillan |

Posted on 12/01/2022 10:58 AM

|

|

Newbie  Posts: 8 Joined: April 01, 2022 |

Thank you all for your answers, I have shared some more photos with you. Renatoa understood everything perfectly, anyway I reaffirm it. Regarding the 750 m3/h mentioned, they are the maximum flow rate given by the extractor manufacturer but I omitted to comment that this extractor is powered by a dimmer which is usually set at 70% to achieve a slight depression inside the tank (setting achieved according to Scott Rao's lighter method). The air circulates through these two pipes and enters the rear of the drum. In the first picture I try to illustrate the air path. The burner heats the 50mm pipes and a heat shield, not directly the drum. I will do the exhaust temp vs air flow test these days, and share the data. |

|

|

|

| allenb |

Posted on 12/01/2022 11:36 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Good to hear you will have variable speed control of your blower. It will be interesting to hear what temperature delta you are able to achieve from your 50mm heat exchanger tubes. In my experience, sheet metal tubes require heat transfer fins in order to achieve any transfer efficiency unless they are extremely long. I'm assuming your tubing is not very long. How did you achieve complete separation between burner gasses and the air entering the rear of the drum? Does any of the heated burner gasses pass over the outside of the drum or does it bypass the drum completely? 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 12/01/2022 3:06 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Not sure that lighter method apply for a roaster like yours, intended for convective roast... I expect the airflow in a Loring style machine to be higher than the rest of the drum roasters market. |

|

|

|

| allenb |

Posted on 12/01/2022 4:17 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote renatoa wrote: Not sure that lighter method apply for a roaster like yours, intended for convective roast... I expect the airflow in a Loring style machine to be higher than the rest of the drum roasters market. The cigarette lighter test Scott Rao was advising people to use was to perform a simple check to see if a drum roasters negative draft was pulling enough to be effective or not. This is done by holding the cigarette lighters flame close to the trier's opening and see if the flame pulled into the opening, did nothing or blew out of the roaster. This would obviously only be viable with drum roasters using an exhaust fan for pulling air up through the burner, then through the back end of the drum and out through the charging funnel. fumsantillans' roaster is utilizing an exhaust fan in the same manner although the hot air source is from the heat exchanger instead of a mix of combustion gasses and makeup air. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Yasu |

Posted on 12/01/2022 4:57 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

That is a great roasting machine. I was also concerned about the relationship between gas combustion and intake air and the turbulence of combustion, so I devised a way to have a separate port for combustion and another port for exhaust airflow so that the flow rate of the combustion section remains constant even if the exhaust air volume is changed. Exhaust airflow and required heat value is 17 kcal/℃ (m3/min) If the intake temperature is to be increased by 250°C, then 3000kcal/250/17 = 0.7, so even with 100% efficiency, it would need to be less than 0.7m3/min. My roaster has an LPG flow meter. It is burning 3l/min of LPG for 1kg of roasting, which is burning 5000kcal. It is not equipped with an air flow meter, but I think it is about 1.2 m3/min, calculated from the drum internal pressure. It seemed to me that it would be better to turn down the exhaust considerably, and if possible, increase the heat as well. Translated with www.DeepL.com/Translator (free version) |

|

|

|

| msantillan |

Posted on 12/02/2022 6:16 AM

|

|

Newbie  Posts: 8 Joined: April 01, 2022 |

Dear friends, your consultation has made me think and I thank you for it. I have expanded the initial publication by including a diagram explaining the air circuit. The combustion gases and forced air are mixed at the rear of the machine and enter the drum. Regarding the lighter method, I thought it was to ensure that there is a vacuum in the drum to remove the residues from the cooking of the grains (smoke, chaff). I would like to ask you what is the meaning of a Loring type machine, what particularity does it have? |

|

|

|

| renatoa |

Posted on 12/02/2022 6:38 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

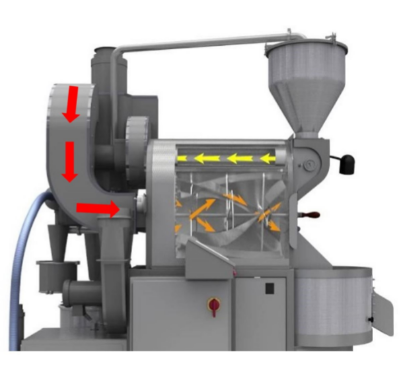

No burner under the drum, hot air produce externally by other methods, and injected into the drum. No "contact" heating transfer because the drum has temperature close to beans, is only for agitation, not for heat exchange. Your machine could be close to this model if there is a heat shield (refracting) under the drum, to avoid direct exposure to flame.

renatoa attached the following image:

Edited by renatoa on 12/02/2022 6:56 AM |

|

|

|

| msantillan |

Posted on 12/02/2022 7:11 AM

|

|

Newbie  Posts: 8 Joined: April 01, 2022 |

I understand perfectly, in the Loring case the cooking is only by convection as if it were a popcorn machine. In my case the drum walls reach temperatures of 240°C, even when there is a heat shield. |

|

|

|

| renatoa |

Posted on 12/02/2022 8:53 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Milder convection than in a fluid bed machine, the hot air has no force, nor role. to levitate beans. The machines using a hot gun as heat source are the closest small scale implementation of such concept. |

|

|

|

| allenb |

Posted on 12/02/2022 10:57 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I'm sure that msantillan's point in mentioning the popper was just to convey the fact that all heat transfer in a popper and in a loring is via convection only where his build is following the classic drum roaster heat transfer convention although with an added heat exchanger in the circuit.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman