Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Skywalker roaster mods

|

|

| Robotic Kitten |

Posted on 02/21/2024 2:28 PM

|

|

Newbie  Posts: 24 Joined: December 04, 2023 |

Quote renatoa wrote: It's just a matter of the commands mix you send. Some sequences could work, some not. If multiple commands of same type are sent, looping them through the while cycle doesn't mean fully processing, just half. The handleXXXX routine(s) overwrites the corresponding buffer value at each pass, and only the last value will be sent to roaster. For example if you send in a fast sequence three heater commands OT1;50-55-60, the buffer sent by sendMessage will contain only the 60 value, thus the false perception they were all three executed... but actually only the last was effective. If the commands in sequence will be of different type, like a fan and a heater command, they each affect a different byte in the buffer, so finally both values are sent to the roaster by sendMessage, thus you are right, while will work for such cases.e For my curiosity, what could be the sequence of commands send to roaster so long and complicate that can't wait 200 ms to execute them individually ? Other than the DROP case, which means HRT:0;FAN:100;COOL:100 ... I can't think to other scenario... let's consider the case #1, "If multiple commands of same type are sent," -- what command should take the precedence??? IMO the last one. For example, if you send "HTR;0; HTR;100; HTR; 50" -- there's no point of executing HTR;0 & HTR;100, just execute the last command. Because if these commands are queued in the buffer, then something is already wrong and there's no point of executing the intermediate commands of the same type. Turning of the heater for 200ms won't do much difference. For case #2, when there're different commands in the buffer, this is a non-issue and just executes all those at once. all of these are minor. the biggest blocker is the blocking "getMessage" as the loop is blocked until the next message is received. |

|

|

|

| HarryDog |

Posted on 02/21/2024 2:33 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

So I'm trying to implement the FILT code. The else if I put at the end. Code Download source } else if (command == "CHAN") { //Hanlde the TC4 init messageI put the FiltTemp under the Temp line, Code Download source // temp = calculateTemp(); I stuck the int filtweight before void getroastermessage. If in the right spot, do I need to add a #endif after the Serial,print? Code Download source void printBuffer(int bytes) {This compiles but fails to read the temp, for sure missed something? Thanks. Edited by HarryDog on 02/21/2024 3:42 PM |

|

|

|

| renatoa |

Posted on 02/22/2024 2:52 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Sent PM, to diagnose off-line. |

|

|

|

| Mike_Mathis |

Posted on 02/23/2024 8:32 AM

|

|

1/4 Pounder  Posts: 125 Joined: August 06, 2019 |

Quote I'm hoping I'm done with messing with this thing for now and can just push through the pounds. You are doing roasters like me a favor with your "roast to the max" test trials. It lets me know that roasting to the level I roast means I can expect pretty good reliability. Roast on!

*Kaffelogic Nano 7

*Skywalker V1 *2023 BC-2 |

|

|

|

| Mike_Mathis |

Posted on 02/23/2024 7:00 PM

|

|

1/4 Pounder  Posts: 125 Joined: August 06, 2019 |

I'm struggling just a little on exactly how to do this solder, splice job on the parallel controller setup. Mostly because I just don't do this type of finesse soldering.......ever. I'm thinking cut out a section of the USB ext cable sheathing about 3/4 inch (19mm). Then snip the 3 wires in the middle, strip about 4mm from each side, and twist them together. Then solder to appropriate points. Even though the cable wasn't that expensive, I prefer to get this right the first time.

*Kaffelogic Nano 7

*Skywalker V1 *2023 BC-2 |

|

|

|

| renatoa |

Posted on 02/24/2024 7:32 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Yeah, same procedure here. My life was made easier because the cable happened to be without any shielding at all, just the 4 individual wires, so no need to dodge fine mesh wires floating around, hunting for potential short circuits. |

|

|

|

| renatoa |

Posted on 02/24/2024 7:52 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Just a notice of warn... the data coming from the roaster could be noisy, so the filtering should be enforced even more, with a separate spike filtering, operating on other logic than rolling average. An example of READ responses sequence, from a recent roast: Rx = 25.00,0.00,135.03,65,55,729 Rx = 25.00,0.00,105.07,65,55,278 Rx = 25.00,0.00,134.47,65,55,732 The effect in Artisan is very annoying, especially on RoR curve. Because they can't be filtered in Artisan at roast time, they affect the RoR trend prediction. Notice the last number in each response packet, is the raw ADC data from the roaster, so I am sure this issue is from source, not a hiccup of code performing numbers crunching. Another anomaly that requires filtering is from Heater/Fan values data decoding, like this packet Rx = 25.00,0.00,120.57,130,120,802 ... showing 130% for heater and 120% for FAN... but such cases are rarer than temperature spikes, and not disturb that much the roasting process. Attached is the Artisan screen of the roast that furnished the data for these anomalies. The most annoying is the mini spike at minute 7, that disturbed seriously the RoR curve, as you can see. This time this is not a data issue, but build/operator issue... is the effect of trier removal ! Just 2 degrees drop and recovering 2 seconds back, and such a mess... The question is: how do you handle such situations ? ~~~

renatoa attached the following image:

Edited by renatoa on 02/24/2024 12:55 PM |

|

|

|

| renatoa |

Posted on 02/26/2024 7:56 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

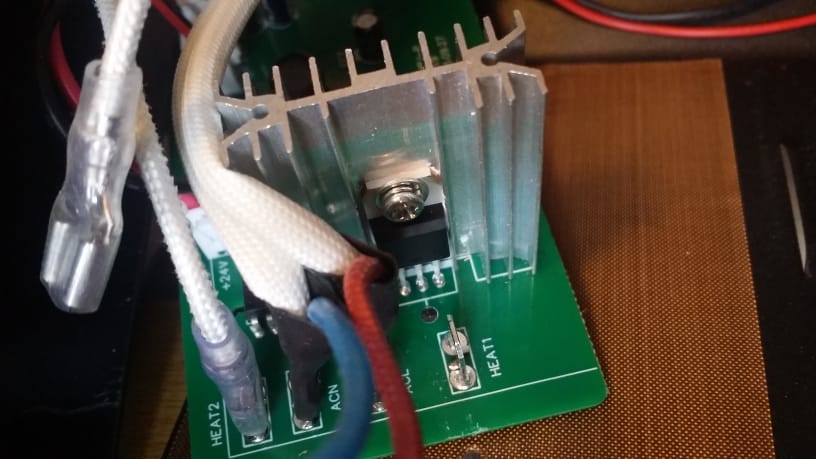

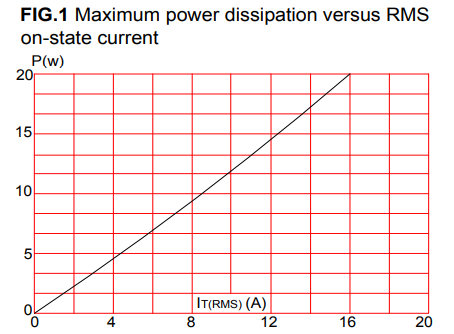

Here is the technical followup of the Skywalker caught fire story posted yesterday in the main Skywalker thread. Opened my unit and so far there is no sign of overheating, but... as guessed, the heater control element is severely undersized, for the load, and even worse, the electronics enclosure don't let the air evacuate the accumulated heat. Attached is a picture of the heatsink, dimensions are 34x12mm, what is visible in the picture, and 40 mm height. A quick search for several similar looking and sized heatsinks revealed that this size/volume means a thermal resistance in the 10 degrees per watt ballpark. In layman terms, each watt dissipated by the SCR will increase the temperature of this heatsink by 10 C degrees, above ambient. From the SCR datasheet, see graph attached, picked some power dissipation values I found relevant for various Skywalker working regimes: - 3Amps => 3.3Watts => 33 degrees more, this is the case of an 230V roaster @70% - 4.3Amps => 5Watts => 50 degrees more, this is the case of an 230V roaster @100% - 6.1Amps => 6.9Watts => 69 degrees more, this is the case of an 115V roaster @70% - 8.7Amps => 10.5Watts => 105 degrees more, this is the case of an 115V roaster @100% Please be aware that all figures above will add on top of ambient temperature !!! As a reference, the maximum temperature of a PC MCU heatsink is recommended to be under 75C degrees. And a PC heatsink is almost in open air, in a large case, under heavy forced ventilation... some of them even fitted with fluid cooling systems... Meanwhile, the Skywalker heatsink is buried in a enclosure without any airflow, or barely minimal, where heat accumulates, and accumulates, and... The conclusion is sad, is not about "if"... not even "when"... but about "hth they are still alive ?!" when we are talking about 115V units... Has anyone experience with a mass recall of a product for a Chinese manufacturer ? Or we accept the situation and start modding our roasters with an appropriate heatsink, placed mandatory outside the electronics enclosure. And place a BIG RED warn at the start of the thread ... ~~~

renatoa attached the following images:

|

|

|

|

| renatoa |

Posted on 02/26/2024 8:27 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

As a confirmation of the above, just ran a preheat on my machine, with the electronics "coffin" open, and the heater became too hot to touch in less than a minute. Thus hotter than 60C. This is called "skin pain test" and is a part of an EU law, for domestic appliances exposing hot surfaces. Should be limited to 60C, which led to skin burns if more than 5 seconds contact. |

|

|

|

| allenb |

Posted on 02/26/2024 9:16 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote with the electronics "coffin" open, and the heater became too hot to touch in less than a minute. Thus hotter than 60C. So, are you meaning the heat sink became too hot to touch or the SCR or other part? 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 02/26/2024 9:38 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Both. The SCR is always internally hotter than the heatsink, because there is also a thermal resistance between silicon chip and the case outer metal plate. The Operating junction temperature range for the SCR is -40-125C. When 125C is reached internally, the silicon burns, and the switch is full ON, permanently. This happens at about 110C heatsink temperature, which is already a lot, enough to start melting the electronics case, if made from standard PVC. From the numbers above you can see that 110C for heatsink is not a fiction, but the reality for 115V models, when in preheat mode, at 100%, and no airflow at all. A palliative, not a real cure, but still a step into right direction, would be to abandon automatic mode preheat at 100%, and use manual mode preheat, at the maximum power that will be used during roast, like 70-75% and some airflow. This regime will help maintaining heatsink temperature under 100C, but not for a long time, surely not for many back to back roasts. Edited by renatoa on 02/26/2024 9:40 AM |

|

|

|

| Lostx403 |

Posted on 02/26/2024 9:38 AM

|

|

Newbie  Posts: 17 Joined: December 07, 2023 |

Definitely a basic heatsink to say the least... You get what you pay for? Was curious what the Kaleido units setup looks like inside for comparison, found this vid where the board is shown for their little M1 unit I haven't had any issues with mine, granted the most roasts I've done in one day is 6 I believe. Would be interesting to see if the manufacturer would back the product or disappear into the night and rebrand their company name if anything bad were to happen. Aside from adding ventilation to the area it's too bad the heatsink isn't slotted for adding a fan, or it coming with a proper setup more so. The Reddit fellow having his unit go south on only the second use is obviously terrible for him but something had to have been faulty from assembly. Edited by renatoa on 02/27/2024 3:21 AM |

|

|

|

| renatoa |

Posted on 02/26/2024 9:47 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

This not related at all to machine cost, but rather to chinese stupidity. Worked in 2010 for a project with them, and they have no clue what they do. All they want is to have a project approved for the US market, to show to their supervisor from communist party, that approve funds for more work. Many small companies have no engineer at all, just workers who are instructed to copycat stuff... do something the looks like this, not WORK like this... You can pay them a lot, will not improve their level too much. Quote I haven't had any issues with mine, granted the most roasts I've done in one day is 6 I believe. Do you have a 230V unit ? As the numbers shows, they have a life A LOT easier, i.e. less hotter than their 115V counterparts. |

|

|

|

| Lostx403 |

Posted on 02/26/2024 10:10 AM

|

|

Newbie  Posts: 17 Joined: December 07, 2023 |

Oh for sure, it's not a direct knock off but the overall premise and features are similar to the Kaleido units but at a fraction of the price. I'm in Canada so not using a 230V unit. Interested to see if we can figure out any proactive measures to prevent failure or something worse. Or maybe by the grace of Chinese magic these units keep humming along. Not to pass the buck but the reddit user having the first major reported failure doesn't mean all units are going to meltdown, was it a lemon? I don't know. I do have a bit of mentality that well I paid $400ish for it, not $4000. Shouldn't be an excuse for it if it died one day, and I love the unit for what it is and what it offers. |

|

|

|

| renatoa |

Posted on 02/26/2024 10:13 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote Lostx403 wrote: Was curious what the Kaleido units setup looks like inside for comparison, found this vid where the board is shown for their little M1 unit - https://youtu.be/s4AGuweYqLI?si=2YgWo4WqS_Wizr2H Very good solution, thank you for the clip ! We have here tons of such mini fans, in the CNC/3D industry, either 30 or 40mm diameter will do the job for Skywalker too. https://www.repra...98,299,300 Also, lot of space inside, to place the micro fan on the heatsink, as in M1. Will keep you updated with the mod, after receiving the fan. |

|

|

|

| HarryDog |

Posted on 02/26/2024 10:53 AM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Don't know if the CNC or 3D fans are better then those old chip set fans but I found the chip set ones are junk. I replaced a couple of those in my video recorder with Noctura fans, moved far more air and 1/3 the noise. I think they were 12v though can see if I still have the part number and double check the size. I should add that if you have any fan it might be best to try it out just to keep that heat in check. Edited by HarryDog on 02/26/2024 11:45 AM |

|

|

|

| Nirecue |

Posted on 02/27/2024 3:07 AM

|

|

Newbie  Posts: 7 Joined: January 17, 2024 |

Quote renatoa wrote: Here is the technical followup of the Skywalker caught fire story posted yesterday in the main Skywalker thread. Opened my unit and so far there is no sign of overheating, but... as guessed, the heater control element is severely undersized, for the load, and even worse, the electronics enclosure don't let the air evacuate the accumulated heat. Attached is a picture of the heatsink, dimensions are 34x12mm, what is visible in the picture, and 40 mm height. A quick search for several similar looking and sized heatsinks revealed that this size/volume means a thermal resistance in the 10 degrees per watt ballpark. In layman terms, each watt dissipated by the SCR will increase the temperature of this heatsink by 10 C degrees, above ambient. From the SCR datasheet, see graph attached, picked some power dissipation values I found relevant for various Skywalker working regimes: - 3Amps => 3.3Watts => 33 degrees more, this is the case of an 230V roaster @70% - 4.3Amps => 5Watts => 50 degrees more, this is the case of an 230V roaster @100% - 6.1Amps => 6.9Watts => 69 degrees more, this is the case of an 115V roaster @70% - 8.7Amps => 10.5Watts => 105 degrees more, this is the case of an 115V roaster @100% Please be aware that all figures above will add on top of ambient temperature !!! As a reference, the maximum temperature of a PC MCU heatsink is recommended to be under 75C degrees. And a PC heatsink is almost in open air, in a large case, under heavy forced ventilation... some of them even fitted with fluid cooling systems... Meanwhile, the Skywalker heatsink is buried in a enclosure without any airflow, or barely minimal, where heat accumulates, and accumulates, and... The conclusion is sad, is not about "if"... not even "when"... but about "hth they are still alive ?!" when we are talking about 115V units... Has anyone experience with a mass recall of a product for a Chinese manufacturer ? Or we accept the situation and start modding our roasters with an appropriate heatsink, placed mandatory outside the electronics enclosure. And place a BIG RED warn at the start of the thread ... ~~~ SCR got around 100.2C at 60% to the heater. Ran this for about 8 minutes. 115V

Nirecue attached the following image:

Edited by Nirecue on 02/27/2024 4:30 AM |

|

|

|

| renatoa |

Posted on 02/27/2024 6:25 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

In EU such thing would fail the first tests of the regulatory boards for CE mark. |

|

|

|

| Mike_Mathis |

Posted on 02/27/2024 12:58 PM

|

|

1/4 Pounder  Posts: 125 Joined: August 06, 2019 |

What about taking the fan that has the USB-C plug out of the filter housing and mount it on the heatsink that is running hot? I think some have already mentioned this. I believe this fan runs during the entire roast if plugged in anyway. I have decided the "smoke filter" is useless anyway.

*Kaffelogic Nano 7

*Skywalker V1 *2023 BC-2 |

|

|

|

| HarryDog |

Posted on 02/27/2024 1:46 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

I think the Filter fan is larger than the heatsink so hard to mount on it well? Maybe angle wise? Not sure. Filter fan works from 0=off 3,4,5,6,7,2, 1=full If I remember. If you don't have those buttons. Add the button you want to the default "ON" button in Artisan. Don't shut off right away after roast. I like the idea of using a separate PSU but to make sure it's on you will need to listen to make sure if inside the case? Before running the roaster. |

|

|

|

| renatoa |

Posted on 02/27/2024 1:56 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

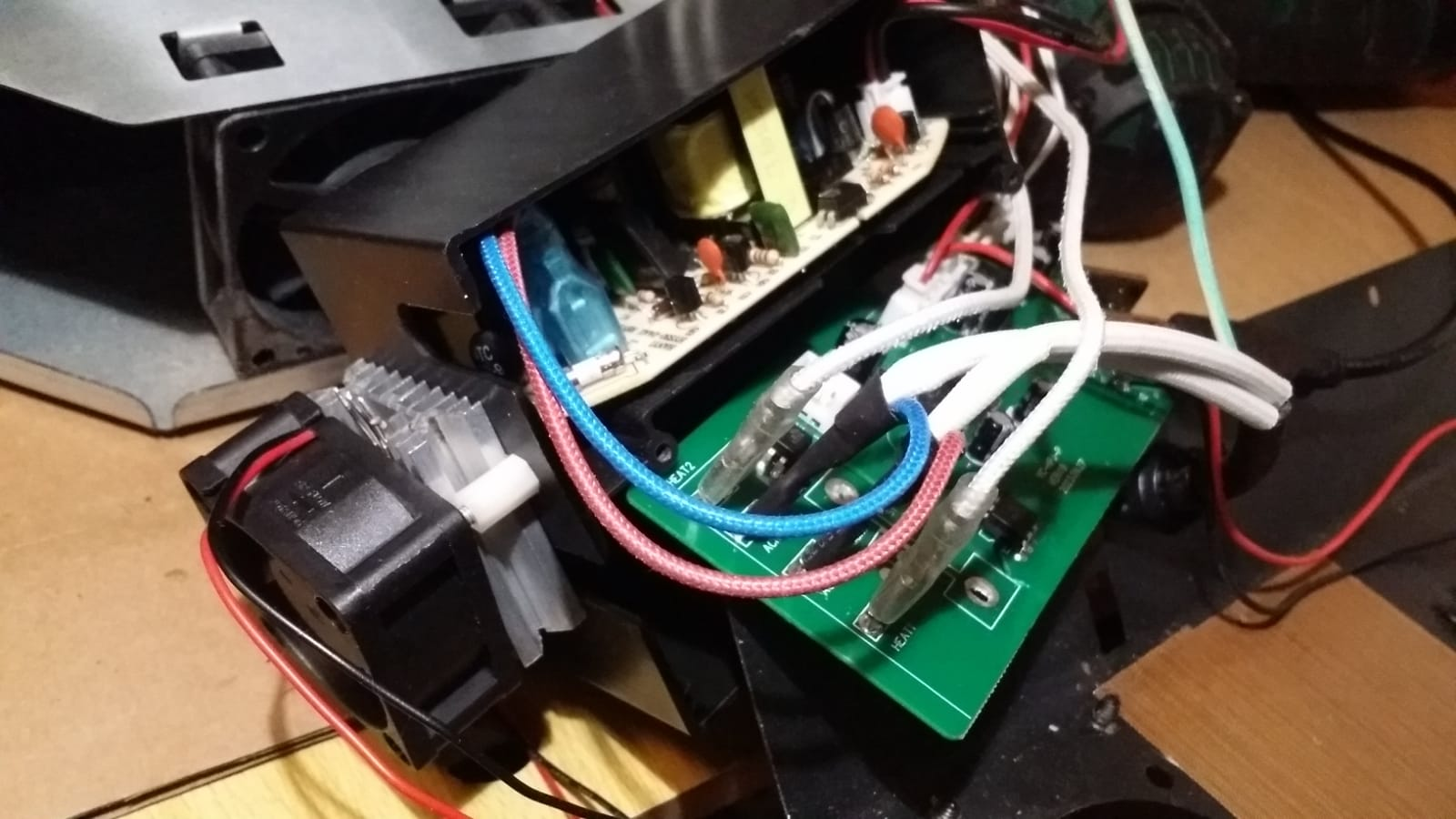

Quote Mike_Mathis wrote: What about taking the fan that has the USB-C plug out of the filter housing and mount it on the heatsink that is running hot? ... Probably too big, imo... The space around heatsink, inside the case can't accommodate a fan bigger than 3cm. Outside the case, near the heatsink also no space, it is sandwiched between two walls, the internal drum panel, and back cover. Because you asked, attached is a spoiler of the mod in progress. The heatsink together with the SCR was been removed from the "sarcophagus", placed outside, under a 40mm 24v fan I found locally. Planned to wire fan permanently to the 24V plug, but your idea about filter is very good ... IF !!! it is using 24V !!! Tomorrow will wire the SCR, i.e. performing sutures  then close back the patient. then close back the patient.

renatoa attached the following image:

|

|

|

|

| Nirecue |

Posted on 02/27/2024 3:09 PM

|

|

Newbie  Posts: 7 Joined: January 17, 2024 |

Quote HarryDog wrote: I think the Filter fan is larger than the heatsink so hard to mount on it well? Maybe angle wise? Not sure. Filter fan works from 0=off 3,4,5,6,7,2, 1=full If I remember. If you don't have those buttons. Add the button you want to the default "ON" button in Artisan. Don't shut off right away after roast. I like the idea of using a separate PSU but to make sure it's on you will need to listen to make sure if inside the case? Before running the roaster. You can mount a 3010 and 3515 fan on the heatsink you can either tap it or just use M3 to tap it in. Edited by Nirecue on 02/27/2024 3:20 PM |

|

|

|

| renatoa |

Posted on 02/27/2024 3:58 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

But keeping the heat inside only prolongs the agony… worked for M1 because the board is open air, not cased at all. At least make holes in the case all around in the heatsynk location... |

|

|

|

| Nirecue |

Posted on 02/27/2024 5:54 PM

|

|

Newbie  Posts: 7 Joined: January 17, 2024 |

Quote renatoa wrote: But keeping the heat inside only prolongs the agony… worked for M1 because the board is open air, not cased at all. At least make holes in the case all around in the heatsynk location... That's the plan |

|

|

|

| renatoa |

Posted on 02/28/2024 1:50 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Because 24V fans aren't common, someone can approach a dual 12V fan setup, connected in series. One fan on the heatsink, and the other on the enclosure, to evacuate hot air inside. |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman