Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Jborks 2kg drum roaster build

|

|

| jborks |

Posted on 01/19/2024 11:38 AM

|

|

Newbie  Posts: 5 Joined: January 18, 2024 |

Goal: Build a 2kg drum roaster with basic tools, readily accessible materials, and at a low(ish) cost. Hi All! Long term reader of this forum and first time poster. I started off roasting coffee in a home-brew turbo oven design that was only able to roast half a pound of coffee. My goal was to build something that could roast >1kg of coffee and after reading this forum for a few years I settled on a drum roaster design. Specifically, one based on UmMerkur build located here: https://homeroasters.org/forum/viewthread.php?thread_id=6720 In general, I love tinkering with things and working with my hands. It is a good escape from my day job and instant gratification. Having said that, I didn’t want to buy fancy equipment or source expensive materials. This is a hobby after all……. My goal was to build a coffee roaster with parts available at Menards or homedepot and use tools that I had on hand. This ended up working for the most part, other than ordering a number of specialty items off amazon. A few caveats: First, I have zero previous welding experience and this made me nervous before starting. However, I found it easy to join metal. The hard part was making it look nice. Please go easy on me if you are a proficient welder! My welds are complete garbage, but functional. I settled on a flux core welder that was $100 off amazon – YESWELDER 135Amp. It worked great. Second, I was limited by sheet metal sizes and gauges available at a big box store. That impacted some of the design (specifically the drum liner) and made for interesting fabrication. General Design ------------ Drum ------------ -- Harbor Freight 5 gallon air tank -- Cut to 9” x 11” -- Volume = 11.47 liters -- 1/6 rule: 11.47 / 6 = 1.9KG pounds of coffee -- 5/8" drum shaft -- "shell" around the outside to deflect heat -- perforated back to allow air in ------------ Burner ------------ -- 60,000 BTU castiron burner -- https://www.amazo...ct_details -- The shape is not ideal but it’s the best I could find ------------ Motor ------------ -- 60RPM 120W 30:1 gear motor -- 20nm torque -- https://www.ebay....6621786710 ------------ Air Handler ------------ -- Harbor Freight Cyclone Dust Separator -- https://www.harbo...57194.html -- I'm really hoping plastic will be OK. -- There will be some distance for the air to cool as it reaches the cyclone. ------------ Control ------------ -- RaspberryPi -- Bean Mass thermocouple -- Air Temp thermocouple -- homebrew python logging script Main Tools: -- YESWELDER 135Amp flux welder -- Angle Grinder with cutoff wheel and Flap Disc -- Bench clamp -- Tin Snips – cutting 22G metal -- Hand Drill – various bits -- Jig Saw with metal cutting blades TO DO: -- attach thermocouplers -- Connect burner -- Connect motor -- Cooling Tray -- configure Cyclone Filter -- Outer shell with insulation Attached are a few images of the progress so far. I'll be including the build process in additional posts. Comments are welcome and appreciated. Thanks for looking!

jborks attached the following images:

Edited by renatoa on 01/19/2024 11:54 AM |

|

|

|

| jborks |

Posted on 01/19/2024 12:29 PM

|

|

Newbie  Posts: 5 Joined: January 18, 2024 |

Frame Construction The frame was pretty straight forward. It needs to be long and wide enough to for the drum plus ~2" in the back for air flow into the perforated drum back. I also allowed ~2" around the top and sides to allow for insulation. Here is a picture of the mock-up

jborks attached the following image:

|

|

|

|

| jborks |

Posted on 01/19/2024 12:35 PM

|

|

Newbie  Posts: 5 Joined: January 18, 2024 |

Drum First I cut the harbor freight air tank to size and used a flap disk to sand off the paint. I then proceeded to weld on small tabs which would allow a small gap between the drum and the shell. The shell is intended to deflect heat and scolding of the beans. Unfortunately, the big box store did not have a long enough piece so I had to weld two sections together around the drum. It wasnt pretty... bit I think it should work.

jborks attached the following images:

|

|

|

|

| jborks |

Posted on 01/19/2024 12:44 PM

|

|

Newbie  Posts: 5 Joined: January 18, 2024 |

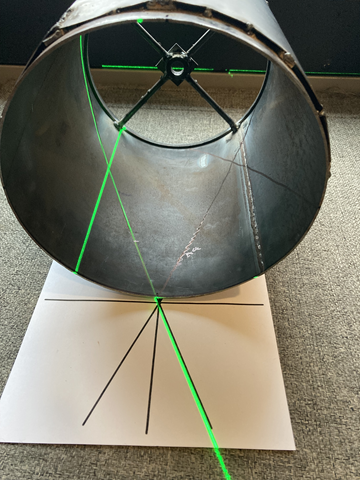

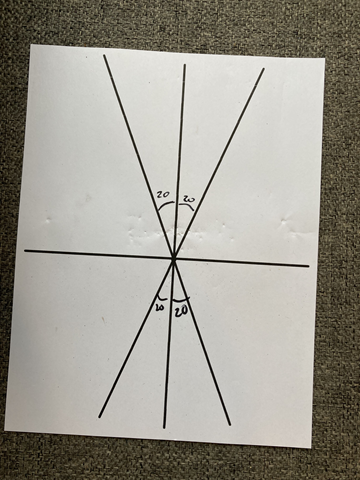

Drum Vanes This was probably the most difficult part. I settled on a 20 degree angle after reading numerous threads. The hard part was tracing that angle onto the drum and cutting vanes to match the curvature. Imagine a half pipe and cutting a vane to fit the curvature; then add a perpendicular twist at 20 degrees. Rather than use fancy math I simply created a 20 degree template and used a laser to trace it into the drum. Then I painstakingly cut a vane template until it fit properly and duplicated that shape 8 times. 4 - pushing vanes 4 - returning vanes 1.5" in height

jborks attached the following images:

Edited by jborks on 01/19/2024 12:50 PM |

|

|

|

| jborks |

Posted on 01/19/2024 3:48 PM

|

|

Newbie  Posts: 5 Joined: January 18, 2024 |

Next up was fabricating the front plate and the various add-ons. Specifically, -- Eyesight from a 20W Halogen light bulb -- Bean Sampler with wooden handle -- Door locking mechanism. I opted against the typical Ball lever approach. -- Bean hopper and Exhaust Exit manifold That is all I have been able to complete to date. Its been months and months of work. I'm hoping to finish things off in the next month and get a test batch running. I'll keep this thread posted!

jborks attached the following images:

|

|

|

|

| allenb |

Posted on 01/20/2024 12:15 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Hi and welcome to HRO! Looks like you have been bitten by the roaster build bug! Looking good. I think you will have a nice functional roaster soon and it's great that you have acquired the tools and skills to bring it all together. Keep us posted and have fun!

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman