Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Hello from sunny southern Alberta

|

|

| oldwood |

Posted on 03/24/2024 9:01 AM

|

|

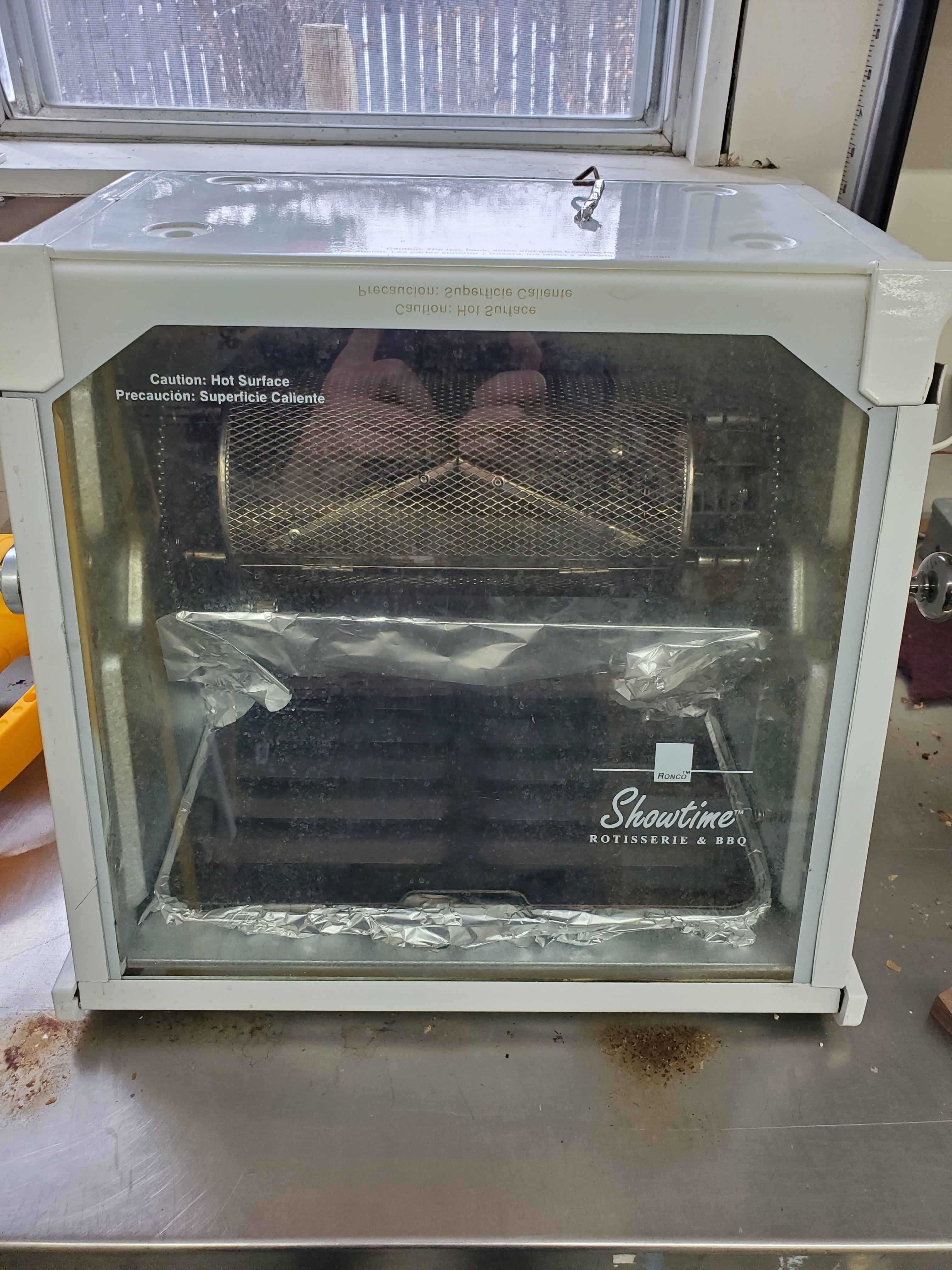

Newbie  Posts: 8 Joined: October 08, 2023 |

I have been roasting for a little less than a year and have learned a lot from reading on the site. My first attempt was with a counter top air fry oven, it roasted the beans but took too long and could not go much past first crack. I tried the oven in our range that also has an air fry setting, and it was faster and would go as dark as I wanted but was hard to get an even roast. I gave a Whirley pop a try, but the gear disengaged, so I gave up on that. Probably me pushing it too hard. My current roaster is a Ronco Showtime roaster with a heat gun to give me more control and some air movement. I log the roast on a spreadsheet and track preheat and temp on 2 minute intervals, first crack and ended time and temp. I have an oven calibration thermometer I used to track the ET. I bought a stainless basket from Amazon and added mixing vanes as needed to get an even roast. I have been using the ET profile I found in a post that was attributed to Jim Schulman, it is this, Basically, this magic profile is a starting temperature of around 325F to 400F (163-204C), and a ramp up to around 450F to 480F(232-250C) in around 6 to 8 minutes, and holding it steady there to the end of the roast, whenever that may occur. I am quite happy with the result I get, and I am roasting 400 grams in around 12 to 15 mins depending on the beans and roast level I stop at. Thanks for all the info, it has allowed me to get to the point where I enjoy the coffee I roast.

oldwood attached the following images:

Edited by oldwood on 03/24/2024 9:44 AM |

|

|

|

| renatoa |

Posted on 03/24/2024 9:59 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Welcome to HRO ! The biggest issue with this kind of baskets is the fact that chaff remains inside and burn. The slow rotation speed also is an issue, but this can be addressed with a bit of tinkering. To counteract the slow rotation speed I advise you to add an internal perforated plate having approximate shape and placement as in the Gene roaster. The back and forth rolling introduced by this plate creates an artificial agitation equivalent to 2-3x speed increase. Gene is 10 RPM, btw. To cure the chaff retention you need patience... a lot  Short story: it is necessary to thin the mesh/sieve. This is done by cutting the basket threads, in a pattern that is sparse enough to create channels for the chaff to escape, but not lose the grain and affect the structural integrity. Simply as that  |

|

|

|

| oldwood |

Posted on 03/24/2024 11:00 AM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

Thanks Renatoa "The biggest issue with this kind of baskets is the fact that chaff remains inside and burn." I have not had a big problem with that, the chaff seems to "mostly" filter through and lay on the base of the roaster. The openings are big enough that beans sometimes catch in the mesh and burn. "The slow rotation speed also is an issue, but this can be addressed with a bit of tinkering." I considered trying to find a motor with a faster rpm but decided it may be more trouble than it is worth. I have added 6 or so mixing plates in the basket that move the beans around until I was getting a nice even roast on all the beans. I will try to find some pictures of the Gene roaster to see how my mixing vanes compare. I used the Behmor as a design when I put the mixing vanes in. The motor on the Ronco runs at 50 rpm but the basket turns at 6 or 7 rpm so pretty slow. Gerry |

|

|

|

| allenb |

Posted on 03/24/2024 12:06 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Great to hear you are getting satisfactory results from your roasting rig! Are you able to maintain a steady and repeatable rate of rise during the development phase? As renatoa mentioned in another thread, this is sometimes a challenge with roasters utilizing infrared heat direct to bean. I'm sure the heat gun added convection somewhat reduces that issue. On the issue of rpm, infrared to bean heat transfer seems to be able to handle much lower levels of agitation without cell structure damage compared to drum heated and convection only roasters. I'm sure there is a point where, if using overly high infrared energy levels, this may not be the case. One way to know if insufficient chaff removal could cause negative outcomes in the cup is if the remaining chaff is being darkened to a point where it is probably burning or if it is staying fairly light in color. Honey processed beans tend to have a darker chaff regardless of being burned or not so this coffee would not be a good example. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| oldwood |

Posted on 03/24/2024 4:59 PM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

Quote allenb wrote: Great to hear you are getting satisfactory results from your roasting rig! Are you able to maintain a steady and repeatable rate of rise during the development phase? As renatoa mentioned in another thread, this is sometimes a challenge with roasters utilizing infrared heat direct to bean. I'm sure the heat gun added convection somewhat reduces that issue. On the issue of rpm, infrared to bean heat transfer seems to be able to handle much lower levels of agitation without cell structure damage compared to drum heated and convection only roasters. I'm sure there is a point where, if using overly high infrared energy levels, this may not be the case. One way to know if insufficient chaff removal could cause negative outcomes in the cup is if the remaining chaff is being darkened to a point where it is probably burning or if it is staying fairly light in color. Honey processed beans tend to have a darker chaff regardless of being burned or not so this coffee would not be a good example. Hi Alan, I am at a bit of a loss on how to track rate of rise with only ET measurements. I can control the temperature very accurately with the heat gun. It has a variable heat control and a 2 speed air control. I leave the air on high and the variable heat control is a bit over 5 with a max of ten. Small adjustments can keep the temp within 2 or 3 degrees of my roast temperature. The Ronco has 2 positions for the rotisserie front and back. I use the front position and prop the front door open with the sides blocked so I get air flow from the gun up through the basket and out the top front. The chaff that is left does not look burned, even if I take the roast to very dark. I have added quite a few mixing vanes in the style of the Behmor. The beans are constantly moving side to side and back to the middle. I roast in my garage, where I have a hobby wood shop with a dust collector. I rigged up a screen with a dust collection hose attached to cool and clean the beans. I can mix with my bare hands in about a minute, and the chaff is pulled through the screen. I am a real rookie when it comes to some of the terminology, but I am reading and learning ;) Thanks, Gerry

oldwood attached the following image:

|

|

|

|

| allenb |

Posted on 03/24/2024 6:20 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I mindlessly asked that question on rate of rise in your roaster without even thinking about your drum arrangement lacking a way to measure BT. Disregard please! If you aren't finding any baked taints to your roasts, you are most likely getting things right after first crack. But, I am super jealous of your table saw and size of your wood shop! 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| oldwood |

Posted on 03/24/2024 6:50 PM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

"If you aren't finding any baked taints to your roasts, you are most likely getting things right after first crack." Honestly, I don't know if my coffee tasting is refined enough to know, but the coffee I get tastes as good to me as any roasted I have purchased. I have read some information that says not to alter temp after first crack and some that says to lower the heat input, so I just try to maintain an even temp until the end. I am a fair distance from the heating elements on the back and with the air movement it seems to work well. Thanks, Gerry |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman