Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 6

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

I could use some help with my Burundi Roast.

|

|

| HarryDog |

Posted on 10/08/2022 10:03 AM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Hello all, I could use some suggestions on improving my Burundi roast. What I get is some nice up front coffee flavor with a fleeting fruity blast with a rich full body but get a weird acidic ashy finish with a sharp bitterness ribbon. I'm kind of torn on roasting a little darker or lighter? Maybe if I roast a touch darker then course the grind maybe it's a better finish? Now I dropped the beans at 170C but the probe is about 2 inch from the lowest part of the base as the beans are coming back down. I estimate the beans are hotter then this probe is reporting, maybe as High as 200C? My popper is a spray beans up the middle version. Looking forward to any suggestions, Thanks. |

|

|

|

| renatoa |

Posted on 10/08/2022 10:31 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

A picture of the probe placement, please? Indeed the drop temperature is unusually low. 200C is the norm for FC, drop could be some 10 degrees higher. |

|

|

|

| HarryDog |

Posted on 10/08/2022 2:39 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Pic attached. It's one of those threaded probes. R=21 ohms The other probe I was using is R=7 ohms and a third bunch of probes I have test around R=55 ohms. They were all listed as type K probes, I expected them to be in the same Resistance range? My meter is a PM6501 can I calibrate it to the probe used? Better Google this?

HarryDog attached the following image:

|

|

|

|

| HarryDog |

Posted on 10/08/2022 3:51 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

I should add that I think FC was over. I was attempting to drop before second crack and that time between is short. After 12 days rest no oil on the beans so one of my lighter roasts for sure. This was brewed on my Breville precision brewer to test how it taste using drip. |

|

|

|

| renatoa |

Posted on 10/09/2022 1:16 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

My K probes are near zero ohms, it's a 2 meter closed loop iron alloy wire, no reason to have that much... Check attached document wire resistance for various types and awg, per double foot, not meter ! ~~~

renatoa attached the following file:

|

|

|

|

| HarryDog |

Posted on 10/09/2022 5:14 AM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Well my cheap digital calipers put the wire size at 0.0145 inch. In the middle of 26-28 AWG. 6.4 feet long double run so 20 ohms might be close? What do you think about probe placement? So the probe is closer to 1.5 inch from the heat screen and .5 inch long probe so the tip will be just in the air stream about 2 rows of air holes in. |

|

|

|

| renatoa |

Posted on 10/09/2022 7:16 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Am I wrong to assume that the bottom of the steel chamber contains an additional funnel as I sketched with red ? If my assumption is wrong, then please draw where is the bottom plate, and how wide is the central column of the beans fountain.

renatoa attached the following image:

|

|

|

|

| allenb |

Posted on 10/09/2022 12:10 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote renatoa wrote: My K probes are near zero ohms, it's a 2 meter closed loop iron alloy wire, no reason to have that much... Check attached document wire resistance for various types and awg, per double foot, not meter ! ~~~ As renatoa stated, thermocouple sensors should all measure close to zero ohms unless the length is extreme or wire is extremely thin. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| HarryDog |

Posted on 10/09/2022 4:39 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Quote allenb wrote: Quote renatoa wrote: My K probes are near zero ohms, it's a 2 meter closed loop iron alloy wire, no reason to have that much... Check attached document wire resistance for various types and awg, per double foot, not meter ! ~~~ As renatoa stated, thermocouple sensors should all measure close to zero ohms unless the length is extreme or wire is extremely thin. Using that chart I though the length was about the right resistance? I don't have any experience with measuring the probes but every one I have from a different supplier is a different resistance. The one that came with the meter reads R=15 Ohms. If they are all junk do you have a supplier you trust? My meter will zero so I think it is ok, Guess I need to find some resistors to check to see if it's close or not. Then do a few tests on some different water temps to see if we have any accuracy? |

|

|

|

| HarryDog |

Posted on 10/09/2022 7:51 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

So some temp comparisons. Room Temp Room Thermostat =23.5C Meat probe 20C Peak Meter probe from roaster=26C Bonavita Kettle tap water=15C Meat probe tap water=15c Peak Meter probe from roaster=18c Bonavita Kettle is set to hold at 180F As the water heats the probe tracks just behind the kettle. When the kettle starts to hold temp at 82C Peak Meter probe from roaster=82C Meat probe=83.5C Test in toaster oven. Meat Probe=221c Rated to 230c Peak Meter probe from roaster=211c Rated to 600c The meat probe looks to have a higher error as the temp rises. The Roaster probe gets a little more accurate at higher temps maybe. Test the probe I used before going to the screw in version. Test in oven. Max temp 213c It looks like my probe placement might be the issue, but the other two poppers were cyclonic? This unit sprays the beans up the middle. These test are about as good as I can do. Not sure where best placement for the thermocouple probe is? |

|

|

|

| renatoa |

Posted on 10/10/2022 2:35 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The best beans probe placement is where it measure as much as beans and as less air as possible, for any machine scenario. Simple to write... The popcorn machines are cyclonic/vortex indeed, for them beans probe is even more difficult to place because the hot air is everywhere, especially on walls, and less in the middle, exactly contrary than hot gun roaster blowing hot air in the middle, and less near the walls. |

|

|

|

| renatoa |

Posted on 10/10/2022 2:45 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote ... Looking inside the the probe is at the edge of the holes, thought it was a bit more into air stream. This make your reading even more strange, should be more than 200, not less... Any measurement method actually measures the temperature of a mix, not of beans themselves. 200C is just a convention, taken from the average drum roaster. In a machine where the airflow is minimal, so much less air than average in that mix, you can have FC even at 185C. This is closest to reality beans surface temperature at FC. Air is hotter than beans always in a FB, so I got FC at 204-208C for most FB machines I tinkered, either vortex or fountain. |

|

|

|

| renatoa |

Posted on 10/10/2022 2:51 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

At the end... the little detail we should emphasize at the start: for roasting the temperatures themselves aren't that important, but the variations. For this reason, just measuring with a thermometer will not help much, if the measurement machine lacks the feature to compute and display the rate of change. A seasoned roster will ignore the exact moment of FC, whatever it happens, at 190-200-205, but will focus more on the rate of change evolution before and after FC. For this reason, never were debates about the probes resistance, people never been concerned about this detail. It matters for RTD probes only, not for thermocouples. |

|

|

|

| HarryDog |

Posted on 10/10/2022 7:52 AM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Quote renatoa wrote: Quote ... Looking inside, the probe is at the edge of the holes, thought it was a bit more into air stream. This make your reading even more strange, should be more than 200, not less... I thought this was odd, at first I looked at the probe as the issue (Resistance) but the tests I ran show they are very close so placement looks to be the factor at play in this roaster. Quote renatoa wrote: The best beans probe placement is where it measure as much as beans and as less air as possible, for any machine scenario. Simple to write... I was thinking this was a good spot, if I used a different charge load the probe would still be in the beans? Now 30c difference seems like a lot when the probes test within 2c in my oven test. I can only think of two other spots, at the top just below where the spray gathers on the side and falls? Second spot would be at the bottom where the beans collect before they are forced up the middle? Too low and it will be mostly in air. First test I think I will just screw the probe out about half way and see if it tests any closer? Quote renatoa wrote: A seasoned roster will ignore the exact moment of FC, whatever it happens, at 190-200-205, but will focus more on the rate of change evolution before and after FC. I use FC as a milestone that I can't miss, I need to focus up even more as the roast level is determined in the next 1-2 minutes. I have been changing too many things to get better as a roaster. I'm implementing my new blower and hope this is my last change for the winter. |

|

|

|

| swines |

Posted on 10/17/2022 3:55 PM

|

|

Newbie  Posts: 2 Joined: October 16, 2022 |

I'm at loss as to why this thread has devolved into temperature probe placement. Temperature probes just give you relative information. As long as the information is consistent you can use that to gauge the roast. You stated the drop temperature but there is no information about the weight of beans being roasted, the total roast time, when the first crack happened (time and temperature), heat gain for every 30 seconds of time over the duration of the roast (heat ramp), whether the roast went to second crack, or finish temperature. All those make up the roast profile and those are the things you need to concentrate on when roasting. Probe placement for heat measurement isn't going to change a bad roast profile. |

|

|

|

| HarryDog |

Posted on 10/17/2022 7:14 PM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

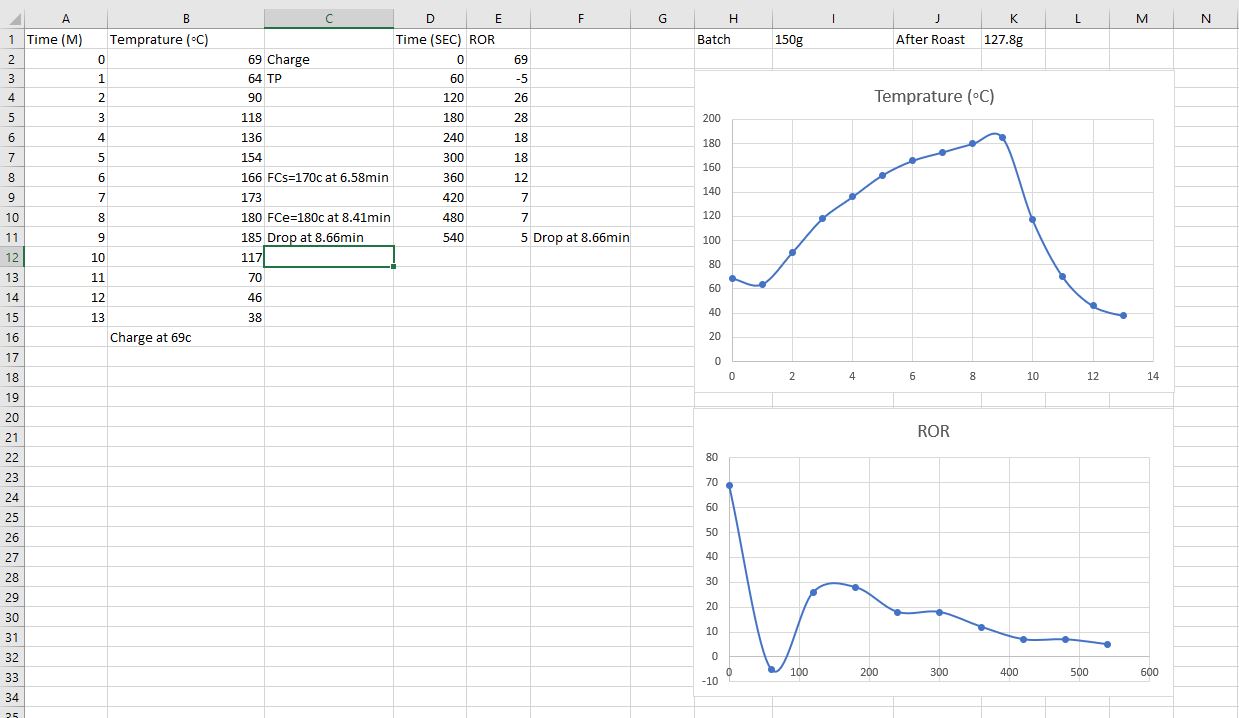

Hello Swines, thanks for your interest. I'm not sure about the consistency of the probe readings, I had 2 roast close and two different roast with about 15c difference. I only have data every 1 min. I need to make a graduated cylinder to calculate density. I don't have the yellow stage marked as outside I could not tell when it just starts to yellow. I used Excel to plot the data picture attached. Density=.732g/mL Measuring Settled Density

HarryDog attached the following image:

Edited by HarryDog on 10/17/2022 8:47 PM |

|

|

|

| swines |

Posted on 10/17/2022 11:49 PM

|

|

Newbie  Posts: 2 Joined: October 16, 2022 |

Please correct my assumptions if they're incorrect. It appears you're using a fluid bed style roaster where the beans are roasted using convection in a heated stream of air. Have you tried measuring the heated air at a point near where it exits the roaster? It would be of some value to know the air temperature at your probe's current location at the bottom of the roaster, as well as at the exit as the beans should absorb some of the heat as the beans are endothermic which should cause a predictable heat loss. As the beans roast, they change from endothermic to exothermic. Generally, the change occurs at the first crack and which should be around 204C and the beans are exothermic. You have to understand that even in a drum roaster, you really aren't measuring only the beans' temperature as the beans fall over the temperature probe in a waterfall action as the beans are rotated in the drum, lifted by the paddles of the drum - and mixed as they roast. So even in a drum roaster, you're getting air temperature along with bean temperature. What should happen is you drop the beans and they absorb a lot of heat. That would cause the air at the exit point to be at a lower temperature than the air at the input area. As the beans roast, the temperature difference will slowly change as the bean temperature rises and finally the exit temperature will be higher than the input temperature as the beans become exothermic. However, what you will have to do is use the information to guide your roasting technique. From the graph you've provided, my first inclination is the beans are under-roasted. I would try roasting them all the way through the first crack until the beans stop cracking. That should be a full-city roast. The beans should be medium brown. Depending upon the bean type they may have small oil drops on the surface that will quickly absorb back into the bean as they cool. A full-city roast is a really good starting point as the beans are neither over-roasted nor under-roasted. The problem with a city roast level (light roast) is sometimes you get the grassy and acidic flavors from the beans as the sugars are not fully developed. I roast using a drum roaster and find that I end most roasts somewhere between 212C and 218C. Very few beans I've roasted seem to be good roasted light (city) and dumped at 204 - 208C, or just as the first crack is slowing down. Likewise, very few beans seem to be really good roasted far into the second crack to French and Italian roast levels. The really dark levels seem best with espresso beans to be used in coffee drinks with milk where the heavier flavor is diluted and carried through the entire drink mixture. |

|

|

|

| HarryDog |

Posted on 10/18/2022 2:27 AM

|

|

1/2 Pounder  Posts: 349 Joined: July 20, 2022 |

Yes I'm using a modified popper, I just took it back apart and found a loose rivet hope this is the issue, I will also be adding some active cooling to the heater controller as well just in case heat was a factor but will pay more attention to the next roast and check the heat sink temp as well. Going to put a top on this roaster and can put in a probe in the exhaust easily. I will be trying to slow the rise before FC a bit and roast to a higher temp or longer? |

|

|

|

| renatoa |

Posted on 10/18/2022 6:12 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote swines wrote: I'm at loss as to why this thread has devolved into temperature probe placement. ... Probe placement for heat measurement isn't going to change a bad roast profile. But a wrong probe placement can make a good roast look as bad... |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman