Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 8

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Observations during 1C

|

|

| allenb |

Posted on 05/28/2023 7:23 AM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

I've been contemplating something I've always seen occur during first crack on my 1 lb drum and would like to know if others see the same thing. I'm using a bare heavy gauge thermocouple which gives almost immediate feedback. On a very consistent basis, there is a slight dip in BT just prior to the first audible snap or two, then holds for somewhere between 5 to 10 seconds, then starts a higher rate of pops for for another 5 seconds or so, then the major drop in BT (usually goes from around 12 degrees (F) per minute down to 4 or 5 per minute with a higher rate of pops and then comes back up within 5 seconds or so to around 7 or 8 degrees per minute and continues till I end the roast. I understand the reason behind the drop being vapor release but have always thought it odd that there are always two vapor release caused sags, one slight and then followed by a larger sag instead of just one sag. It would appear that the vapor release happens in 2 stages. Curious to know if others using fast reacting sensors have noticed similar outcomes? 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| btreichel |

Posted on 05/28/2023 11:25 PM

|

|

1/4 Pounder  Posts: 187 Joined: May 07, 2007 |

I heard about that happening, but never seen it myself. |

|

|

|

| oldgrumpus |

Posted on 05/29/2023 12:01 PM

|

|

1/2 Pounder  Posts: 225 Joined: July 25, 2012 |

My 3lb drum roaster has very fast temp probes. They are 2mm diameter. I've taken screenshots of 4 recent roasts and see a dip in 3 of them. My graphs are set with the red line as ET and blue line as BT. So for me I do see some evidence of it, but some show on the ET curve and others on the BT curve and interestingly, #3 has no evidence of any dip in either line.

oldgrumpus attached the following images:

|

|

|

|

| renatoa |

Posted on 05/29/2023 12:39 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

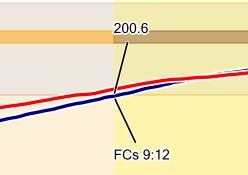

The dip is even better visible in rate of change (delta) graph(s). See attached for an example of what I mean. The thin blue line graph is the rate of change of the thick line, the derivative, i.e. a magnifier of the irregularities. Near FC, at minute 10, you can clearly see the flick followed by crash, in the lower (rate of change) graph, while the upper graph, of BT, is as smooth as it gets.

renatoa attached the following image:

|

|

|

|

| ETomczak |

Posted on 05/29/2023 10:58 PM

|

|

Newbie  Posts: 39 Joined: February 06, 2023 |

I've been reading through all of this thread on HB, and it's been really interesting: https://www.home-...37175.html No mention there about the two down ticks you're observing. I'm not sure what that could be. I've definitely observed the down tick after FCs, and the resulting upturn after a minute to 90 seconds or so. The above thread is the first time I've heard of it possibly resulting in anything negative though. |

|

|

|

| renatoa |

Posted on 05/30/2023 2:10 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Actually, could be simply a measurement issue, due to relationship between averaging window and measurement system resolution. At low rate of change, under 6C/min, as we have in development, a single decimal (0.1 C) resolution measurement system is no more suitable to compute a reliable RoR value, if the averaging window is less than 12 seconds. At RoR 3 you need even more, at least 20 seconds... I would rather question if the theory that flick-crash as a sign of a bad roast is still viable... Even Rao step back in his courses from his article wrote 7 years ago. |

|

|

|

| Piotrkurak |

Posted on 05/30/2023 1:25 PM

|

|

1/4 Pounder  Posts: 82 Joined: March 01, 2023 |

Got a 7 degree drop in EGT during a good 1C in the behrmore, got so excited forgot to stop the roast, went to 2nd crack. Ugh. Oh well, will grind and brew it anyways. Shouldn't waste good coffee As an ex space grade instrumentation tech, you'all should be running bare thin thermocouple if you want to see faster response. The specs say 5 second lag on shielded probes, so you have missed the event |

|

|

|

| CK |

Posted on 05/30/2023 3:59 PM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

Quote Piotrkurak wrote: you'all should be running bare thin thermocouple if you want to see faster response. The specs say 5 second lag on shielded probes, so you have missed the event Been running these for the past 2 years and they've been great. Both ET and BT sensors are of this type. https://www.amazo...&psc=1 |

|

|

|

| allenb |

Posted on 05/30/2023 6:27 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

Quote Even Rao step back in his courses from his article wrote 7 years ago. The flick Rao was seeing with clients roasts was the uptick in RoR near the end of 1C. Here's one of his statements in the cropster interview: In a typical 10-14 minute drum roast, the flick occurs approximately 90-120 seconds after the onset of first crack. If I'm doing a full city, which I rarely do, this can happen to me if I don't decrease input energy near the end of 1C. The sag I'm referring to is just barely into 1C and occurs in two stages. I don't think this has any effect on the outcome of the roast but was just an observation and wanted to see if anyone else noticed it in their roasters. 1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 05/31/2023 1:14 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Too fast response isn't good either, means noise... If using slow PPM as heater control method, and a good measurement system, you can see in the readings the one second pulsing, as some degrees cyclic variation in ET. Edited by renatoa on 05/31/2023 9:29 AM |

|

|

|

| ETomczak |

Posted on 05/31/2023 8:57 AM

|

|

Newbie  Posts: 39 Joined: February 06, 2023 |

Quote renatoa wrote: Too fast response isn't good either, means noise... If using slow PPM as heater control method, and a good measurement system, you can see in the readings the one second pulsing, as 1-2 degrees cyclic variation in ET. Can you adjust noise reduction later down the line though? Like in the TC4 firmware (if you're using one), or Artisan? I guess the question is; how thin is too thin? Roasted beans have a pretty low mass by weight, and have terrible thermal transfer efficiency, so you may have to go extremely thin before it becomes a problem. I'm going to try a bare wire probe in my roaster, I'm really curious. |

|

|

|

| renatoa |

Posted on 05/31/2023 9:29 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Sure you can, but the result is the same, introducing delays. Thermal or software, all are averaging/integrating methods, and introduce lag/delay. 80% in TC means 4 seconds delay, same as a 3mm SS probe. 85% in TC means 6 seconds delay, same as a 4mm SS probe. Brass sheath are faster than SS, by 1-2 seconds. Same for smarter filtering, like Savitzky-Golay instead a rolling average. Naked wire can sense even 5 degrees pulsing during one second period, as you can see here: Edited by renatoa on 05/31/2023 9:35 AM |

|

|

|

| Piotrkurak |

Posted on 05/31/2023 9:48 AM

|

|

1/4 Pounder  Posts: 82 Joined: March 01, 2023 |

Not sure it is "noise" or if the TC is actually experiencing that. If a constant heat source varies, it would be noise. Not sure my bean source is that uniform for temperature. Ahhh good data on response times for junctions Finer than 32 gauge means handling errors and lack of robustness |

|

|

|

| renatoa |

Posted on 05/31/2023 12:20 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

It's a bare TC, no sheath, in a TO based machine, exposed to both hot air, but also to IR radiation. Probably what you see on display is mainly due to the lamp pulsing, not to hot air, hard to believe that 8 litres of air reacts so fast. Surely is not noise, there is no randomness in the pulses, it's a constant 1Hz "heat beat". |

|

|

|

| ETomczak |

Posted on 05/31/2023 12:39 PM

|

|

Newbie  Posts: 39 Joined: February 06, 2023 |

Interesting, yes, that makes sense. For folks using an uneven heat source like PWM at 1hz, then certainly there can be a problem. For the sake of trying to get the most accurate bean temperature readings possible, let's say your roaster has PAC instead of slow PWM. Is there a downside to a well-placed thin wire bare TC? It sounds like Allen isn't running into issues. I'll try it in my machine. I'm very interested to hear that bit about the brass TC sleeves by the way. I have some small brass tubing laying around, and as long as it tests negative for lead, I'd like to try it out too. I tried doing an internet search on brass thermocouple sleeves but came up with nothing. It makes sense that it would react faster though. |

|

|

|

| Piotrkurak |

Posted on 05/31/2023 1:08 PM

|

|

1/4 Pounder  Posts: 82 Joined: March 01, 2023 |

If you have bare TC, then those are the most sensitive. You put them into sheaths because you don't want to replace them often and fast sensitive accuracy is not as important. Nor is precise actual temprature. I can't tell the difference in a 406f roast and one that is 415f or if I even got to either temperature or blew past them |

|

|

|

| renatoa |

Posted on 09/28/2023 4:15 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

An interesting approach of FC detection, other than audible and/or rate of change monitoring: https://www.baris...-up-to-be/ |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman