Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 7

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 2 of 2: 12

|

|

New to roasting. Could you help me with roasting advice?

|

|

| Ben N |

Posted on 05/15/2024 8:33 AM

|

|

Newbie  Posts: 11 Joined: January 22, 2024 |

I think many of your lessons learned will translate to any roaster in the future. Maybe not directly but the knowledge of bean behavior during the roast, and your own preferences will work with another machine. And it seems there is always more to learn, the logging really helps. I also like my artisan based SR, it does what I want in a batch size that lets me roast often  |

|

|

|

| Skyhawk4 |

Posted on 05/16/2024 12:24 PM

|

|

Newbie  Posts: 27 Joined: November 19, 2023 |

Quote Ben N wrote: I think many of your lessons learned will translate to any roaster in the future. Maybe not directly but the knowledge of bean behavior during the roast, and your own preferences will work with another machine. And it seems there is always more to learn, the logging really helps. I also like my artisan based SR, it does what I want in a batch size that lets me roast often  I'm curious, with your SR do you have a sweet-spot overall time range for your roasts that you try to keep within? My best medium roasts seem to be in that 8 to 9 minute range. I have had some good tasting coffee from longer roasts too though. |

|

|

|

| oldwood |

Posted on 05/18/2024 3:44 PM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

Quote Skyhawk4 wrote: Quote Ben N wrote: I think many of your lessons learned will translate to any roaster in the future. Maybe not directly but the knowledge of bean behavior during the roast, and your own preferences will work with another machine. And it seems there is always more to learn, the logging really helps. I also like my artisan based SR, it does what I want in a batch size that lets me roast often  I'm curious, with your SR do you have a sweet-spot overall time range for your roasts that you try to keep within? My best medium roasts seem to be in that 8 to 9 minute range. I have had some good tasting coffee from longer roasts too though. I recently read this; "The overwhelming industry consensus, from 3rd Wave roasters to Folger's, is that roast times under 7 minutes or over 14 are not good. Another overwhelming consensus is that environmental temperatures above 500F are not good. A less strong consensus, but one held by all the third wavers, sees roast profiles that are described as Slow Start/Fast Finish as better than Fast Start/Slow Finish profiles." This is from this thread, https://www.home-barista.com/roasting/timing-first-crack-heat-reduction-t11144.html I had previously read this, "Basically, this magic profile is a starting temperature of around 325F to 400F, and a ramp up to around 450F to 480F in around 6 to 8 minutes, and holding it steady there to the end of the roast, whenever that may occur." For some reason, I interpreted the whenever that may occur part to imply it was not important when it occurred, but have changed my roasting technique, so my roasts end at around 13 minutes and have seen an improvement in the taste. I am using a DIY mesh drum roaster, but it seems Jim's advice applies to all types. |

|

|

|

| renatoa |

Posted on 05/19/2024 3:01 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Jim states clearly that his formula is for hot air machines. And also, do not skip the second half part of the quote, is equally important as the numbers: Quote This ET part is basic roasting chemistry, and the same for all roasters and coffees. But the heat inputs required moment by moment to achieve this ET curve is based on the roaster's thermal characteristics, and is different for every roaster design. " No, for machines not based on hot air ET is less or not relevant at all. For example the IR roasting machines, as recently Skywalker roaster shows. ET in that machine is the lowest temperature in the whole chain. Go figure... Even the continuous declining RoR mantra is no more mandatory to have awesome roasts. Old style big machines commercial roasters often goes into 15-20 minutes and they get good results... because so demand the machine, and heat transfer specifics. Machine heat transfer understanding is the most important, more than adopting someone "consensus", without understanding how your/others machine work. |

|

|

|

| oldwood |

Posted on 05/19/2024 7:23 AM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

"Machine heat transfer understanding is the most important, more than adopting someone "consensus", without understanding how your/others machine work." Once again, my attempts to find a simple solution to a complex problem are dashed ;) My problem with my roaster is I can not track the bean temp as I can not insert a probe in the bean mass. I must work ET and time. Thanks, Gerry |

|

|

|

| renatoa |

Posted on 05/19/2024 8:13 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Solution is simple, if you know that in hot air machines ET is a function of power. Not totally proportional but close. Other words, if you read 150C ET at 40% power, then there are great chances to have 220-225C at 60%. More about this approach here: https://homeroast...post_74953 |

|

|

|

| oldwood |

Posted on 05/19/2024 8:57 AM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

Quote renatoa wrote: Solution is simple, if you know that in hot air machines ET is a function of power. Not totally proportional but close. Other words, if you read 150C ET at 40% power, then there are great chances to have 220-225C at 60%. More about this approach here: https://homeroast...post_74953 That makes good sense for the air roaster. For my situation I have a resistance style electric element at the back of the roaster that has only an on off control and a heat gun that gives me air flow and extra heat, so I can get fine control of the ET. I use a kilowatt style meter to give a better idea of what the gun is putting out. I think the 2 heat sources is going to make the formula complicated and messy ;) If the temp is controlled and the air flow is increased, would the heat transfer rate to the beans also increase, or is the temp the only controlling factor? I try to control air flow direction so it is forced over the beans in the drum, but have no volume control of air. |

|

|

|

| Skyhawk4 |

Posted on 05/23/2024 3:19 PM

|

|

Newbie  Posts: 27 Joined: November 19, 2023 |

Quote Ben N wrote: I think many of your lessons learned will translate to any roaster in the future. Maybe not directly but the knowledge of bean behavior during the roast, and your own preferences will work with another machine. And it seems there is always more to learn, the logging really helps. I also like my artisan based SR, it does what I want in a batch size that lets me roast often  This was a long journey for me to understand the entire process from buying green beans that I like, roasting coffee I liked, resting, grinding... everything including the final brewing of a cup of coffee that I liked - it was a lot to understand, daunting. I read a lot about the entire process and watched a lot of YouTube videos. But when I actually tried doing it, I was pretty depressed. With my first attempts the coffee was un-drinkable. The factors involved in making good coffee began to seem impossibly complex to me. But with a lot of trial and error I gradually began to get better and better results. But you are right, the logging helped. Now I actually enjoy doing this, where in the beginning it just stressed me out. Also, now I know more about the green coffee I buy (what coffee to buy that I like the taste of). Like you said about the SR, I like the smaller batch sizes so I can roast often and have a nice variety of my favorite coffees... kind of what I am in the mood for. I only roast what I will use up within a week or 10 days. I'm probably imagining things, but the coffee seems better if I don't let it age beyond that... like is loses something in flavor. Anyway, I'm finally comfortable with this entire coffee making process and that feels mighty good. It was a steep learning climb for me... at times I felt about as intelligent as a monkey (LOL, seriously, I was feeling pretty down at times). Hey, thanks to everyone for your help on this journey. All of your posts were very helpful. Edited by Skyhawk4 on 05/23/2024 4:05 PM |

|

|

|

| renatoa |

Posted on 05/24/2024 1:46 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

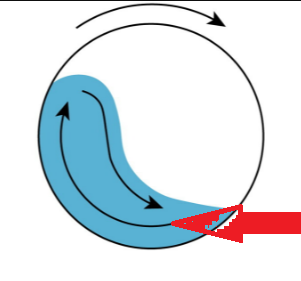

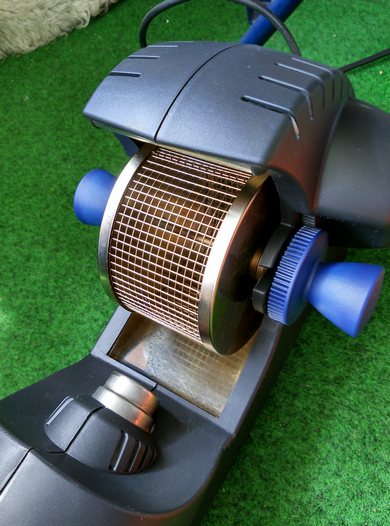

Quote oldwood wrote: If the temp is controlled and the air flow is increased, would the heat transfer rate to the beans also increase, or is the temp the only controlling factor? I try to control air flow direction so it is forced over the beans in the drum, but have no volume control of air. Yes, more convection, i.e. airflow speed, decrease the roast time. This is valid even for basket rotation speed, the beans will move faster in the air mass, thus more (auto)convection. Why over the beans instead into the bean mass ? Have a look at Dieckmann Roestmeister machine, I own one, was my first commercial, and delivers very fine results. That is the right way to push air in a rolling beans bed, at the base and tangential of mass. The curved wall behind the basket will force the airflow rise too, following the beans movement. btw, the rotating speed is 20 RPM, for this 12 cm diameter wire cage, to achieve that cascading flow of beans. This machine roast using same power for all the seven so called "programs". The power is constant up to a point, and depends on ambient temperature only. The goal seems to be having about 330C at the hotgun exit, 3 cm away from cage wire woven. When first crack begins, which is signaled by operator, pushing a button, the power is reduced to about 80% equivalent to about 300C hot air. This is where the programs start to differentiate, 45 seconds to 3 minutes for programs 1-4, 4 to 6 minutes for programs 5-7, the later marked with dark beans, as "for espresso". Then stops and cool using cool air from same hotgun. If operator forget to press first crack button, the roast will stop and start cooling at minute 10. This is all the intelligence of this machine. ~~~

renatoa attached the following images:

Edited by renatoa on 05/24/2024 2:07 AM |

|

|

|

| oldwood |

Posted on 05/24/2024 8:58 AM

|

|

Newbie  Posts: 8 Joined: October 08, 2023 |

"Why over the beans instead into the bean mass ?" Yes, my wording was inaccurate. The air is directed upward at the bottom of the drum, with the only air outlet on the top front. I fashioned a curved shield covered in tinfoil to keep the airflow directed more focused on the bean mass. The rotation of my basket is only about 10 rpm, so I added lots of mixing vanes inside the basket to keep the beans moving. I have not investigated a higher rpm motor yet. These Ronco machines have 2 locations you can use the drum at, one more towards the front and lower and one further back and up a bit. When I read about keeping roast time under 14 minutes I moved to the back and up and my roast times are about 12 minutes ending in a full city+ which is about as dark as I ever roast. That is an interesting looking machine. I am finding the world of coffee roasting much more technical than I first imagined. I have been reducing the power to the heat gun a bit at first crack, buy I am concerned about stalling, so don't know how much I can get away with. Thanks, Gerry

oldwood attached the following image:

Edited by oldwood on 05/24/2024 9:11 AM |

|

|

|

Page 2 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman